Solar cell panel

a solar cell and panel technology, applied in the field of solar cell panels, can solve the problems of increasing the cost of installing the insulating barrier, the weight of prior art solar cell panels, and the increase in the cost of solar cell panels. achieve the effect of adequate safety margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

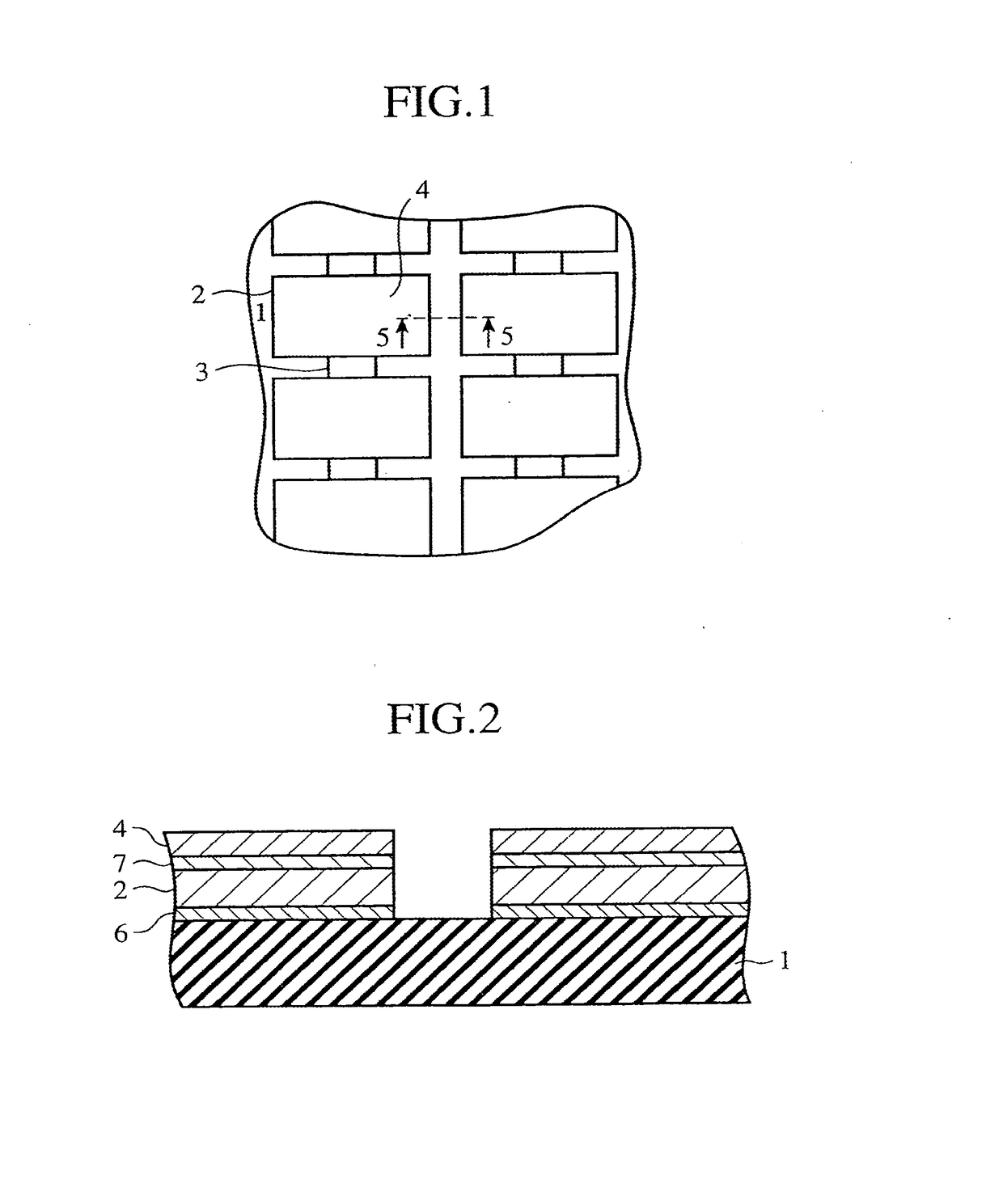

[0021]FIG. 1 is a plan view showing embodiment 1 of the present invention. In FIG. 1, solar cells 2 are secured to a surface of an insulator 1. Interconnectors 3 are connected to each of the solar cells 2, and a cover glass 4 is bonded to each of the solar cells 2.

[0022]FIG. 2 is a cross-sectional view showing a cross section of FIG. 1 taken along the line 5-5.

[0023]As shown in FIG. 2, each solar cell 2 is secured to the surface of the insulator 1 by an adhesive 6, and the cover glass 4 is secured to the light receiving surface of each solar cell 2 by an adhesive 7.

[0024]In FIGS. 1 and 2, wiring for connecting among solar cell assembly series is not shown.

