Method and station for filling gas tanks

a gas tank and gas technology, applied in the field of methods and stations for filling gas tanks, can solve the problems of high cost of purification steps, inability to ensure such a degree of purity continuously, and known and relatively inexpensive industrial manufacturing processes, and achieve the effect of saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

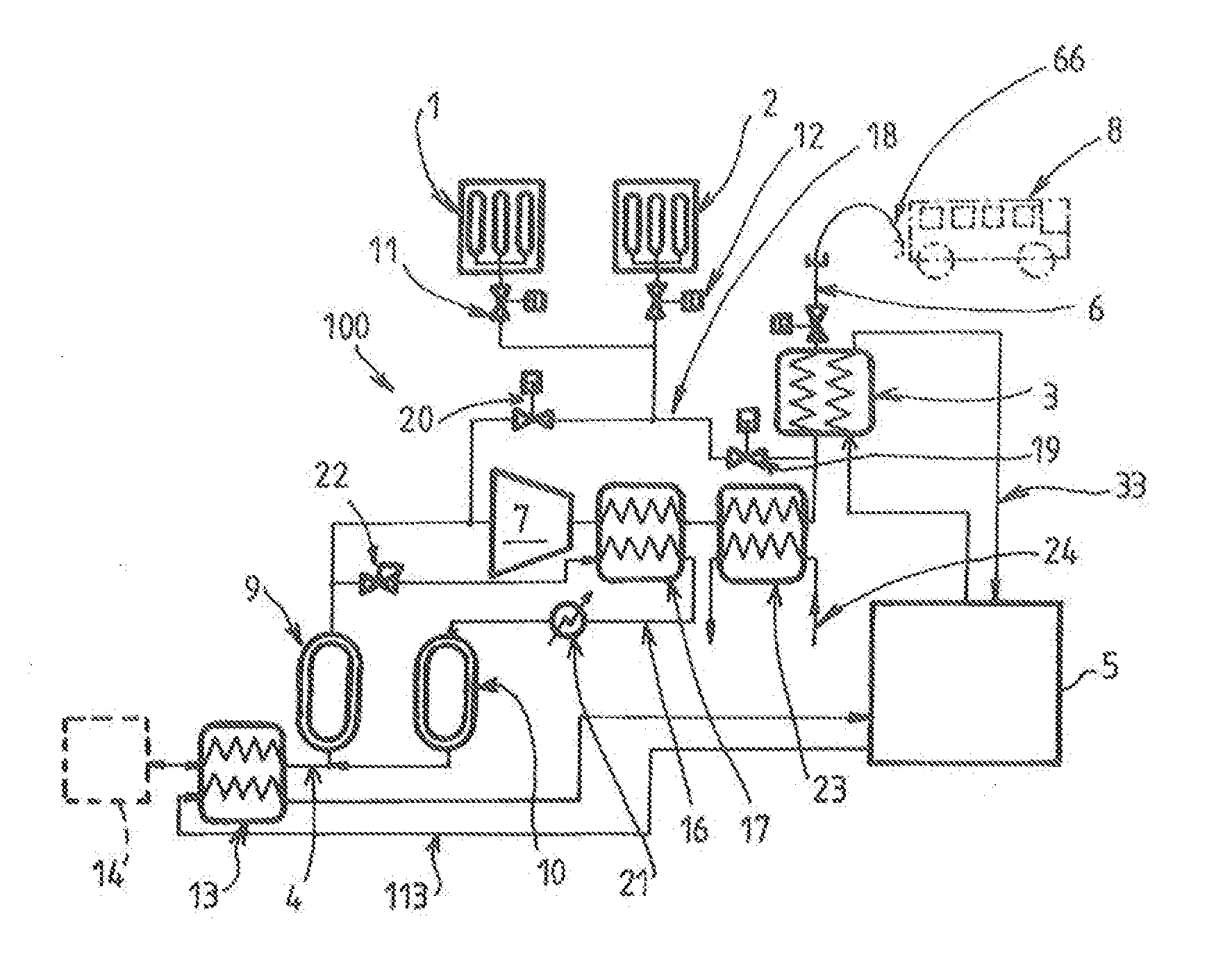

[0037]The filling station 100 represented by way of nonlimiting example is a station provided in order to carry out the filling of tanks 8 of gaseous hydrogen at high pressure (for example at a pressure between 300 and 850 bar).

[0038]Conventionally, the filling station 100 comprises several buffer containers 1, 2 (two in this nonlimiting example but there may be one, three or more than three thereof).

[0039]Each buffer container 1, 2, is a tank or set of tanks provided in order to contain gaseous hydrogen pressurized to a given pressure, for example respectively 450 bar and 850 bar. The station 100 comprises a fluid circuit 11, 12, 18, 4, 6 comprising a plurality of pipes and valves. The circuit is connected to the buffer containers 1, 2. The circuit comprises a first end 4 intended to be connected to at least one source 14 of gaseous hydrogen in order to enable the filling of the buffer containers 1, 2 with gas originating from the source 14.

[0040]The source 14 of hydrogen may conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com