Patents

Literature

31results about How to "Increase the inner surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

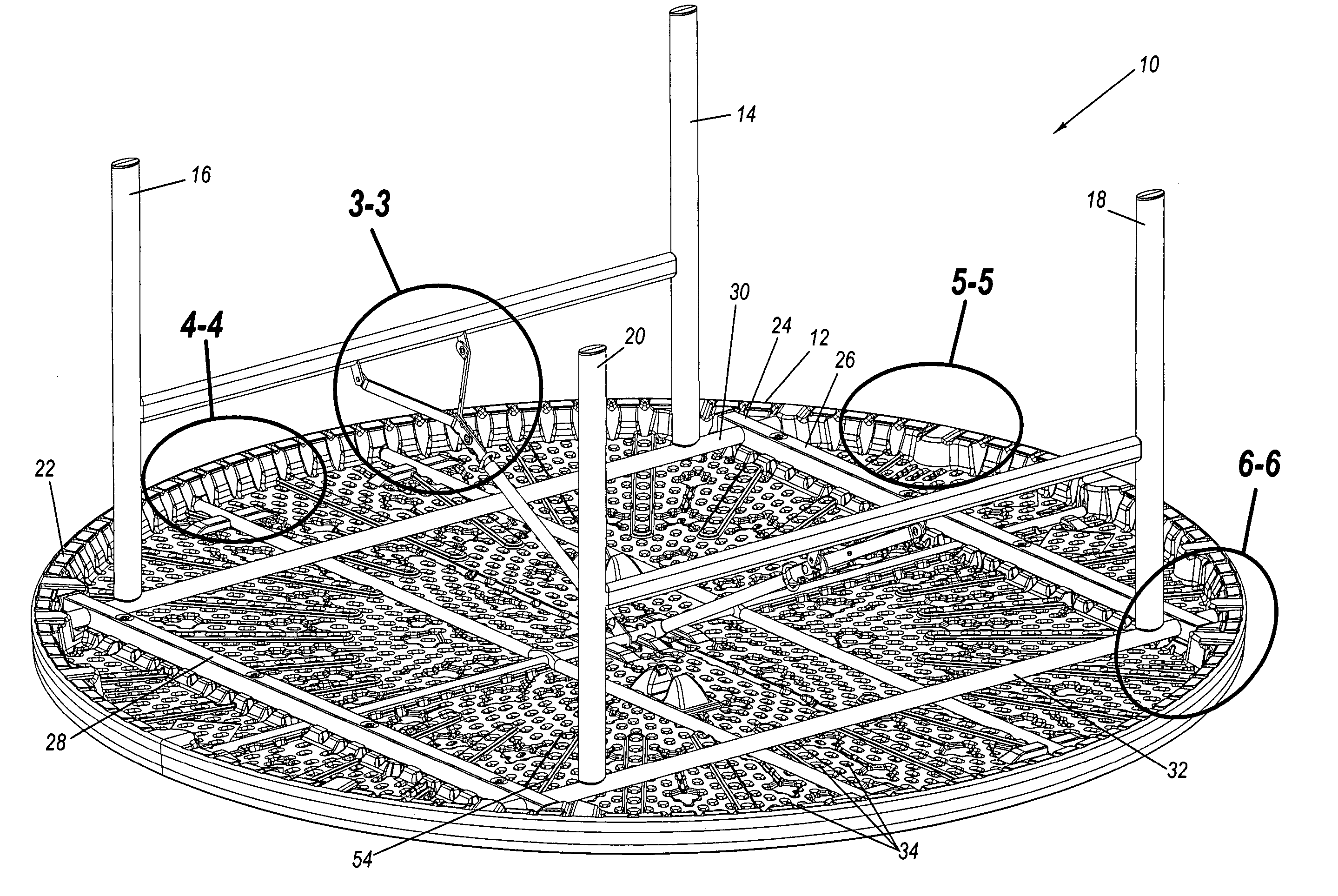

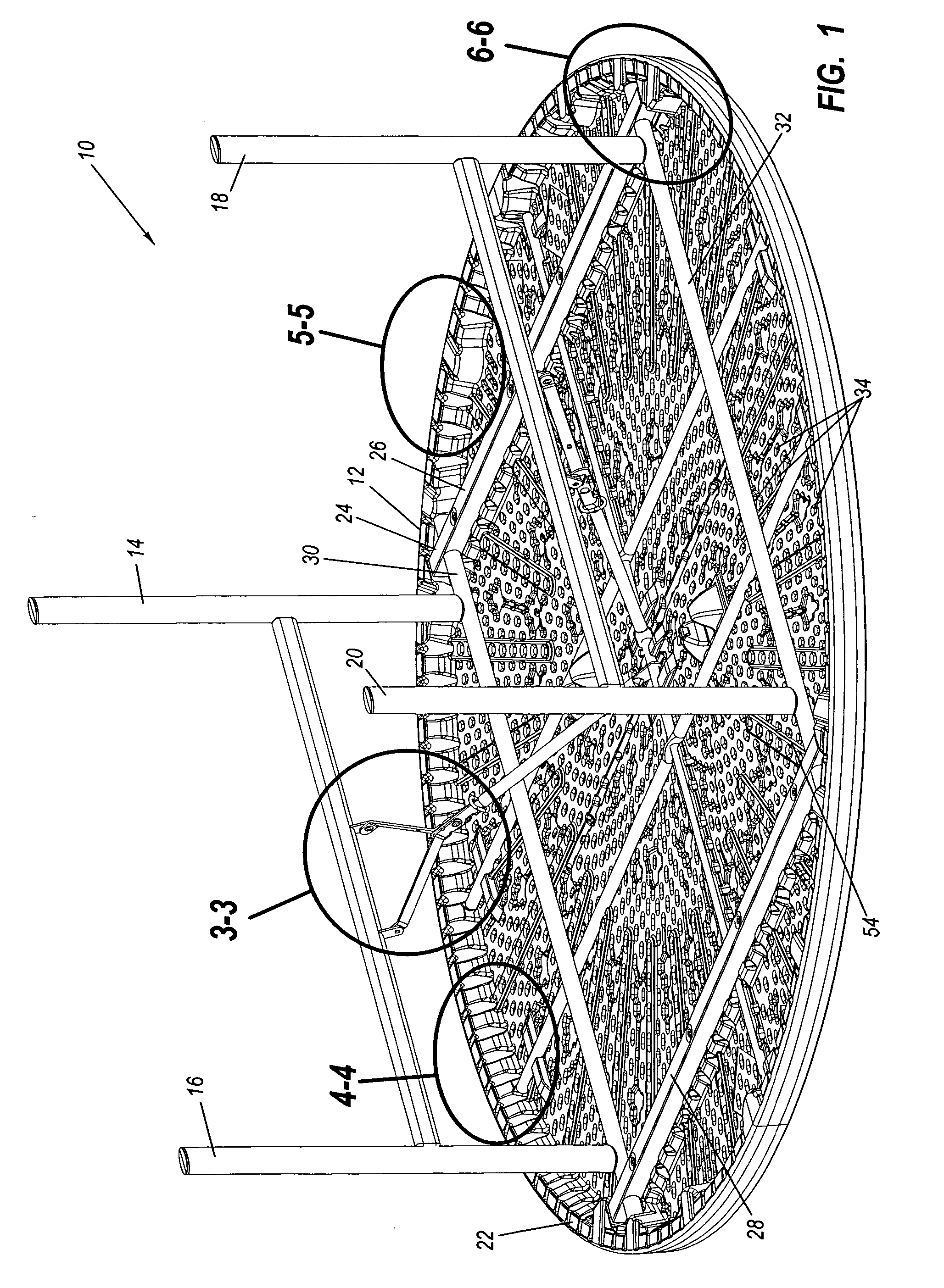

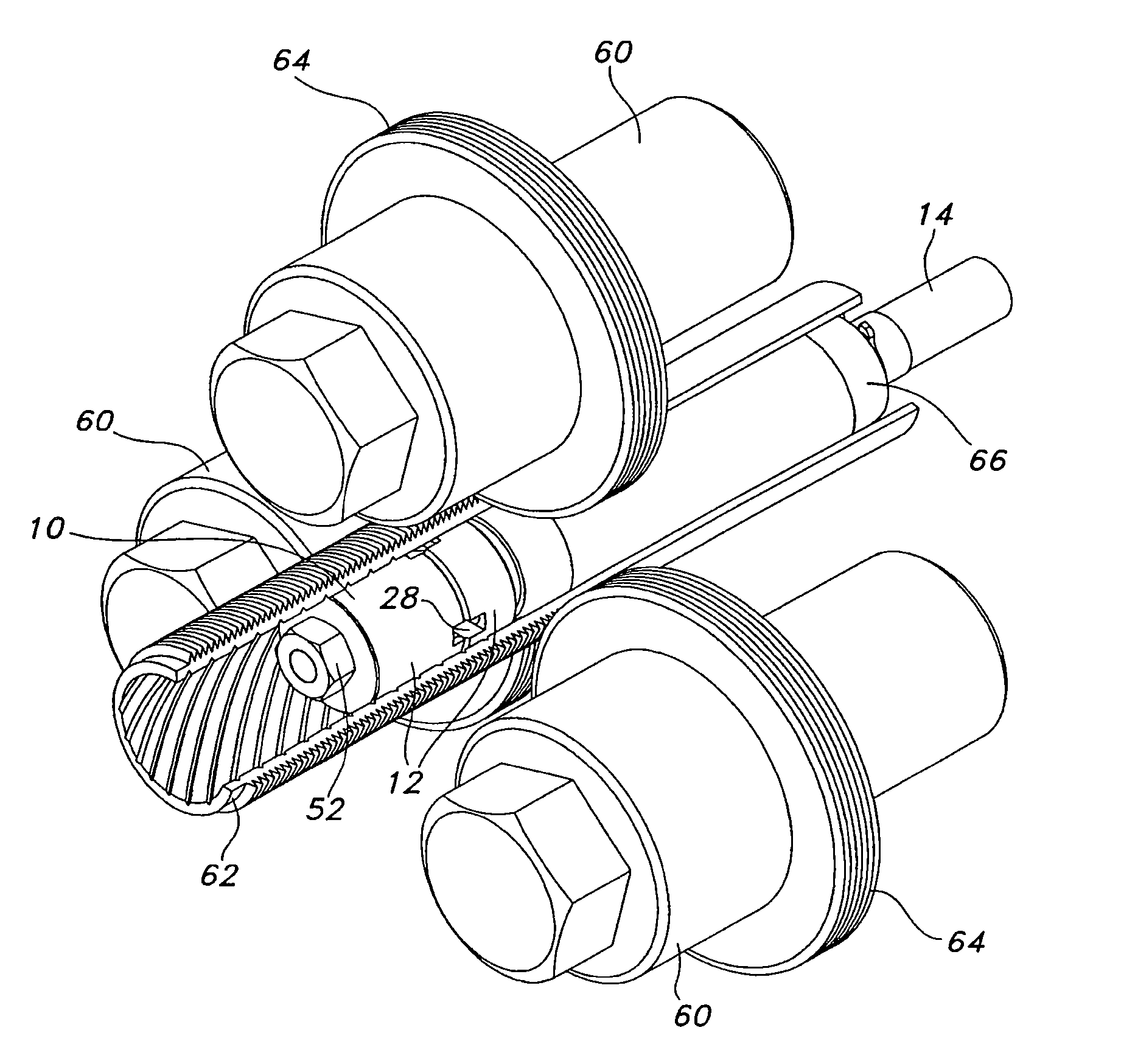

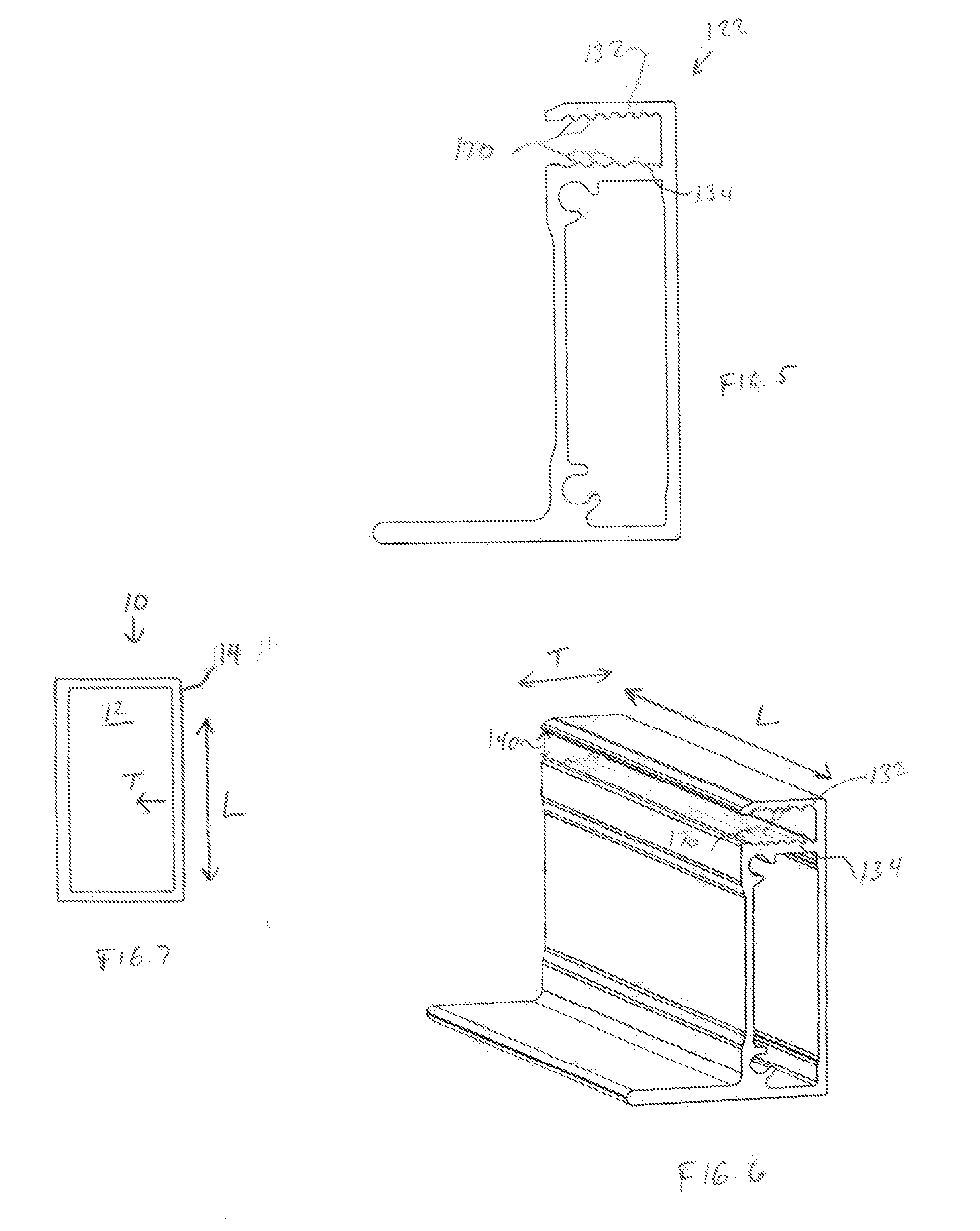

Table with edge support structures

InactiveUS20060236902A1High strengthImprove rigidityFoldable tablesStowable tablesEngineeringUltimate tensile strength

