Load cell having an elastic body

a technology of load cell and elastic body, which is applied in the field of load cell, can solve the problems of increasing the dimensions, affecting reducing the accuracy of load cell, so as to achieve easy and efficient manufacturing and marketing, and low manufacturing cost. , the effect of low price of sal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057]Referring now to the drawings, and particularly to FIGS. 1-10B, an embodiment of the load cell having an elastic body of the present invention will be described.

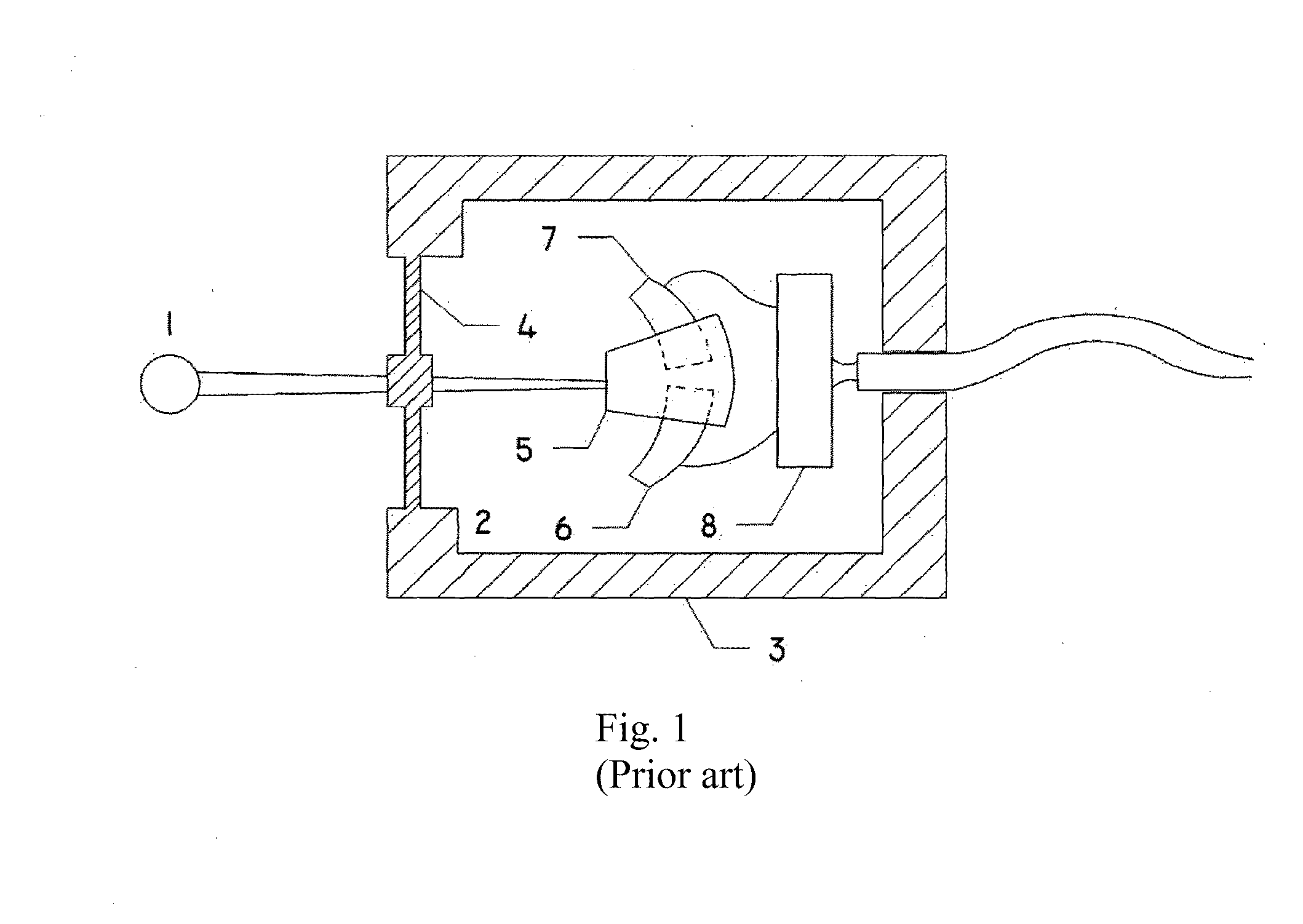

[0058]The sensor in FIG. 1 shows, as prior art, a simple sensor where the lever 1, is protruding into the sealed cavity 2, placed in the sensor body 3, through the flexible elastic wall 4, for activating the capacitive sensor means, by moving the grounded vane 5, in relation to the capacitance sensors 6 and 7 when the lever 1 is activated. The capacitance sensors 6 and 7 are connected to the capacitance measuring circuit 8.

[0059]This type of sensor, with different sensor means, is widely used as a joy stick for controlling machinery and the flexible wall protects the sensor means from humidity and corrosion in machinery in tough environments.

[0060]It is easily seen that a sensor according to FIG. 1 is quite unsuitable as a load cell because the forces for activating the sensor means are dependent on the length of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com