Bowling aid

a technology for assisting and catching bowls, applied in the field of assisting bowls, can solve the problems of chafing of the thumb and fingers of the bowler, the inability to maintain manual control, and the inability to grasp the ball with sufficient force, so as to improve the fit of the thumb, improve the internal frictional characteristics of the rigid sleeve, and reduce the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

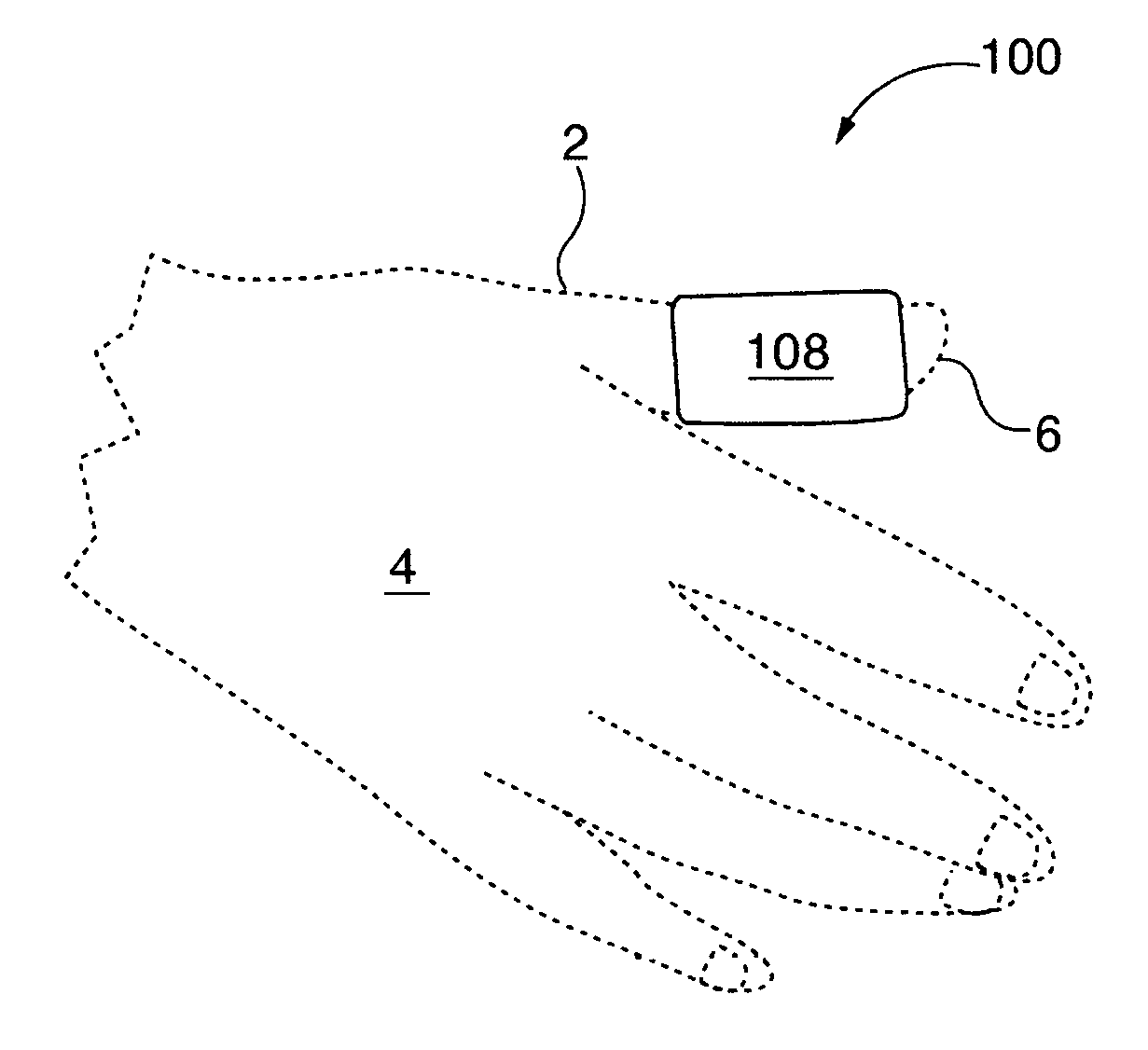

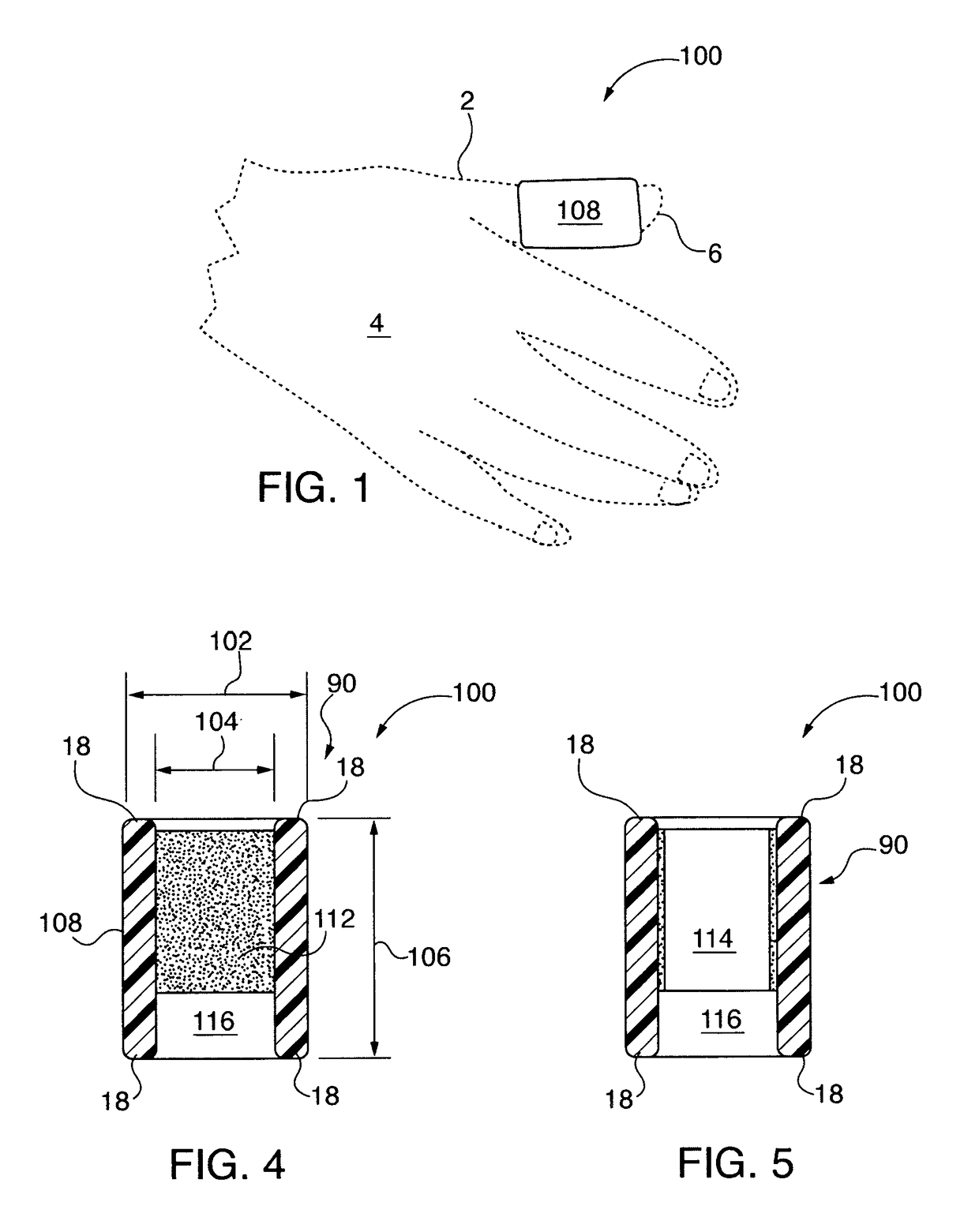

