Assembling and dismantling-beforehand structural template system and construction method thereof

a structural template and before-hand technology, applied in the field of construction engineering, can solve the problems of increasing the cost of labor and materials, delaying the construction schedule, and affecting the overall structural rigidity of the template system, so as to reduce the processing difficulty and cost of the template, improve the template turnover rate, and improve the template stress state of the corner par

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]To clarify the technical problem solved by the present invention, technical scheme and its beneficial effects, the present invention is further described in details in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiment described here is merely used to explain general principles of the invention, instead of limiting the scope of the invention.

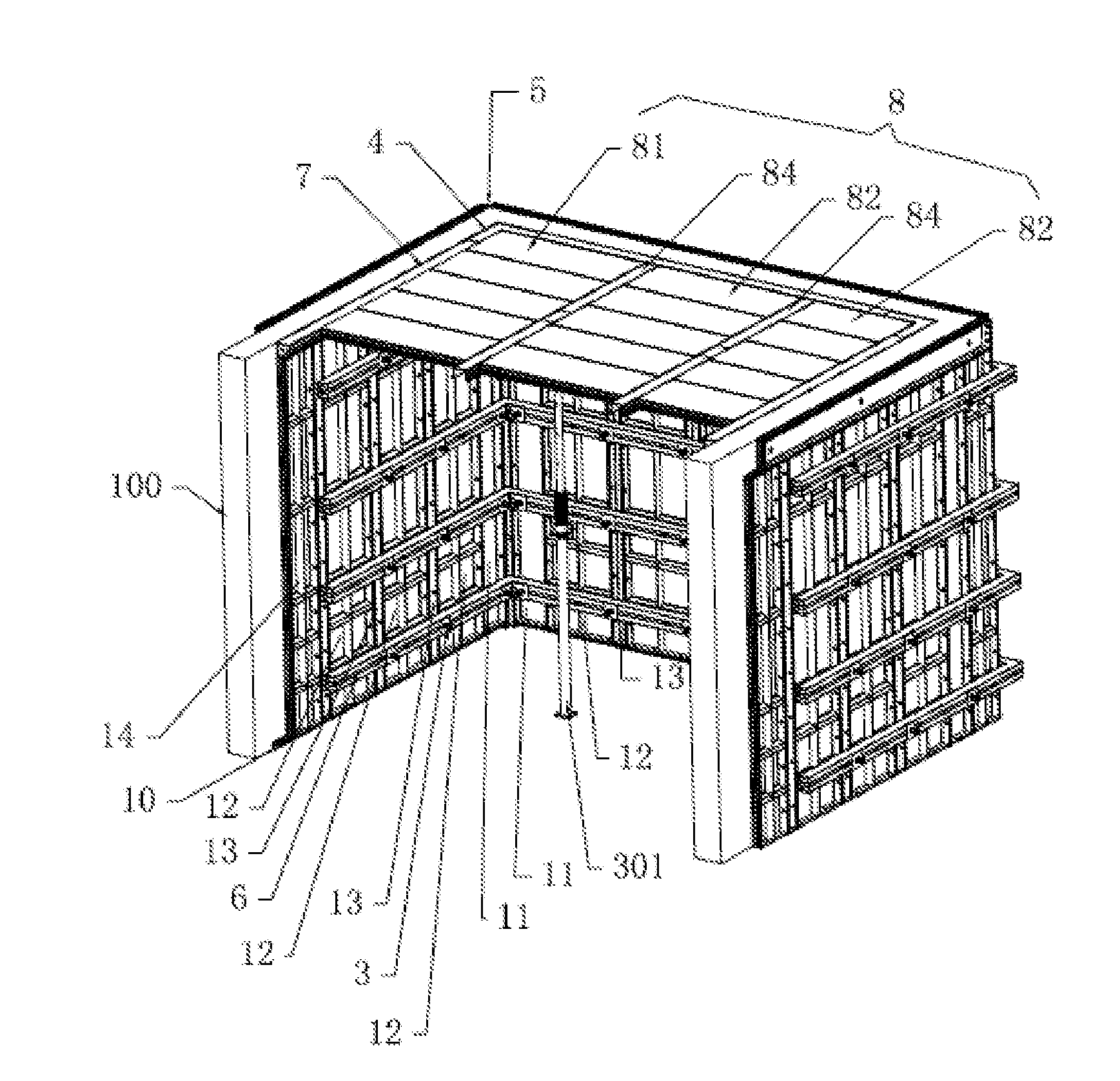

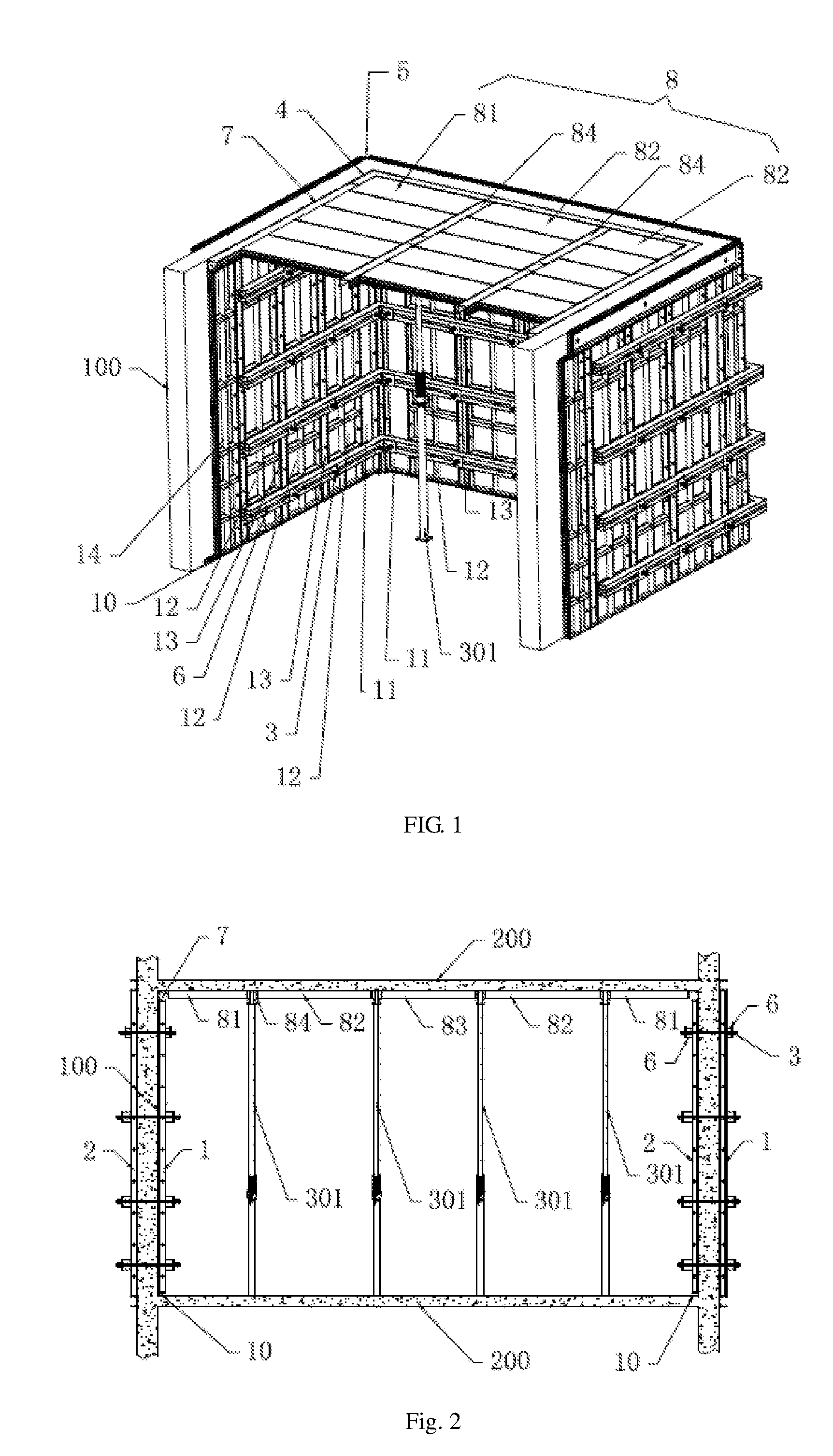

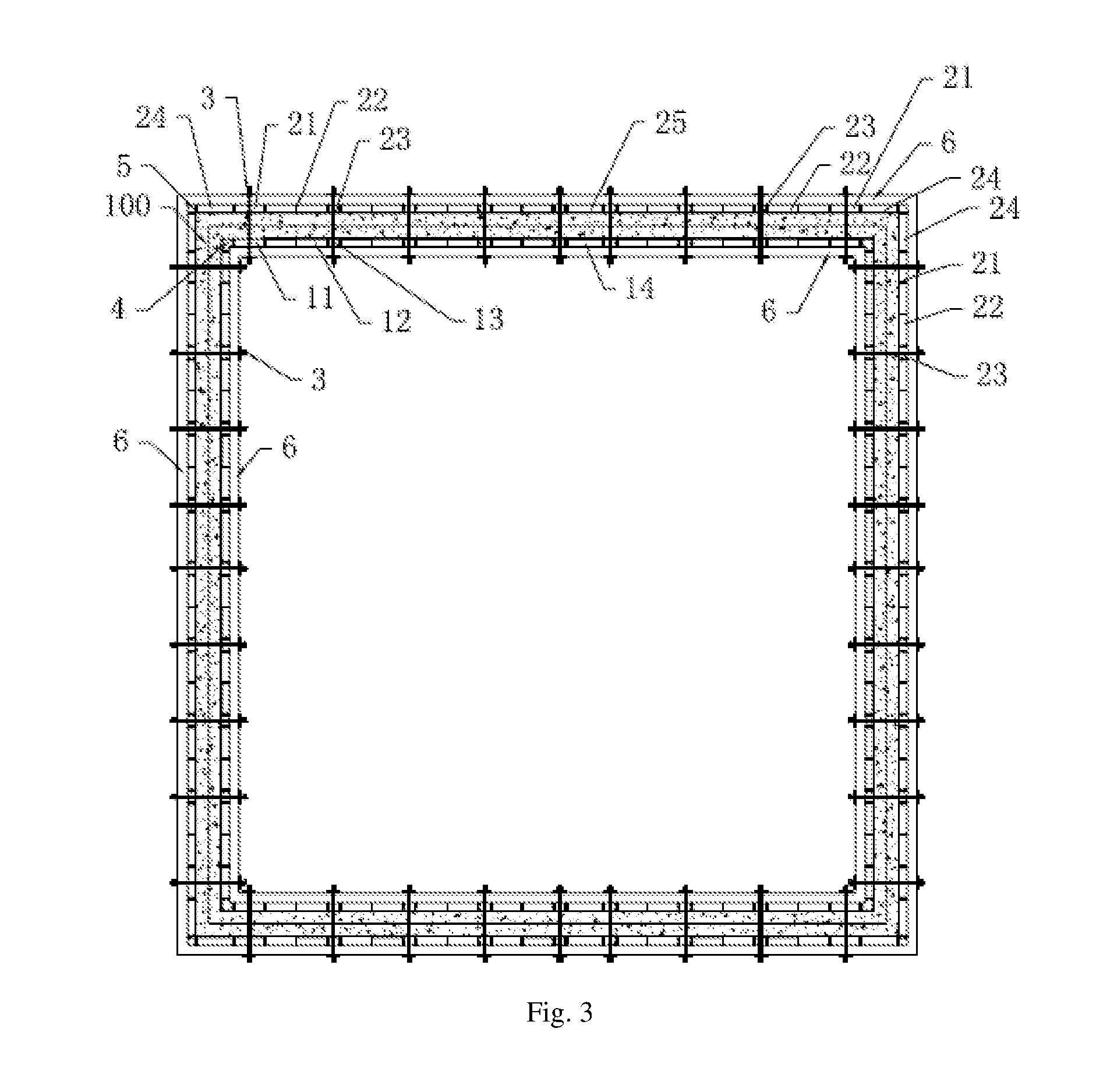

[0040]As shown in FIG. 1 to FIG. 6, according to one preferred embodiment of the present invention, an assembling and dismantling-beforehand structural template system comprises a vertical structural template system, a horizontal structural template system, and a support system.

[0041]The vertical structural template system comprises an interior-wallboard 1, an exterior-wallboard 2, an interactive wiredrawing bar group 3, a vertical internal-corner template 4, a vertical external-corner template 5 and a back beam 6.

[0042]The back beam 6 is horizontally mounted at the relative pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com