Mechanical lift vehicle and installation comprising this vehicle

a technology of mechanical lift seats and mechanical lifts, which is applied in the direction of railway tracks, locomotives, constructions, etc., can solve the problems of inability to add mechanical stresses to the structural elements of mechanical lift seats, the weight of this movable structure may sometimes require the addition of a support pylon, and the difficulty of adapting the equivalent supply device to old installations, etc., to achieve the effect of limiting the complexity and cost of implementation, low mass and low maintenance cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

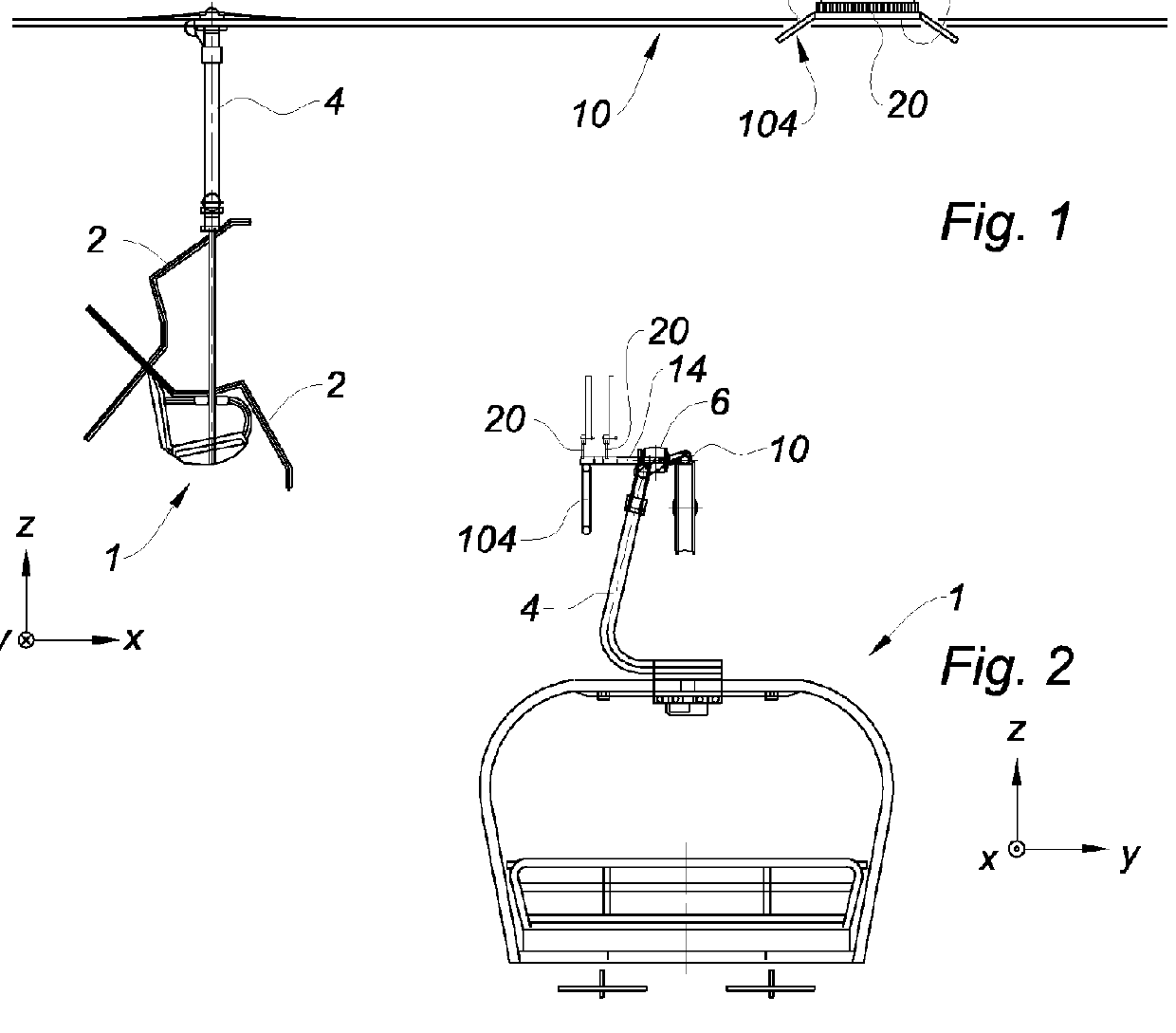

[0043]FIGS. 1 and 2 show a mechanical lift vehicle 1 according to an embodiment of the invention, in particular an aerial transport vehicle, in this case a mechanical lift seat. This mechanical