Owner:LIFETIME PRODUCTS

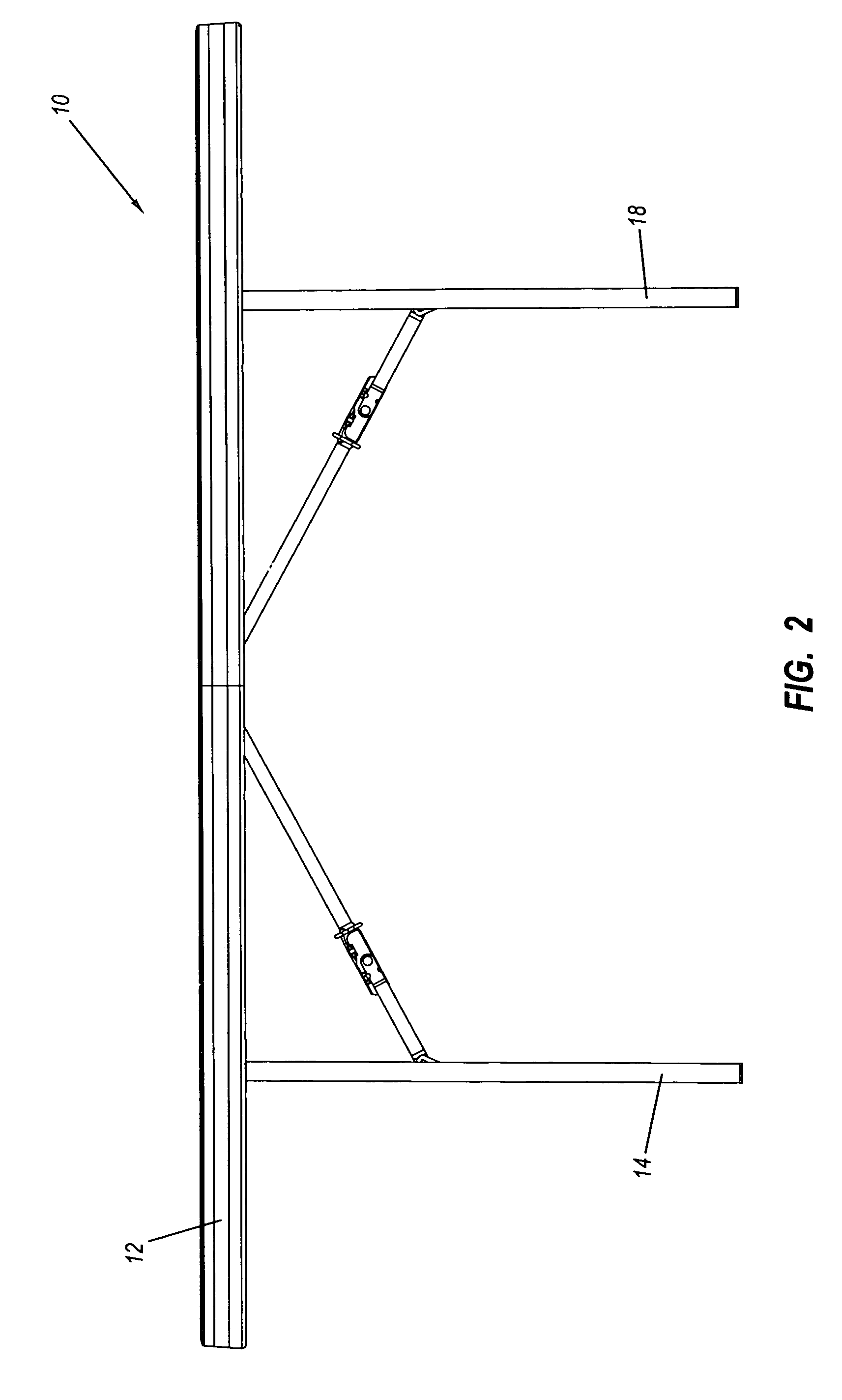

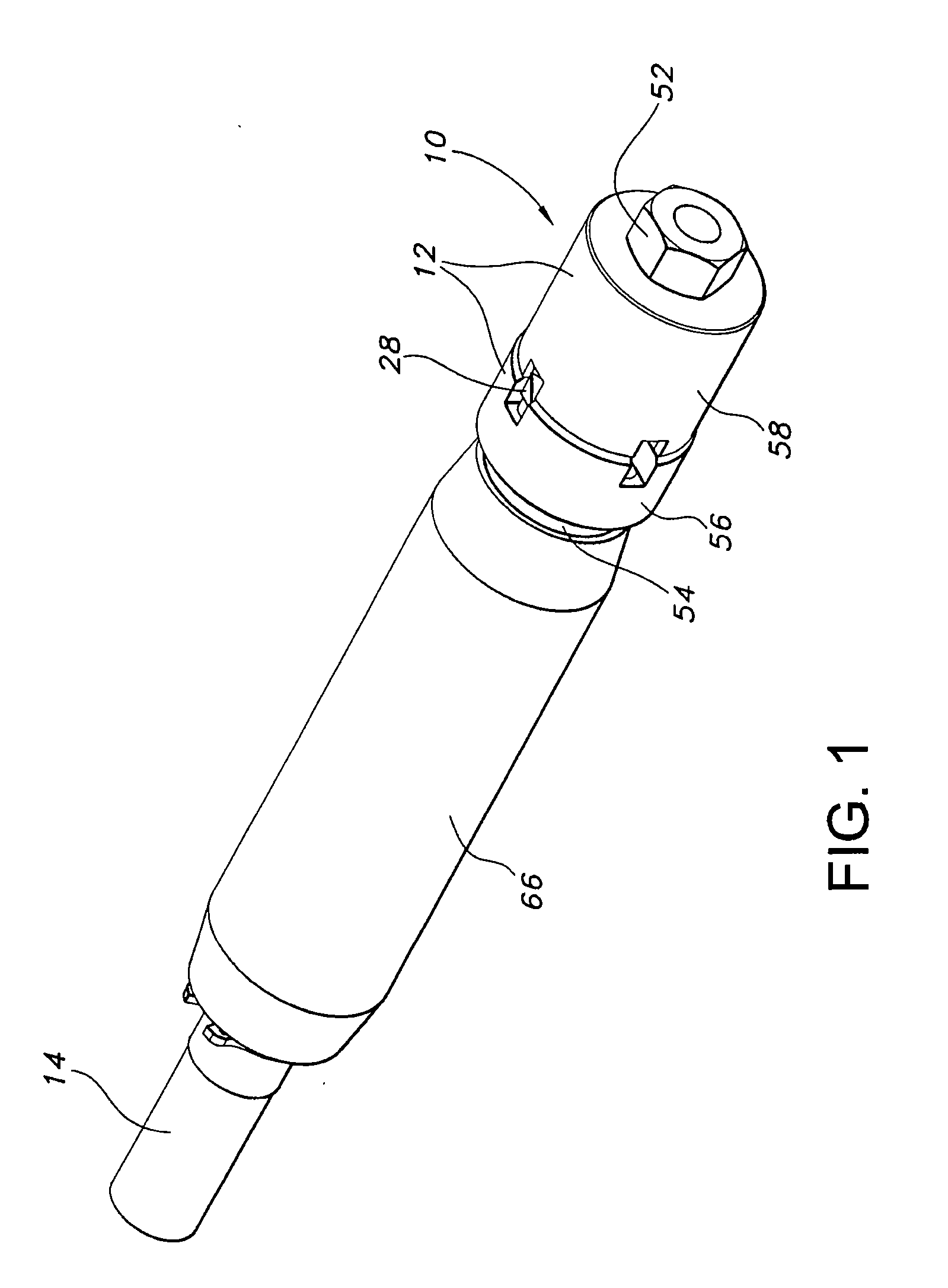

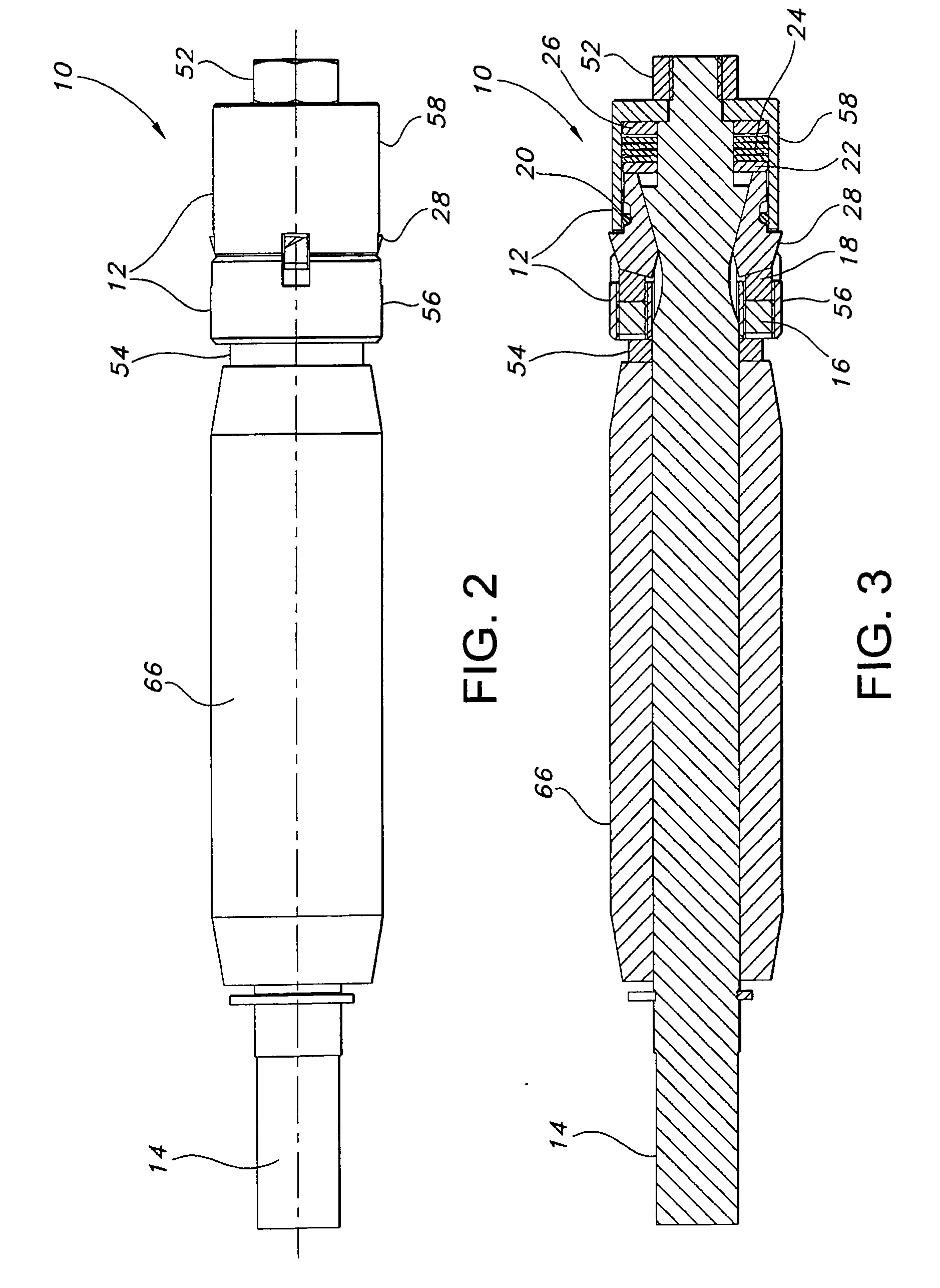

Retractable finning tool and method of using

InactiveUS20070157456A1Improve heat transfer performanceReduce resistanceThread cutting toolsTurning machine accessoriesBiomedical engineeringHeat transfer tube

An improved tool and method for enhancing the surface of a heat transfer tube are provided. The tool, which can be easily added to existing manufacturing equipment, includes cutting bits that may be retracted with a housing. The cutting bits include a cutting edge to cut through the surface of a tube and a lifting edge to lift the surface of the tube to form protrusions. A method for enhancing the inner surface of the tube includes mounting a tool on a shaft, positioning the tool in the tube and causing relative rotation and axial movement between the tube and the tool to cut at least partially through at least one ridge formed along the surface of the tube to form ridge layers and lift the ridge layers to form protrusions.

