Alignable coupling assembly for connecting two prosthetic limb components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 10

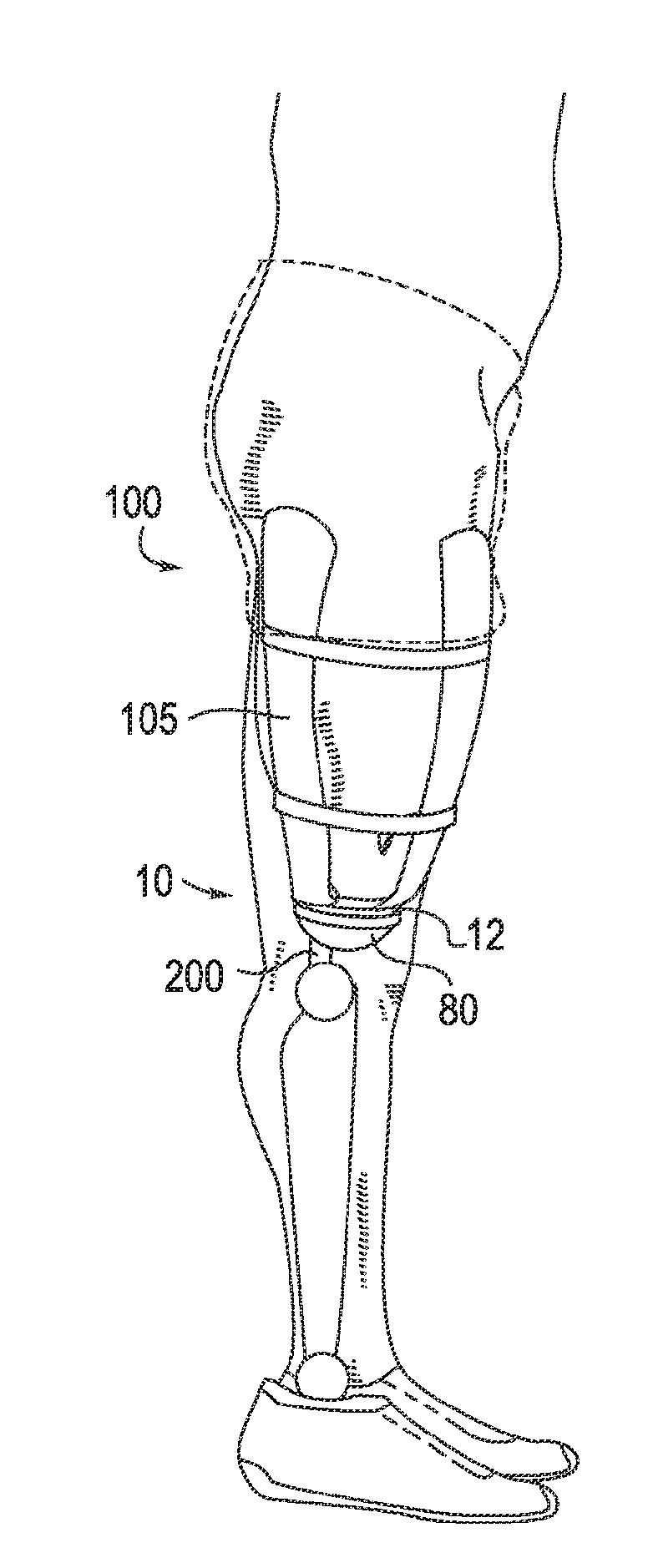

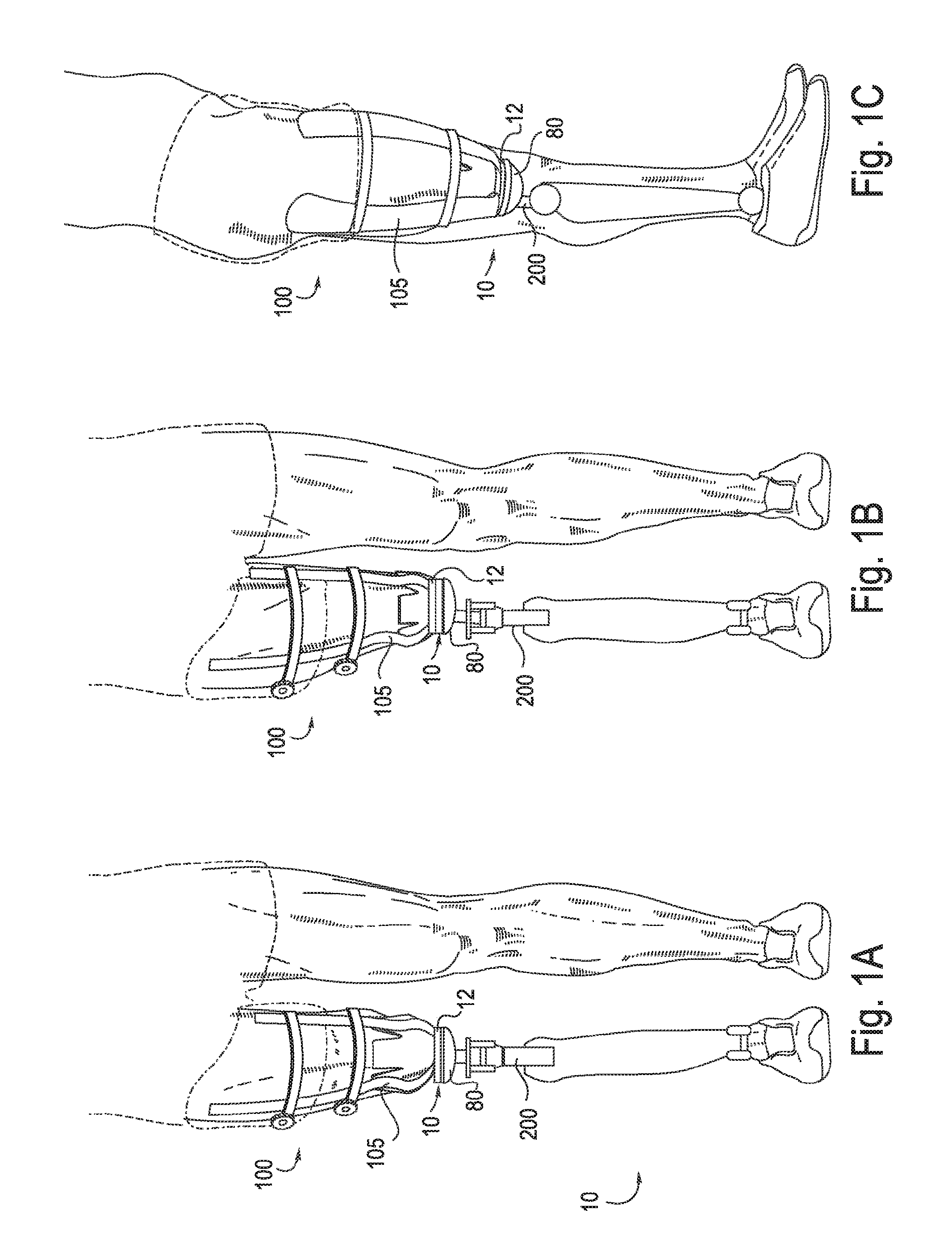

[0089]FIG. 1B is a front view of an embodiment of a modular prosthetic socket 100 with the alignable coupling assembly 10 adjusted so the longitudinal axis of the distal prosthetic component 200 is shifted in a lateral direction with respect to the longitudinal axis of the prosthetic socket. FIG. 1C shows a side view of the modular prosthetic socket 100 with the alignable coupling assembly embodiment 10 adjusted so the longitudinal axis of the distal prosthetic component 200 is shifted in a posterior direction with respect to the longitudinal axis of the prosthetic socket. Each of these shifts or adjustments in the position of the distal component with respect to the proximal prosthetic component is a common type of positional shift that makes biomechanical sense for a patient, and each type of shift is enabled by embodiments of an alignable coupling assembly, as provided herein.

