Semiconductor device

a technology of semiconductor devices and semiconductors, applied in the direction of semiconductor devices, basic electric elements, electrical equipment, etc., can solve the problems of reducing the breakdown resistance of semiconductor devices, failure to take sufficient measures, and n-type emitter regions, so as to reduce reduce the number of n-type emitter regions, and reduce the effect of the number of emitter regions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

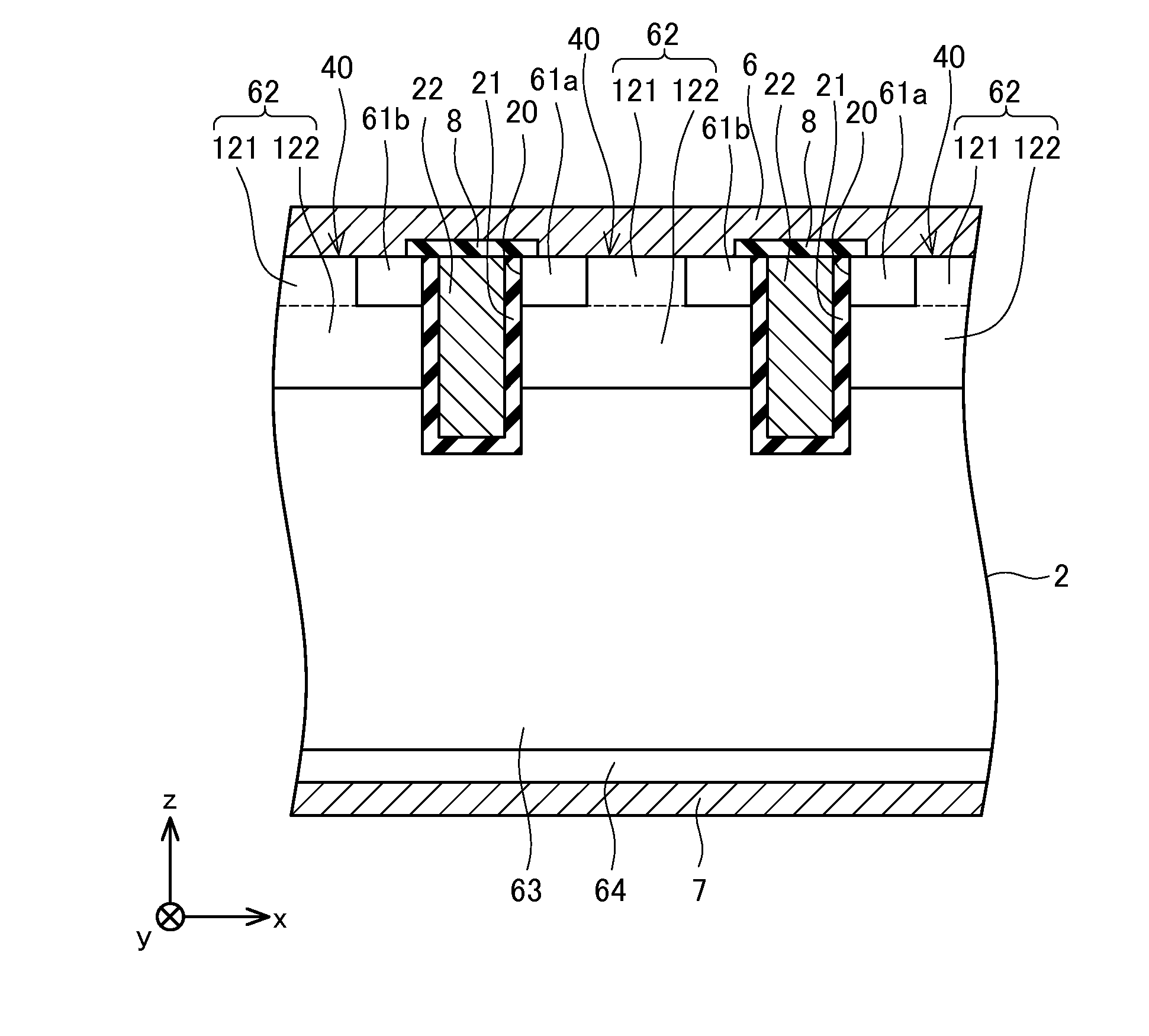

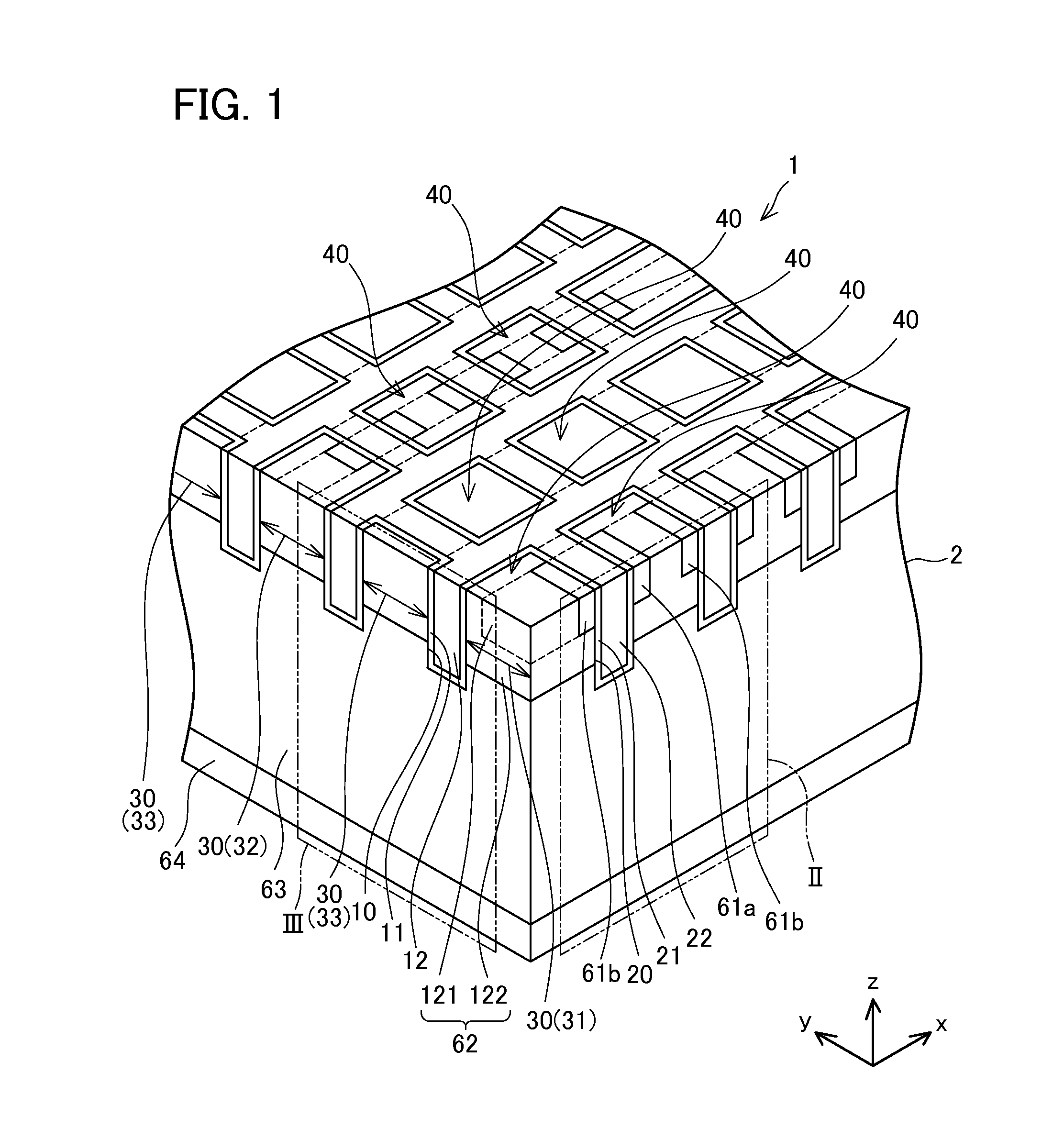

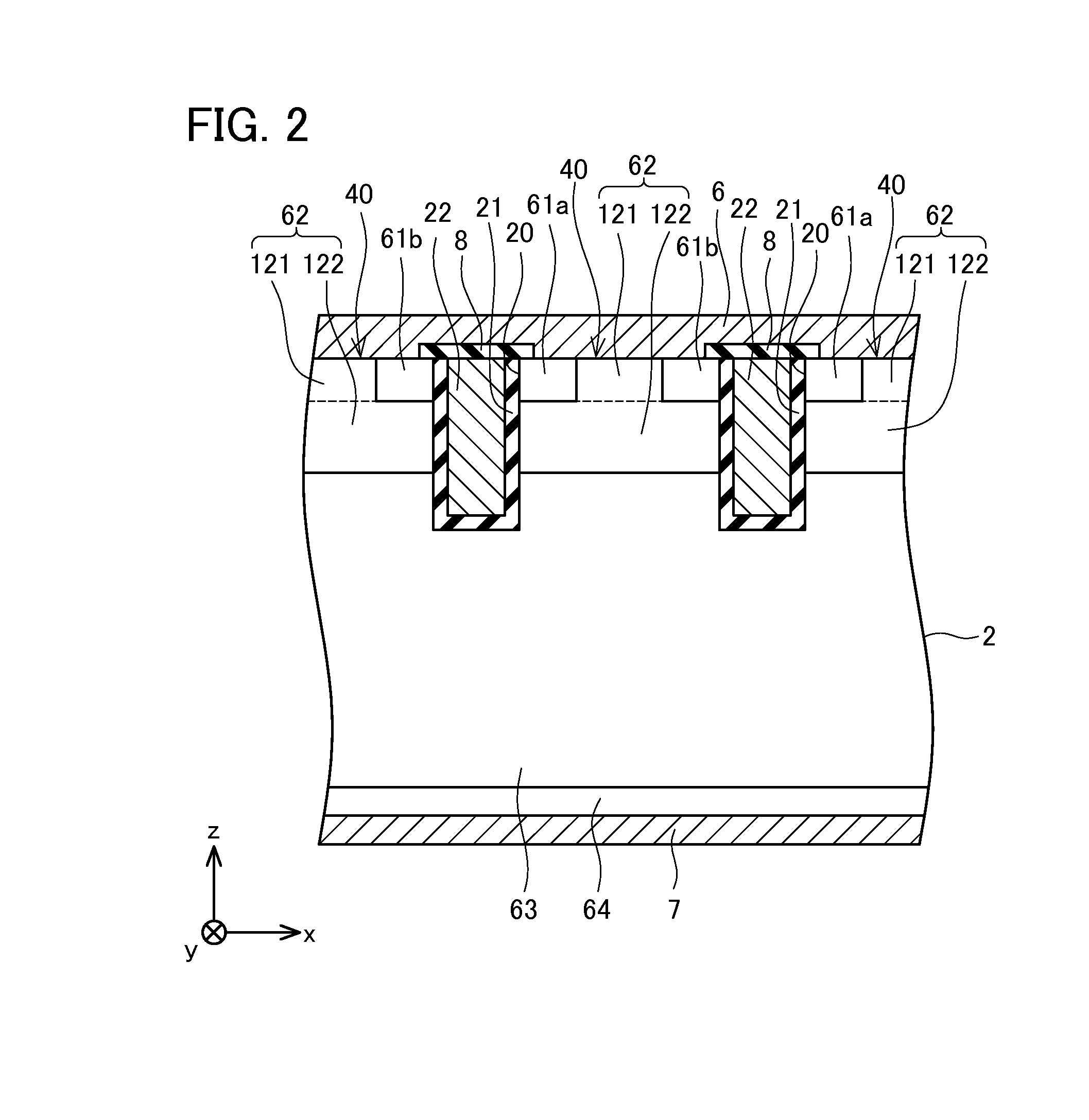

[0021]An embodiment will be described below with reference to the accompanying drawings. As shown in FIGS. 1 to 3, a semiconductor device 1 according to a first embodiment includes a semiconductor substrate 2, a front surface electrode 6, and a back surface electrode 7 (Note that, for the sake of viewability of the drawing, FIG. 1 omits to show the front surface electrode 6 and the back surface electrode 7.).