Owner:WIELAND WERKE AG

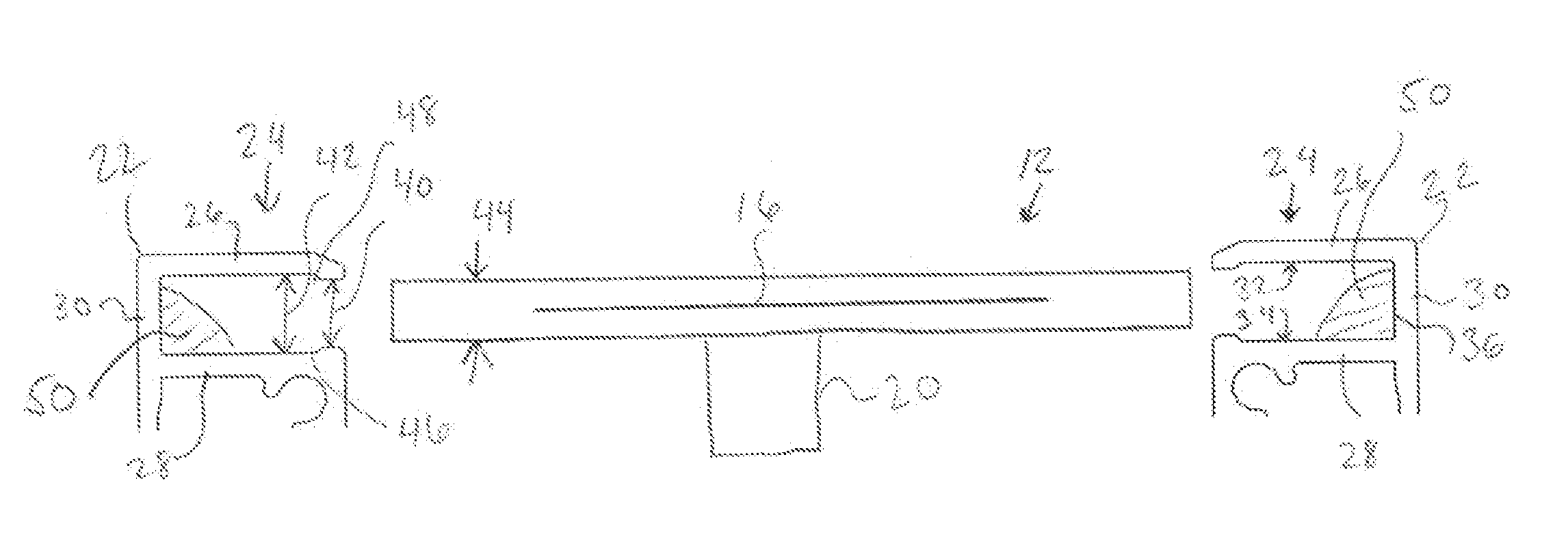

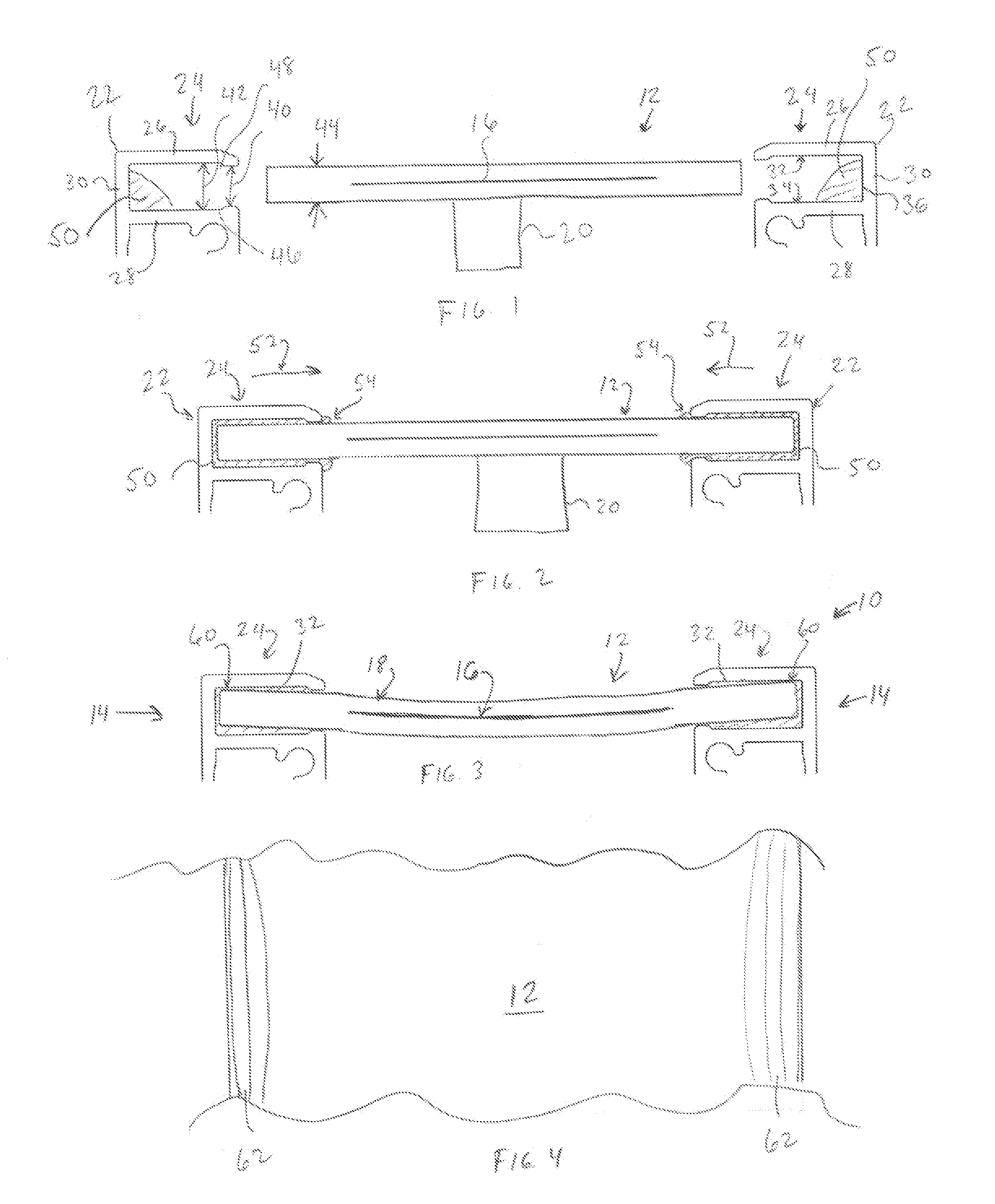

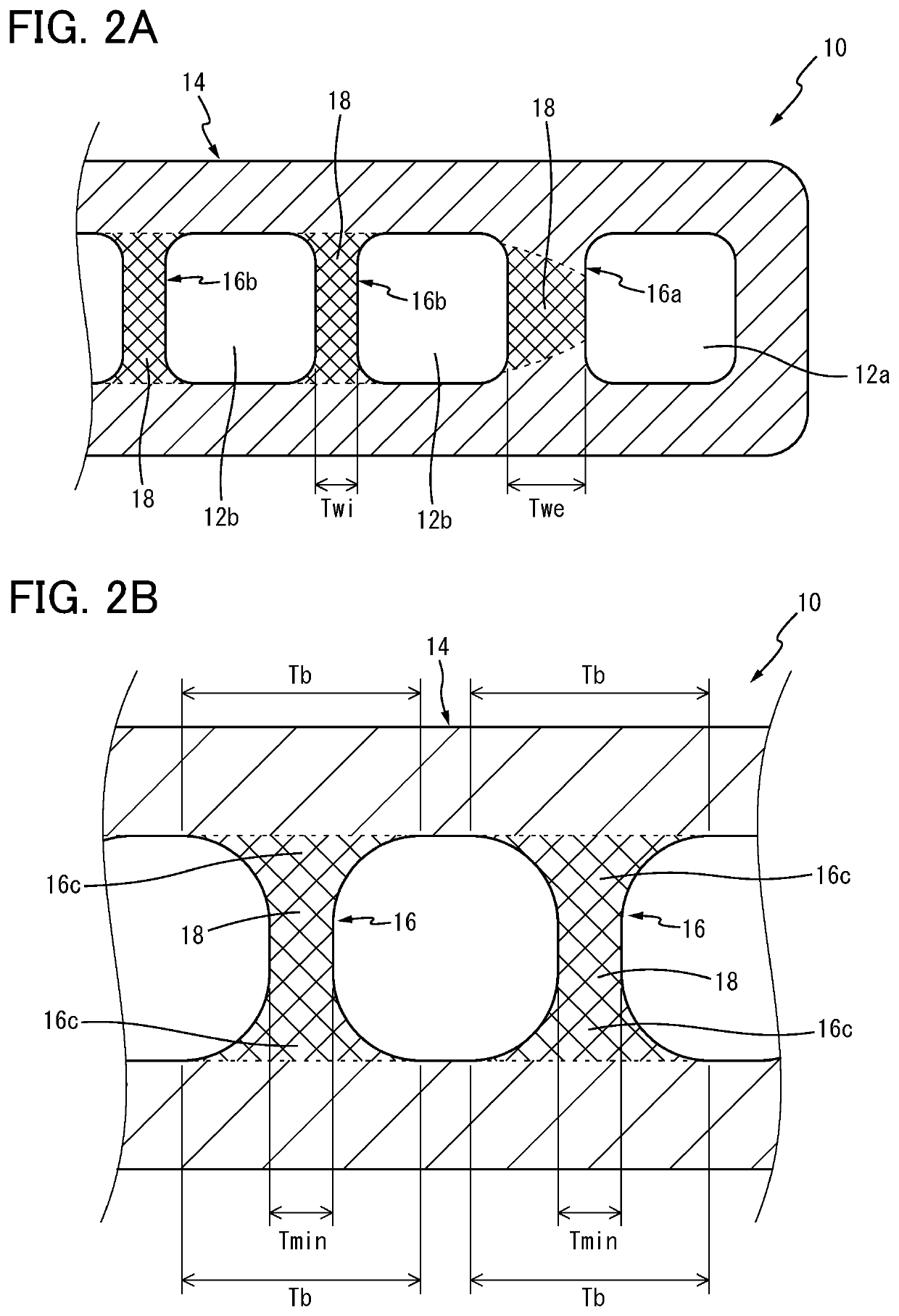

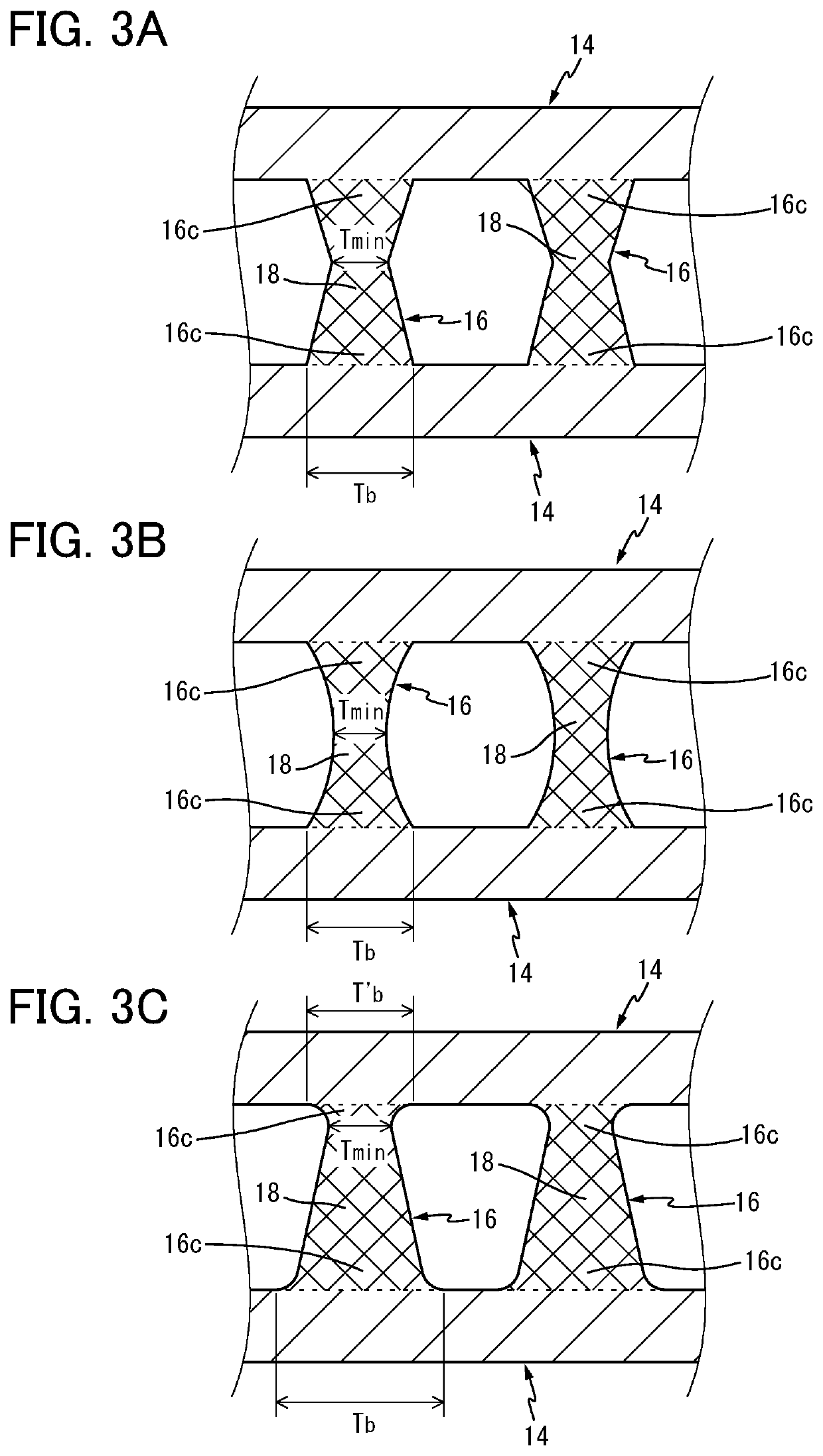

Photovoltaic module frame with improved bondability

InactiveUS20140182661A1Quantity maximizationFail prematurelyPV power plantsPhotovoltaic energy generationEngineeringUltimate tensile strength

A photovoltaic module can be formed with a laminate bonded to frame members. The frame members can extend around the periphery of the laminate. The frame members can include surface features which increase the surface area of the portion of the frame member bonded to the laminate, and thereby improve the bond strength between the frame member and the laminate. Further, the surface features can extend generally longitudinally along the peripheral edges of the laminate, thereby helping to guide a flow of liquid adhesive, during the manufacturing process, along longitudinal direction and thus reduce the amount of adhesive that leaks out onto the laminate during the manufacturing process.