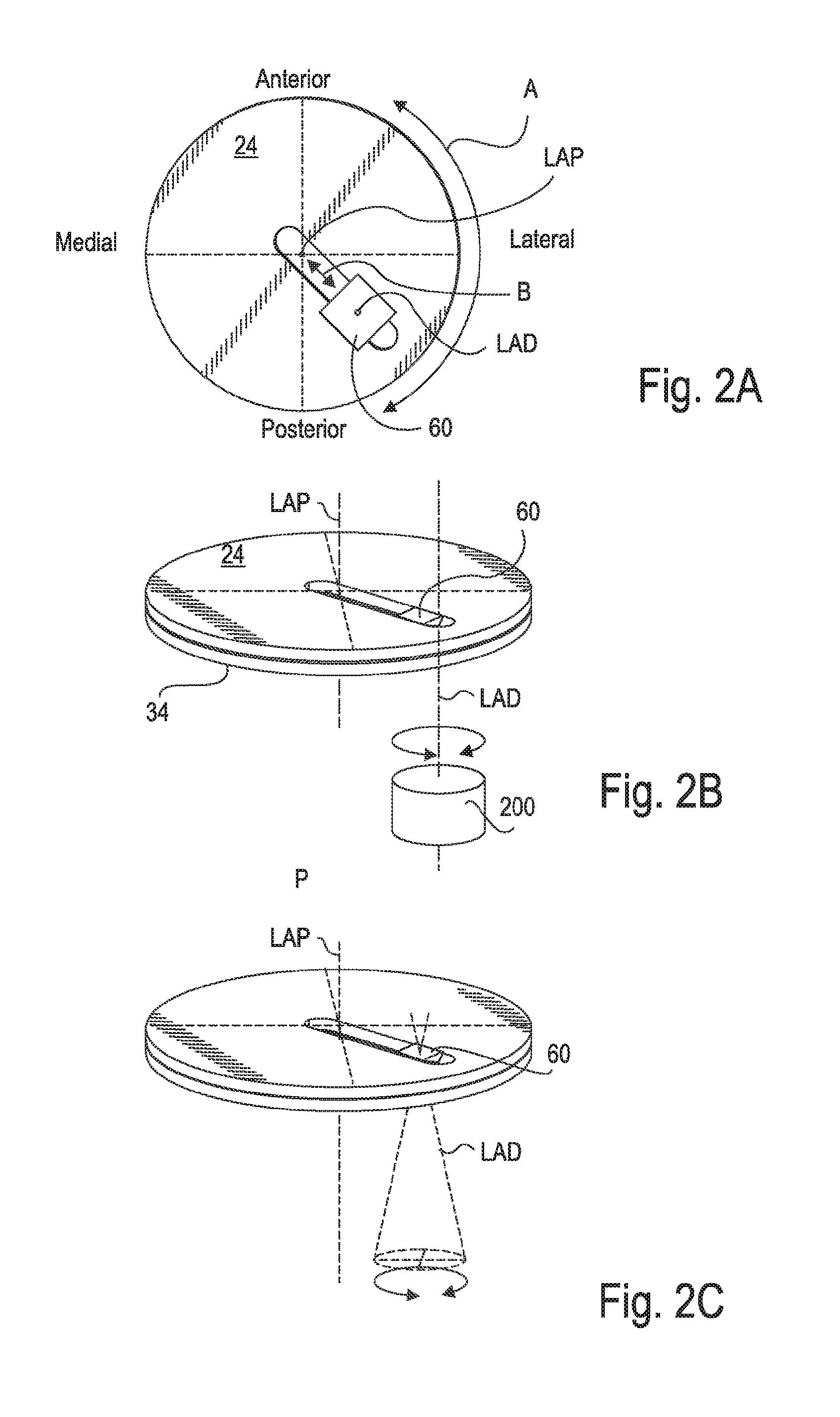

[0090]FIGS. 2A-2C are schematic representations of various aligning or positioning capabilities provided ...

embodiment 160

[0104]The second rotational option takes advantage of an embodiment of the alignable coupling assembly in which an alternative longitudinal connector embodiment 160 has a 2-part arrangement that includes a proximal slider portion that has a circular receptacle that rotatably houses a distally projecting distal portion of longitudinal connector. This rotational capability is shown in FIG. 10C, wherein the distal connecting feature 66 of longitudinal connector 60 is seen in a position that is rotated with respect it its position shown in FIG. 10B.

[0105]Rotation of circular plates 24 and 34 within circular receptacle 52 of support plate 50 actually provides a third rotational option. Rotation of the circular plates 24 and 34 within circular receptacle 52 rotates longitudinal connector 60 that is hosted within slot 40. The axial center of rotation is, unlike the first and second options above, the longitudinal axis of the proximal prosthetic component; nevertheless, a rotation of the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com