Collective container, collective container blank and collective container kit with individual containers

a collective container and container kit technology, applied in the field of collective containers, can solve the problems of labor and time consumption, high cost and burden of empty boxes from distribution centres, and the time inside the box is relatively long, and achieve the effect of high packaging strength and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

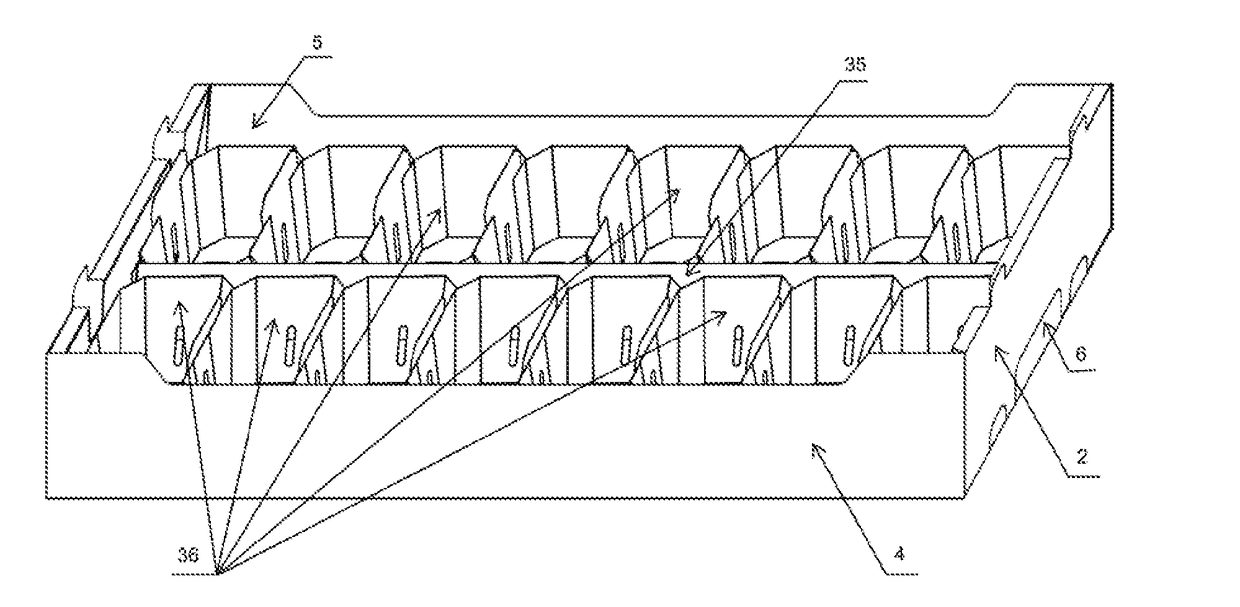

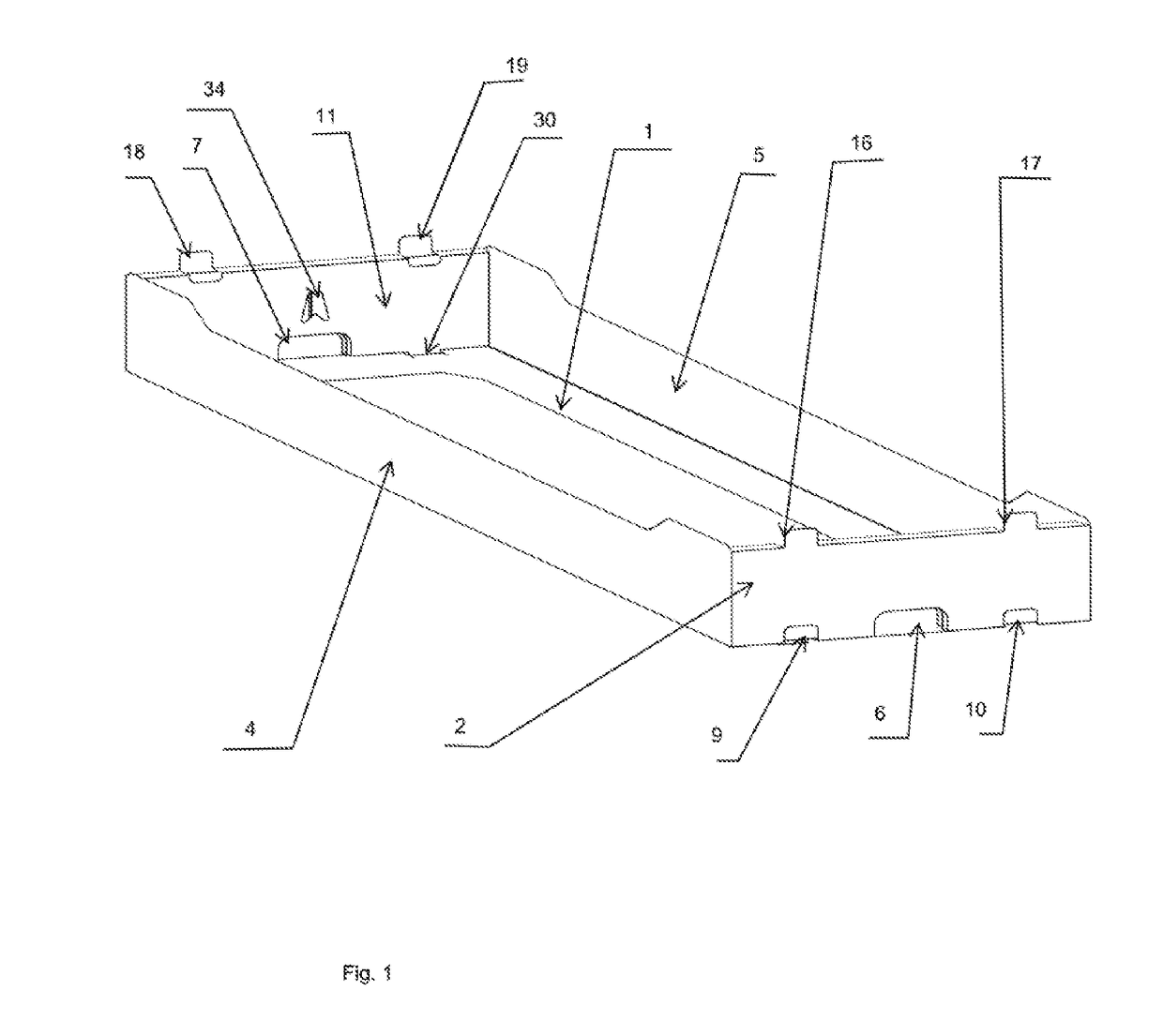

[0125] the invention applies to the collective container presented in FIG. 1 cut out from a sheet of corrugated cardboard and designed for manual folding. The aspect of the invention was also presented in the form of the container blank in the form of a sheet cut out of corrugated cardboard presented on FIG. 5 and FIGS. 8-11 presenting subsequent stages of folding the container from flat blank to three-dimensional collective container. Even though that in this aspect the collective container is designed for manual folding, it does not exclude the option of automatic or semi-automatic folding.

[0126]FIG. 5 presents collective container in the form of sheet blank before it is folded along bending lines and manually or otherwise folded in to the collective container form. As shown in FIG. 5, the container blank has a form of a flat, rigid sheet material, which has a bottom 1, whose area is open in at least 70%. Persons ordinary skill in the art will notice that 70% of open bottom area c...

