In-vehicle equipment

a technology for in-vehicle equipment and equipment, which is applied in the direction of process control, safety/protection circuit, instruments, etc., can solve the problems of increasing cost, increasing device size, and unable to avoid the increase in cost, so as to reduce the size and cost of in-vehicle equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

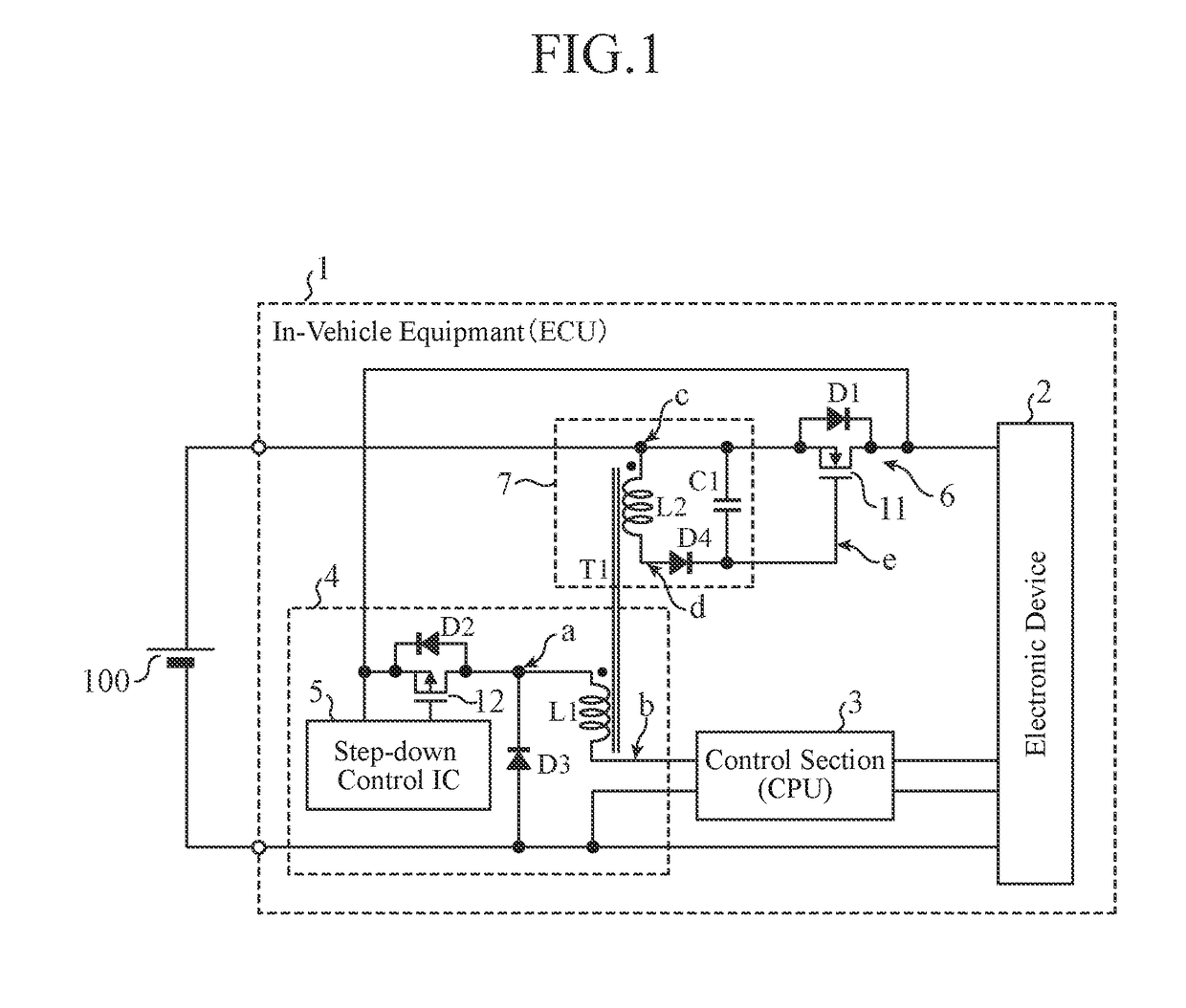

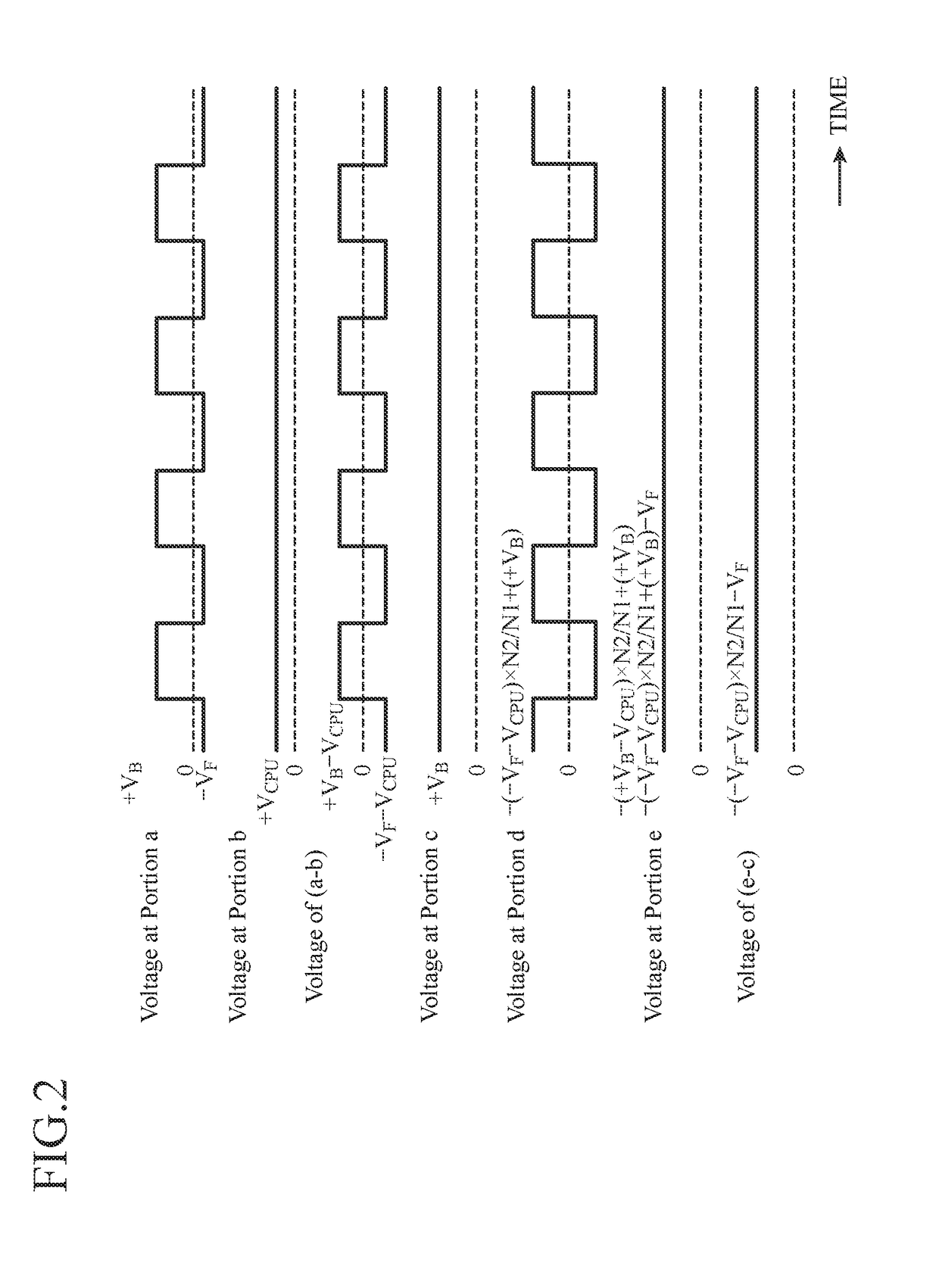

[0026]As shown in FIG. 1, in-vehicle equipment 1 according to Embodiment 1 includes: an electronic device 2 that operates using an in-vehicle battery 100 as a power supply; a control section 3 that controls the electronic device 2; a first power supply section 4 of a step-down DC / DC converter (buck converter, step-down converter etc.) type that supplies power to the control section 3; a power supply reverse connection protection section 6 that prevents a reverse current that flows in a case where the battery 100 and the electronic device 2 are connected with a reverse polarity; and a second power supply section 7 that generates a drive voltage to drive the power supply reverse connection protection section 6.

