Centrifugal rotor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

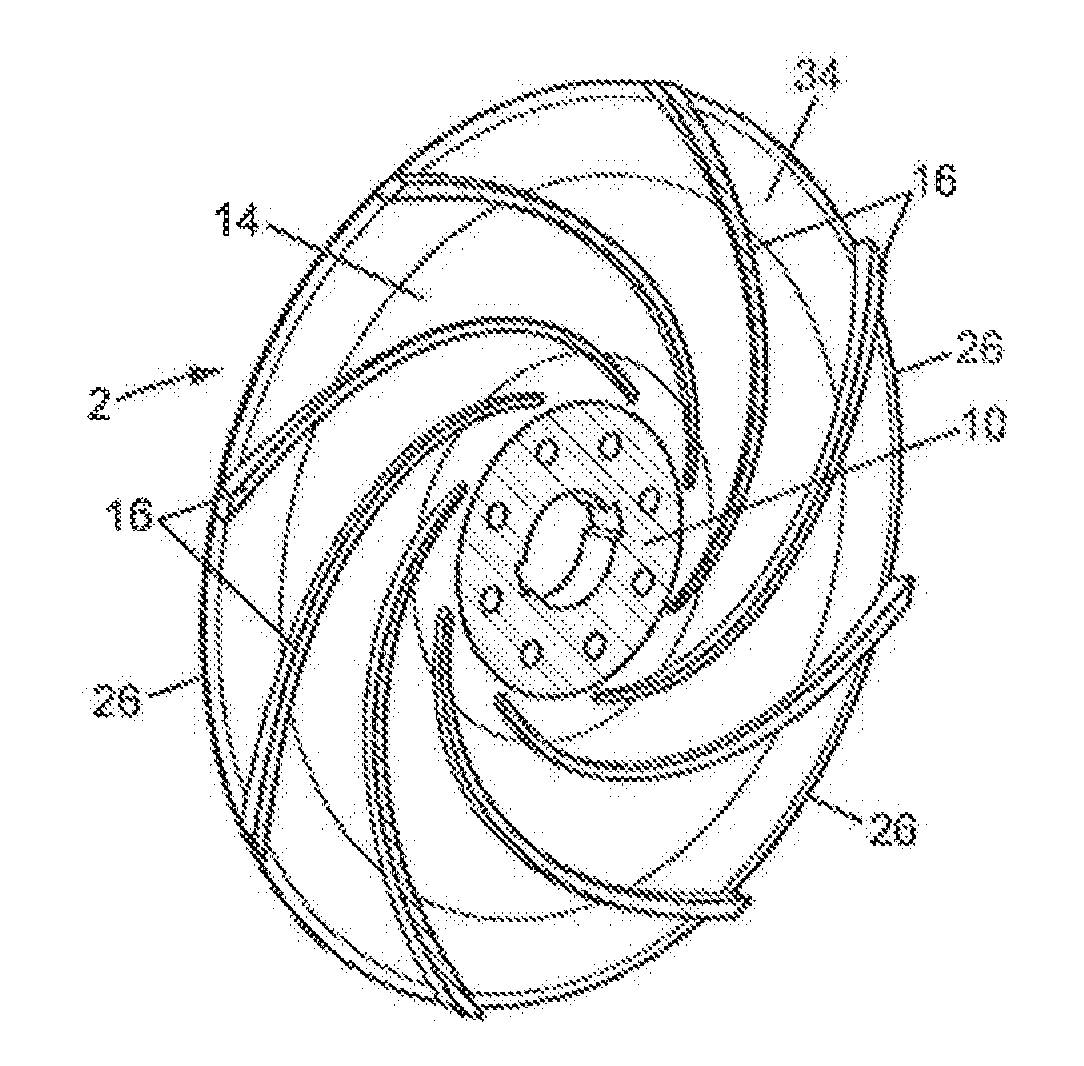

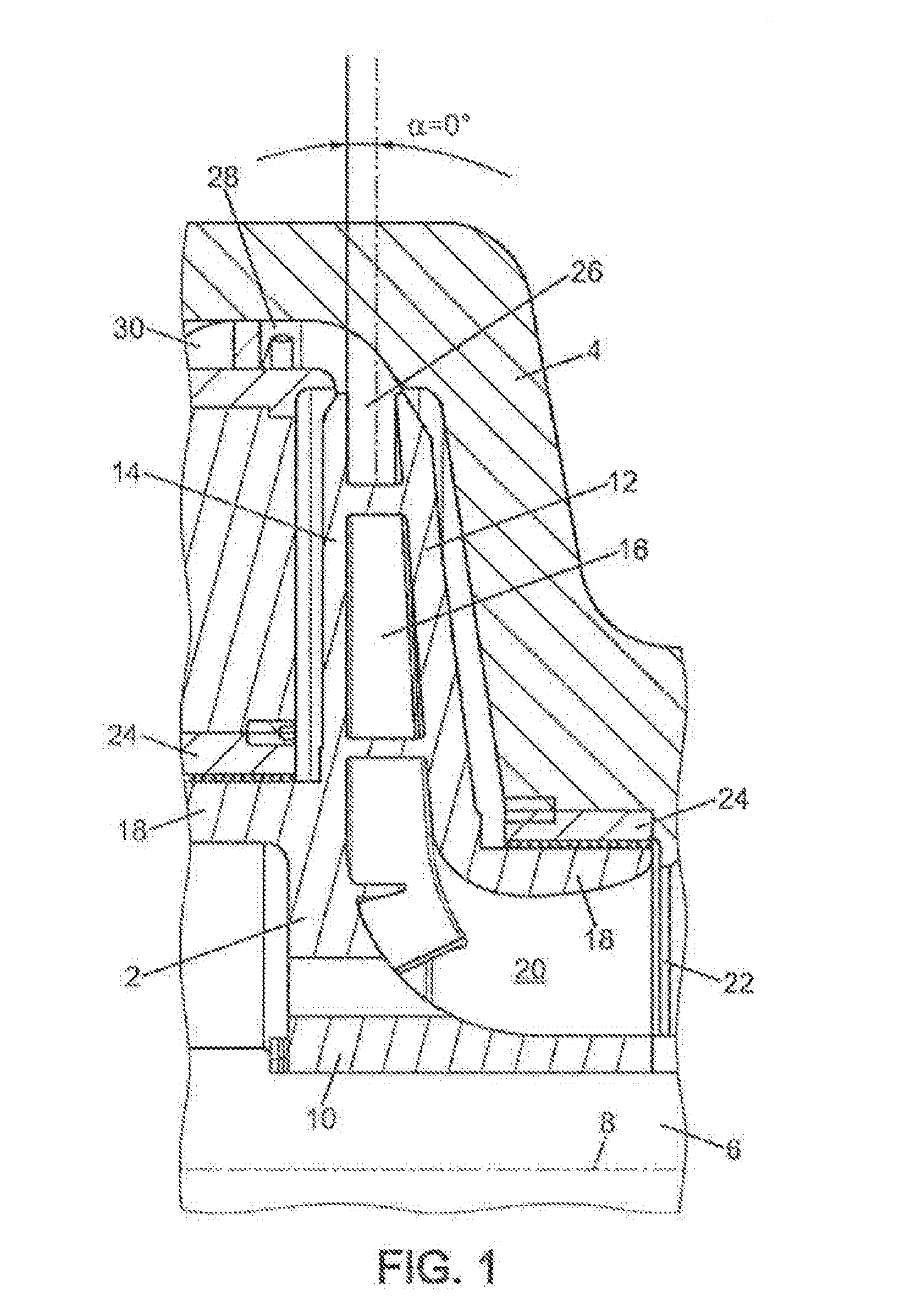

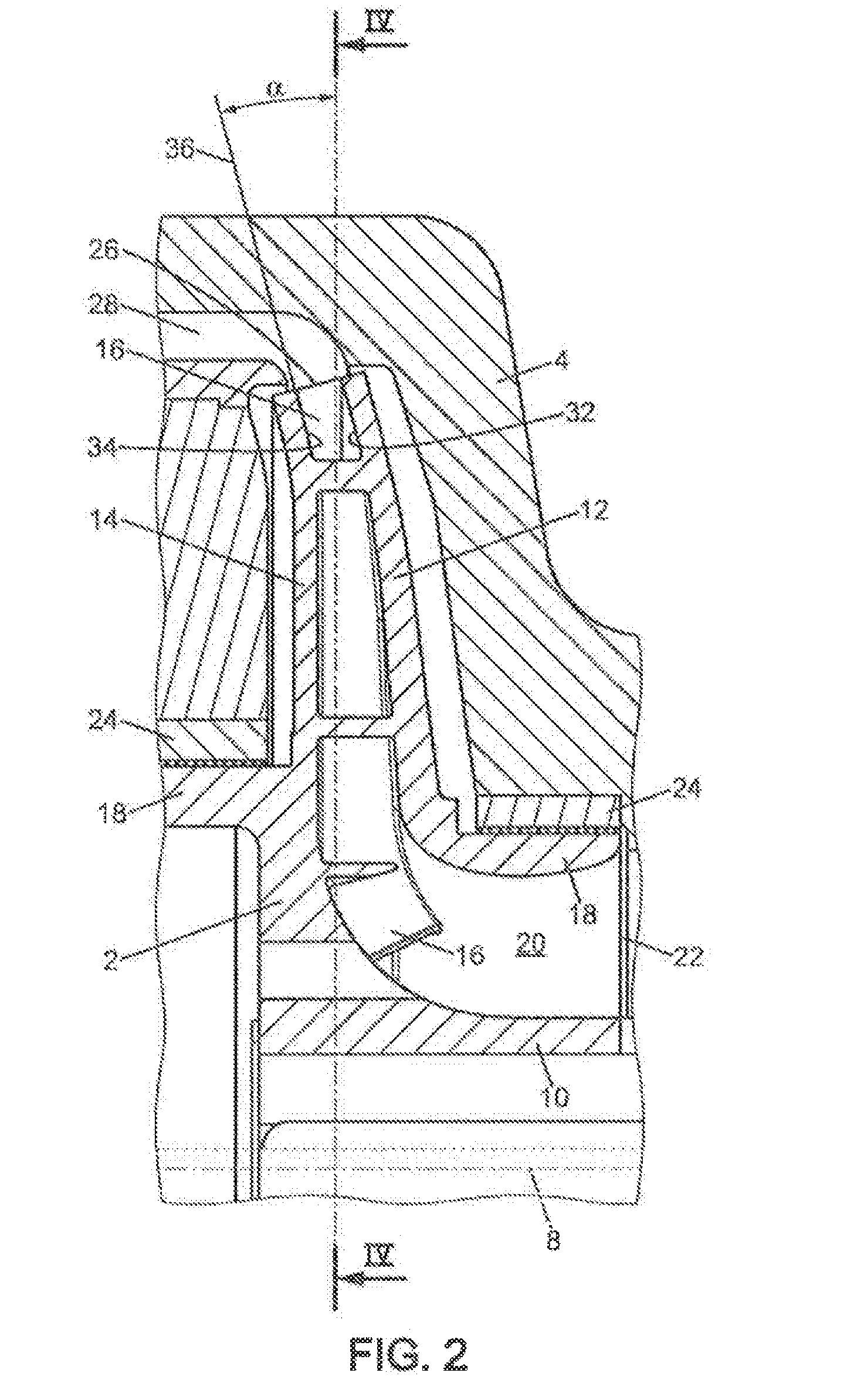

[0027]Those skilled in the art will recognize a centrifugal rotor 2 in FIG. 1 mounted inside a housing 4, for example a compressor housing, and a shaft 6 having a longitudinal axis 8. The following description will be made with reference to a working air compressor (or more generally a gaseous fluid compressor), but this invention may also be applied to pumps for liquids.

[0028]When the centrifugal rotor 2 is rotated by the shaft 6, the air (or other gaseous fluid) is drawn into the centrifugal rotor 2 in a longitudinal direction relative to the longitudinal axis 8, and is driven in a mixed flow motion in the centrifugal rotor 2 while rotating and appear radially with respect to the longitudinal axis 8.

[0029]The centrifugal rotor 2 is built in one piece and comprises a hub 10, a first flange or upstream flange 12, a second flange or downstream flange 14 and vanes 16.

[0030]The hub 10 enables a connection between the shaft 6 and the centrifugal rotor 2. It has an overall circular, cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com