lift seat can comprise a movable guard-rail 2 between a high position wherein the guard-rail 2 releases a space to allow passengers embarking or disembarking, and a low position wherein the guard-rail 2 forms an obstacle to prevent passengers from falling. High and low positions are simultaneously represented in FIG. 1.

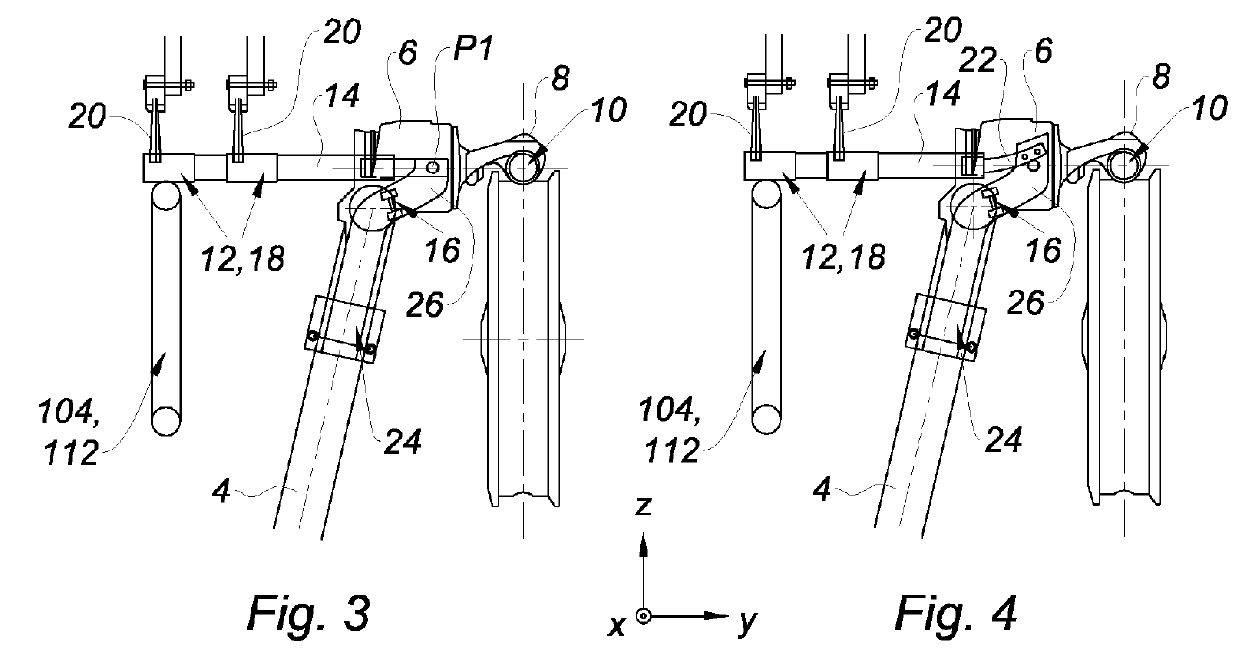

[0044]It is to be specified that the description is carried out with respect to a Cartesian reference frame, visible in FIGS. 1 and 2, related to the mechanical lift vehicle 1, the X axis being orientated in a longitudinal direction of the mechanical lift vehicle 1, the Y axis being orientated in a transverse direction of the mechanical lift vehicle 1, and the Z axis being orientated in a vertical direction of the mechanical lift vehicle 1. Longitudinal, transverse or vertical,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com