Abutment Plate for Water Control Gate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

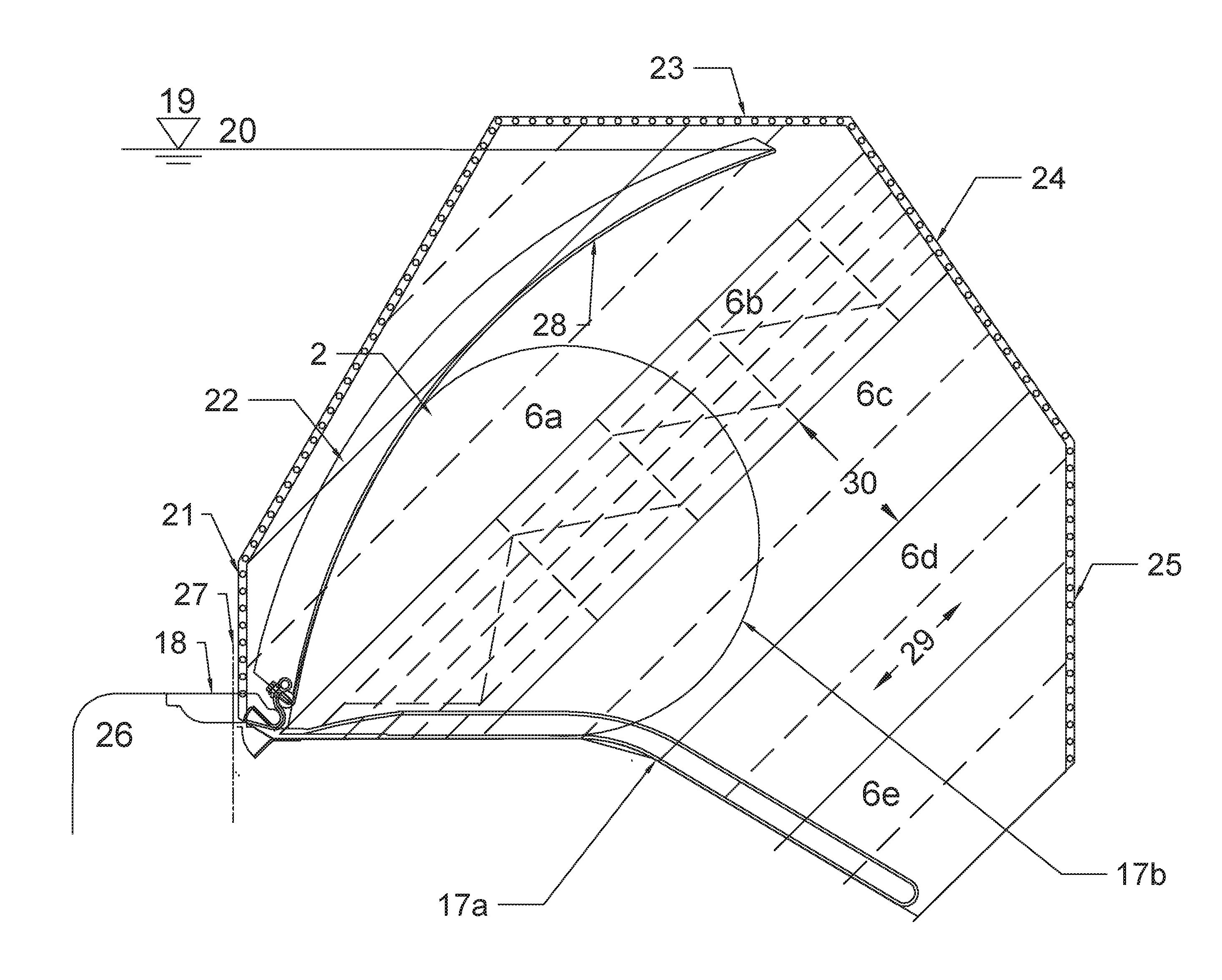

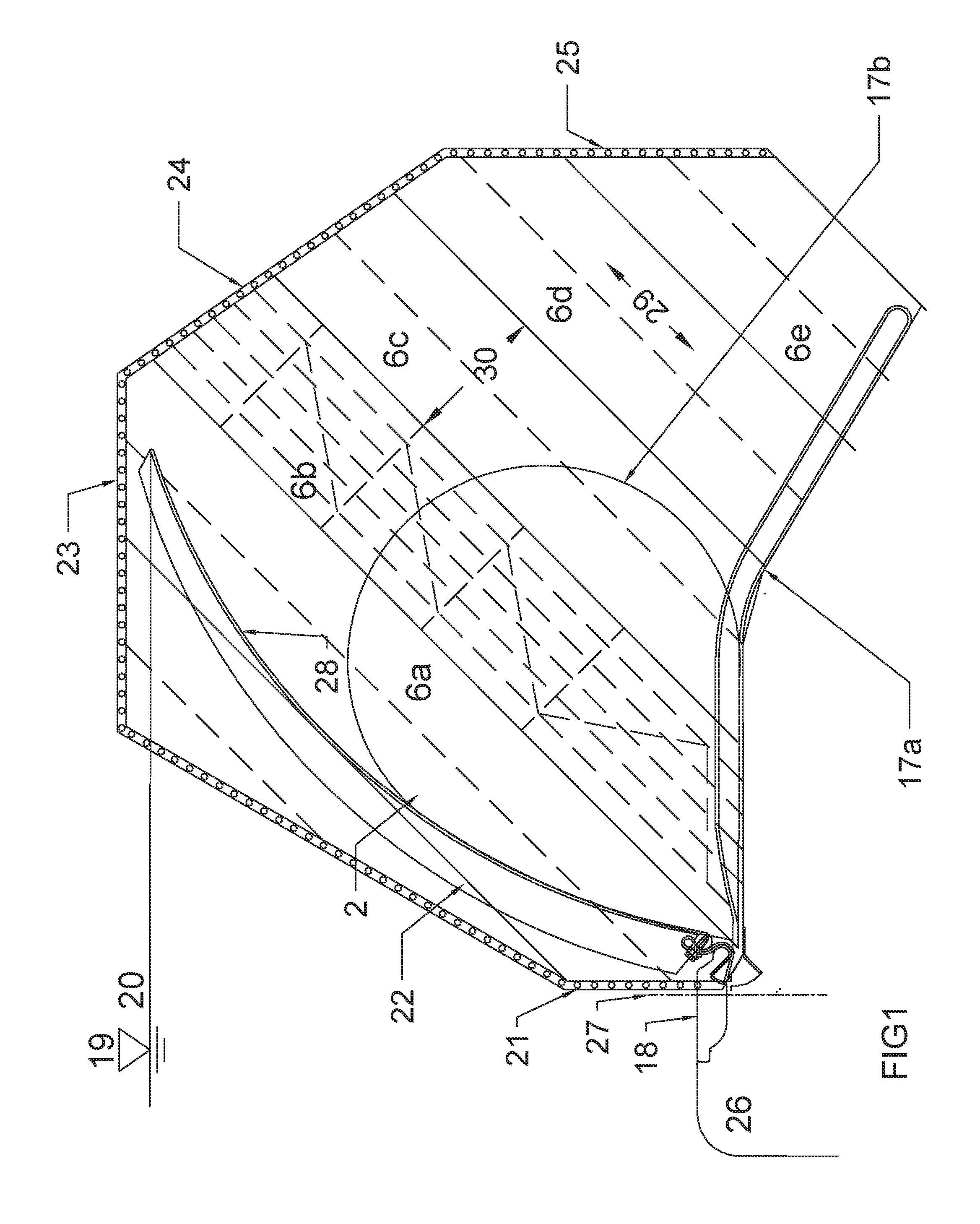

[0035]Referring to FIG. 1, Abutment plate 6a, 6b, 6c, 6d, and 6e are attached to concrete abutment 19. Inflated air bladder 17b actuates gate panel 28 to which is affixed abutment seal 2. The upstream edges of abutment plate strip 6a are clamped to concrete abutment 19 by clamps 21 and 22. The remaining edges of the abutment plate strips 6a, 6b, 6c, 6d and 6e are secured by clamps 23, 25, and 25. The abutment plate of this invention is applicable to a wide variety of water control gates in addition to the one illustrated.