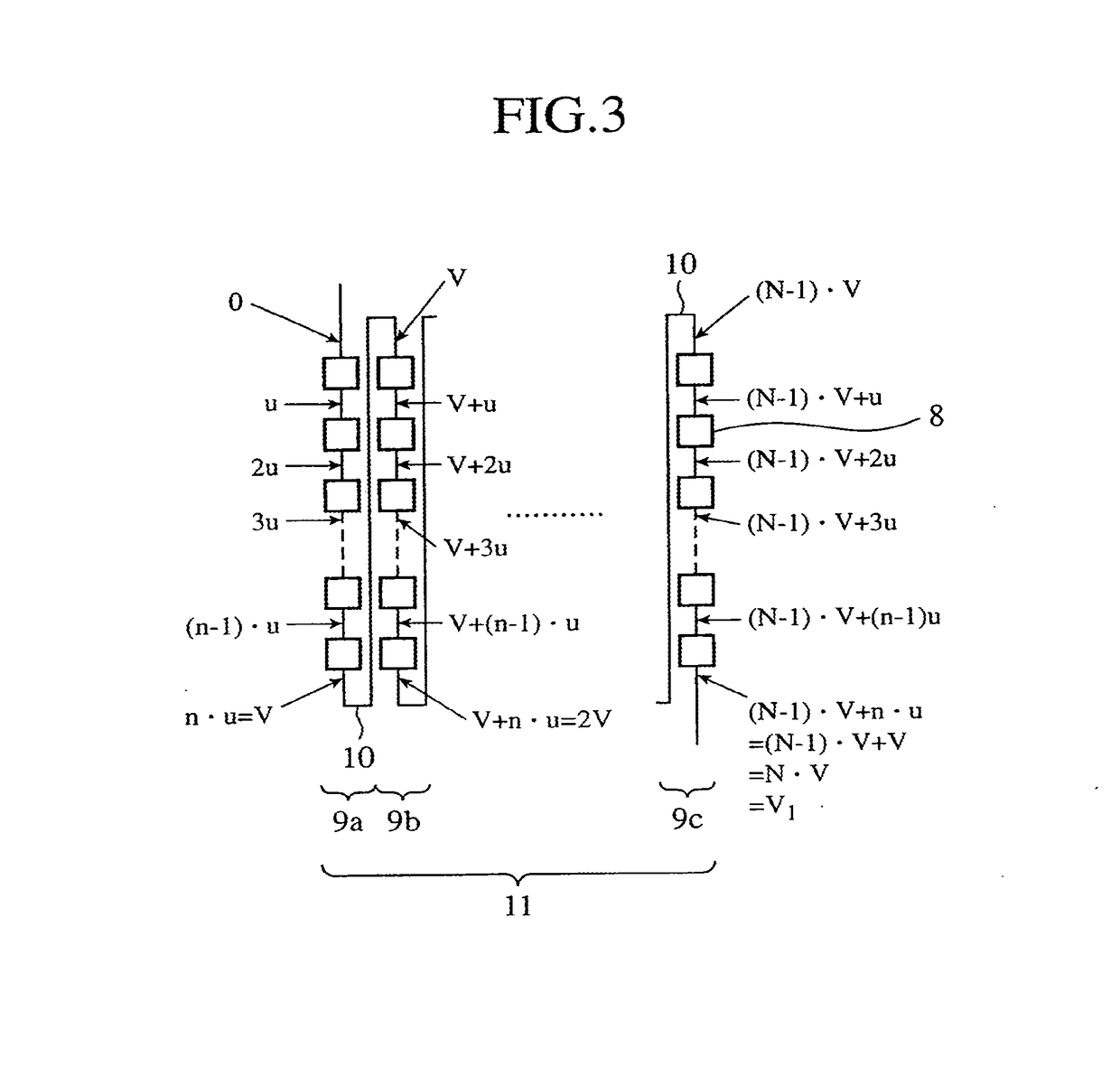

[0025]FIG. 3 is a diagram showing the structure of solar cell circuitry according to embodiment 1 of the present invention.

[0026]In FIG. 3, n solar cell assemblies 8 each having a maximum output voltage u are arranged substantially in a line so that each solar cell assembly series 9 is constructed. Each solar cell assembly series 9...

embodiment 2

[0030]FIG. 1 is a plan view showing embodiment 2 of the present invention. FIG. 2 is a cross-sectional view showing a cross section of FIG. 1 taken along the line 5-5.