[0027]In the following, a case where the battery 100 is connected to the in-vehicle equipment 1 with a positive polarity is referred to as normal connection, and a case where the battery 100 is connected to the in-vehicle equipment 1 with the reverse polarity is referred to as r...

embodiment 2

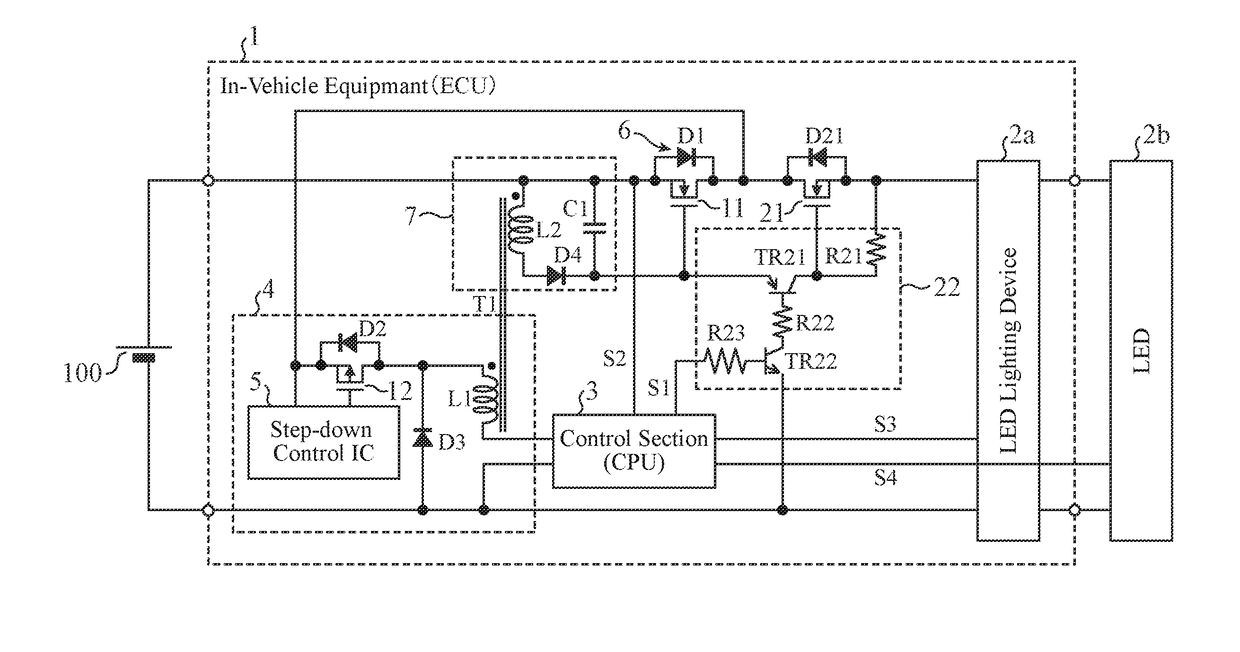

[0057]FIG. 3 is a circuit diagram showing a configuration of in-vehicle equipment 1 according to Embodiment 2. Parts in FIG. 3 identical or equivalent to those in FIG. 1 are denoted by the same reference numerals, and descriptions thereof will be omitted.

[0058]In Embodiment 2, an N-channel FET 11a of the power supply reverse connection protection section 6 is arranged on the minus terminal side of the battery 100.

[0059]In the case where the N-channel FET 11 is connected to the plus terminal side of the battery 100 (FIG. 1), the anode terminal of the parasitic diode D1 is connected to the battery 100 and the cathode terminal thereof is connected to the electronic device 2, while in the case where the N-channel FET 11a is connected to the minus terminal side (FIG. 3), the anode terminal of the parasitic diode D1 is connected to the electronic device 2, and the cathode terminal thereof is connected to the minus terminal of the battery 100. In addition, the winding end portion of the pr...

embodiment 3

[0061]FIG. 4 is a circuit diagram showing a configuration of in-vehicle equipment 1 according to Embodiment 3. Parts in FIG. 4 identical or equivalent to those in FIG. 1 are denoted by the same reference numerals, and descriptions thereof will be omitted.

[0062]In Embodiment 3, a P-channel FET 11b is used as the semiconductor switch of the power supply reverse connection protection section 6.

[0063]In the case where the N-channel FET 11 is used (FIG. 1), the winding start portion of the secondary winding L2 of the transformer T1 is connected to the battery 100 and the winding end portion of the secondary winding L2 is connected to the rectifier diode D4, while in a case where the P-channel FET 11b is used (FIG. 4), the winding direction of the secondary winding L2 of the transformer T1 is reversed, the winding end portion of the secondary winding L2 is connected to the battery 100, and the winding start portion of the secondary winding L2 is connected to the rectifier diode D4. In add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com