Sw-sagd with between heel and toe injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085]The present disclosure provides a novel well configurations and method for SW-SAGD.

[0086]This novel modification to the conventional single-well SAGD (SW-SAGD) process varies the location and number of steam injection points during the production phase, and the same points can be used in preheat or cyclic preheat.

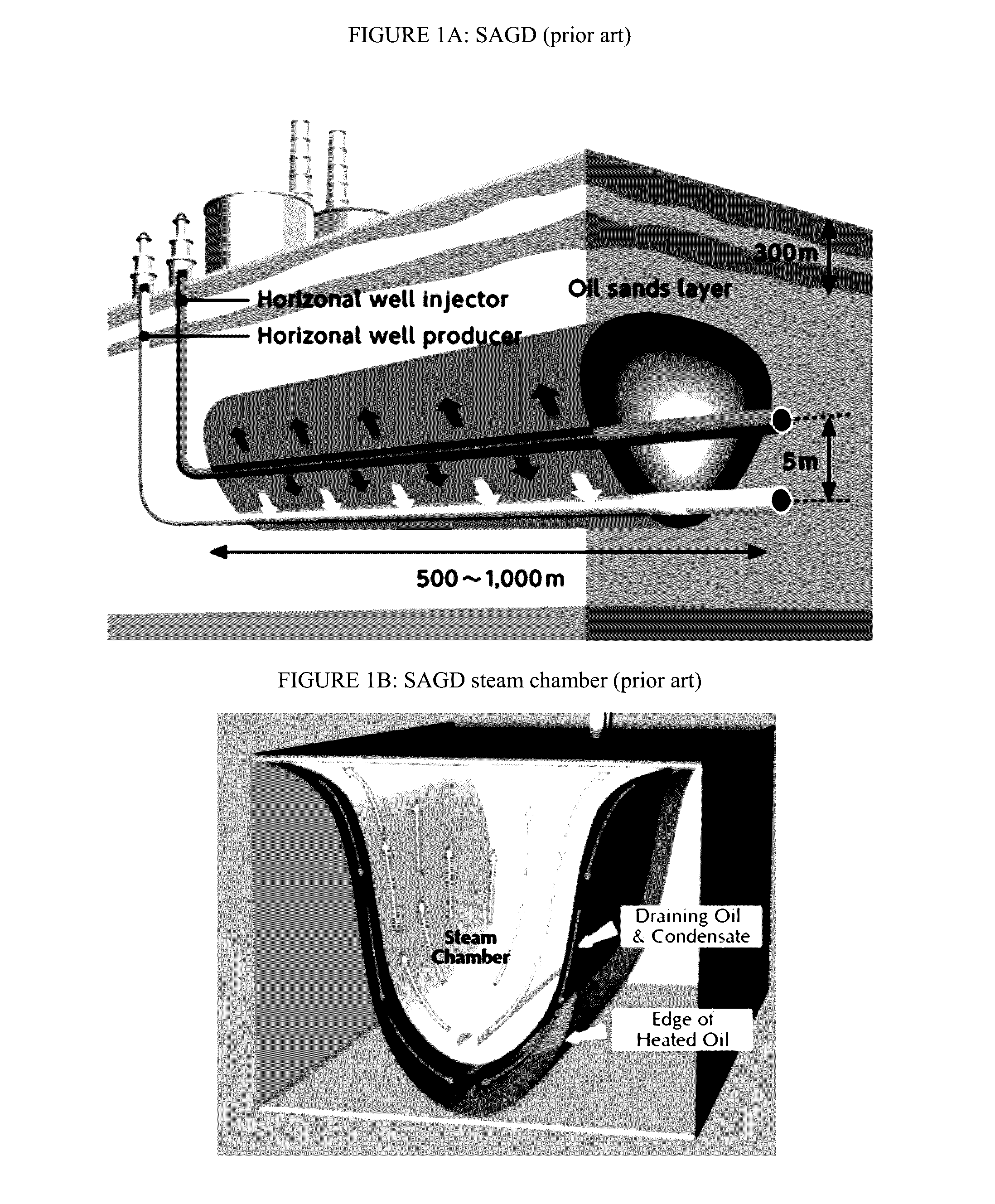

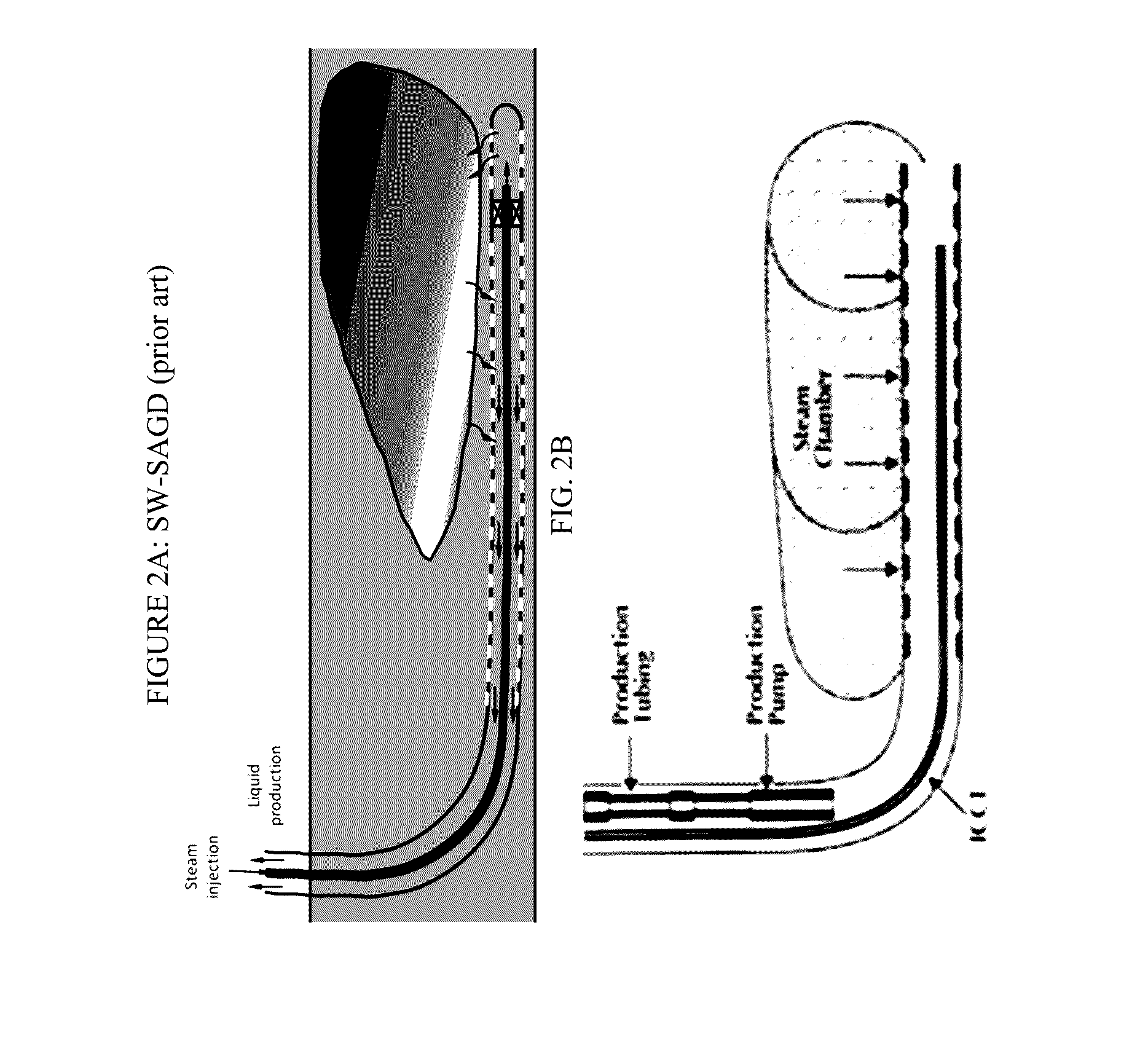

[0087]The conventional SW-SAGD process grows a steam chamber and drains oil by gravity by utilizing one single horizontal well with steam injected only at the toe and liquid produced through the rest of the well. SW-SAGD has potential to unlock vast thin-zone (5-20 m pay) oil sand resources where SAGD using well pairs is economically and technically challenging.

