Rotary type dusting device

a dusting device and rotary technology, applied in the direction of vacuum cleaners, carpet cleaners, applications, etc., can solve the problems of time-consuming and labor-intensive both ways, difficult to wash strips, and ineffective bristles, etc., to achieve easy and quick attachment and reduce assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

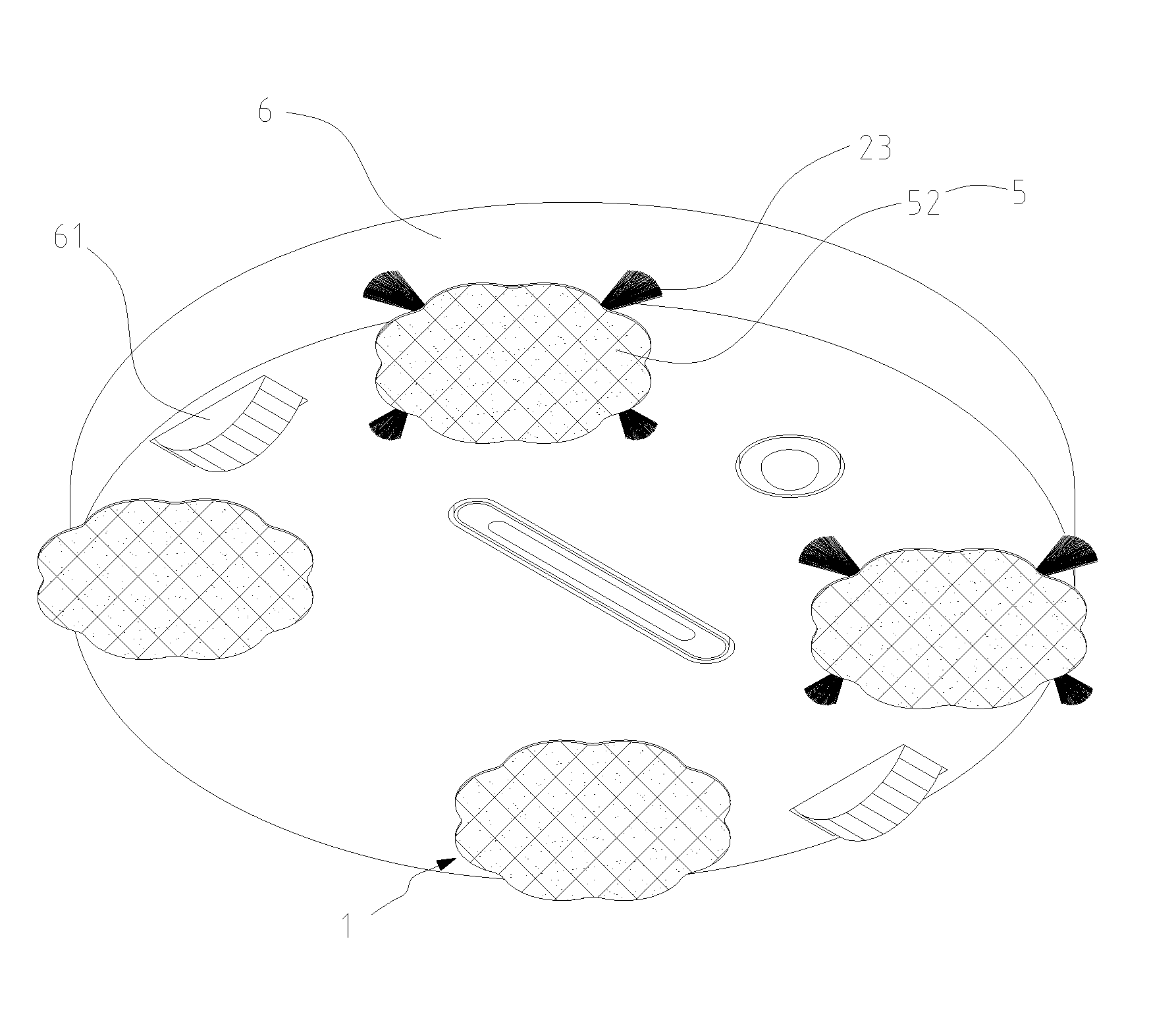

[0020]Referring to FIGS. 1 to 6 showing a preferred embodiment of a rotary type dusting device 1 of the present invention, the rotary type dusting device 1 is detachably assembled to an automatic cleaning machine 6. The automatic cleaning machine 6 functions as a vacuum cleaner and is equipped with two wheels 61 at a bottom thereof for allowing the automatic cleaning machine 6 to move automatically without manual control.

