Preparation method of polymer modified demulsifier with broad spectrum

A high-molecular and broad-spectrum technology, applied in the field of polymers, can solve problems such as differences in physical and chemical properties, and achieve the effect of reducing dosage, reducing dosage, and increasing benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

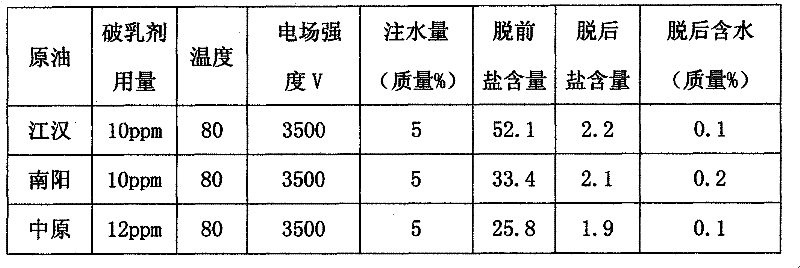

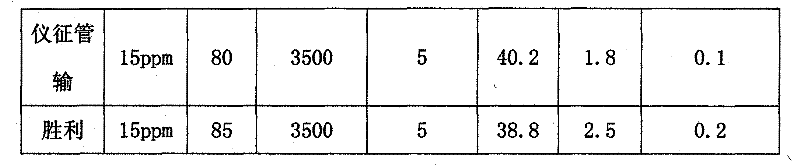

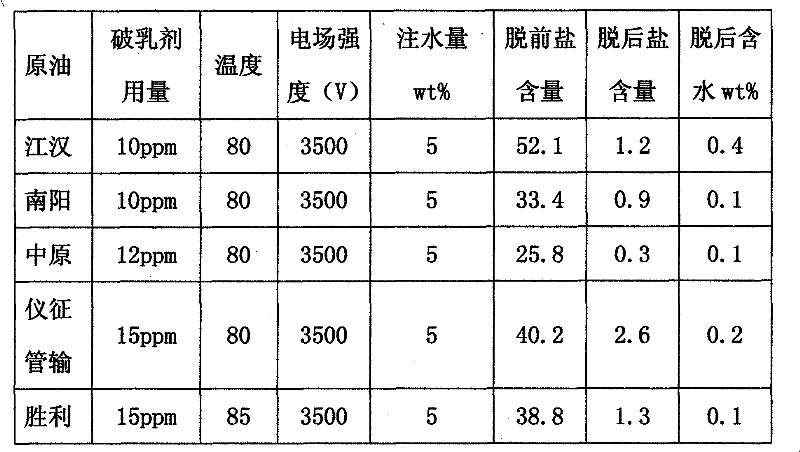

Examples

Embodiment Construction

[0011] The present invention will be further described below.

[0012] 1. Preparation method of polyol ethylene oxide propylene oxide high polymer

[0013] 1. Raw material ratio:

[0014] Octadecanol: propylene oxide=1~10: 2~60 (ratio by weight)

[0015] Propylene oxide: ethylene oxide=2~8: 8~2 (ratio by weight and number)

[0016] The amount of DMC complex catalyst accounted for raw materials: 0.5 ~ 2% (wt%)

[0017] Reaction temperature: 120-180°C.

[0018] The general formula of described DMC complex catalyst is: M 3 [M'(CN) 6 ] 2 ·xA·yB, where M is the metal ion Zn 2+ , M′ is Co 3+ , A is ZnCl 2 , B is ethylene glycol dimethyl ether, wherein x, y are the numbers representing A and B respectively.

[0019] 2. Preparation process:

[0020] Add the measured stearyl alcohol and DMC complex catalyst into the autoclave, seal the autoclave, purge with nitrogen to get rid of the air in the autoclave, after vacuuming, raise the temperature of the autoclave to the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com