A prefabricated panel building system

a prefabricated panel and building system technology, applied in the direction of walls, building components, constructions, etc., can solve the problems of prefabricated wall building systems, requiring labor and time in erecting traditional studs, prior art composition boardroom wallboard panels are not designed for convenient water and electricity installation, etc., to achieve the effect of substantial rigidity and integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

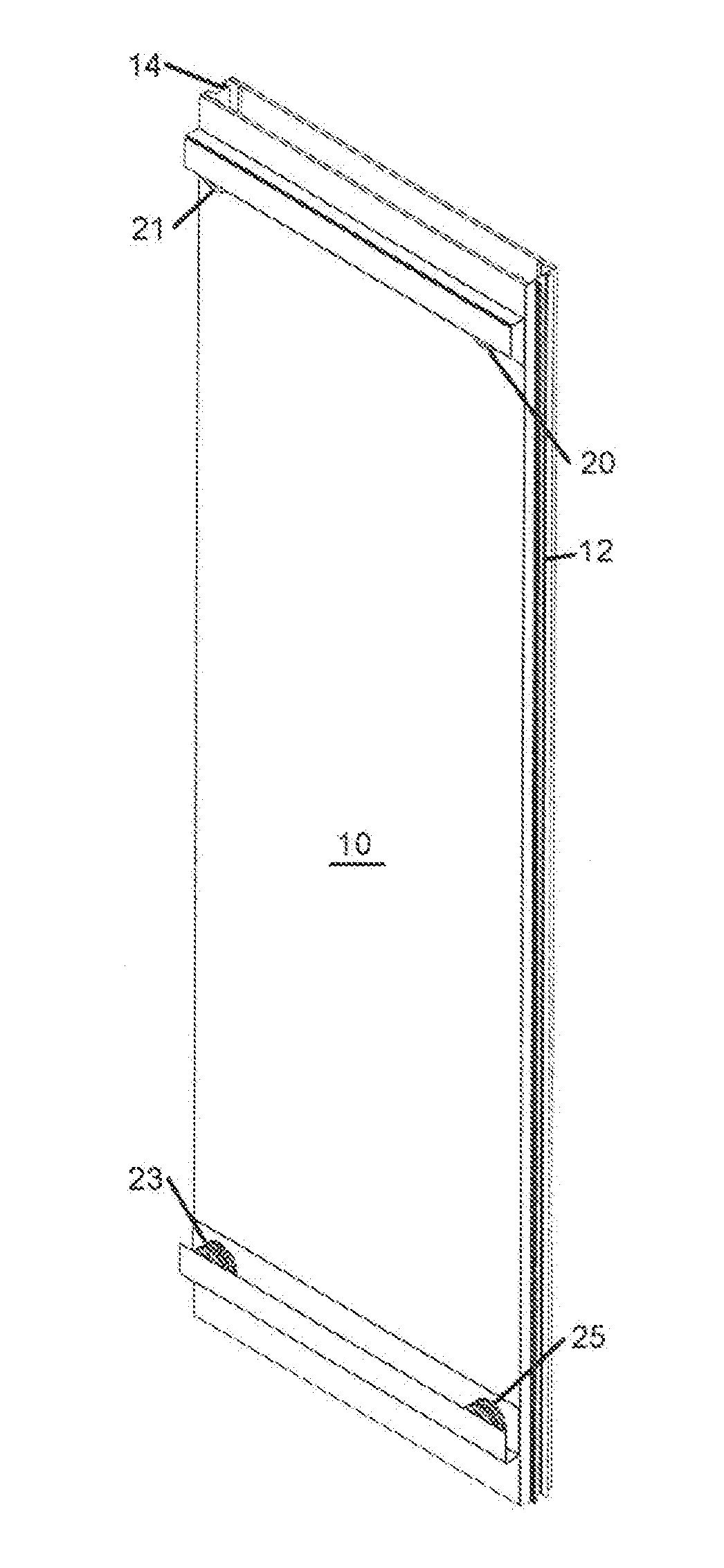

