Exterior Fire Stop Hybrid Wall Panel

a hybrid wall panel and exterior fire stop technology, applied in the direction of walls, constructions, building components, etc., can solve the problems of inferior mwp to cfp, weaker structural strength of mwp, and heavier mwp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

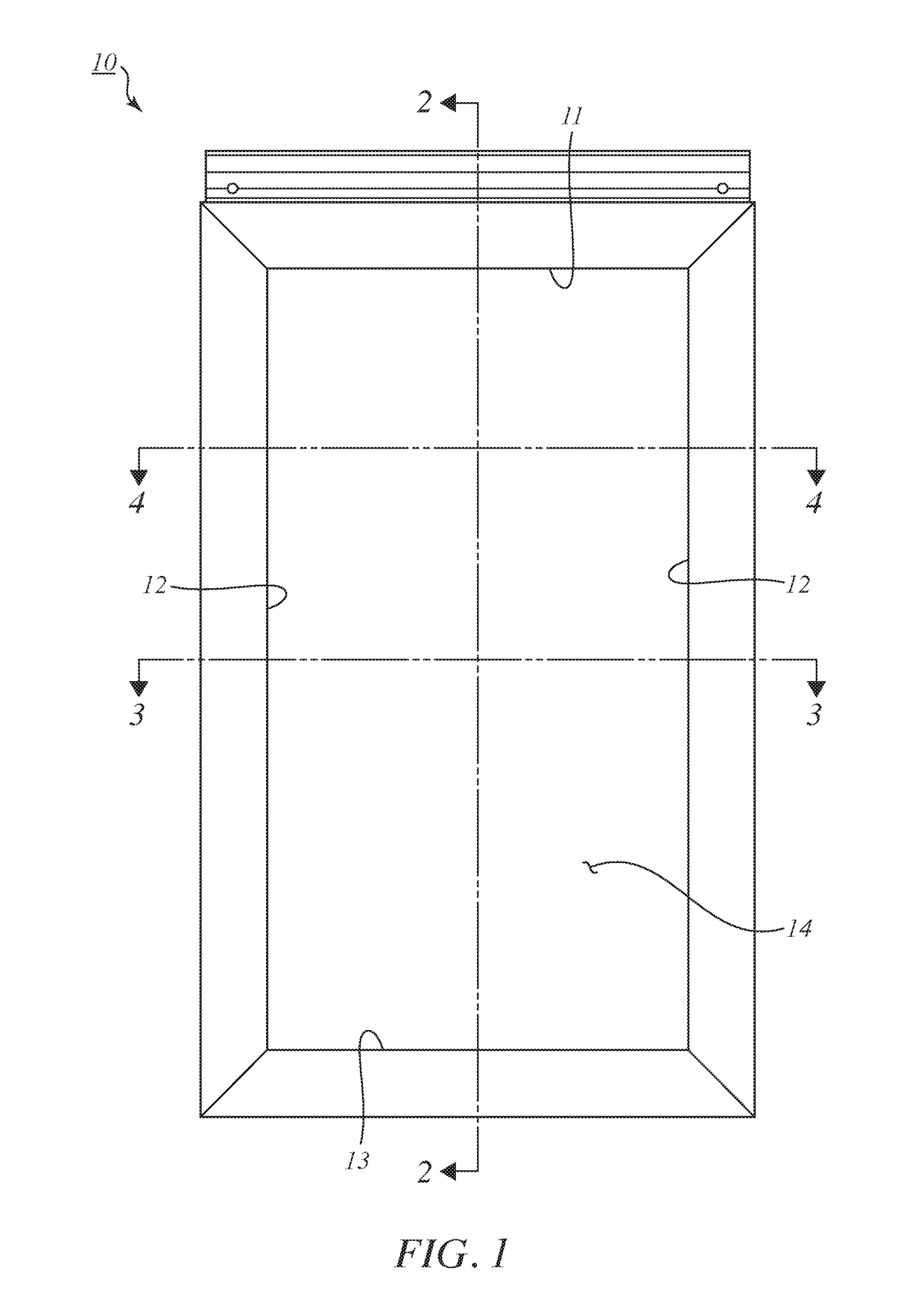

[0012]FIG. 1 shows the front (exterior) view of a typical hybrid framed wall panel 10 of the present invention. The panel frame is formed from a head frame member 11, two jamb frame members 12, and a sill frame member 13. A wall panel having a continuous fire-resistant exterior infill 14 is glazed into the panel frame. With respect to the fire-resistant exterior infill 14, the term “continuous” means that fire-resistant material covers the entire area of the wall panel that is exposed to the exterior.

