Ship equipped with main propeller and additional propeller and hybrid operating method therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]An embodiment of the present invention will be described with reference to the attached drawings.

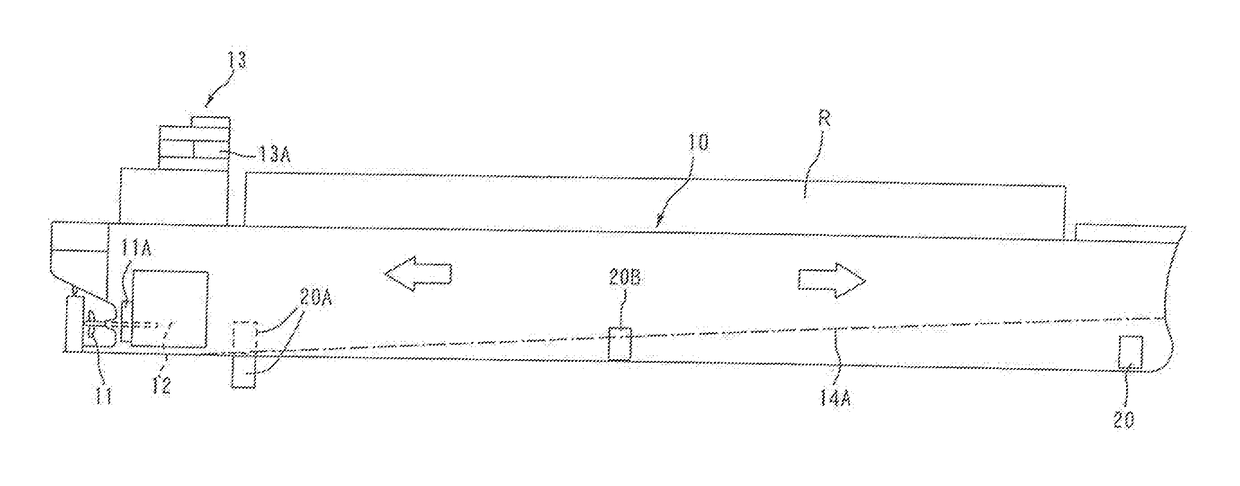

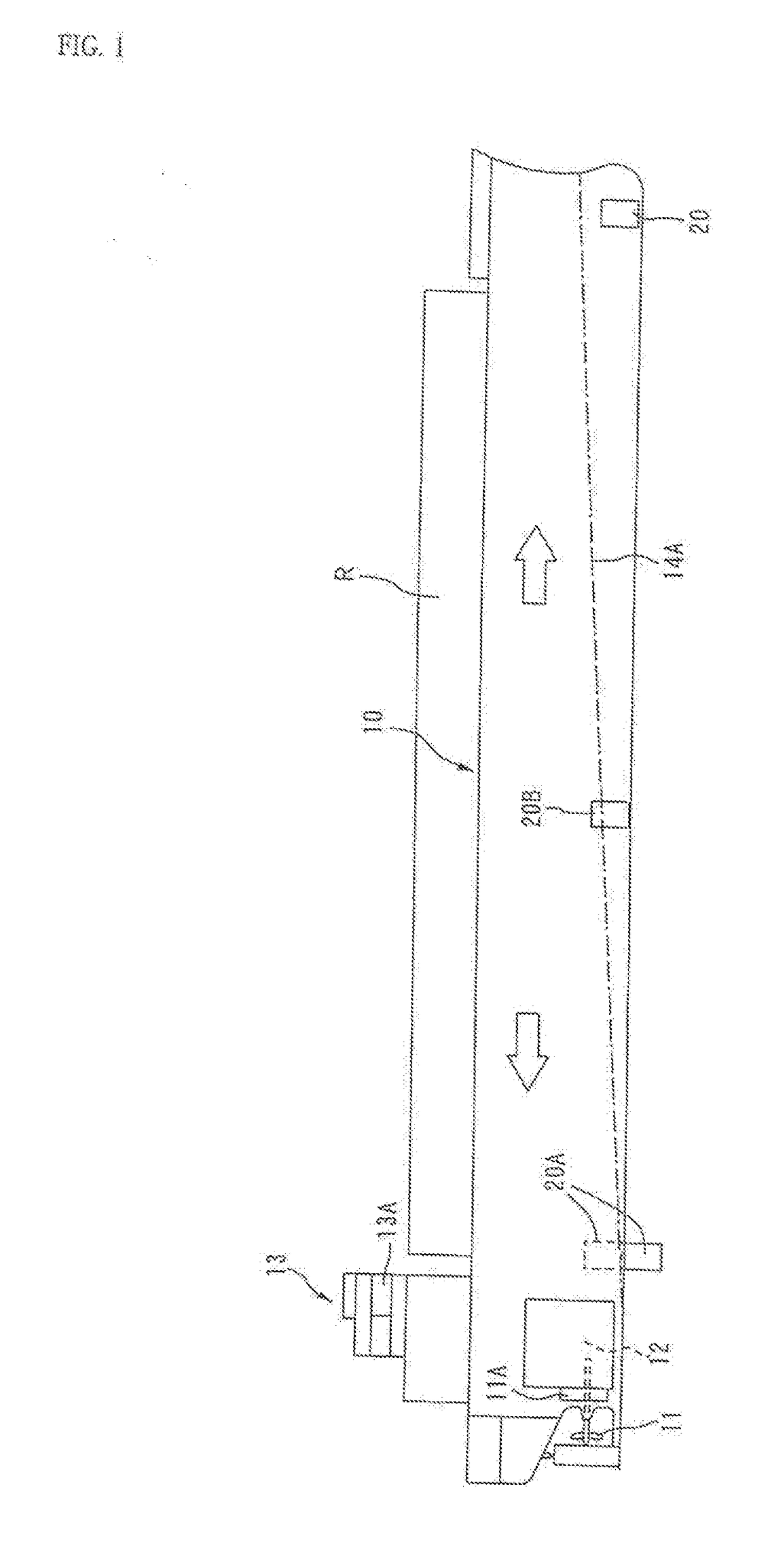

[0051]FIG. 1 is a schematic front view of a ship according to the present invention, for example, a commercial ship 10 loaded with cargo, such as a cargo ship. The commercial ship 10 obtains propelling force by driving a main propeller 11 by a main engine (propulsion engine) 12 such as a diesel engine. The reference sign 14A represents