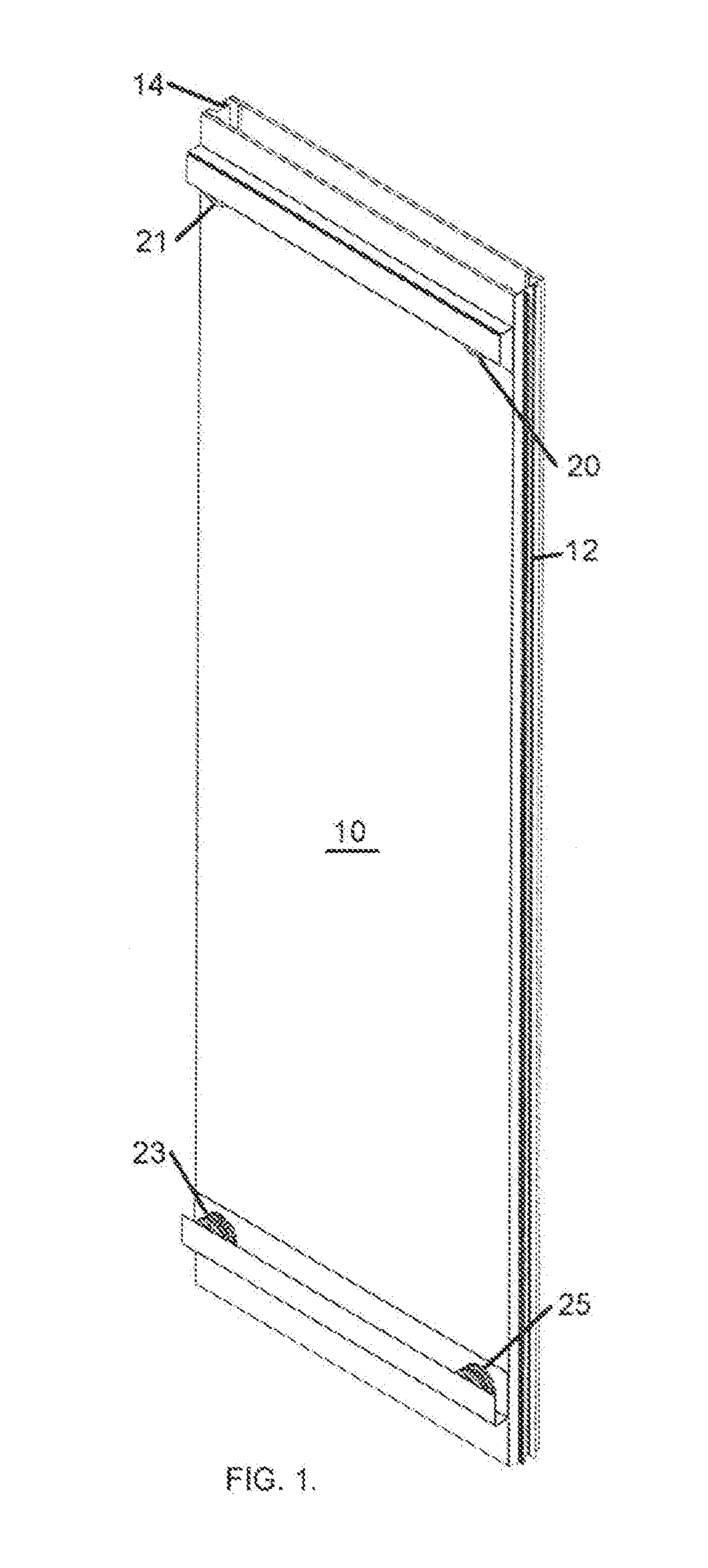

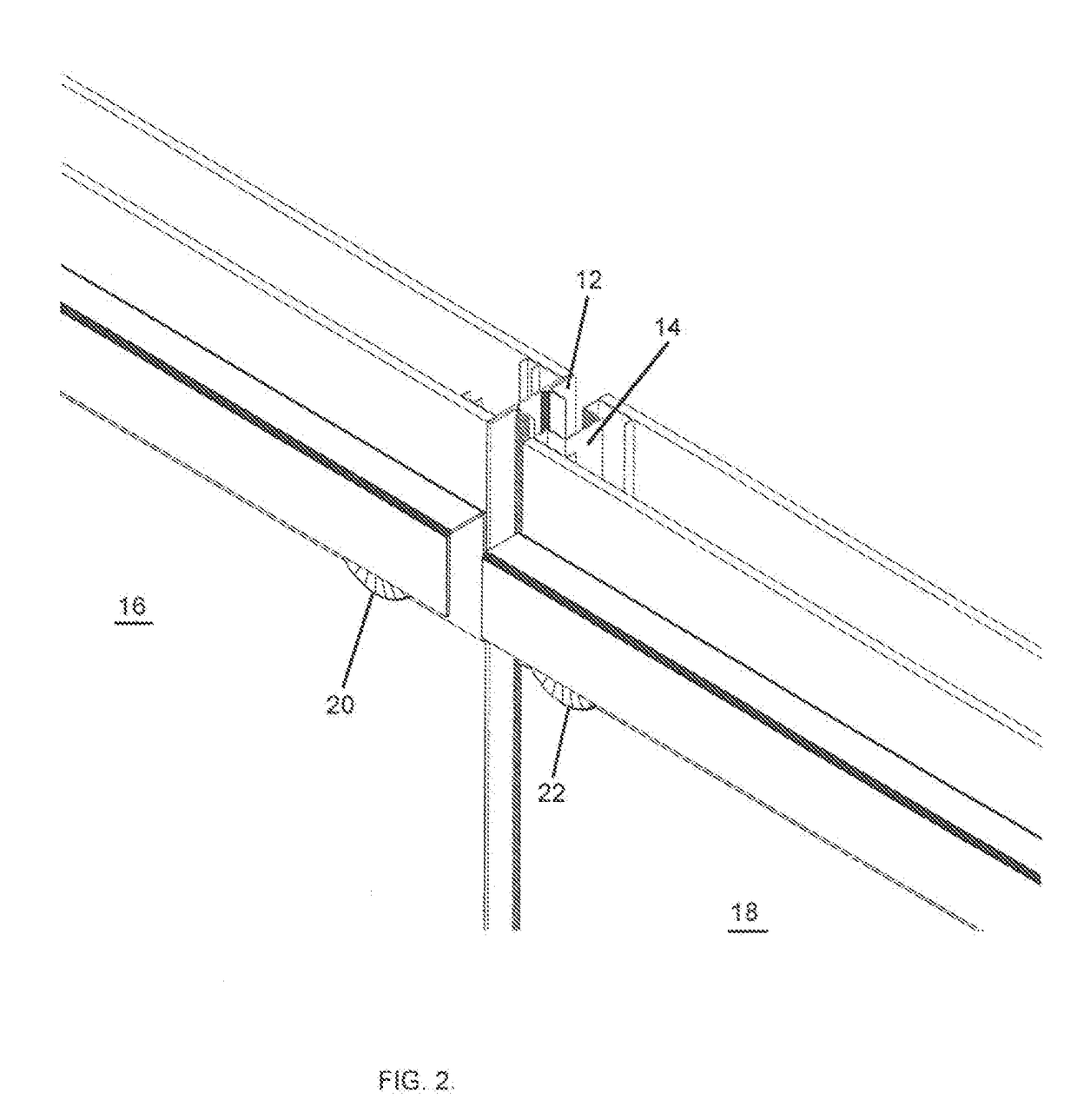

[0059]As shown in the following drawings, the invention aims to provide a novel and versatile prefabricated panel building system characterized by fast installation, rapid construction, high fire resistance, high weight capacity, high cost performance and good sound insulation when compared to the prior art. The present invention comprises a plurality of wallboard panels joined together. Each panel 10 as typically shown in FIG. 1 includes specially adapted interlocking edge members 12,14 having complementary profiles configured to be interlocked with the edge members of adjoining panels (not shown) to form integrated stud or cross members. The resulting integrated arrangement conferring substantial rigidity and integrity to the erected structure.

[0060]The preferred panel includes an inner waif decoration layer, a fiber calcium silicate board, a thermal-protective layer and an external wallboard cladding, which are preferably arranged in this sequence. A gap is preferably provided be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com