Method and device for manufacturing titanium objects

a technology of titanium objects and manufacturing methods, applied in the direction of auxiliary welding devices, process and machine control, program control, etc., can solve the problems of high material use of titanium metal, large lead time in fabrication, less suited to large volume production, etc., and achieve the effect of rapid layered manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

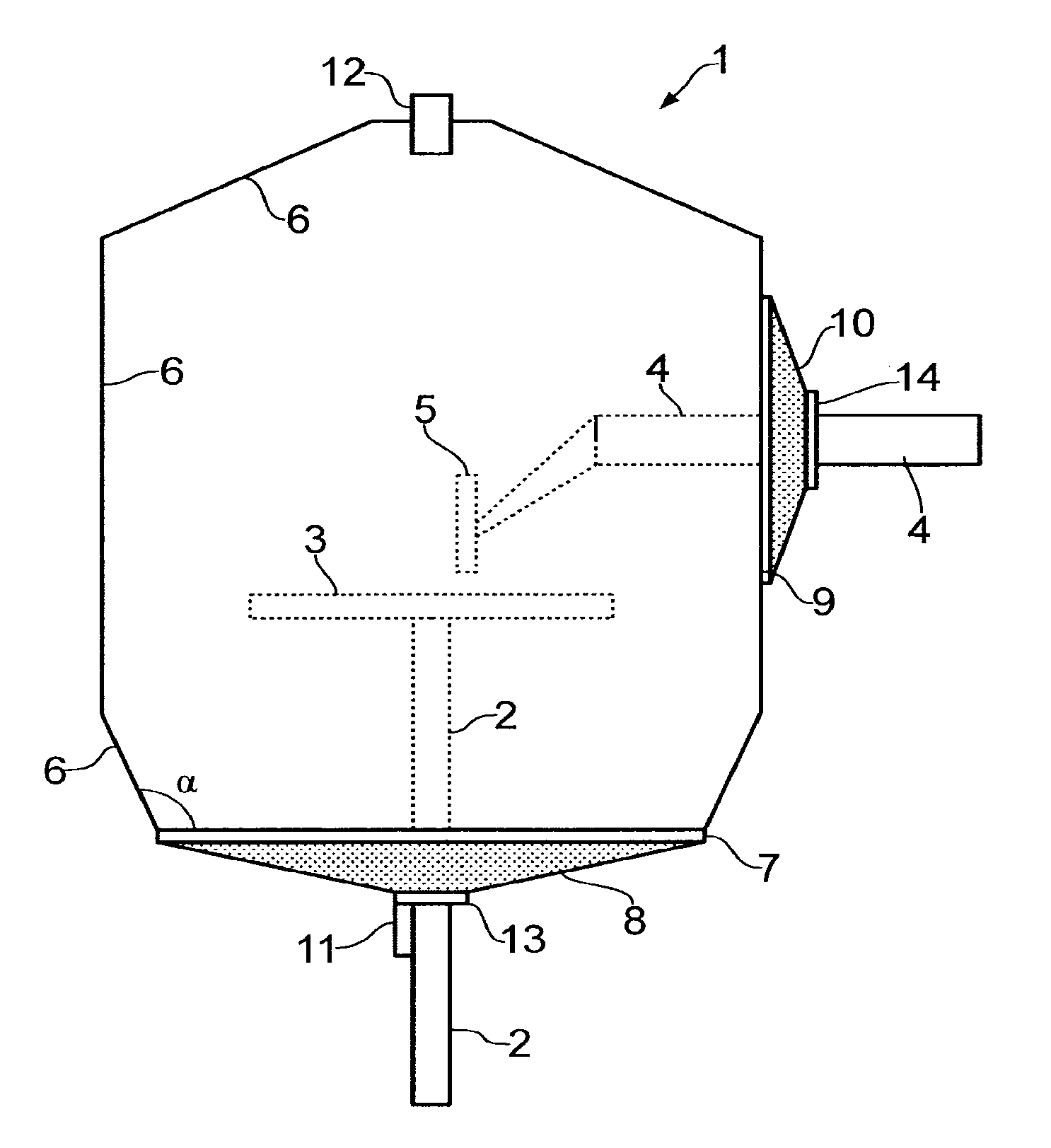

[0052]The inventive features of the invention according to the second aspect of the invention are schematically presented in FIG. 3.

[0053]The figure shows a reactor 1 with an internal closed compartment made by a set of wall elements 6. The wall elements 6 are positioned such that there are no sharp edges, that is, edges with walls angled at angles of 90° or less. All internal wall angles, a, of the reactor chamber are obtuse (larger than 90°). An actuator 2 which controls the position and movement of a support substrate 3 is located outside of the reactor chamber and protrudes through an opening 7 such that the support substrate 3 is located inside the reactor chamber. The opening 7 is closed by an elastic gas tight membrane 8. An actuator 4 which controls the position and movement of a high energy plasma transferred arc welding torch 5 with wire feeder for feeding a wire of the weldable material is located outside of the reactor chamber and protrudes through an opening 9 such that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com