a water line in an unload condition, indicating a state of trim by head in which the water line gradually becomes higher in a bow direction and intersects with a ship bottom line in a stern direction. In FIG. 3, the reference sign 14B represents a water line, indicating a state of trim by the stern which is a reverse state of the above state.

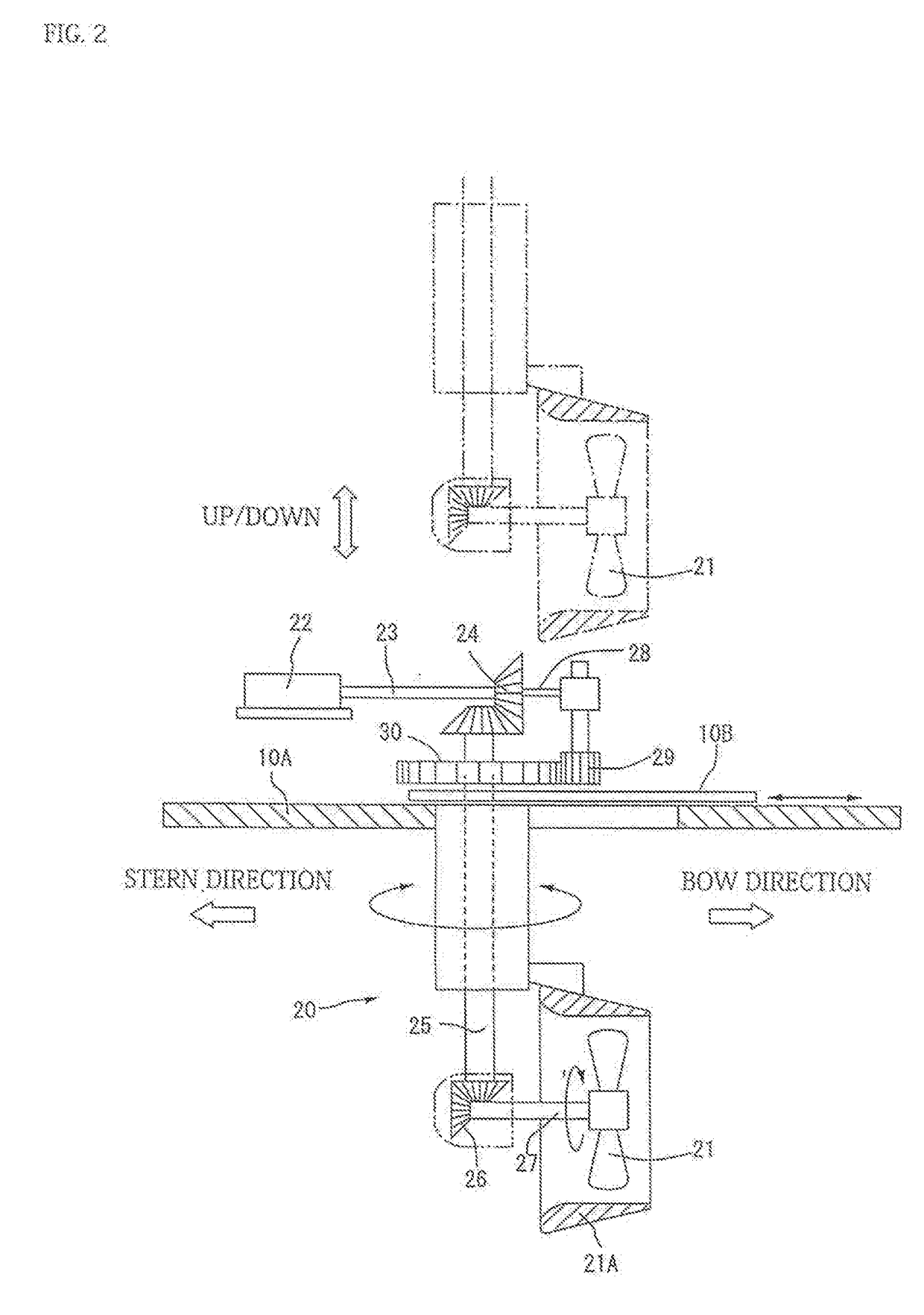

[0052]As is referenced in FIG. 2, the ship is provided with an additional propeller 20 including a driving unit 22 therefore and a duct propeller 21.

[0053]This additional propeller 20 is disposed to a position di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com