second embodiment

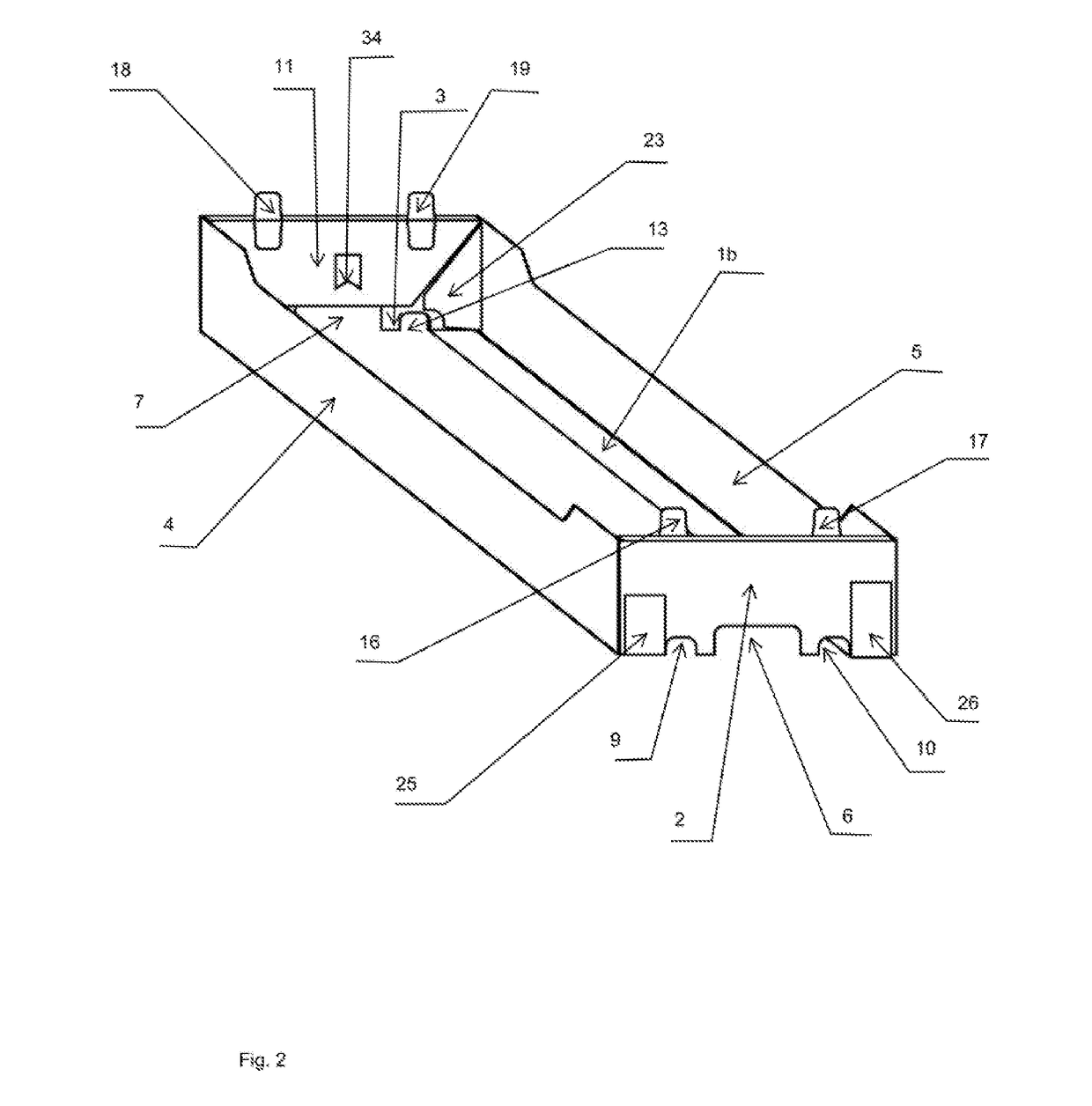

[0142]According to the invention presented in the form of a container in FIG. 2 and in the form of corresponding container blank in FIG. 6, the container has a form of cut out sheet of corrugated cardboard and designed for semi-automatic folding. This does not exclude the option of automatic or manual folding.

[0143]FIG. 6 presents collective container in the form of sheet blank before it is folded along bending lines and connected by cold gluing or using two-sided adhesive tape into the collective container form.

[0144]FIG. 6, bottom 1 of the blank is composed of two bottom strips 1a, 1b equipped with bottom leaves 25, 26, 31, 32, adequately adjacent to shorter edges of the bottom strips 1a, 1b, i.e. edges perpendicular to edges adjacent to side walls 4, 5. Surface of the bottom is open to about 70%. Persons ordinary skill in the art will notice that in case of this embodiment, one cannot use a hole, as in case of the first embodiment. Space in the bottom is formed by placing special...

third embodiment

[0150]FIG. 7 presents two elements of the sheet blank before the two elements are bent along the bending lines and connected by means of a hot or cold applied adhesive or two-sided adhesive tape into the form of the collective container according to the

[0151]Each of the blank elements has one bottom strip designated as 1a or 1b with bottom leaves designates as 25, 27 or 31, 28, 32, adequately adjacent to the shorter edges of the bottom strip 1a or bottom strip 1b, i.e. edges perpendicular to edges adjacent to side wall 4 or side wall 5. Moreover, each of the blank elements has a side wall designated as 5 or 6 located adjacent to one of the bottom strips 1a, 1b. Each of the elements has one external vertical wall designated as 2 or 3, wherein the external vertical wall is positioned adjacently with its first side edge to the side wall designated as 5 or 6 and the other side edge of external vertical wall remains free. The external vertical wall 2 or external vertical wall 3 adjoins w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com