Solid Milk And The Method Of Manufacturing Thereof

a technology of solid milk and manufacturing method, which is applied in the field of solid milk, can solve the problems of not being able to utilize the high dissolubility manufacturing technique of high dissolubility in the manufacturing of intraoral fast disintegrable tablets into the method of manufacturing solid milk, and it is not easy to actually make powdered milk into solid state, etc., to achieve convenient transportation, convenient measurement and making method, and preferred solubility and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

reference example 1

Making Powdered Milk

[0139]The various powdered milk including various components as shown in table 2 were prepared from the mixture of liquid with fat, sugar, protein, milk, and mineral group added to water and executed homogenization, concentration (evaporation), and spray drying in this order.

TABLE 2CompositionPowdered milk 1Powdered milk 2Protein [wt %]1512Fat [wt %]1826Sugar [wt %]6057Lactose in suger [wt %]4351Ash [wt %]42Water, other [wt %]33

reference example 2

Manufacturing of Solid Milk

[0140]In the step of humidifying compressed powdered milk, we used Combi Oven, “FCCM6”, manufactured by Fujimak Corporation as a humidifier. We maintained the temperature within the humidifier to be 65° C. and humidity of 100% RH. We kept the compressed powdered milk for 45 seconds (humidifying duration) under the condition. In the step of drying the humidified compressed powdered milk, we used an air thermostat “DK600” manufactured by Yamato Scientific Co., Ltd as a drying machine. In the step we dried the humidified compressed powdered milk for 5 second under 95° C. and humidity of 10% RH. Finally, we obtained solid milk.