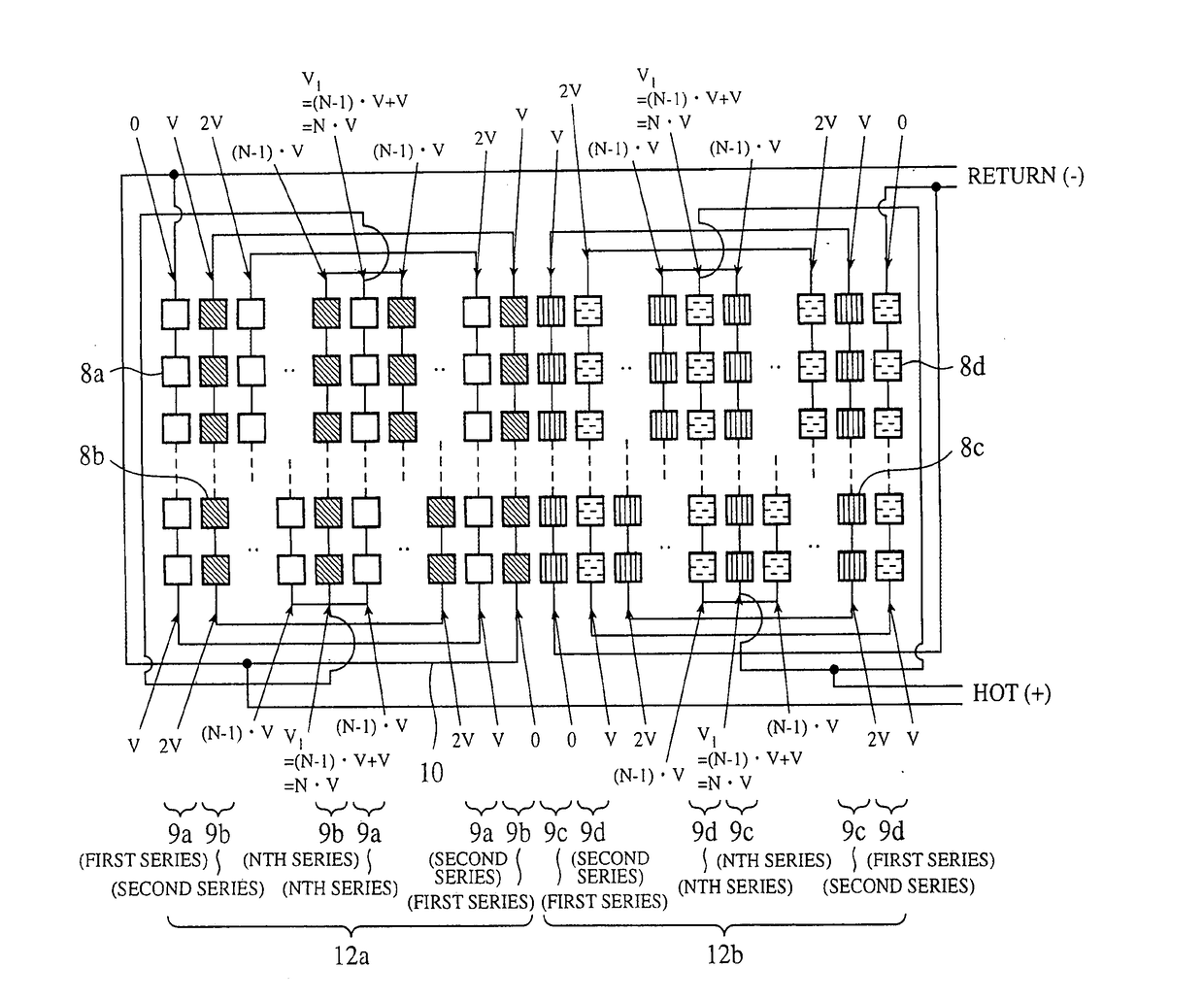

[0031]FIG. 4 is a diagram showing solar cell circuitry according to embodiment 2 of the present invention.

[0032]In FIG. 4, n solar cell assemblies 8a each having a maximum output voltage u are arranged substantially in a line so that each solar cell assembly series 9a is constructed. Each solar cell assembly series 9a has a maximum output voltage V=n*u.

[0033]Furthermore, N solar cell assembly series 9a are electrically connected in series byway of connection lines 10 so that a solar cell string 11a is constructed. Similarly, n solar cell assemblies 8b each having a maximum output voltage u are arranged substantially in a line so that each solar cell assembly series 9b is constructed. Each solar cell assembly series 9b has a maximum output voltage V=n*u.

[0034]Furthermore, N solar cell assembly series 9b are electrically...

embodiment 3

[0039]FIG. 1 is a plan view showing embodiment 3 of the present invention. FIG. 2 is a cross-sectional view showing a cross section of FIG. 1 taken along the line 5-5.

[0040]FIG. 5 is a diagram showing solar cell circuitry according to embodiment 3 of the present invention.

[0041]In FIG. 5, n solar cell assemblies 8a each having a maximum output voltage u are arranged substantially in a line so that each solar cell assembly series 9a is constructed. Each solar cell assembly series 9a has a maximum output voltage V=n*u. Furthermore, N solar cell assembly series 9a are electrically connected in series by way of connection lines 10 so that a solar cell string 11a is constructed.

[0042]Similarly, n solar cell assemblies 8b each having a maximum output voltage u are arranged substantially in a line so that each solar cell assembly series 9b is constructed. Each solar cell assembly series 9b has a maximum output voltage V=n*u. Furthermore, N solar cell assembly series 9b are electrically con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com