Owner:SUNPOWER CORPORATION

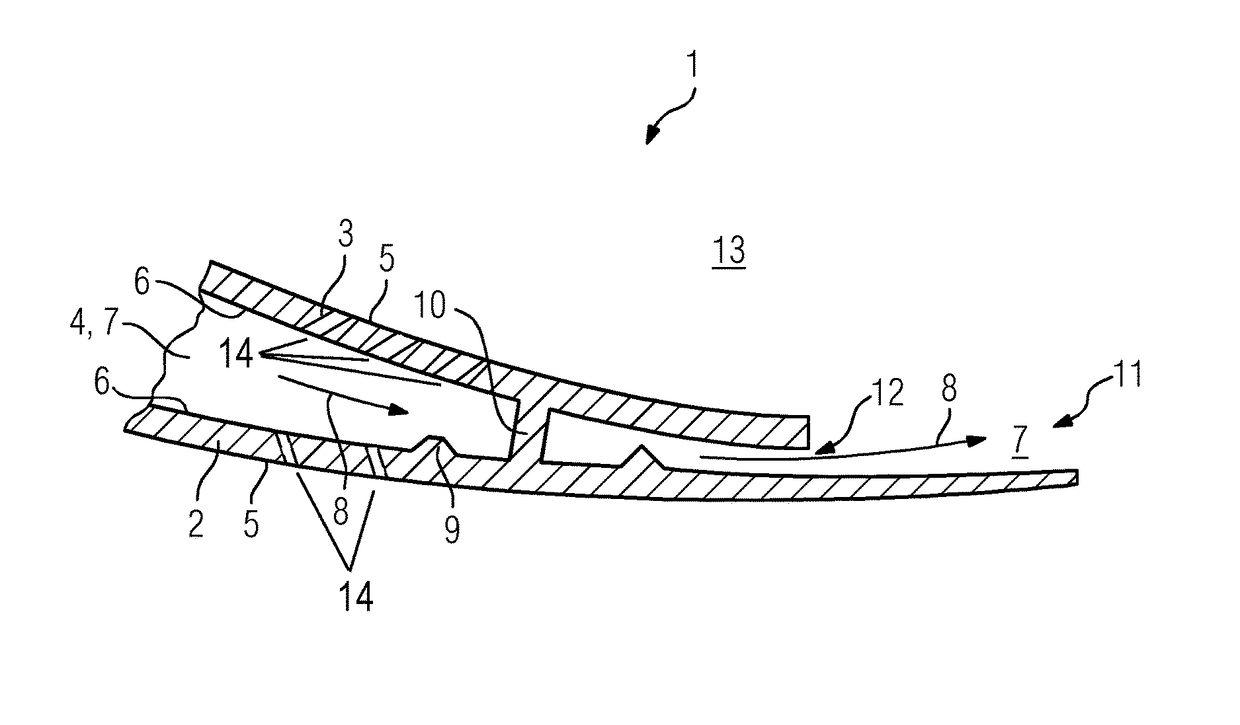

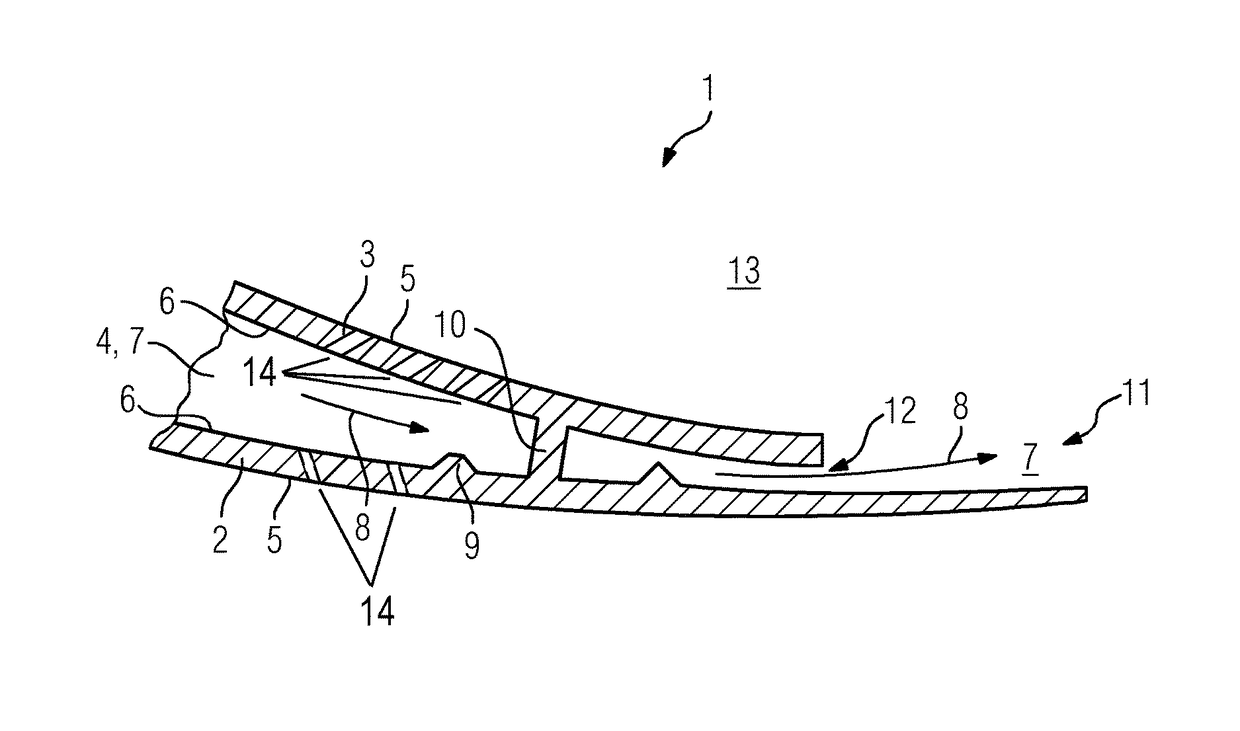

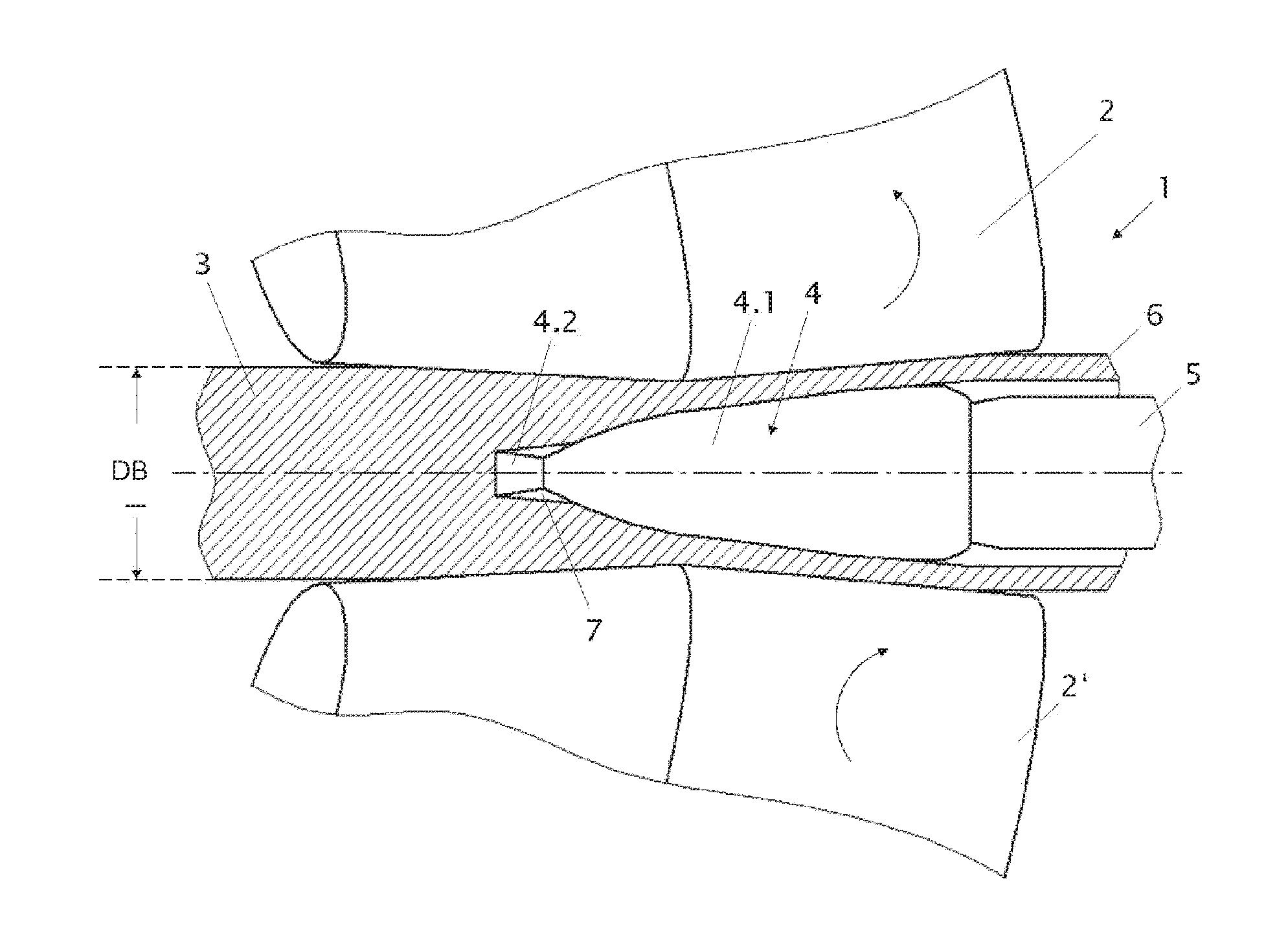

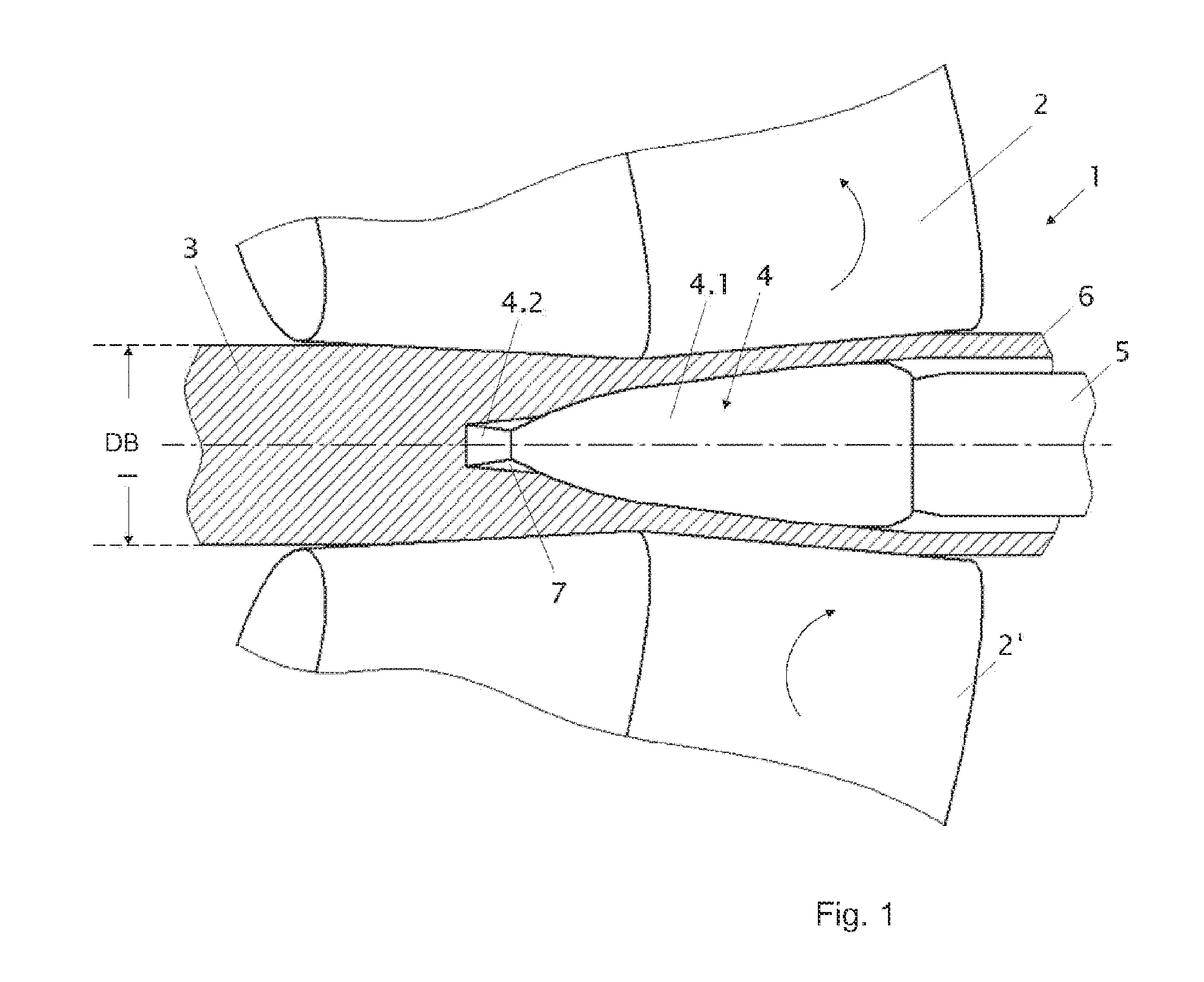

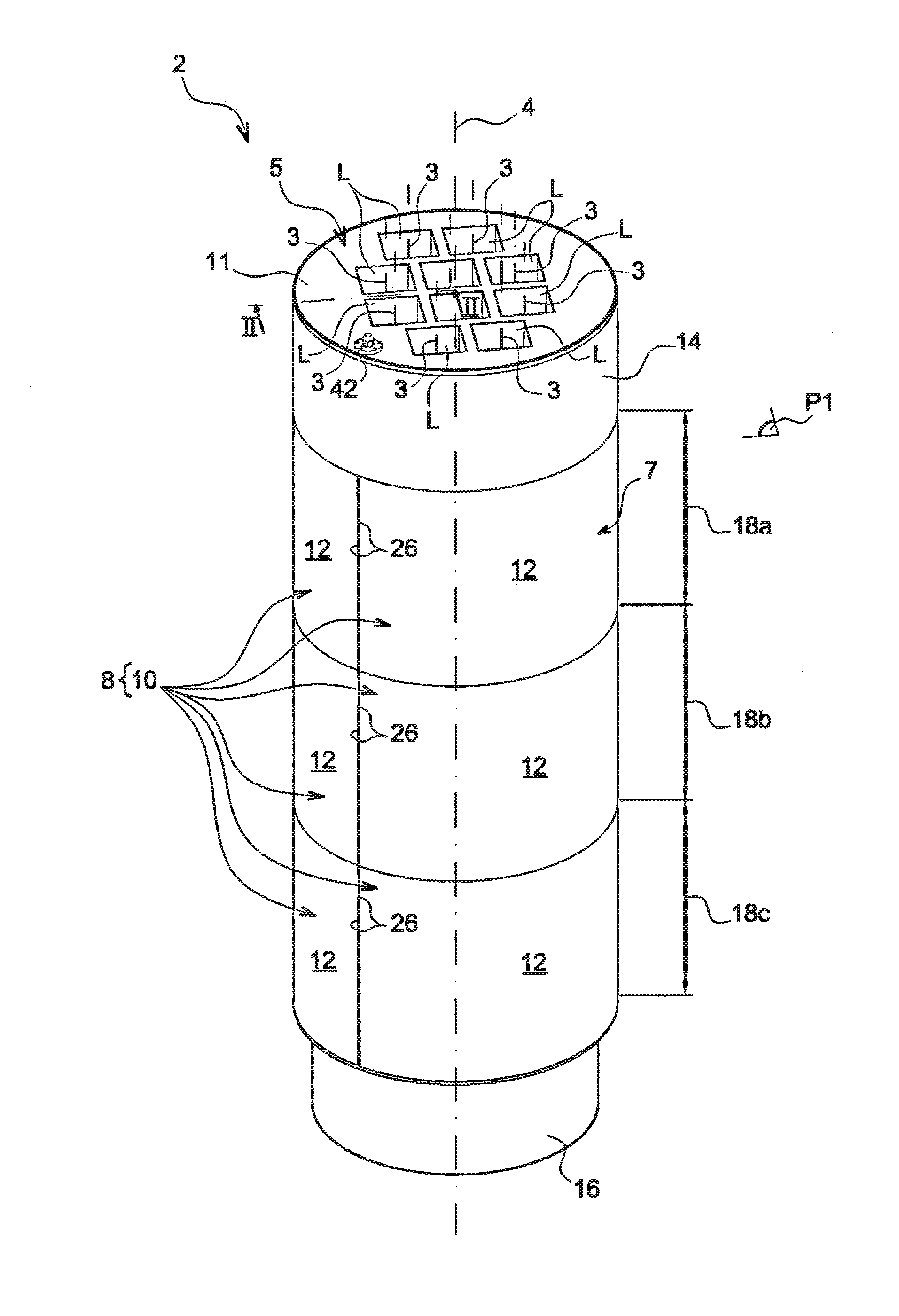

Cooled turbine guide vane or blade for a turbomachine

InactiveUS9896942B2Improve heat transfer performanceReduce the amount requiredEngine fuctionsBlade accessoriesSuction stressEngineering

A turbine airfoil has a suction side wall and a pressure side wall of an airfoil cavity, through which a cooling fluid flows for cooling of the side walls. The suction side wall has one or more protrusions extending therefrom into the airfoil cavity. The protrusions are arranged such that: a number of the one or more protrusions on the suction side wall is higher than a number of protrusions on the pressure side wall; and / or a protrusion density on the suction side wall is higher than a protrusion density on the pressure side wall, and / or a total protrusion surface area on the suction side wall is larger than a total protrusion surface area on the pressure side wall, so that the heat transfer from the suction side wall to the cooling fluid is higher compared to that of the pressure side wall during operation of the turbomachine.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

