Laser clad knife guard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

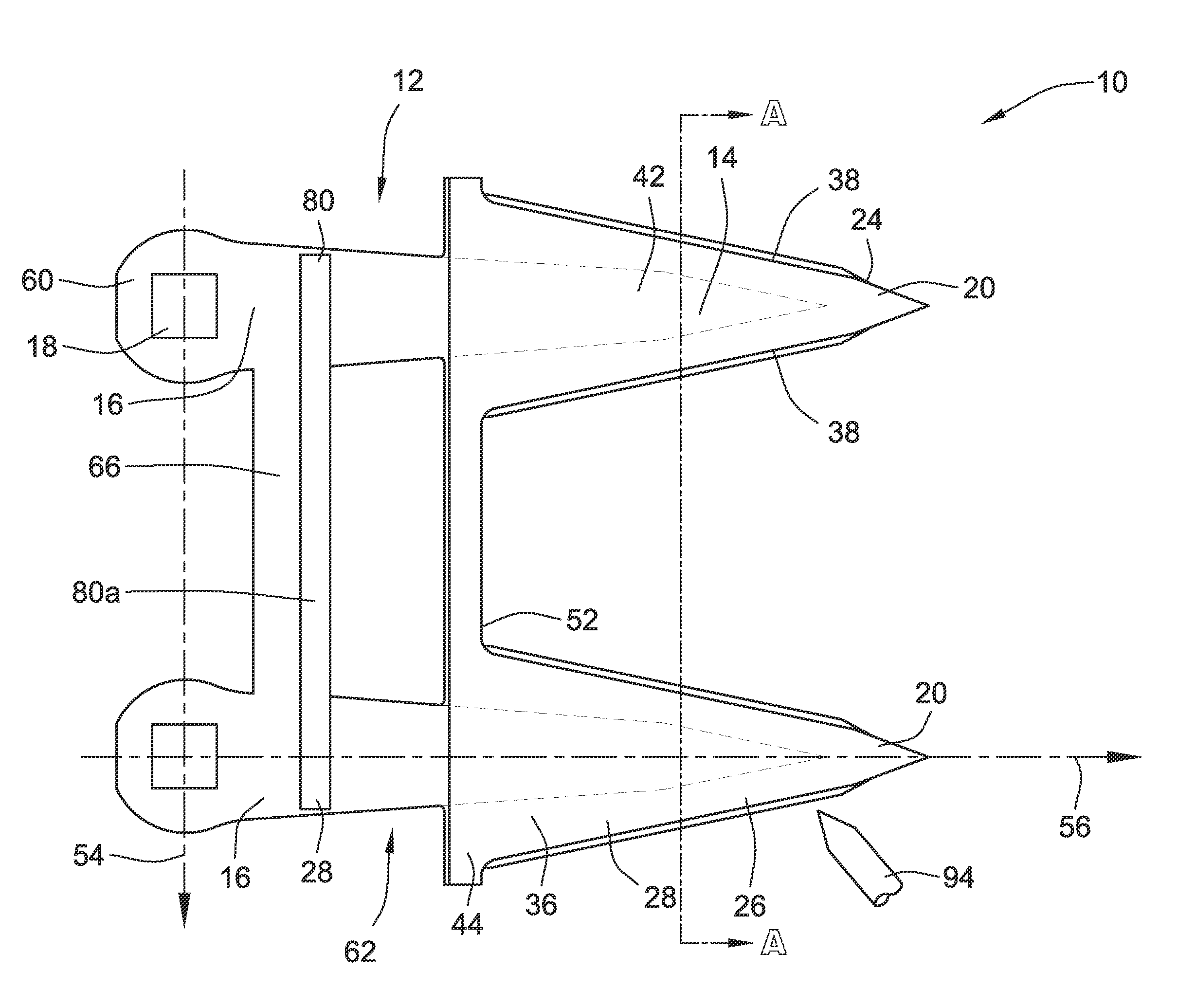

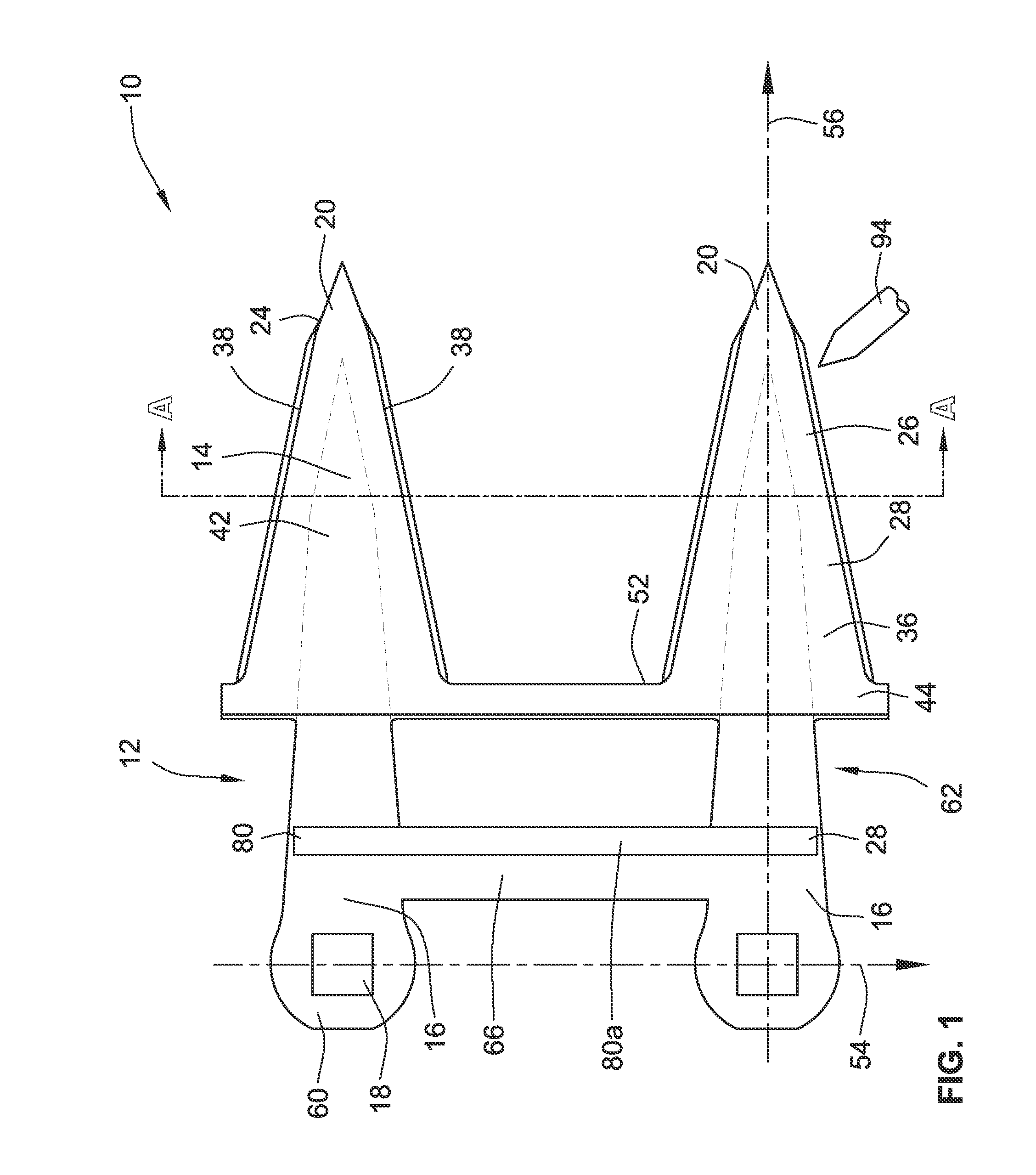

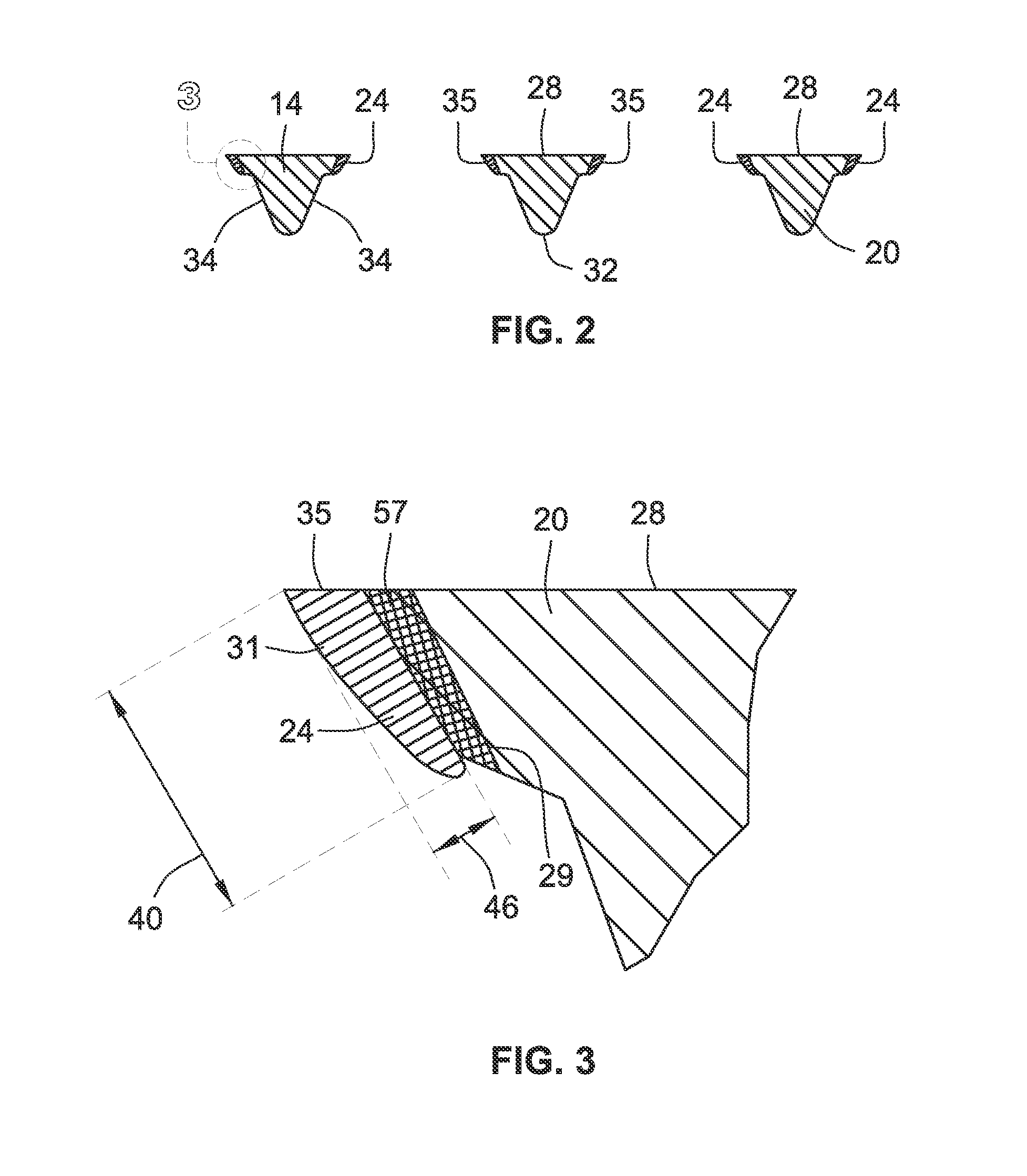

[0045]As shown in FIG. 1, a laser clad knife guard 10 according to an embodiment of the present invention is illustrated. A knife guard 10 comprises a guard body 12 and is comprised of a base material 14 such as steel material, that includes a mounting bar 16, which defines at least one bolt hole 18 and at least one tine 20 projecting forward 56 from the mounting bar 16. The base material 14 has a first hardness 22 and a clad material 24 is deposited on the base material. The clad material 24 comprises a second hardness 26, greater than the first hardness 22 and can be deposited in horizontal strips running lengthwise from a rear portion toward the tip or front portion of the tine.

[0046]The knife guard 10 includes a ledger surface 28 that is adapted to bear against or at least face a sickle bar assembly 30. Typically the ledger surface 28 will come into contact with the sickle bar assembly 30 to guide or maintain linear reciprocating movement of the sickle bar assembly 30. FIG. 5 il...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com