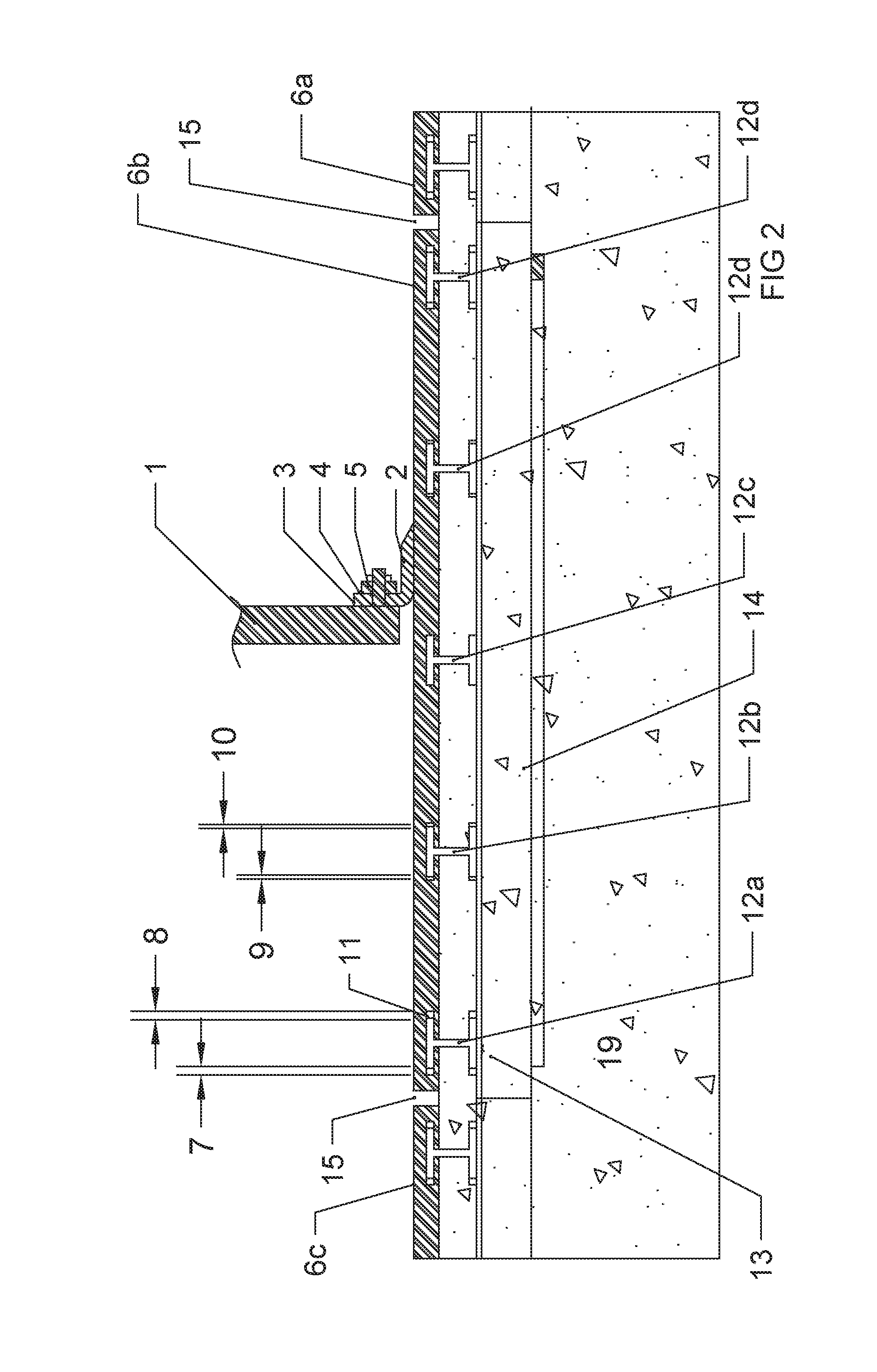

[0036]Referring now to FIG. 2, a cross section of an abutment plate assembly is shown. Guide rails 12a, 12b, 12c, 12d and 12e secure abutment plate 6b to concrete pier 19. Clearances 7, 8, 9, and 10 vary in proportion to distance from the center rail 12c where only minimal clearance need be provided. The rails are connected, by welding for example, to spacer member 13 which may in turn be connected to diagonal brace 14.

[0037]Referring now to FIG. 3, clamp 22 secures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com