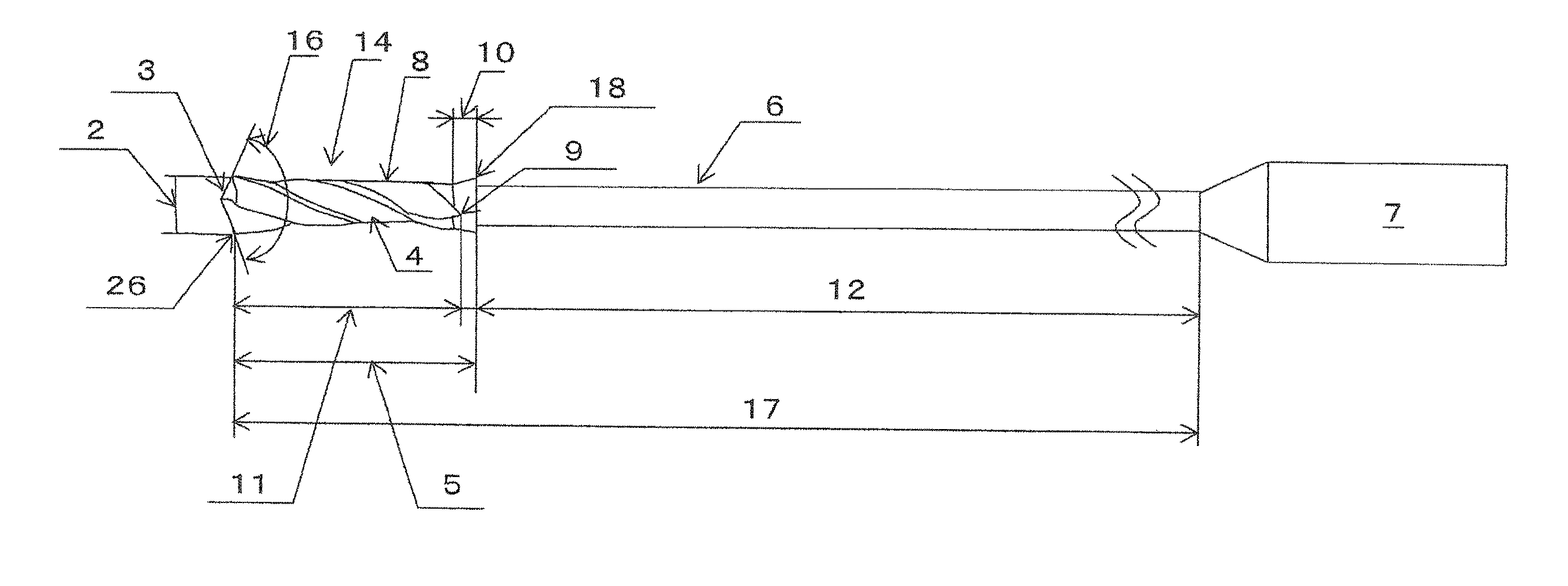

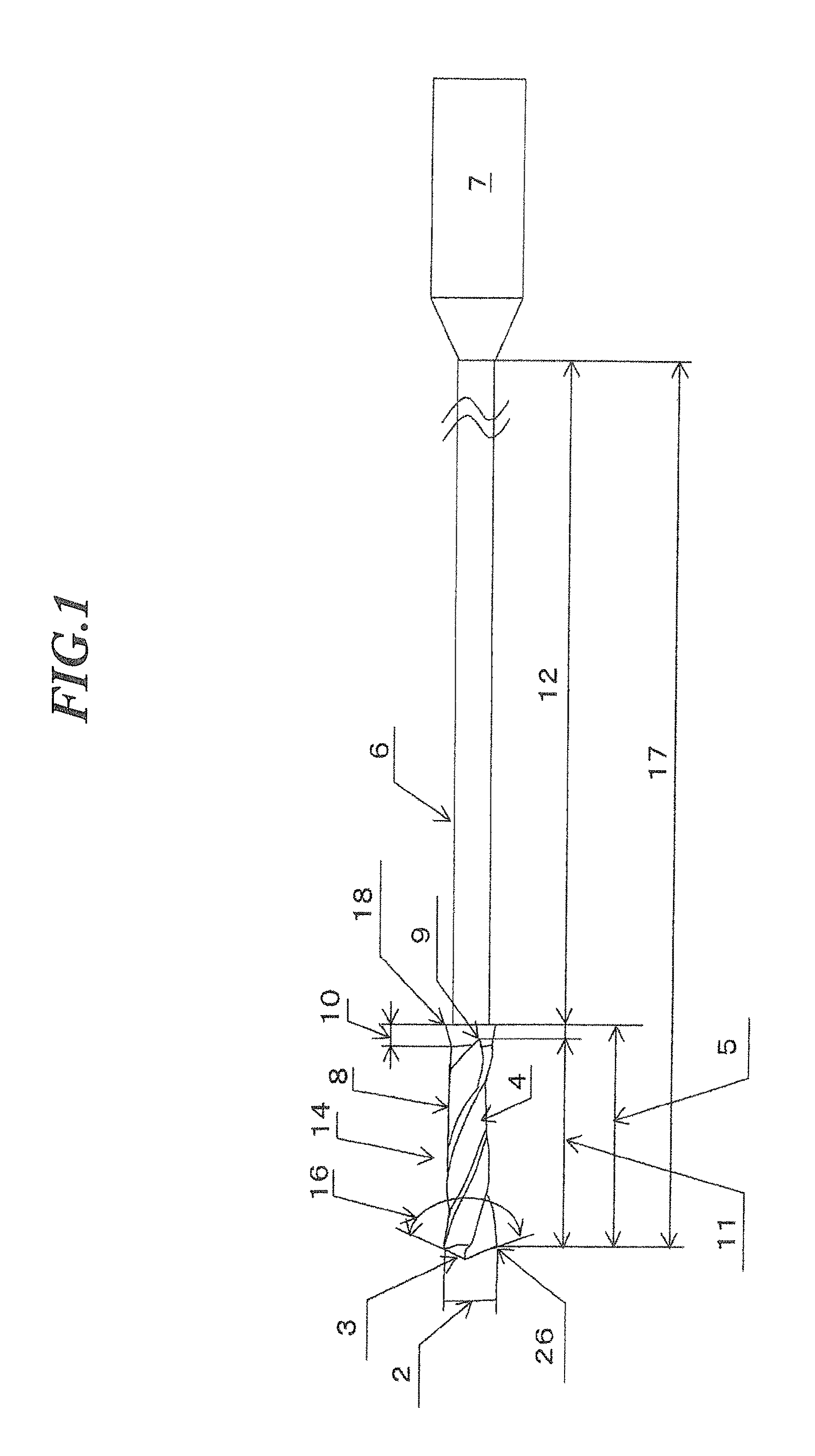

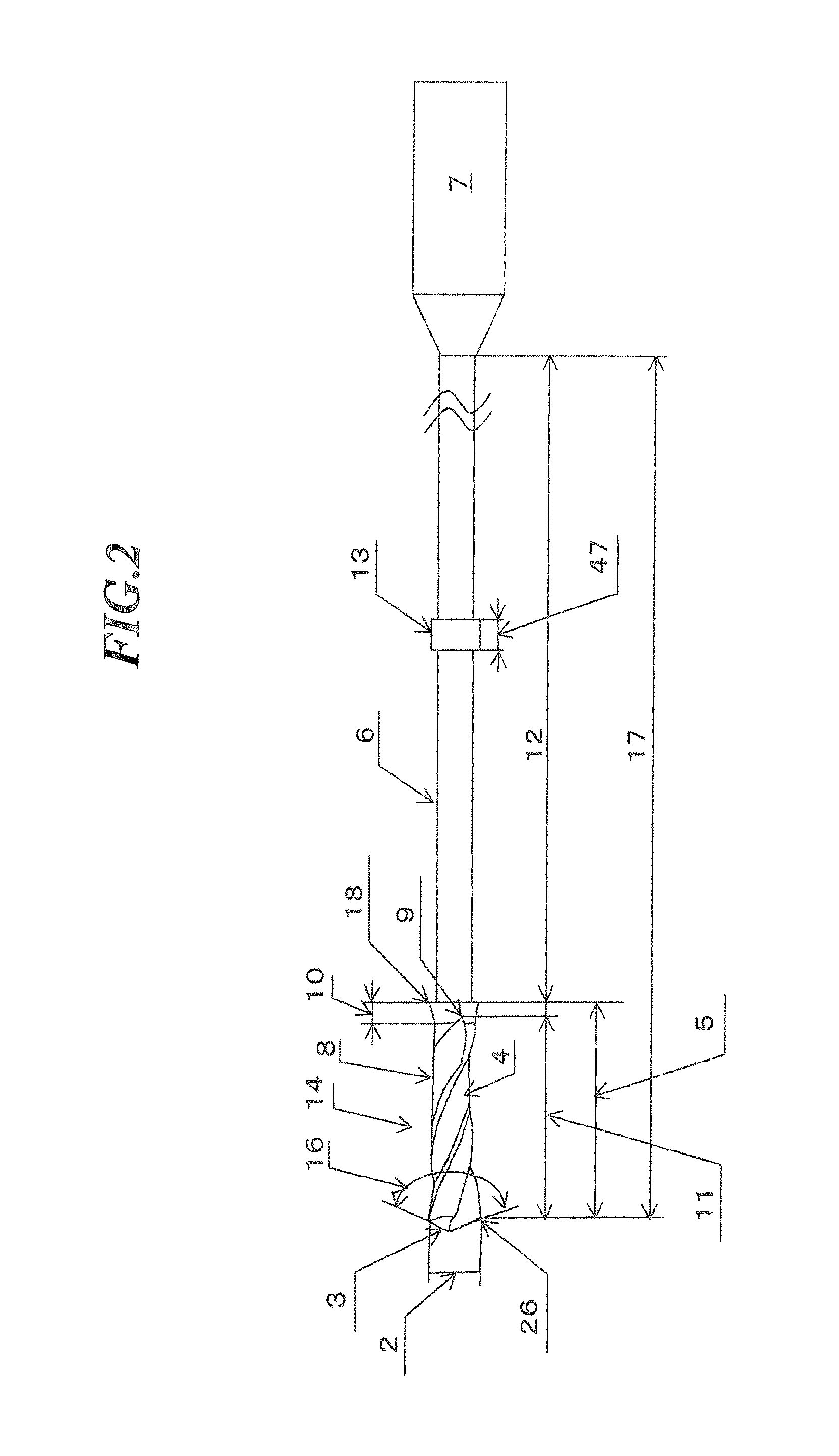

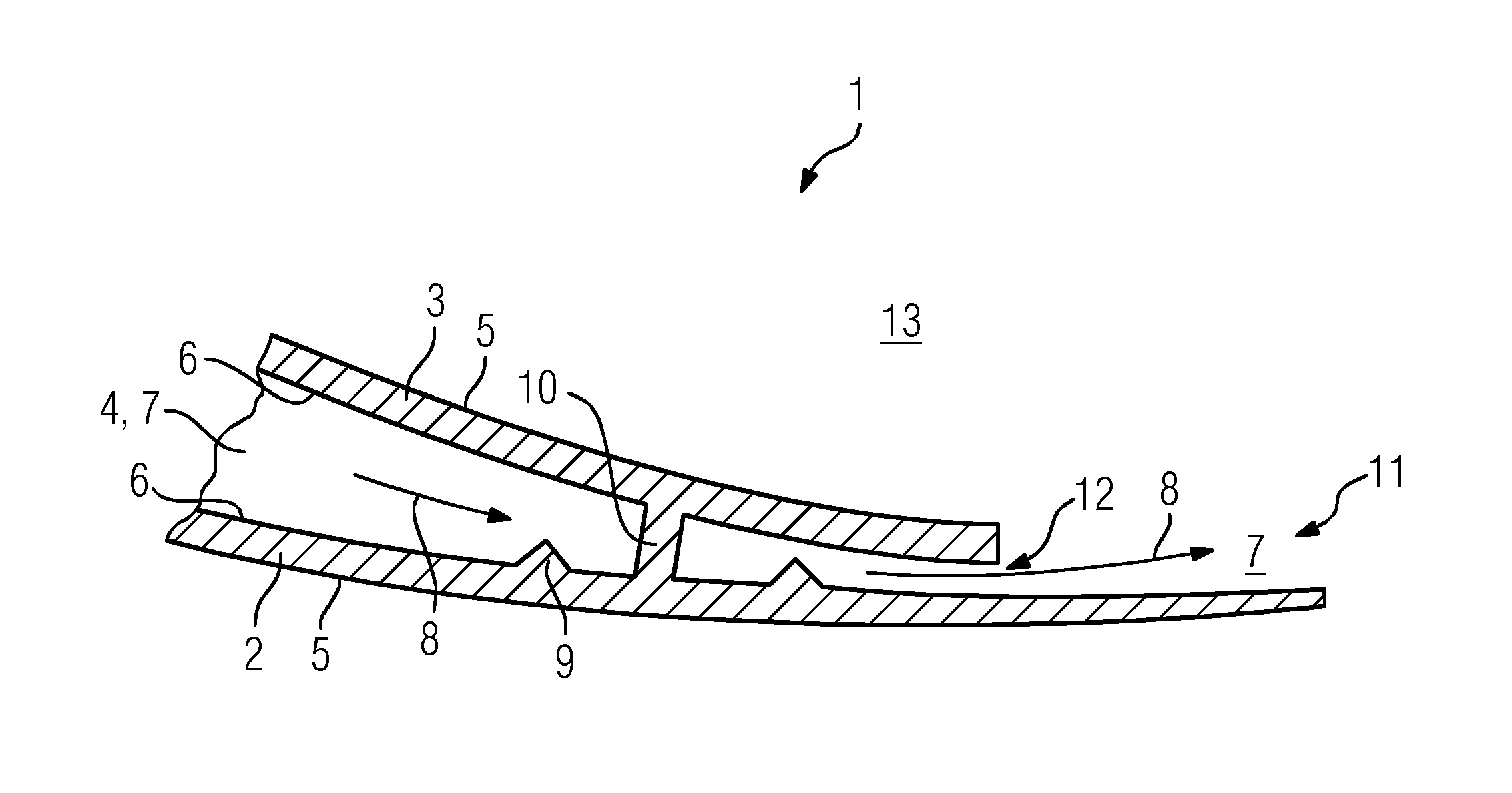

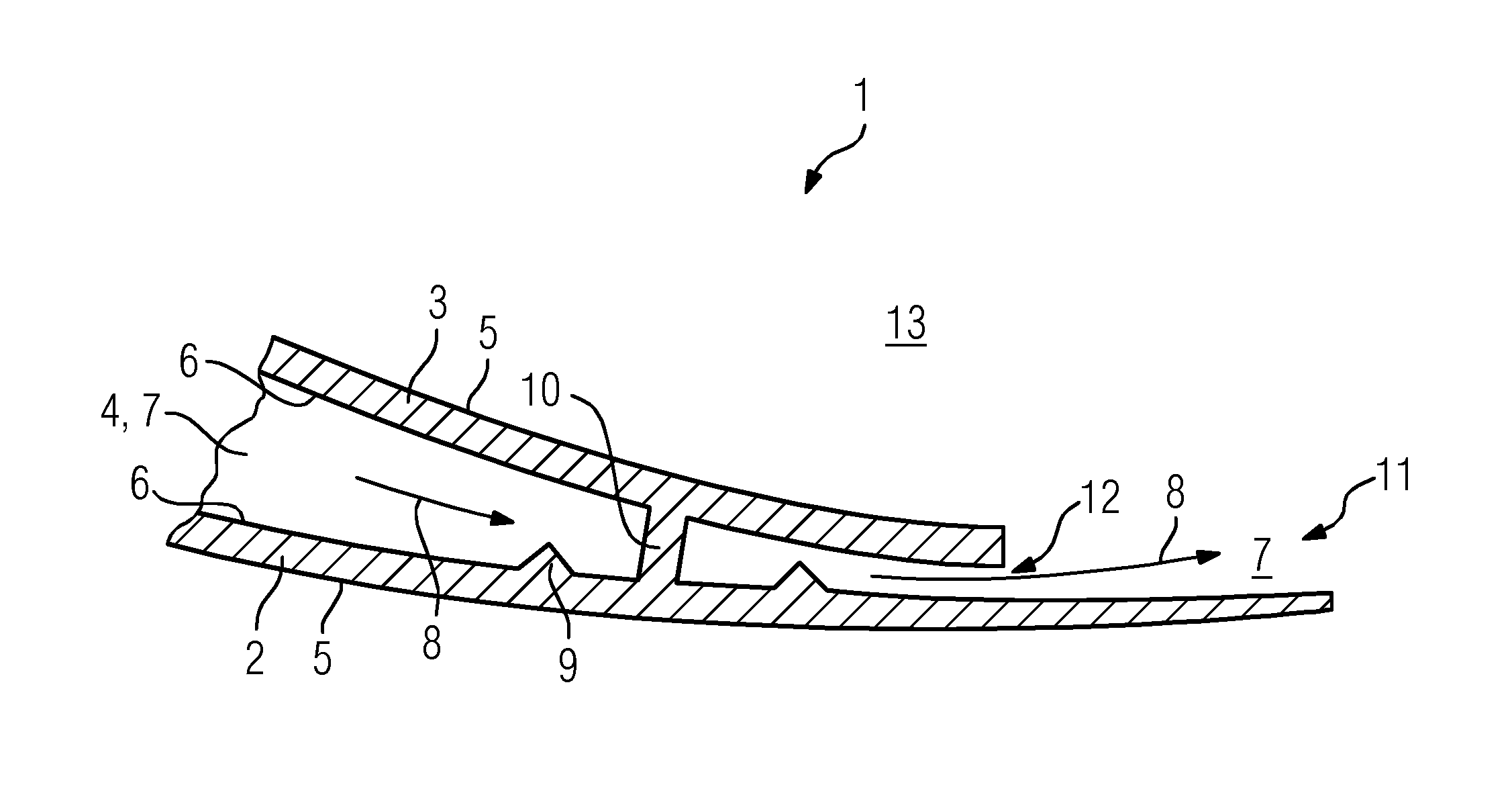

Small-diameter deep hole drill and a micro deep hole drilling method

InactiveUS7909549B2Acceptable roughnessImprove straightnessDrilling/boring measurement devicesThread cutting machinesFluteDeep hole

A small-diameter drill for deep hole drilling is provided which is capable of inhibiting the cutting chips from getting bitten and producing a straightness for a drilled hole, thus suitable for drilling a hole having a depth (L) which is 15 or more times the diameter (D) of a drilled hole. The small-diameter drill 1 has a diameter 2 which is 1 mm or less and a drill section 5 including cutting edge(s) 3 and flute(s) 4. The length 11 of the flute 4 is at least 5 times and at most 10 times the drill diameter 2. The diameter of the drill section 5, after being reduced in diameter from the cutting edge 3 toward the rear of the drill section 5, is expanded in diameter so that the outer diameter at the end of the flute 4 becomes at least 0.9 times and at most 0.98 times the drill diameter 2. An expanded-diameter portion 10 is provided between the drill section 5 and a neck section 6 connected to a shank 7 and is expended in diameter from the outer diameter at the end 9 of the flute 4 up to 1 or less times the drill diameter 2. The diameter of the neck section 6 is smaller than the drill diameter 2, and the length 12 of the neck section 6 is 10 or more times the drill diameter 2.

