Projector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

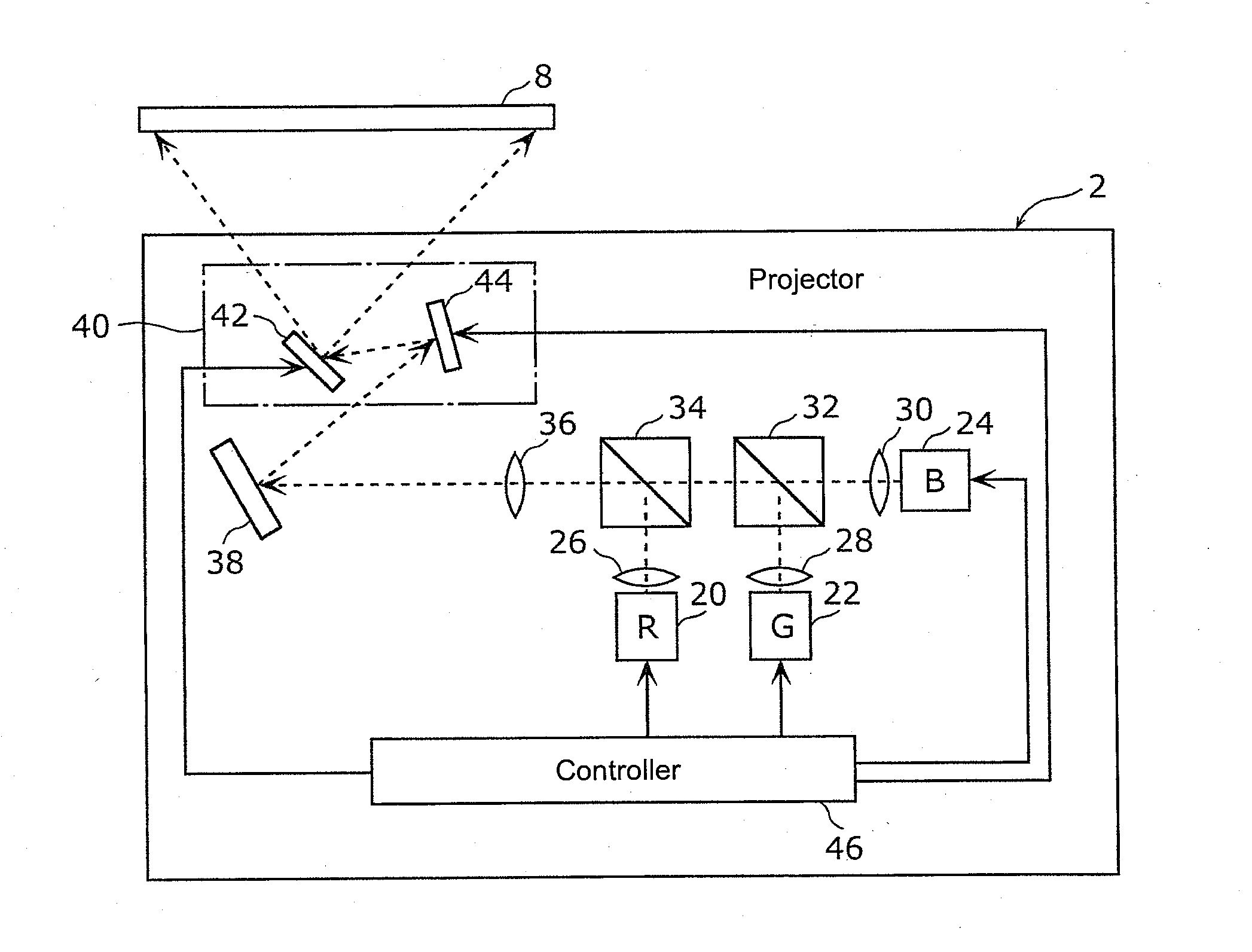

[0049]An optical element and a projector having the optical element according to a first embodiment is described below.

[1-1. Configuration of Head-Up Display Device]