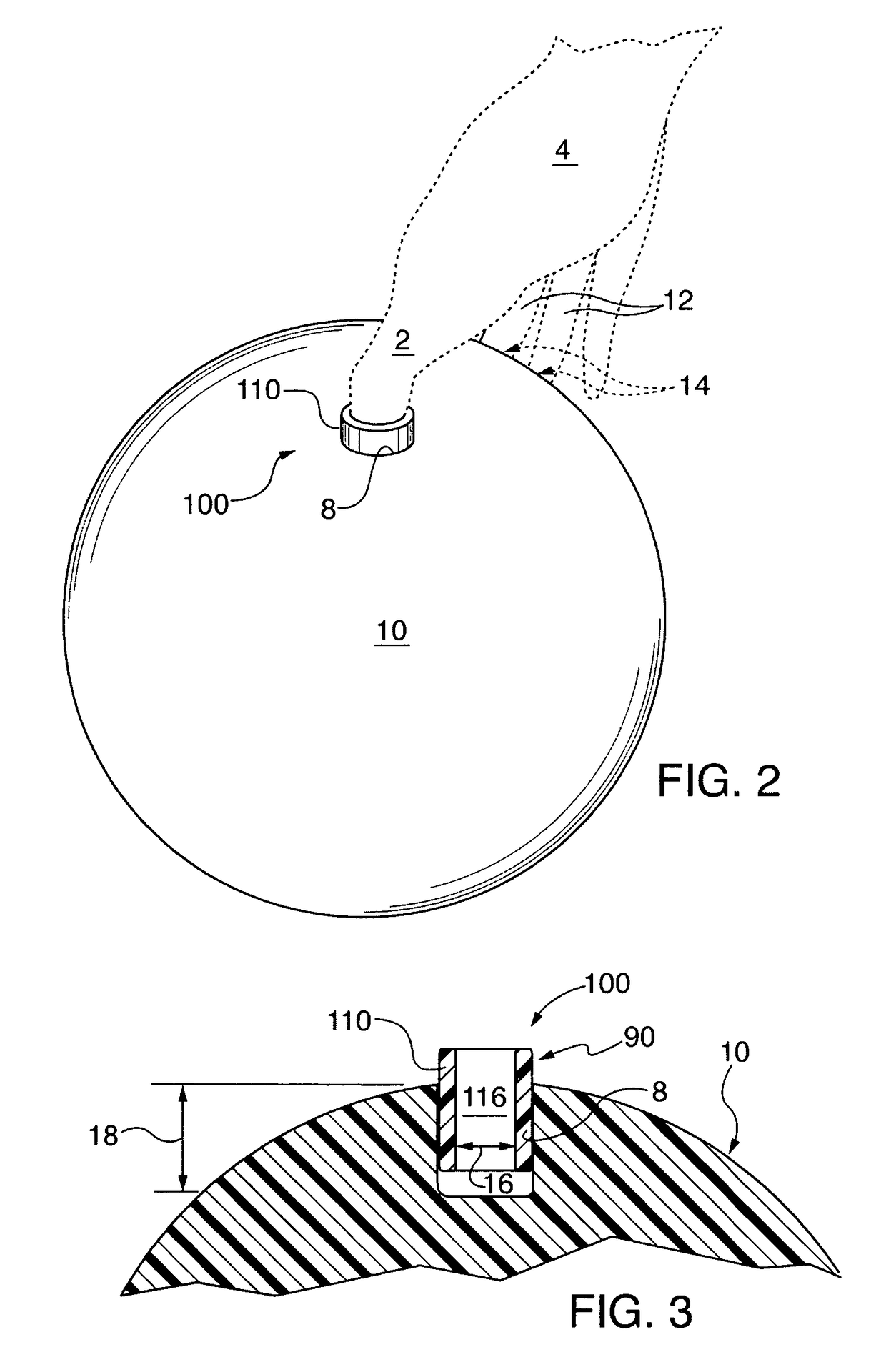

[0022]Referring first to FIG. 1, according to at least one aspect of the disclosure, there is shown a rigid sleeve 100 shown placed over a thumb 2 of a hand 4 of a bowler (not shown in his or her entirety). The tip 6 of thumb 2 is shown projecting outside rigid sleeve 100 to the right, as seen in FIG. 1. Rigid sleeve 100 may if desired be long enough to enclose tip 6 of thumb 2.

[0023]In certain exemplary embodiments, rigid sleeve 100 may comprise a length of tubing material such as polyvinyl chloride (PVC) tubing. PVC tubing of the type commonly sold at retail facilities / stores for household plumbing is suitable, although furniture grade PVC tubing is currently regarded as having desirable additional properties. In exemplary embodiments, these properties include strength, ultraviolet radiation resistance, commercial availability in diverse colors, low or no toxicity, and glossy surface finish. The latter characteristic may result in a quicker release from a bowler's grasp, compared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com