Owner:HITACHI TOOL ENG LTD

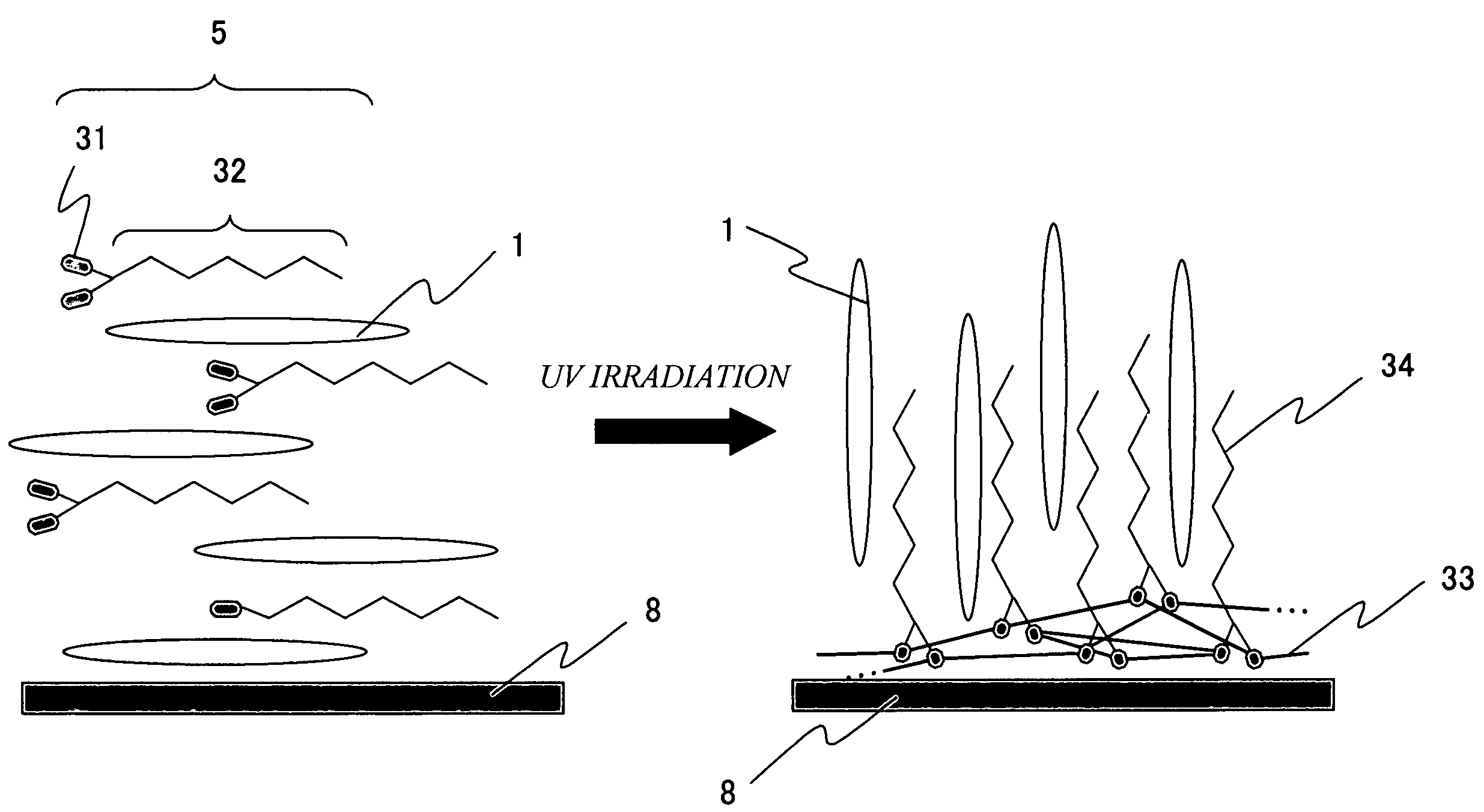

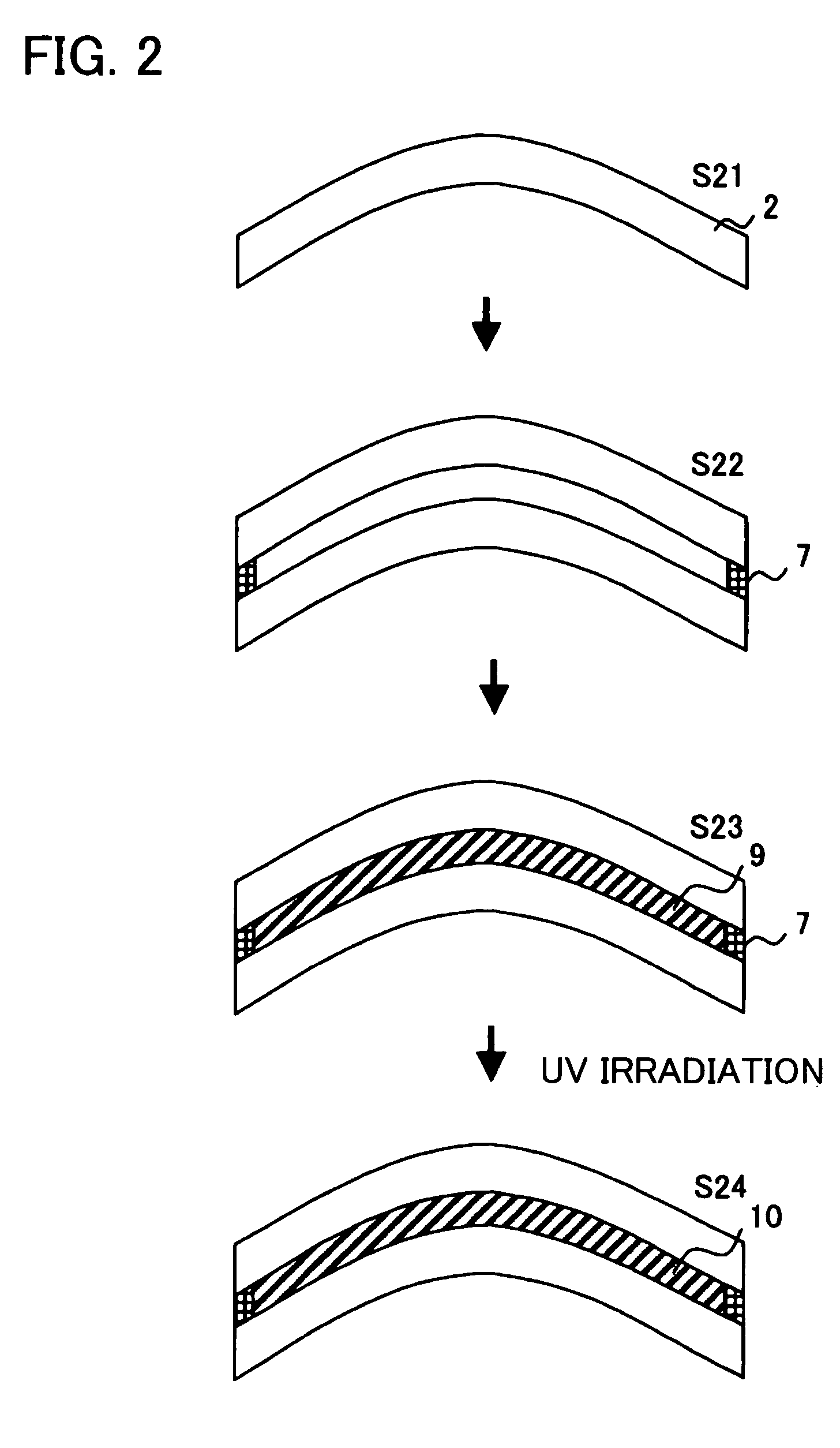

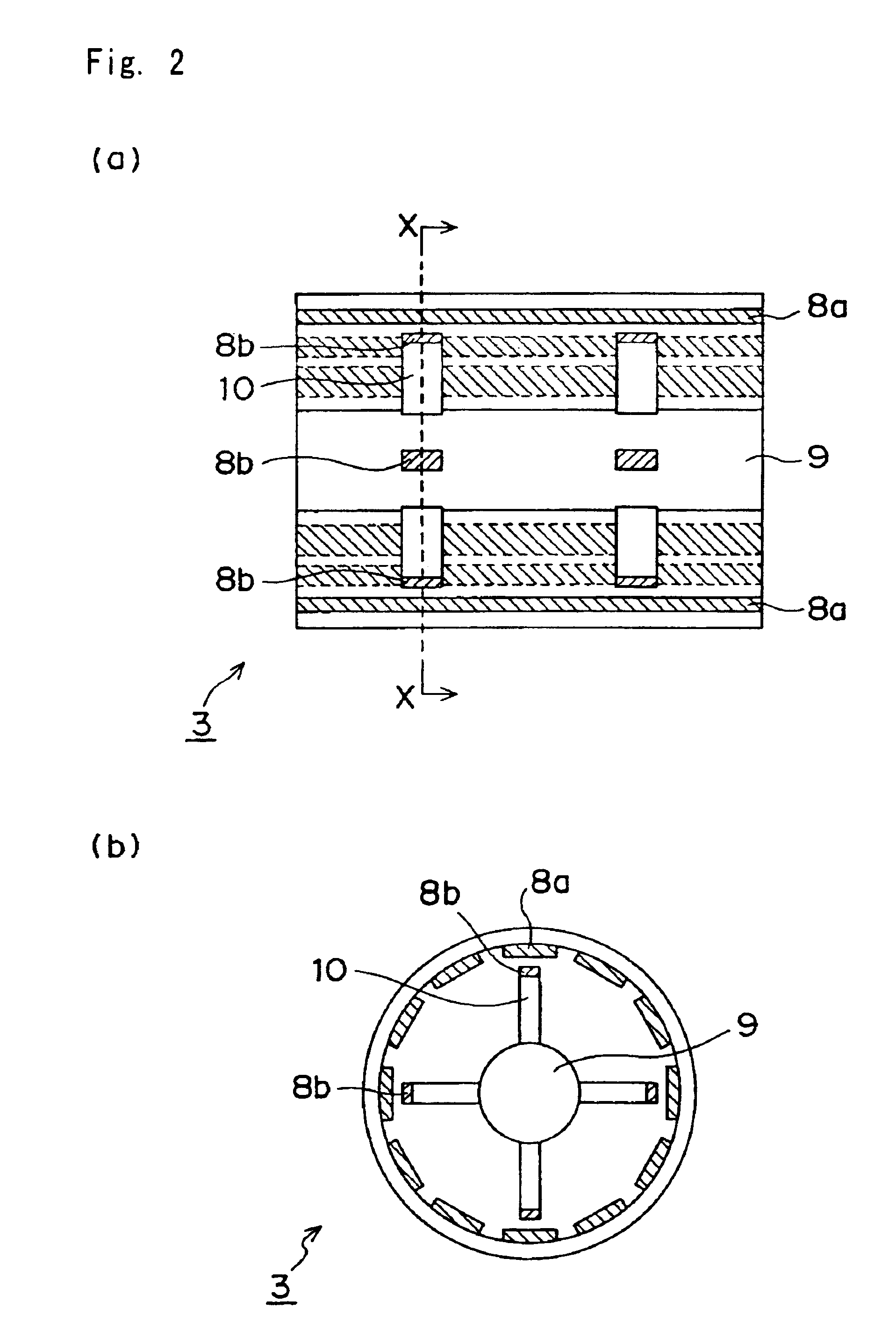

Liquid crystal panel

ActiveUS7279203B2Freedom in appearanceLight device weightLiquid crystal compositionsThin material handlingCrystallographyCross-link

A liquid crystal panel is provided that has a liquid crystal layer sandwiched between a pair of substrates, wherein the liquid crystal layer comprises a liquid crystal and a cross-linked resin, the cross-linked resin comprises a cross-linked structural part adhered to a liquid crystal layer contacting surface and a terminal part rising from the liquid crystal layer contacting surface, and at least one of three conditions: the outer surface of at least one substrate is curved; a liquid crystal layer contacting surface is curved; and the thickness of one of the substrates is not more than ½ of the thickness of the other substrate, is satisfied. It is possible to obtain a liquid crystal panel having increased freedom in the appearance, device weight reduction, simplified structure, etc. by improving the outer and / or inner surfaces of the device.

Owner:MERCK PATENT GMBH

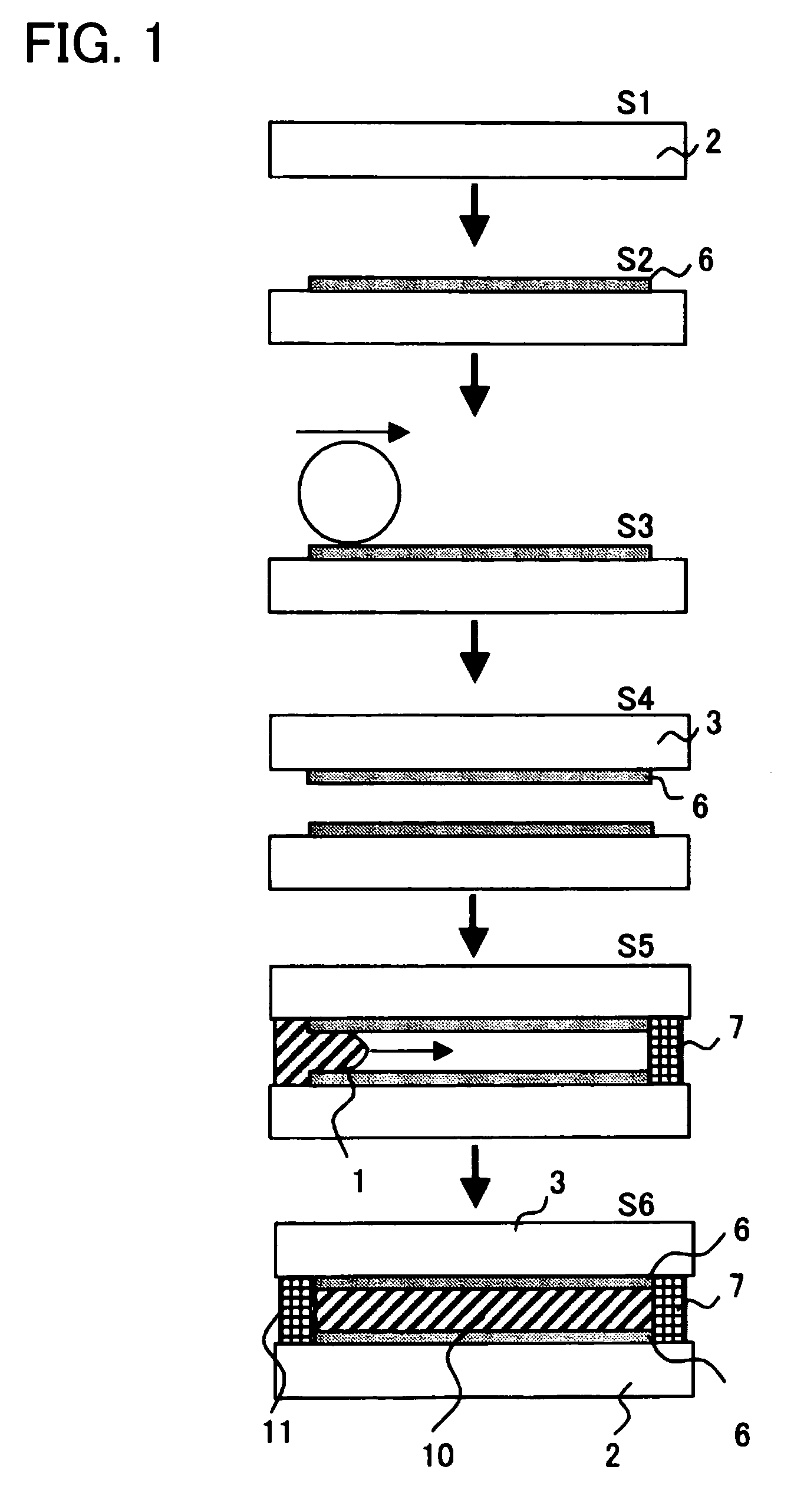

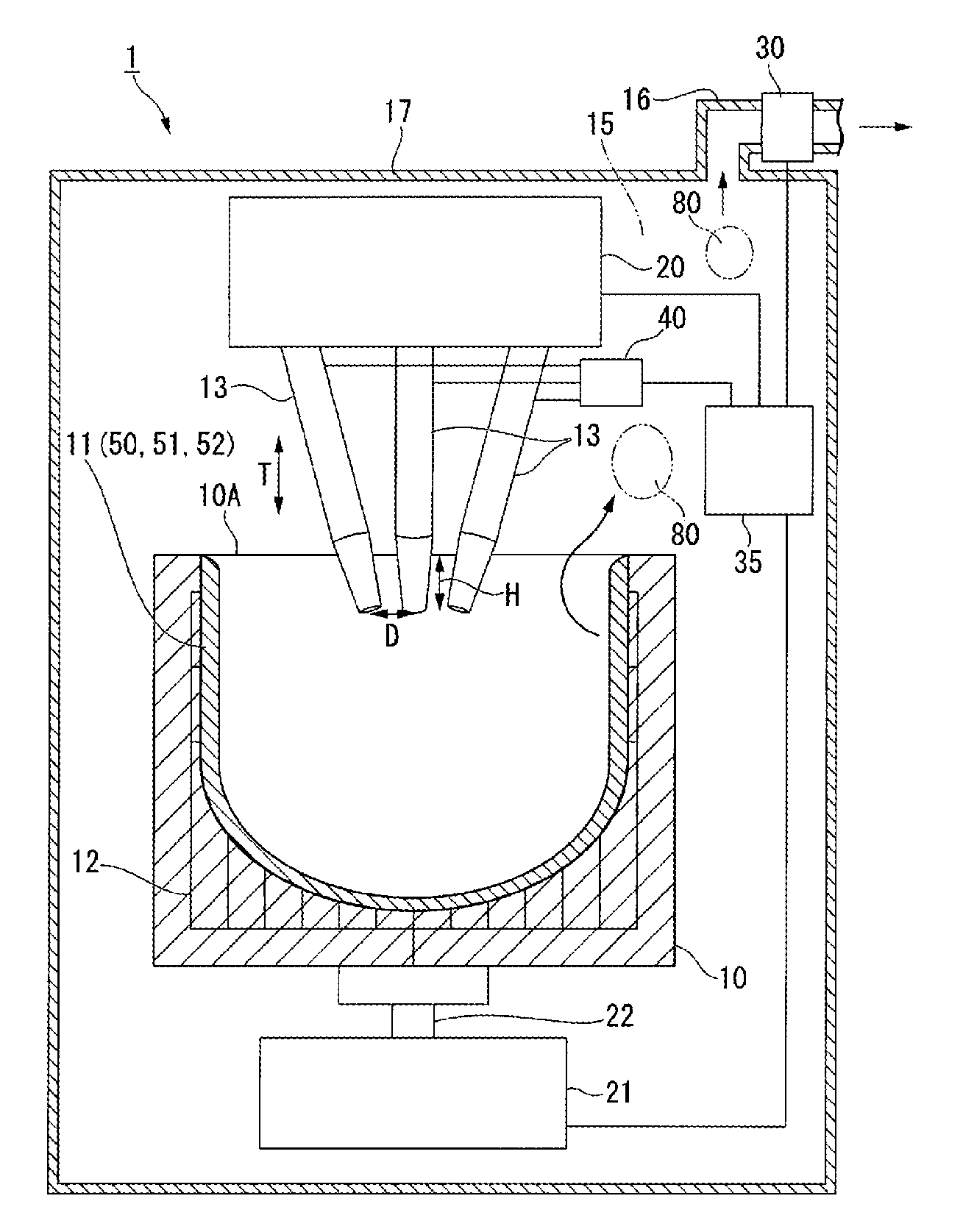

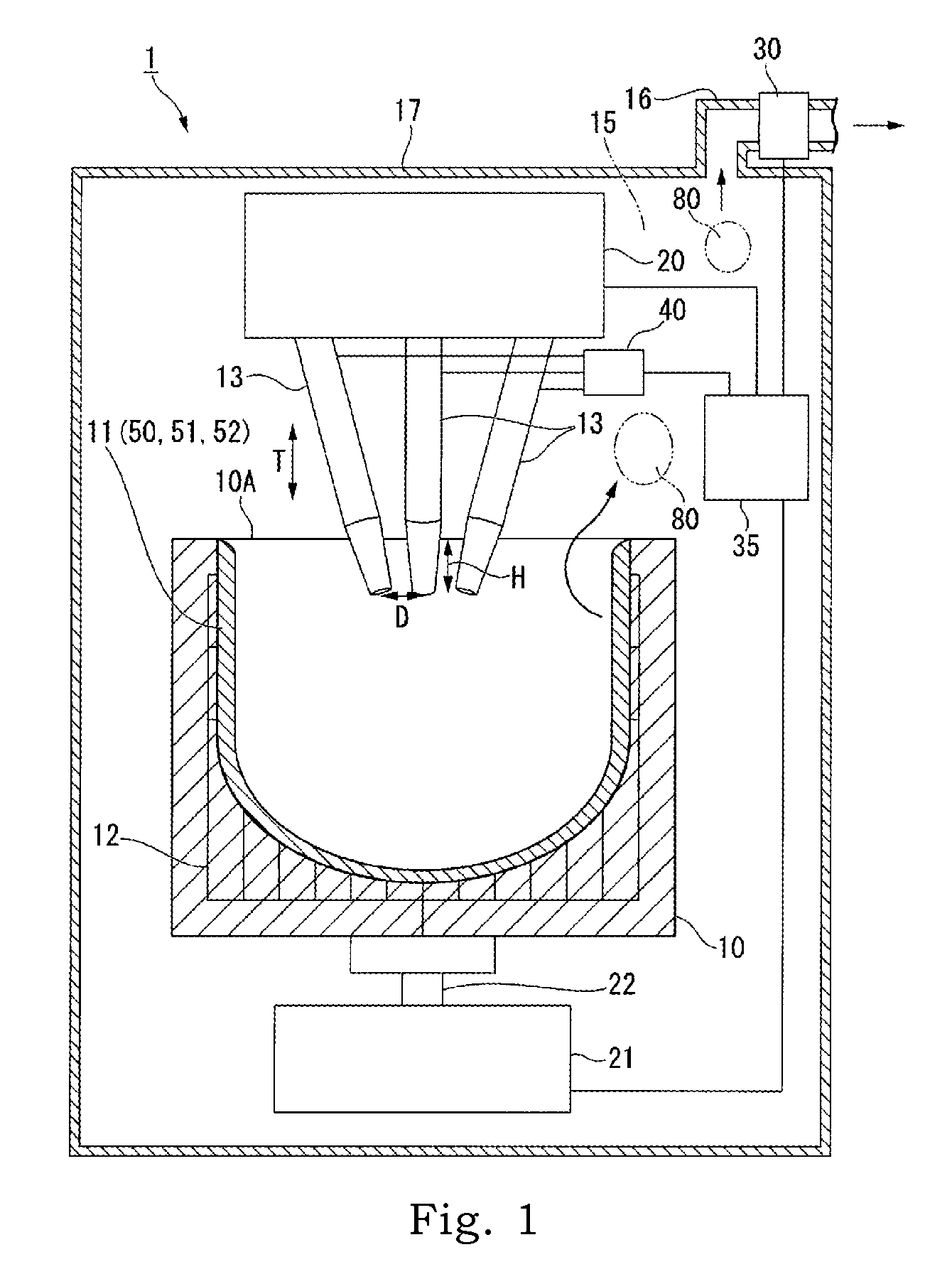

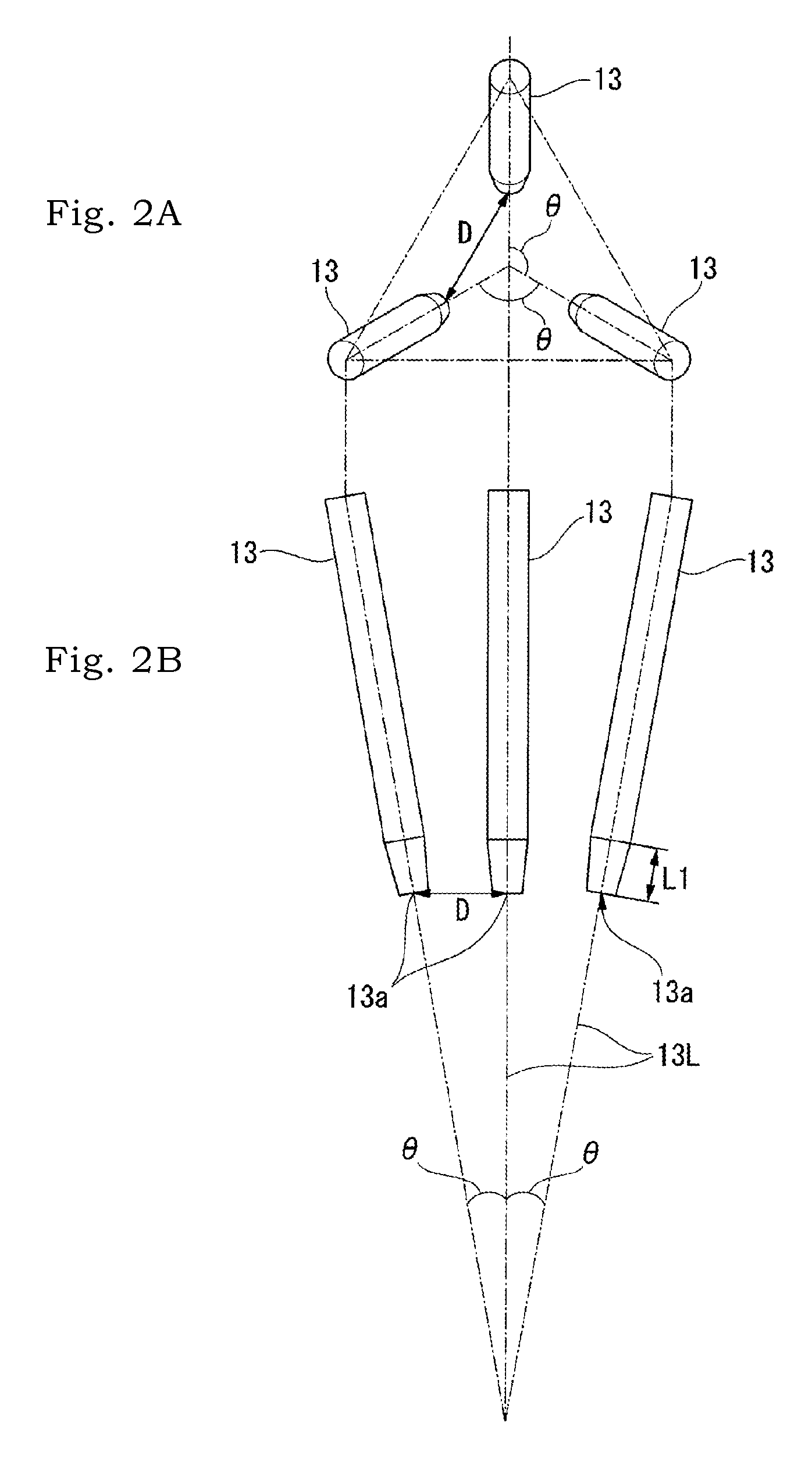

Apparatus and method for manufacturing vitreous silica crucible

ActiveUS20110079047A1Stable quality controlGood inner surface propertyBlowing machine gearingsGlass furnace apparatusCrucibleTime control

Provided are an apparatus and a method for manufacturing a vitreous silica crucible, which enable accurate measurement of a fume generation amount, prevention of deterioration of an inner surface property, and real-time control of a raw material melting state. Provided is an apparatus for manufacturing a vitreous silica crucible 50 by supplying silica powder into a mold 10 to form a silica powder layer 11, and heating and melting the silica powder layer 11 by arc discharge. The apparatus includes the mold 10 for defining an outer shape of a vitreous silica crucible, an arc discharge unit having a plurality of carbon electrodes 13 and a power-supply unit 40, and a fume-amount measurement unit 30 for detecting an amount of fumes 80 generated in the mold 10.