example 1

Technical Effect of Amorphous Lactose in Powdered Milk, Ingredient

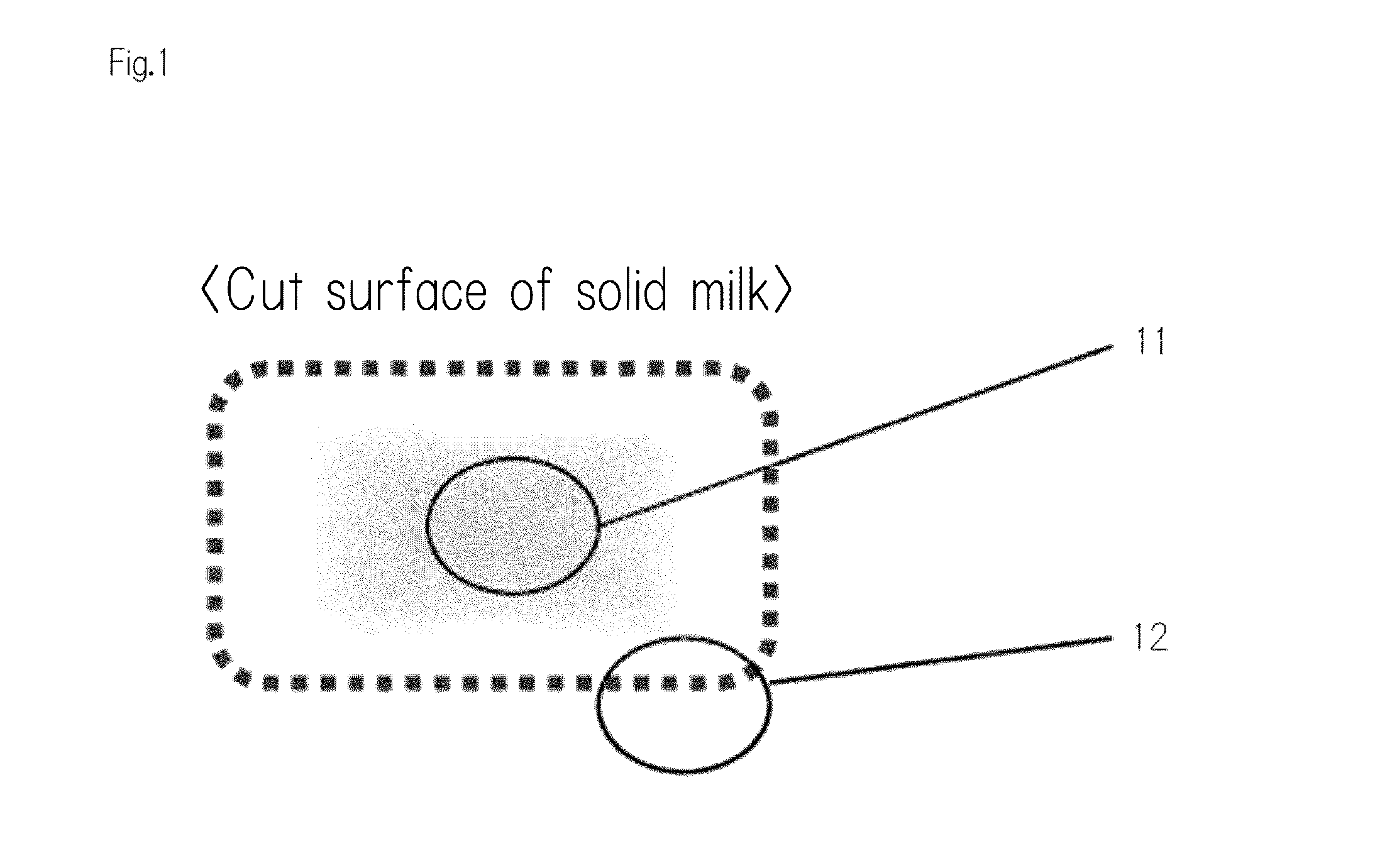

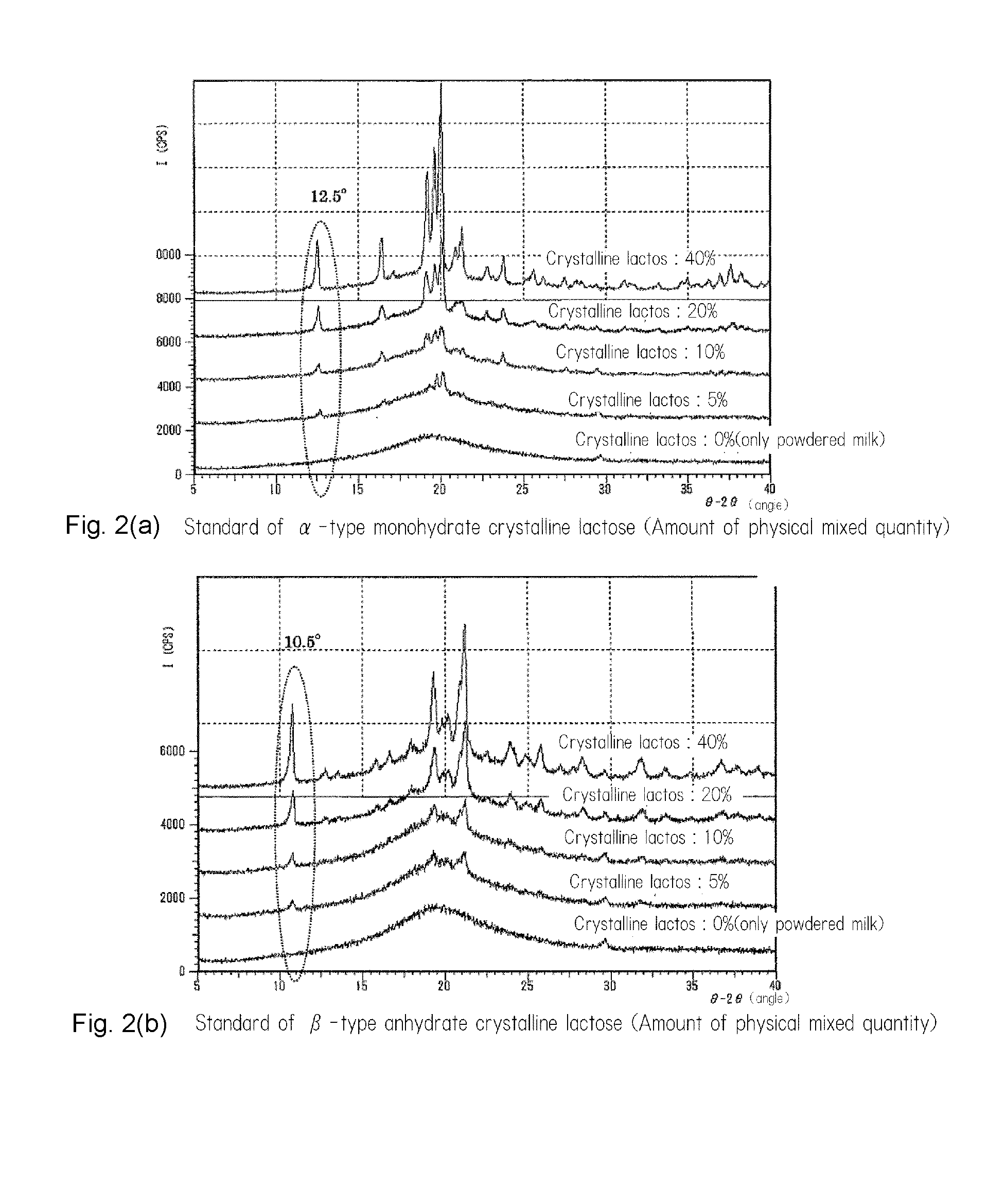

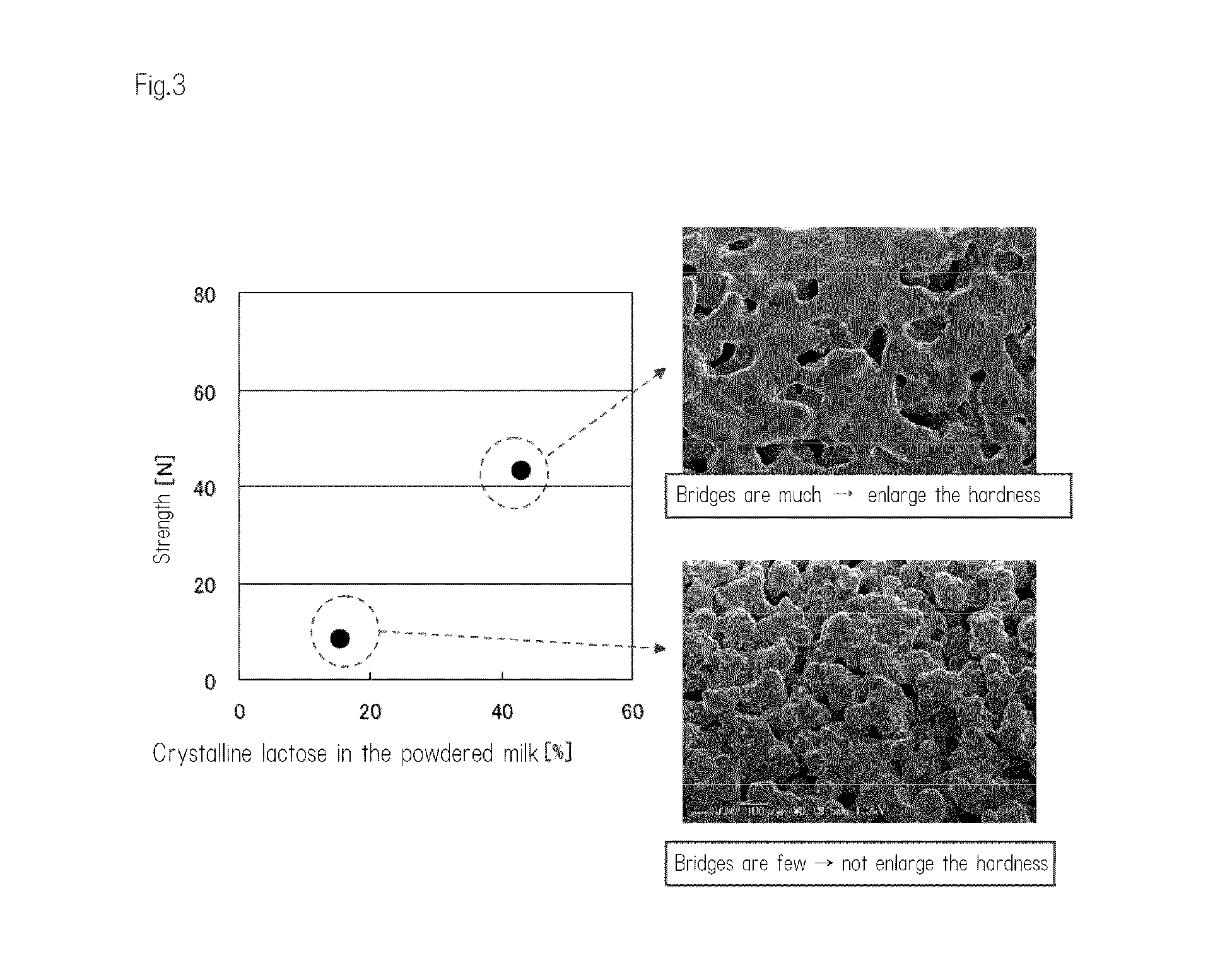

[0141]We manufactured several solid milks that have different amount of amorphous lactose that has composition of powdered milk 1 (total lactose 43%). These solid milks had almost the same porosity. The strength of solid milk with 15.5% amorphous lactose was as low as 8 N, and that of solid milk with 43.0% amorphous lactose was 43 N (table 3). The result of investigation by scanning electro micrometer, SEM, shows that both solid milks have different amount of bridging among granules. Generally speaking amorphous has higher solubility than that of crystalline. We estimate that steam made amorphous lactose at the surface of the compressed powdered milk dissolved once. Then the dissolved granules attached each other to form bridges to enlarge the strength of the solid milk. It shows that, in case of solid milk that has high porosity to have high solubility, when the ingredient, powdered milk, comprises amorphous lactose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com