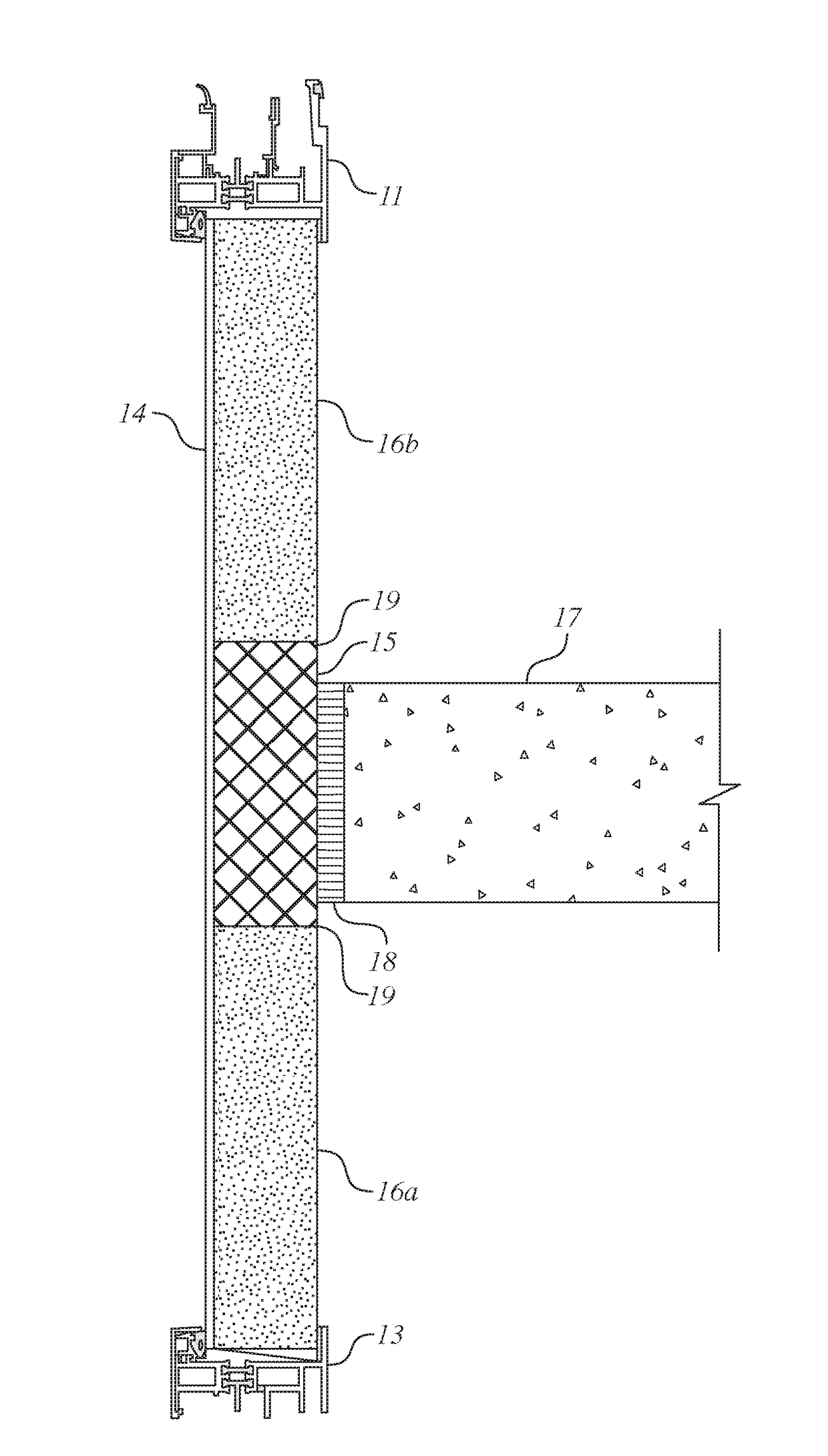

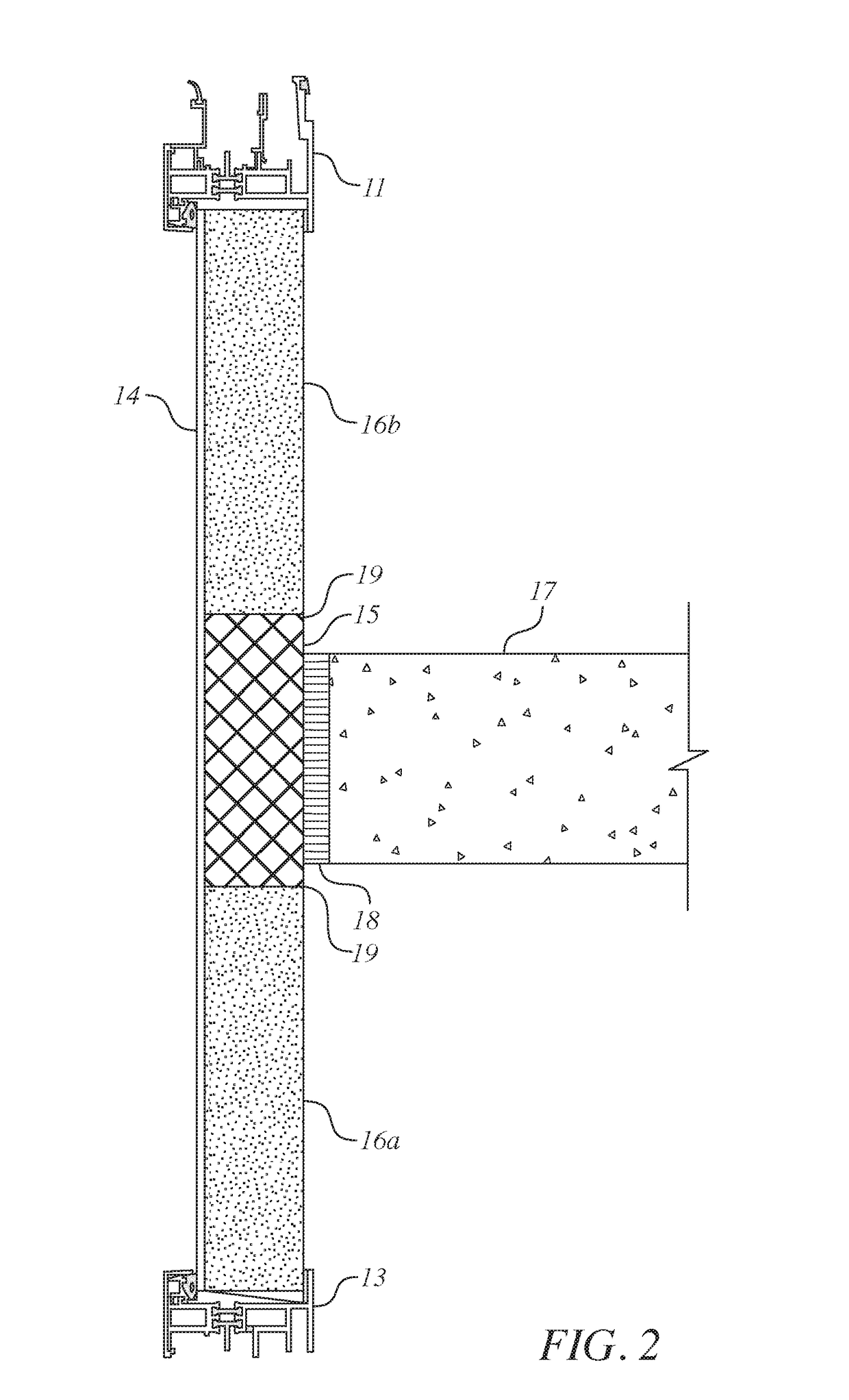

[0013]FIG. 2 shows one embodiment of the cross-section taken along Line 2-2 of FIG. 1 for an erected hybrid framed wall panel. As shown, the head frame member 11 and the sill frame member 13 are for the preferred airloop system. A short piece of an interior MWP infill 15 is located near the edge of a floor slab 17 and butted against inter-floor fire safing 18. Two interior CFP infills 16a and 16b are butted with the MWP infill 15 to form butt joints 19 to complete the interior infill st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com