Owner:SUMCO CORP

Cooled turbine guide vane or blade for a turbomachine

InactiveUS20150016961A1Improve heat transfer performanceReduce the amount requiredPropellersPump componentsSuction stressEngineering

A turbine airfoil for a turbomachine is provided. The airfoil includes a suction side wall and a pressure side wall bordering an airfoil cavity, which receives a cooling fluid for cooling the airfoil. The suction side wall includes one or more protrusions extending inside the cavity. The number of protrusions on the suction side may be higher than the number of protrusions on the pressure side. The density of protrusions on the suction side may be higher than the density of protrusions on the pressure side and / or the surface of protrusions on the suction side may be larger than the surface of protrusions on the pressure side, so that heat transfer from the suction side to the cooling fluid is higher compared to heat transfer from the pressure side to the cooling fluid during operation of the turbomachine.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

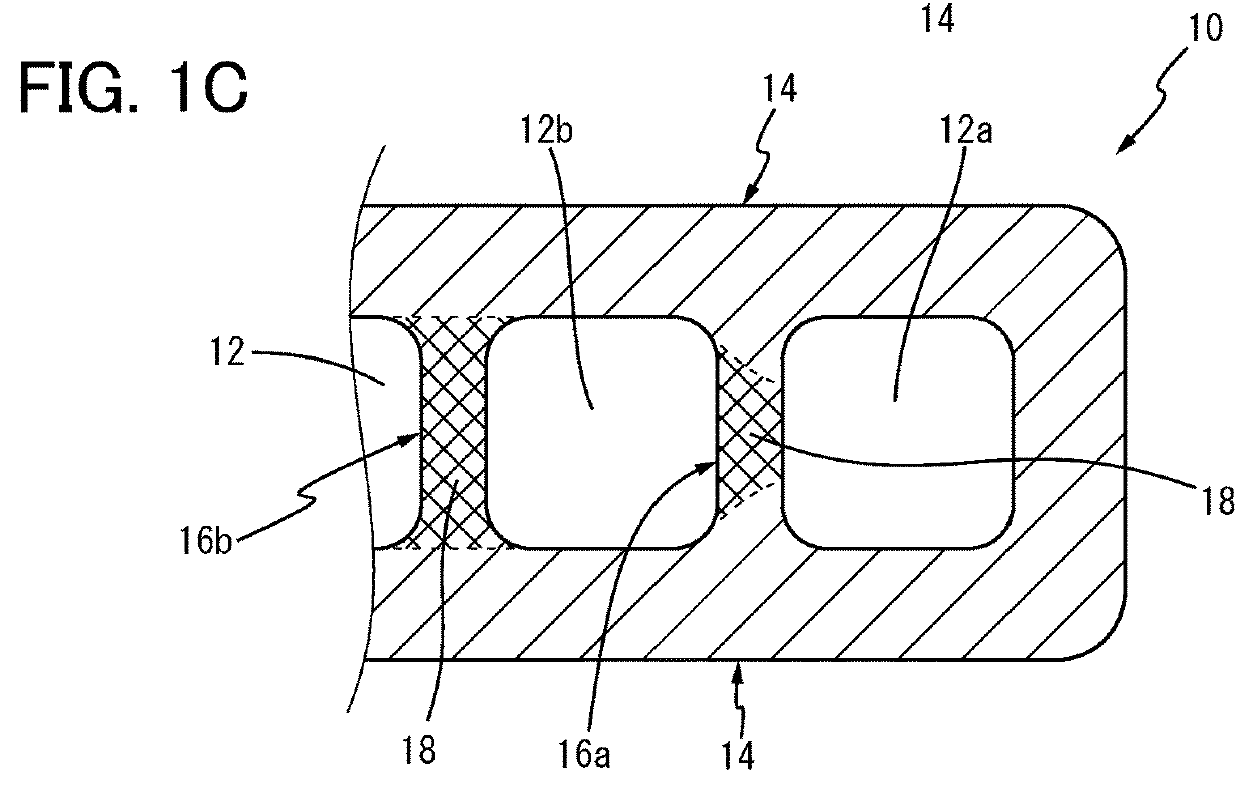

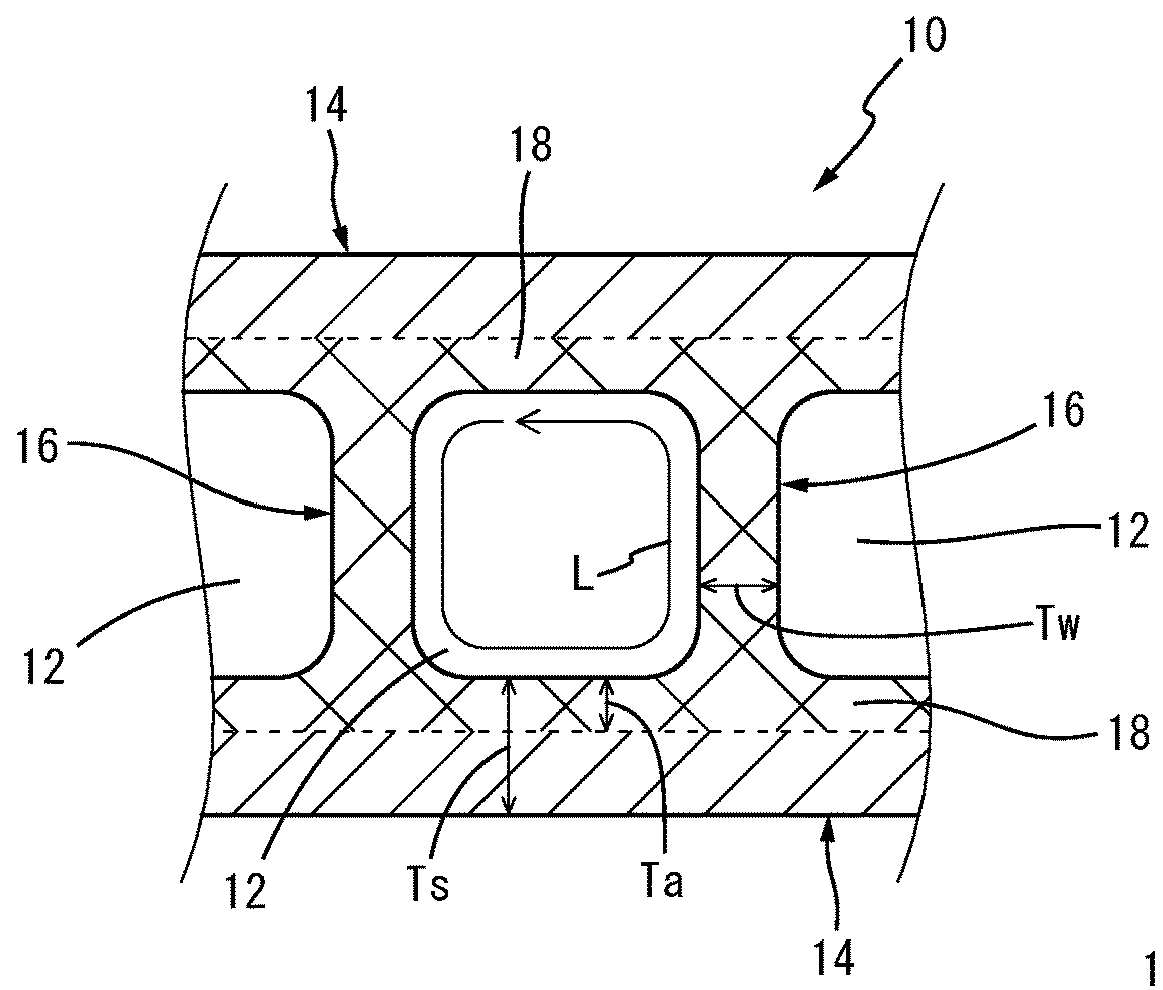

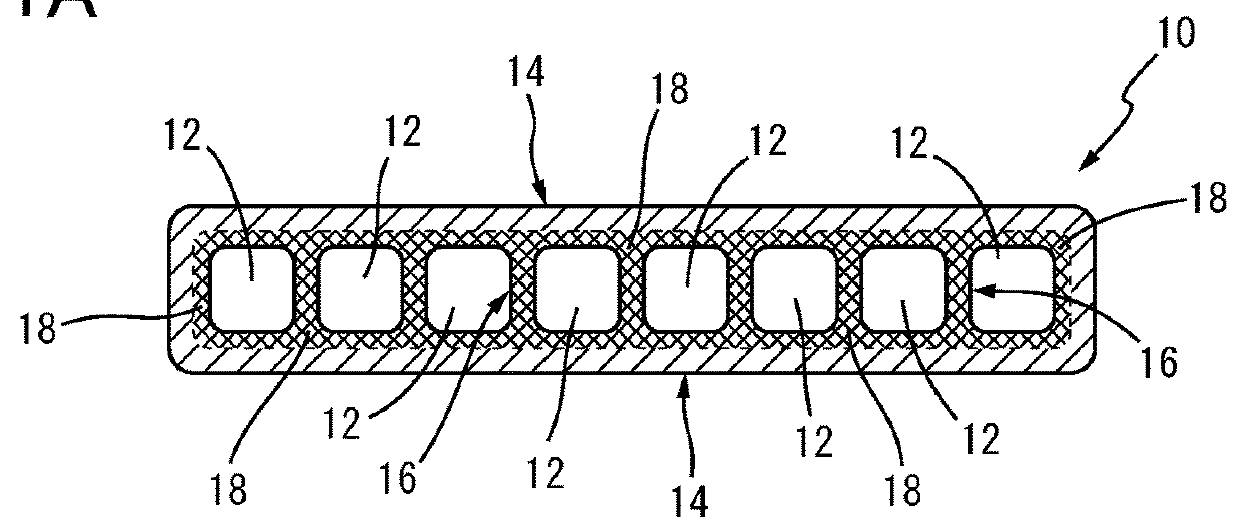

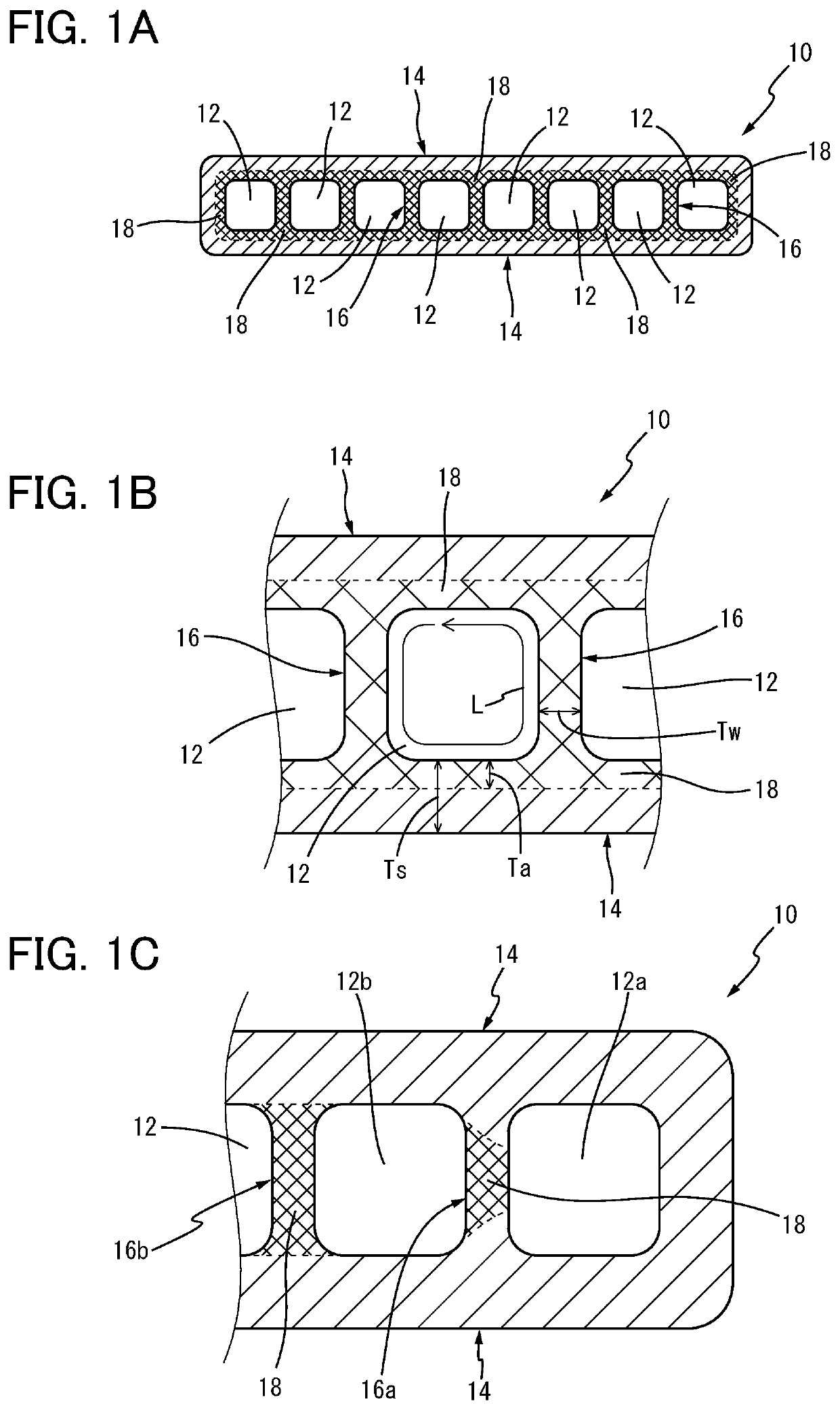

Flat extruded aluminum multi-port tube whose inner surface is highly corrosion-resistant and an aluminum heat exchanger using the tube

InactiveUS20180164052A1Design freedomSpeed up heat exchangeCoatingsTubular elementsMulti portCorrosion resistant

In this flat extruded aluminum multi-port tube, the corrosion-resistance, at inner surfaces of a plurality of flow passages independently and parallelly extending in the tube axial direction, is effectively enhanced. In a flat extruded aluminum multi-port tube 10 formed by an extrusion by employing an aluminum tube material and an aluminum sacrificial anode material having an electrochemically lower potential than the aluminum tube material, the aluminum sacrificial anode material is exposed to form a sacrificial anode portion 18 at least in a part of an inner circumferential portion in each of the plurality of flow passages 12.