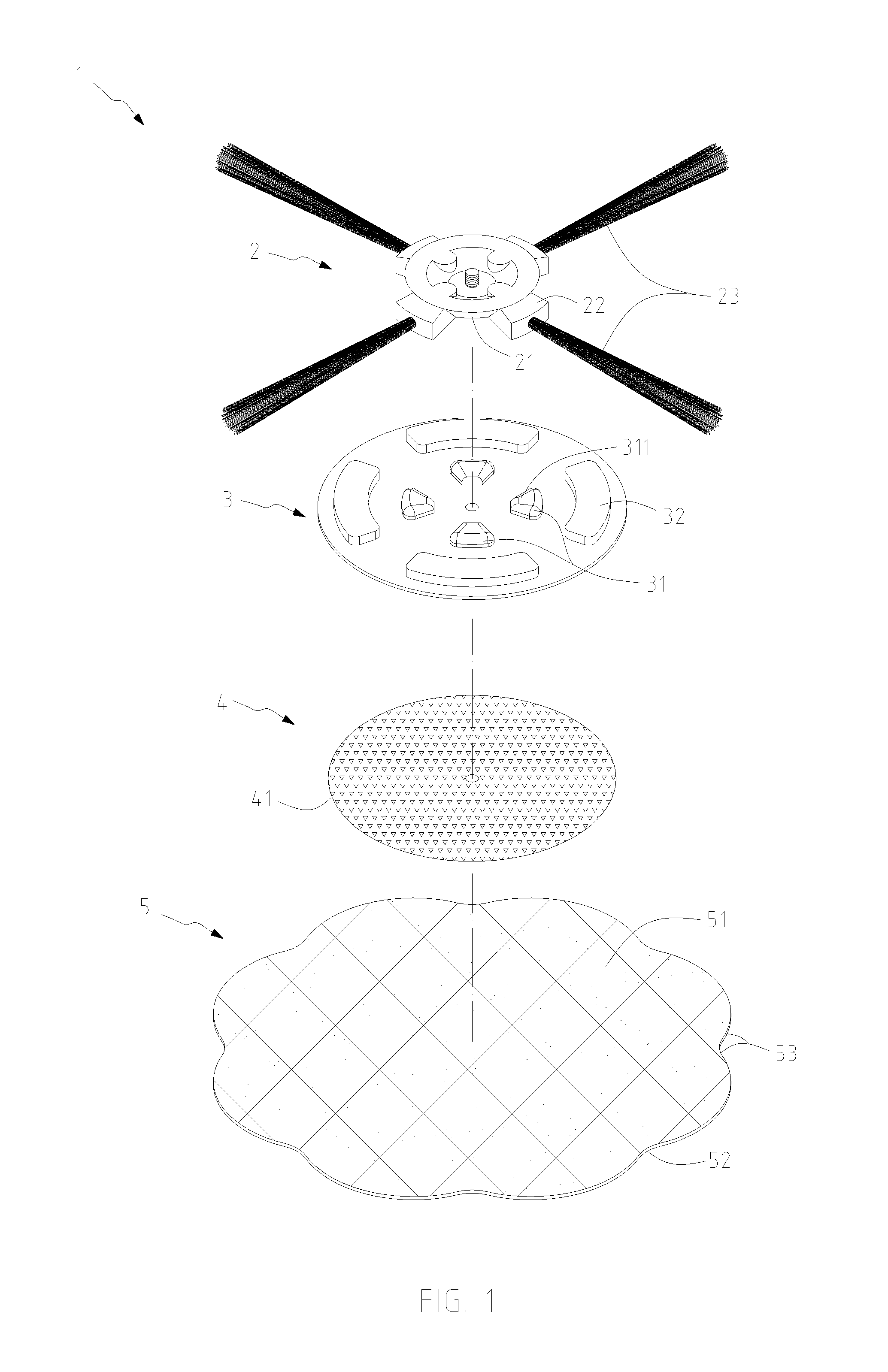

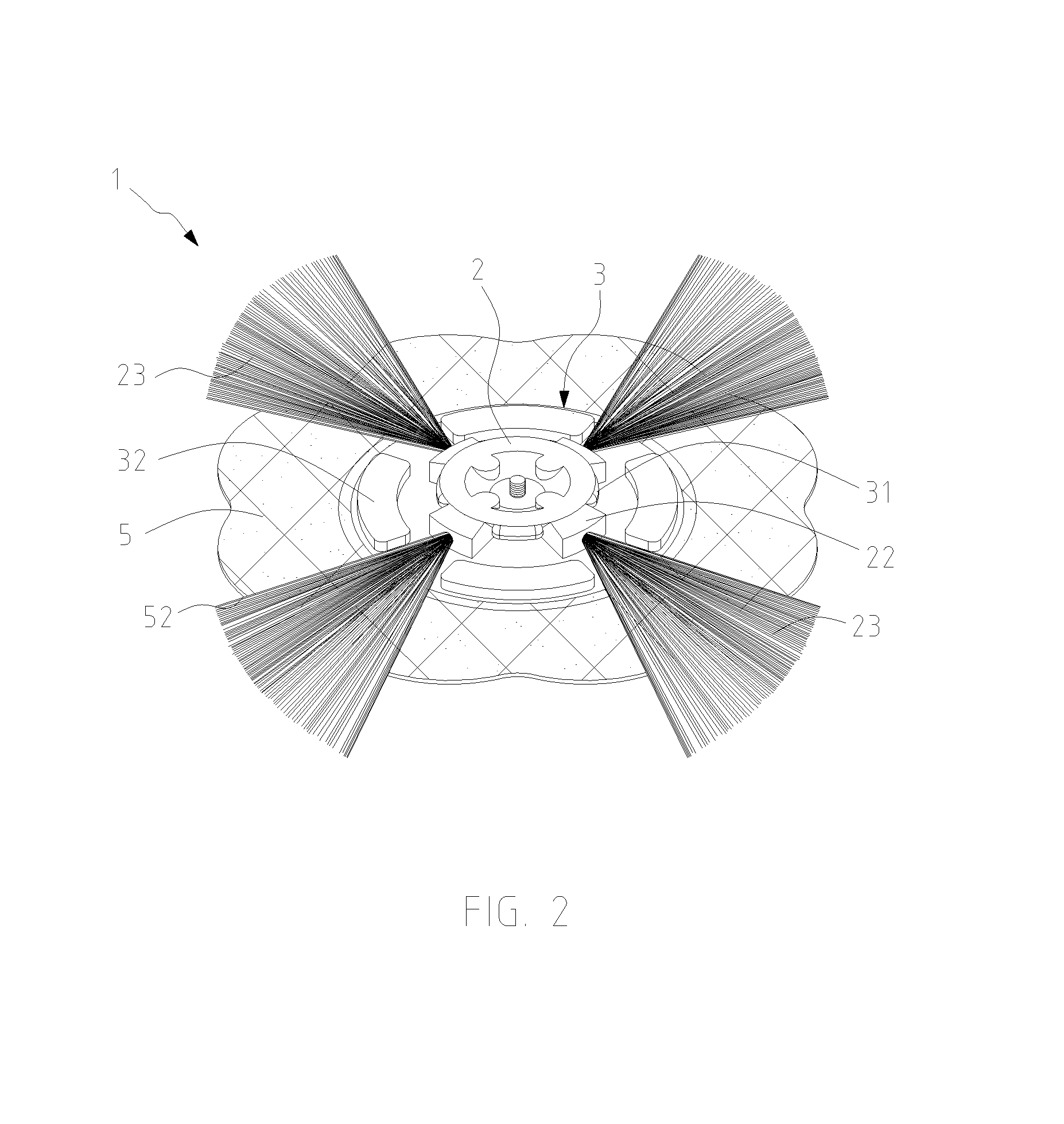

[0021]The rotary type dusting device 1 comprises a connecting base 2, a rotary disc 3, an affixing element 4, and a dusting element 5. The connecting base 2 is pivotably connected to the bottom of the automatic cleaning machine 6 through a drive shaft (not shown) connected to a built-in motor (not shown) so as to be driven by the drive shaft to rotate. In this embodiment, the connecting base 2 has a round shape and comprises a plurality of interference portions 21 and mounting portions 22 arranged around the connecting base 2. The interference portions 21 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com