Heat pipe

a heat pipe and heat exchanger technology, applied in indirect heat exchangers, heat exchange apparatus, lighting and heating apparatus, etc., can solve the problems of difficult to ensure a space serving as the vapor passage, difficult to improve the flow performance of working fluid, and the evaporating section would be dried out, so as to reduce the heat resistance in the evaporating section, the working fluid can be efficiently evaporated, and the inner section can be enhanced. the effect of capillary pumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

[0033]Hereinafter, a preferred example of the heat pipe according to the present invention will be explained in more detail with reference to the accompanying drawings.

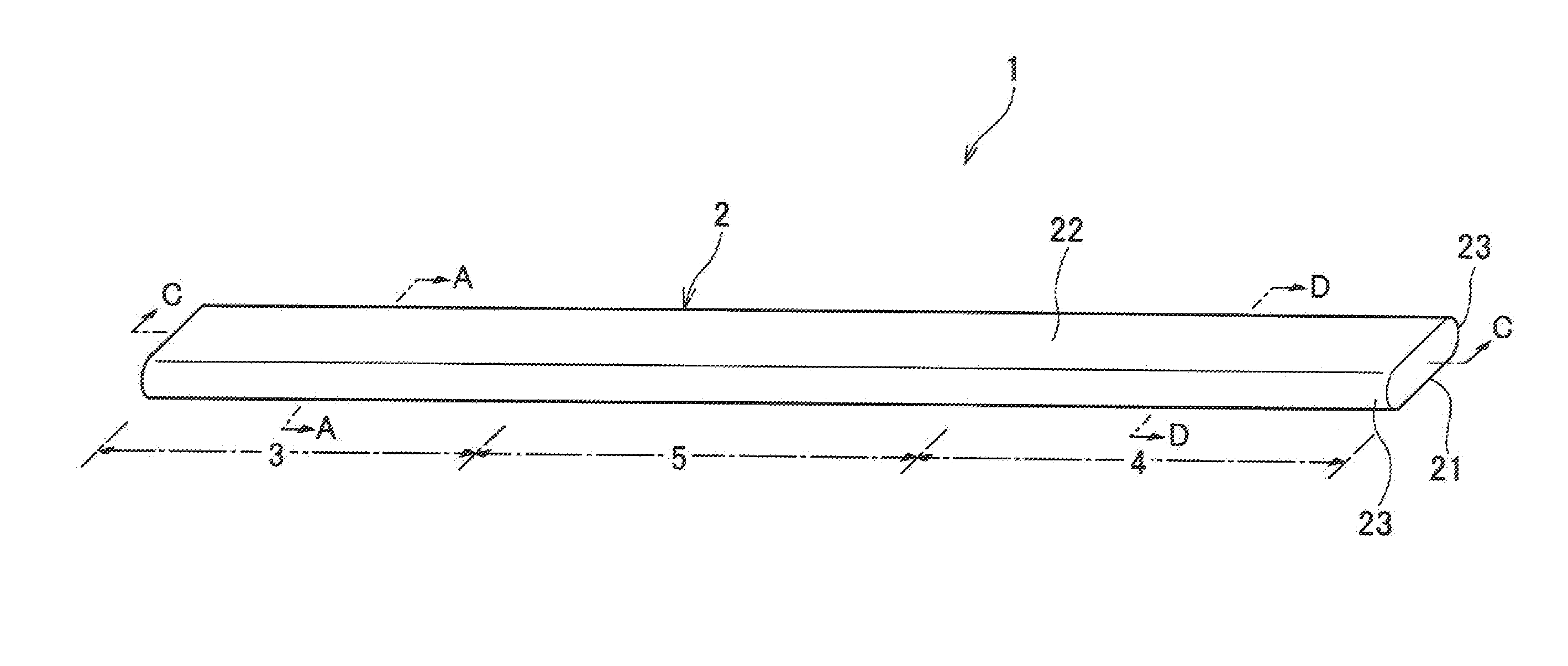

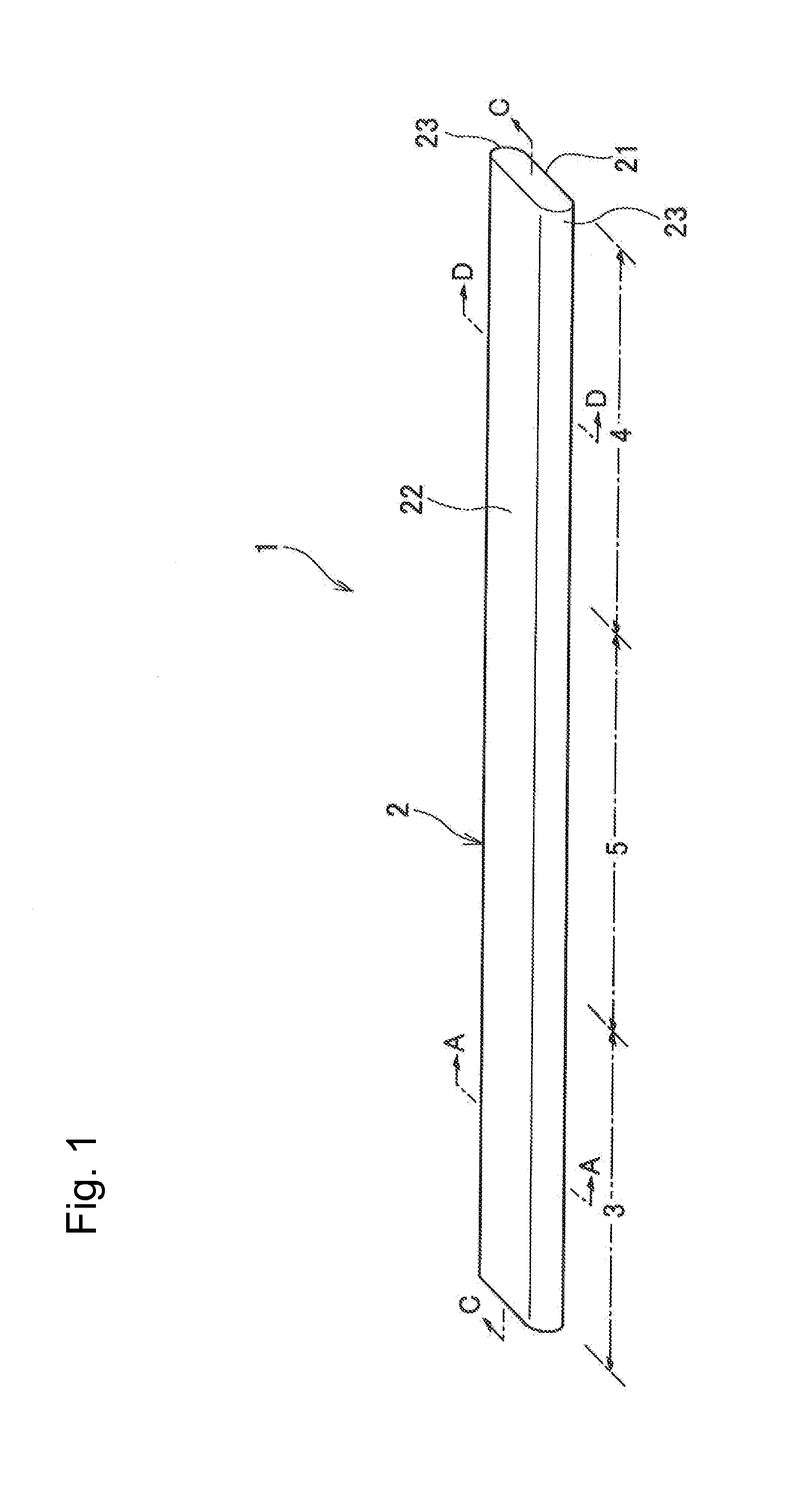

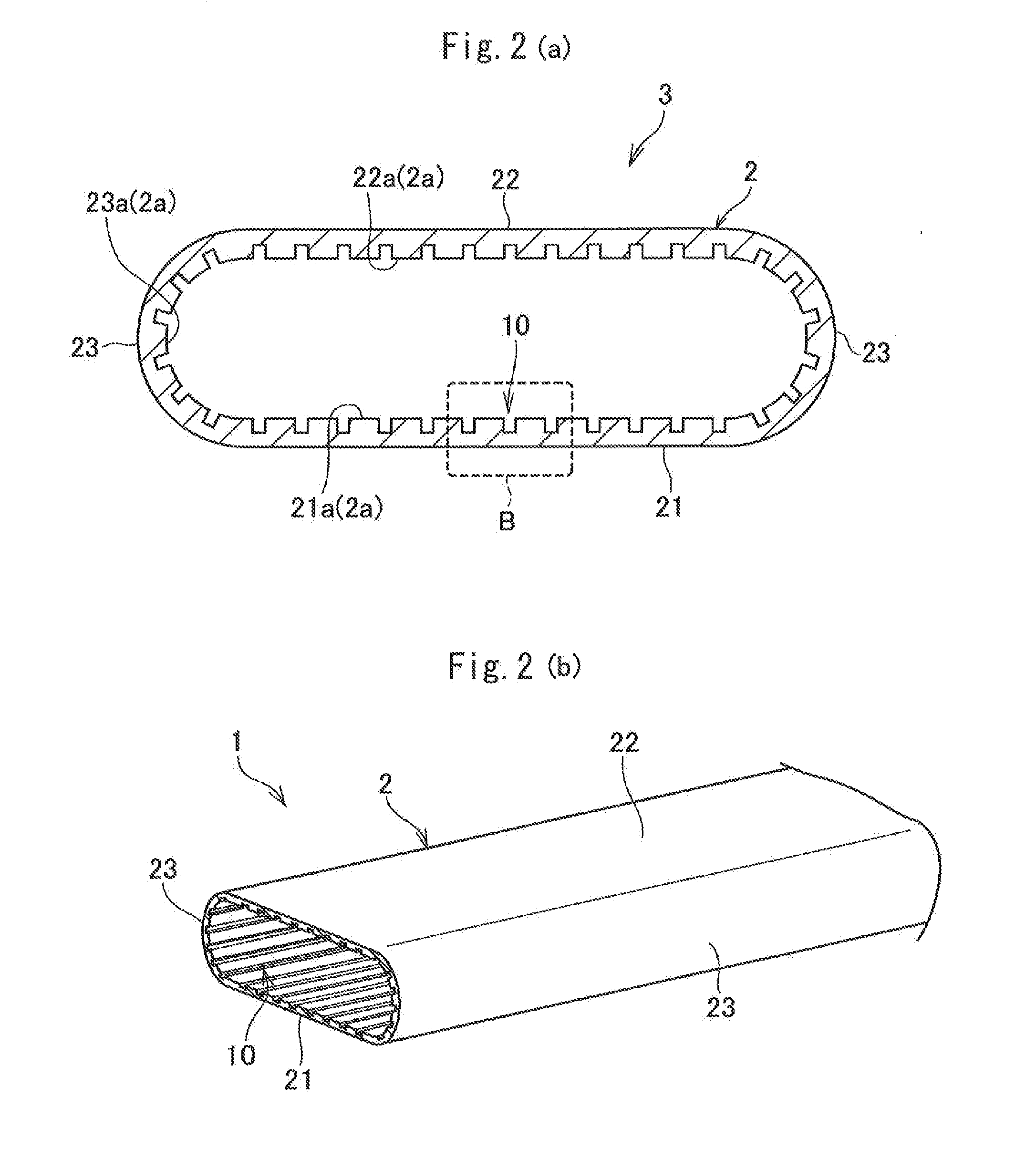

[0034]Referring now to FIG. 1, there is shown a structure of a heat pipe 1 according to the preferred example. The heat pipe 1 is a heat transfer device utilizing a latent heat of phase changeable working fluid encapsulated in a sealed container 2 as a straight rectangular tube.

[0035]The container 2 is a hollow flattened rectangular tube having a thickness narrower than a width, and both longitudinal ends thereof are sealed. In an inner space of the container 2, a width dimension is accordingly larger than a thickness dimension. The container 2 is made of metal material having excellent heat conductivity such as copper, steel and aluminum.

[0036]For example, the container 2 is formed by pressing a metal tubular material into a flat shape. Specifically, the container 2 thus formed is comprised of a first flat wall 21 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com