[0088]However, the conventional SW-SAGD normally suffers from slow steam chamber growth and low oil production rate as the steam chamber can only grow from toe gradually towards the heel. This appears to be very ineffective, and seriously limits the usefulness of SW-SAGD.

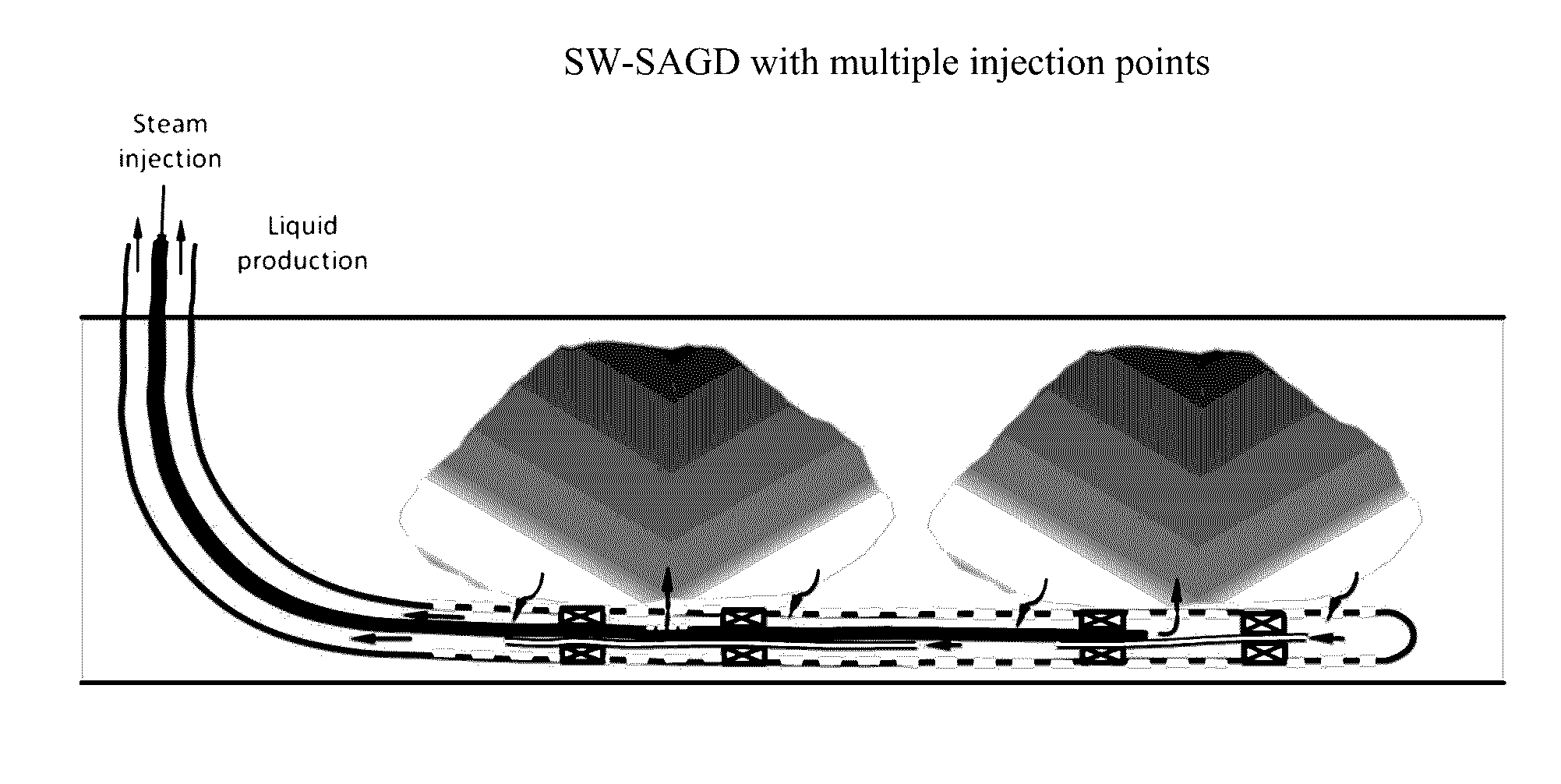

[0089]In this invention, we propose an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com