Turbo engine with torsional coupling integrated to at least one driving or driven shaft driving

a technology of torsional coupling and turbo engine, which is applied in the direction of non-positive displacement fluid engine, liquid fuel engine components, pump components, etc., can solve the problems of complex layout of shaft assembly, manufacturing problems, and present fragility zones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

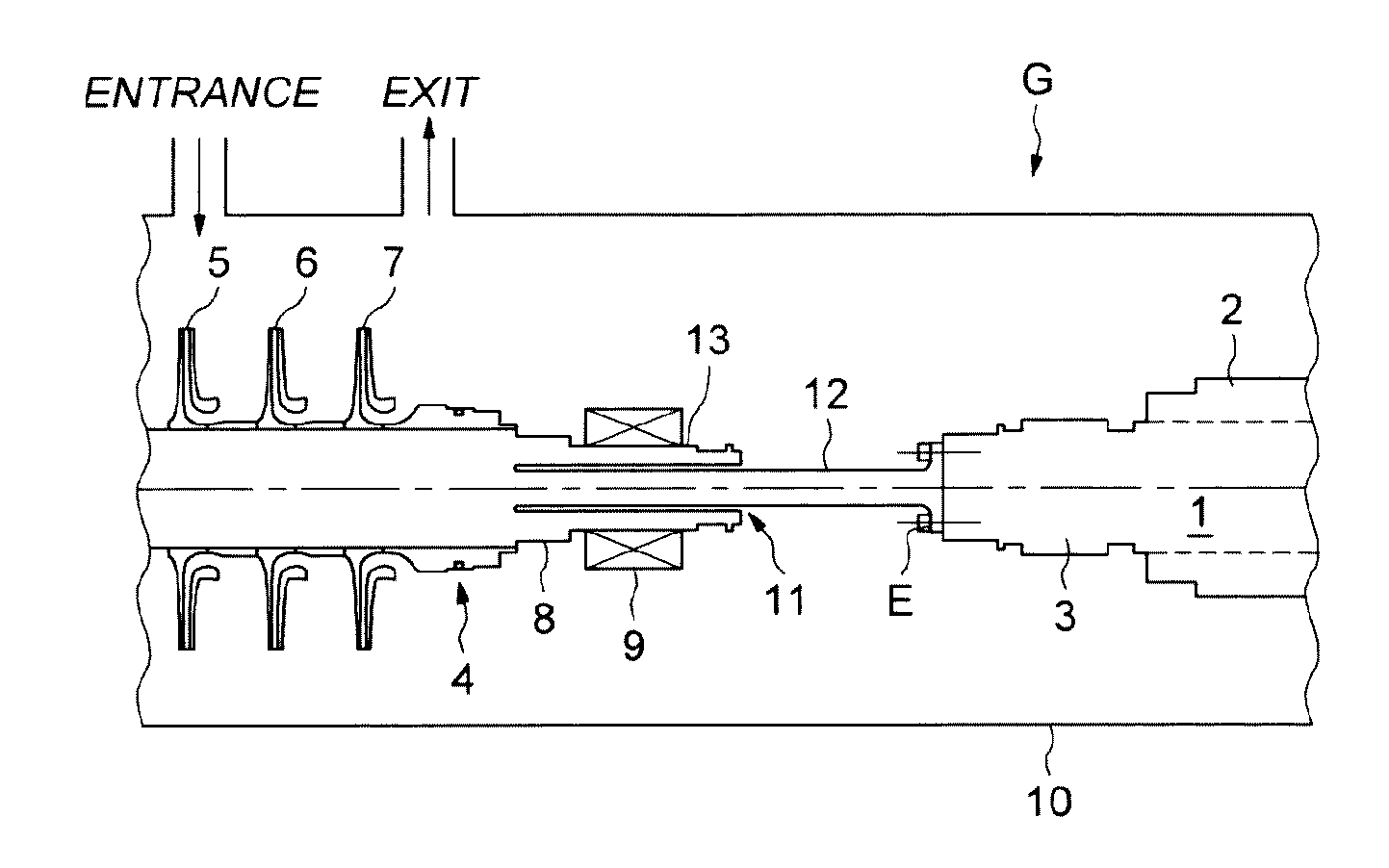

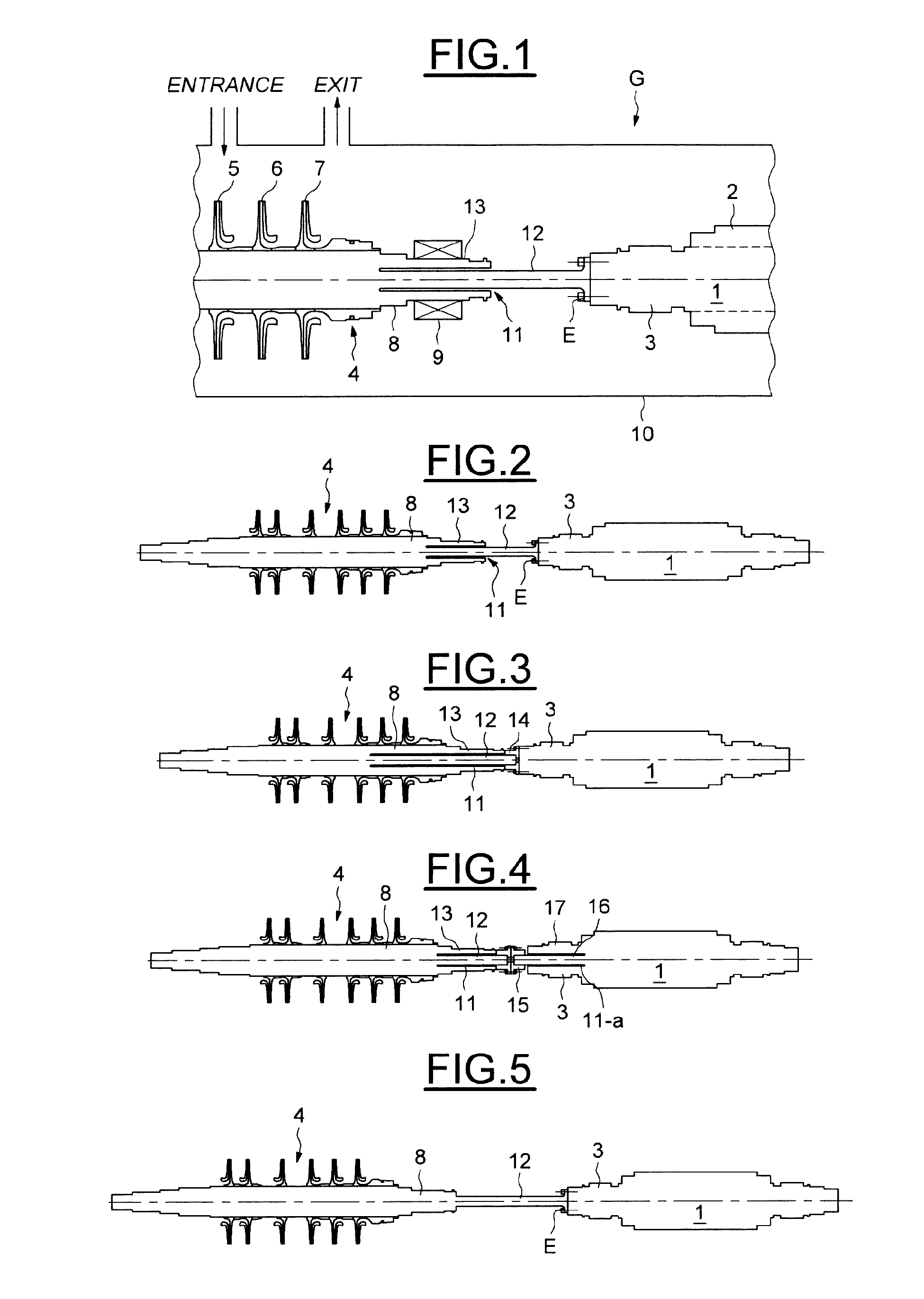

[0032]Referring first to FIG. 1, a motor-driven compressor according to an embodiment of the present invention, designated by the general reference G, comprises essentially a motor 1, for example an electric motor with high rotational speed, for example between 6,000 and 16,000 revolutions / minute, powered by a frequency converter and comprising a stator 2 and a rotor 3 forming a driving shaft for the motor-driven compressor group, and a compressor group 4 comprising a set of wheels with blades 5, 6 and 7, here three in number, mounted on the driven shaft 8. As it can be seen, the driven shaft 8 is supported by the radial bearings 9.

[0033]The arrangement is mounted on a base (not shown) and is located in a common casing 10, which is impermeable to the gas generated by the motor-driven compressor group. The casing 10 comprises an input “INPUT”, through which the gas to be generated is drawn by suction into the compressor and an output “OUTPUT”, through which the compressed gas is deli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com