[0022]The semiconductor substrate 2 is made of silicon carbide (SiC). In another embodiment, the semiconductor substrate 2 may be made of silicon (Si), gallium nitride (GaN), or the like. A semiconductor element is disposed in the semiconductor substrate 2. The present embodiment takes an IGBT (insulated gate bipolar transistor) as an example of the semiconductor element.

[0023]The front surface electrode 6 and the back surface electrode 7 are made of a conductive metal such as aluminum (Al), copper (Cu), or the like. The front surface electrode 6 is disposed on a front surface o...

second embodiment

[0046]In the embodiment described above, a single middle inter-trench region 33 was disposed in between the first inter-trench region 31 and the second inter-trench region 32. However, the present disclosure may not be limited to this configuration. In a second embodiment, as shown in FIG. 6, a plurality of middle inter-trench regions 33 may be disposed between the first inter-trench region 31 and the second inter-trench region 32. At least one middle inter-trench region 33 should be disposed between the first inter-trench region 31 and the second inter-trench region 32. Such a configuration also makes it possible to, while suppressing local concentration of currents, suppress the number of electrons that are implanted.

third embodiment

[0047]In the embodiment described above, the second trenches 20 are disposed in the middle inter-trench region 33 interposed between the first inter-trench region 31 and the second inter-trench region 32. However, the present disclosure may not be limited to this configuration. In a third embodiment, as shown in FIG. 7, the second trenches 20 may not be disposed in a middle inter-trench region 33 interposed between the first inter-trench region 31 and the second inter-trench region 32. Such a configuration also makes it possible to, while suppressing local concentration of currents, suppress the number of electrons that are implanted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com