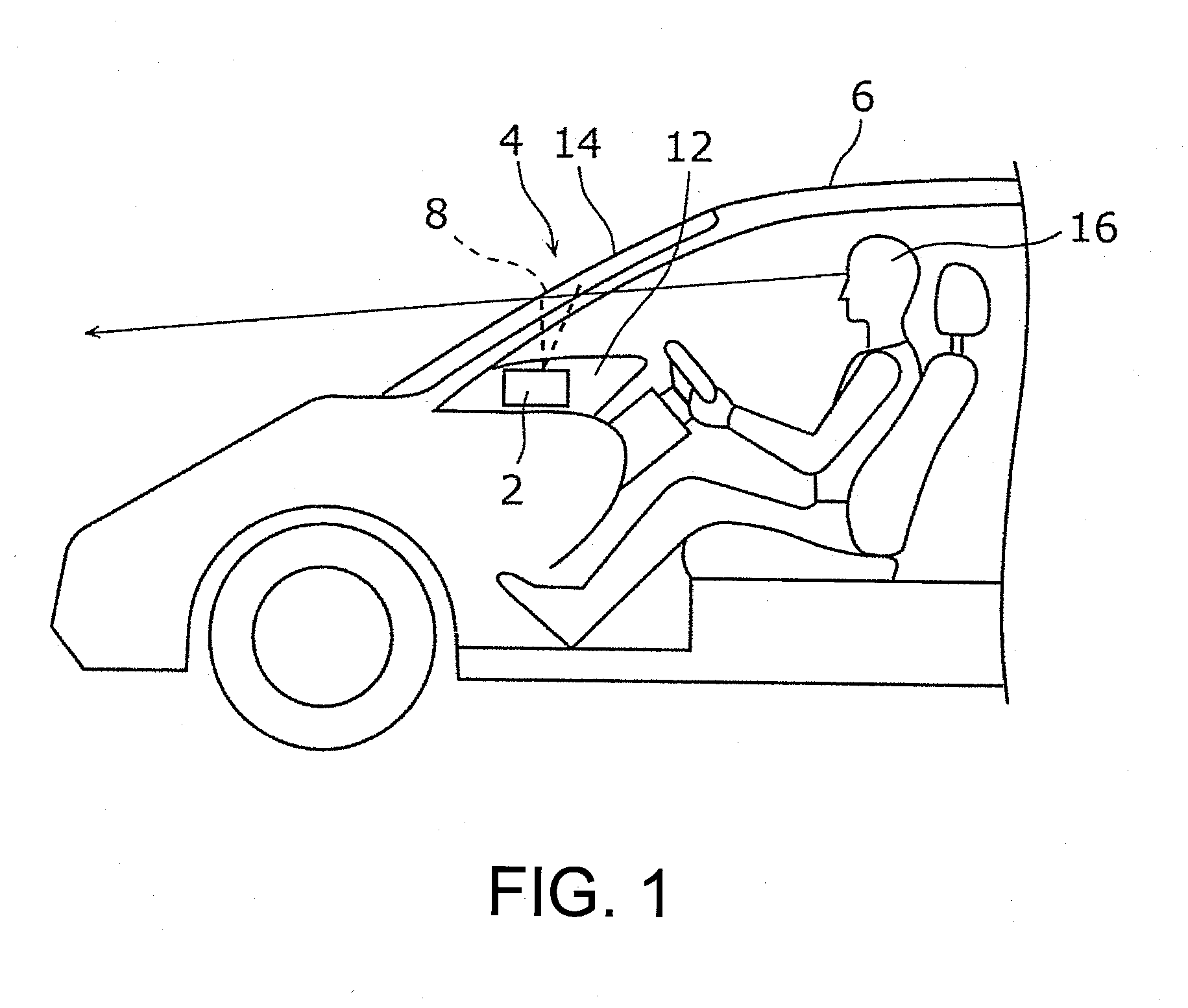

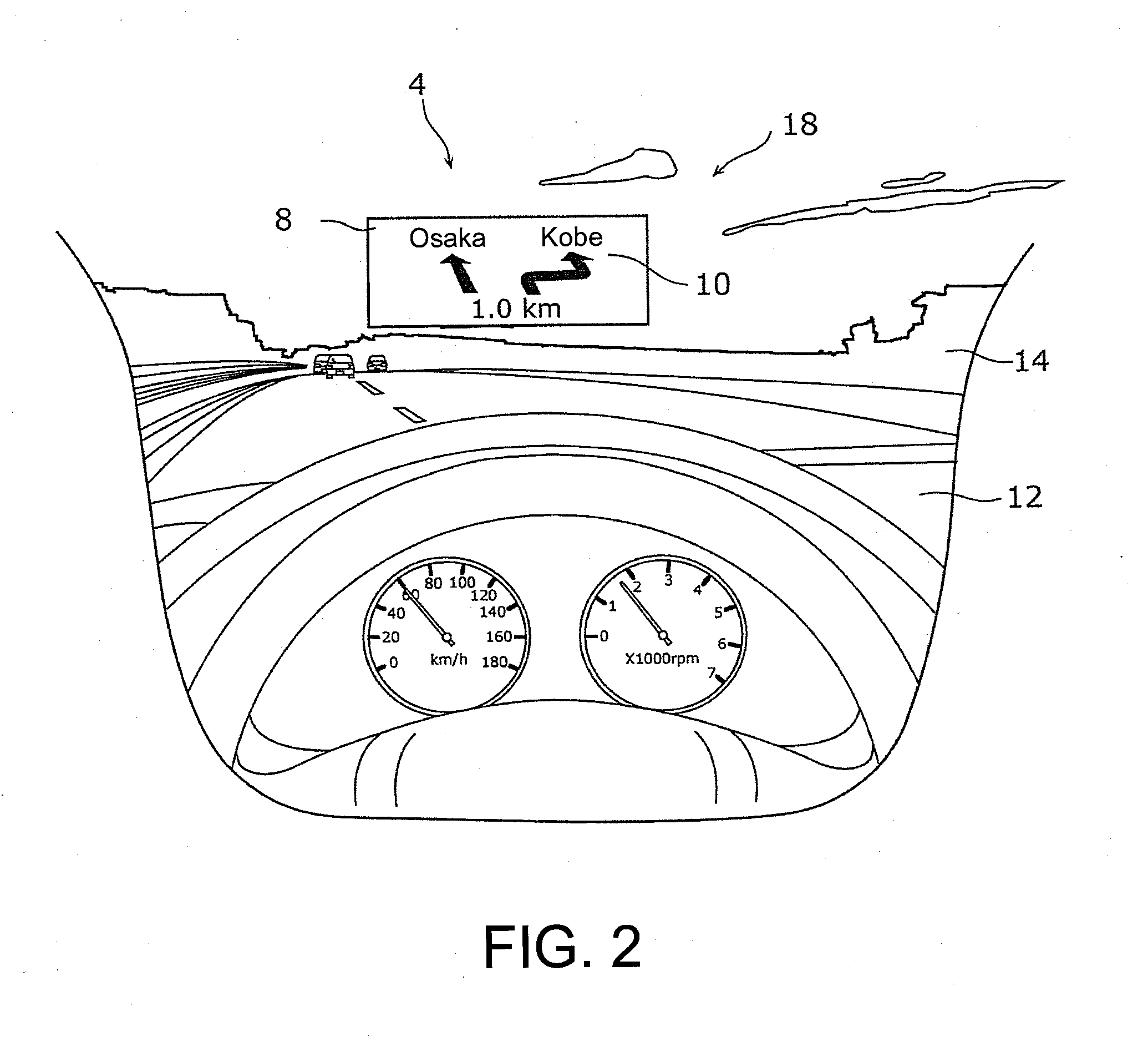

[0050]A projector 2 according to the first embodiment, for example, is mounted to a head-up display device 4. First, a configuration of the head-up display device 4 is described with reference to FIGS. 1 and 2. FIG. 1 is to describe a configuration of a head-up display device 4 equipped with the projector 2 according to a first embodiment. FIG. 2 illustrates a display sample of an image 10 by the head-up display device 4 of FIG. 1.

[0051]As shown in FIG. 1, the head-up display device 4, for example, is mounted to an automobile 6, and includes the projector 2 and a combiner 8 (also referred to as “projection surface 8” below). The projector 2 projects the image 10 onto the combiner 8, and is disposed in a dashboard 12 of the automobile 6. The combiner 8, for example, is constructed by a half mirror or such, and is disposed...

embodiment 2

[0081]Next, a configuration of the first optical element 26A according to a second embodiment is described with reference to FIG. 8. FIG. 8 is a side view illustrating a first optical element 26A according to a second embodiment. In the following embodiments, the same reference numbers as the aforementioned first embodiment are used to describe the same components, and their description thereof is omitted.

[0082]In the first optical element 26A according to the second embodiment, a shape of a second lens surface 54A that is formed on the emitting surface 50 is different compared to the aforementioned first embodiment. Namely, as is shown in FIG. 7, a shape of the second lens surface 54A is a spherical shape. A radius of curvature of the second lens surface 54A, for example, is −1.48 mm.

[0083]Even with this configuration, similar to the aforementioned first embodiment, the laser beam that is shaped by the first lens surface 52 is converted from a divergent beam into a parallel beam by...

embodiment 3

[0084]Next, a configuration of the first optical element 26B according to the third embodiment is described with reference to FIGS. 9 and 10. FIG. 9 is a perspective view illustrating a first optical element 26B according to a third embodiment. FIG. 10 is a side view illustrating a first optical element 26B according to a third embodiment.

[0085]In the first optical element 26B according to the third embodiment, a shape of a first lens surface 52B that has a convex shape formed on the incident surface 48B is different compared to the aforementioned first embodiment. That is to say, as shown in FIGS. 9 and 10, a shape of the first lens surface 52B has a first radius of curvature in a first direction (Y axis direction), and has a second radius of curvature in a second direction (X axis direction) that is orthogonal to the first direction, and is a so-called biconic surface shape. The first radius of curvature and the second radius of curvature are different in size. Preferably, a ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com