Owner:FURUKAWA SKY ALUMINUM CORP +2

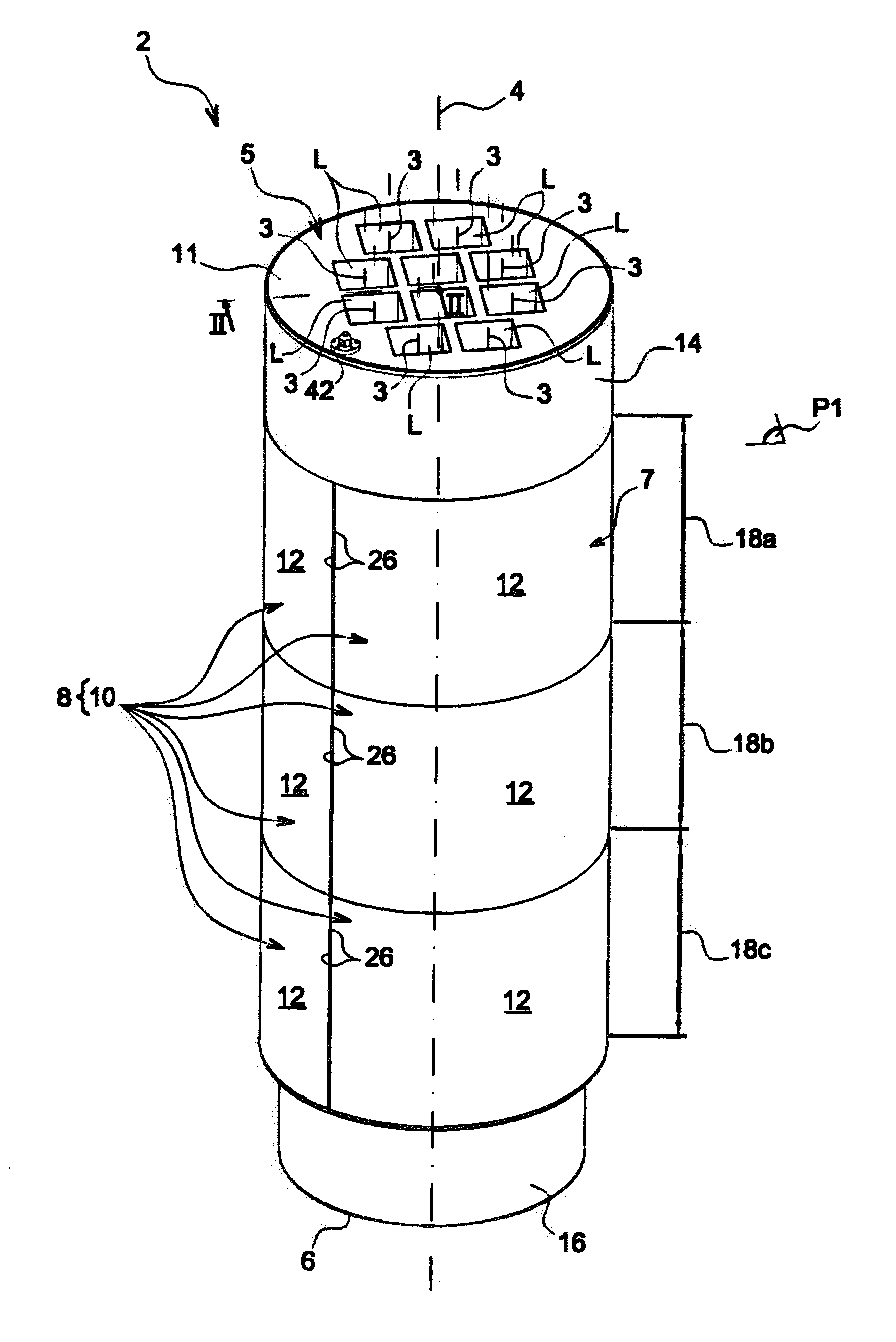

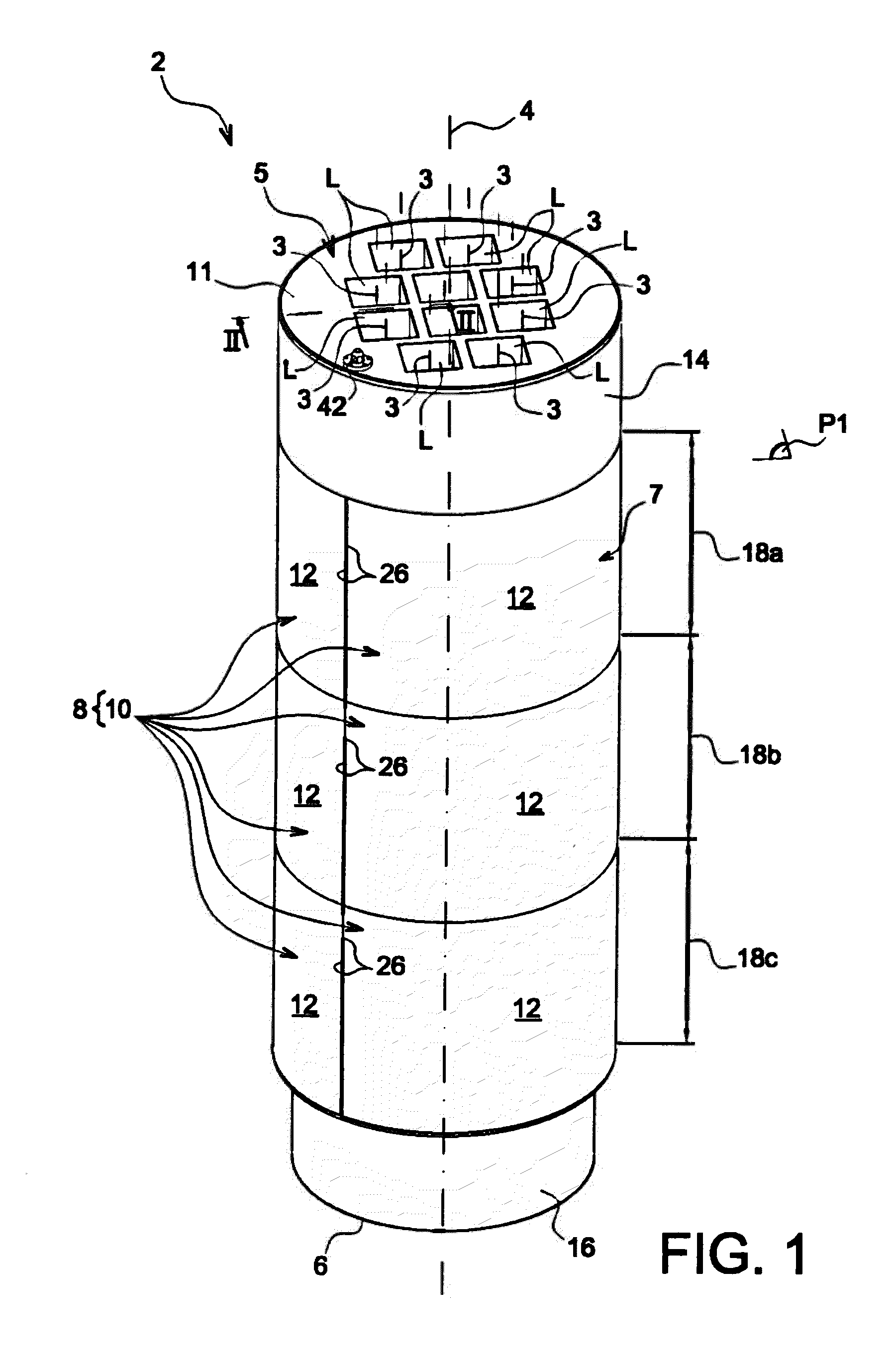

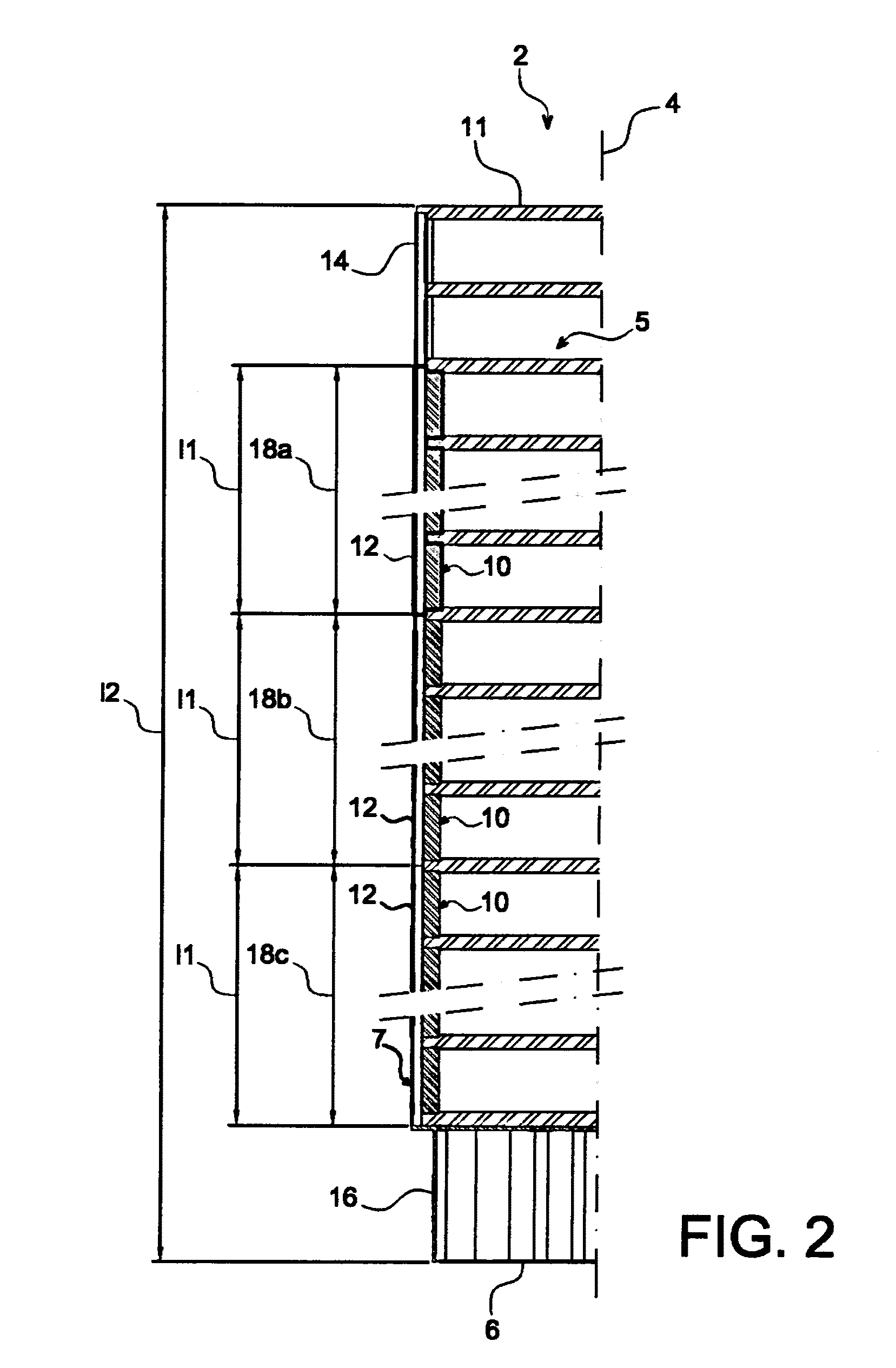

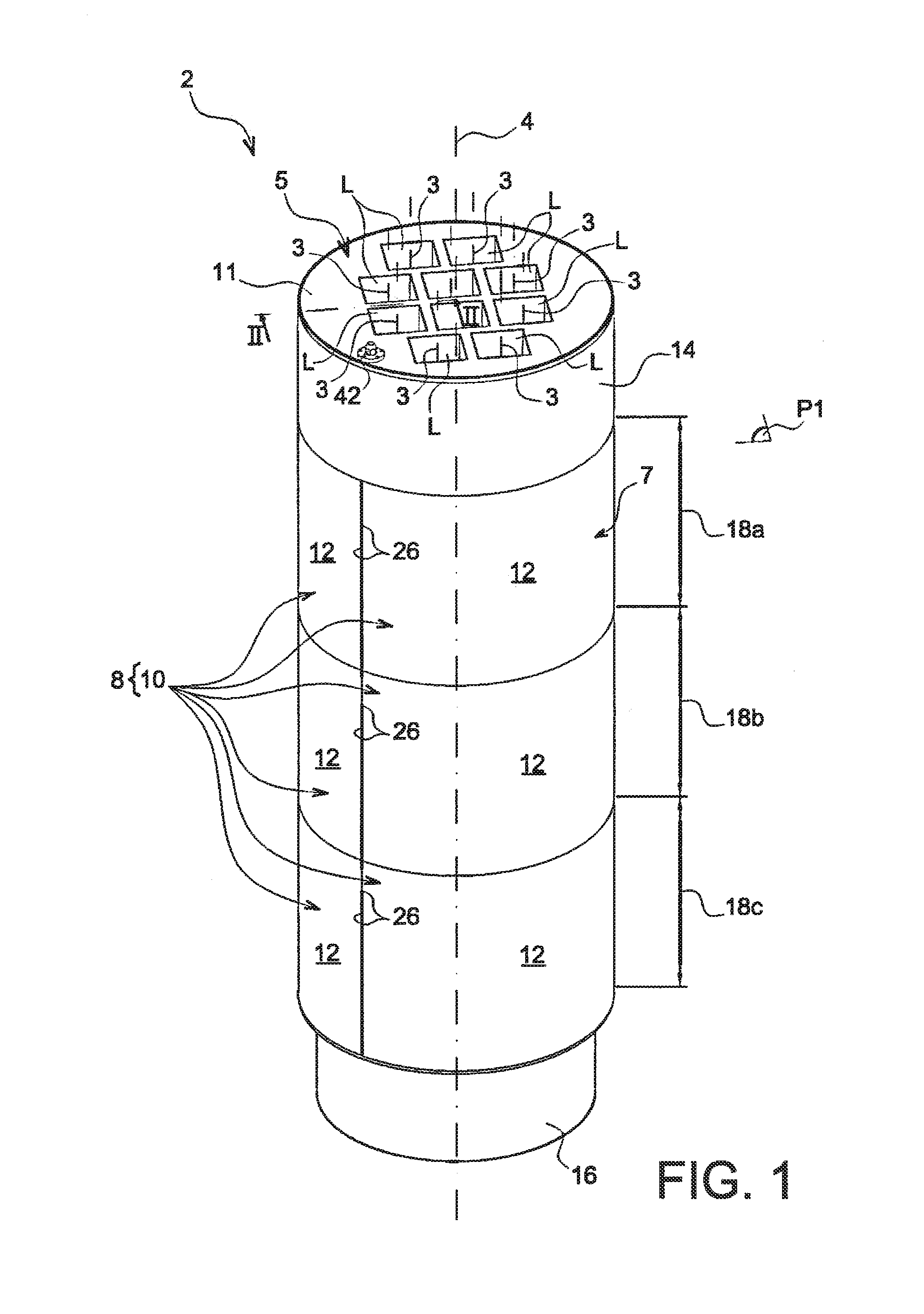

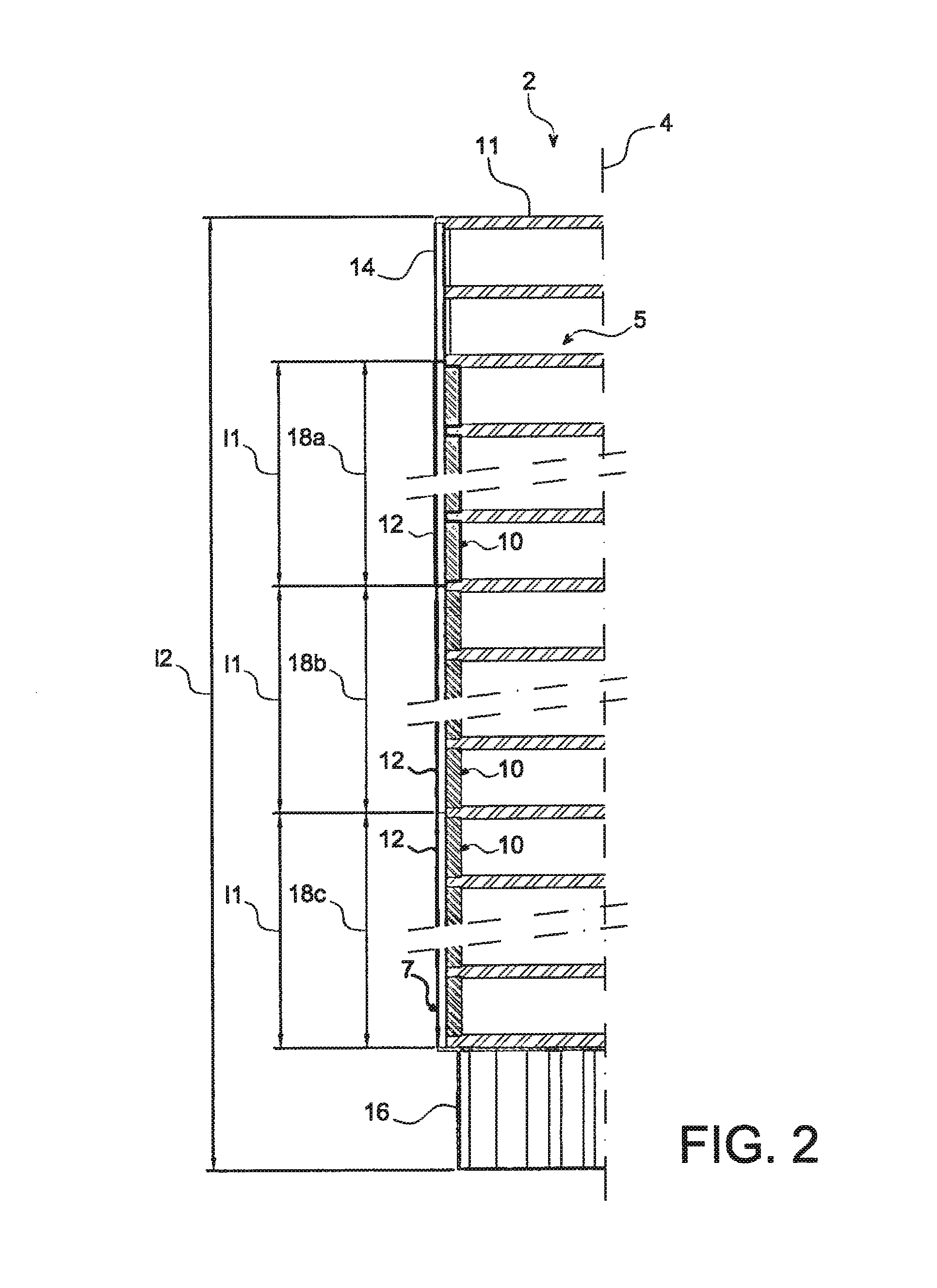

Container for the transport and/or storage of nuclear materials, the container comprising a mobile heat conduction structure

ActiveUS20100119029A1Reduce playImprove heat transfer performanceDucting arrangementsDrying gas arrangementsNuclear engineeringNuclear material

Owner:TN INT (FR)

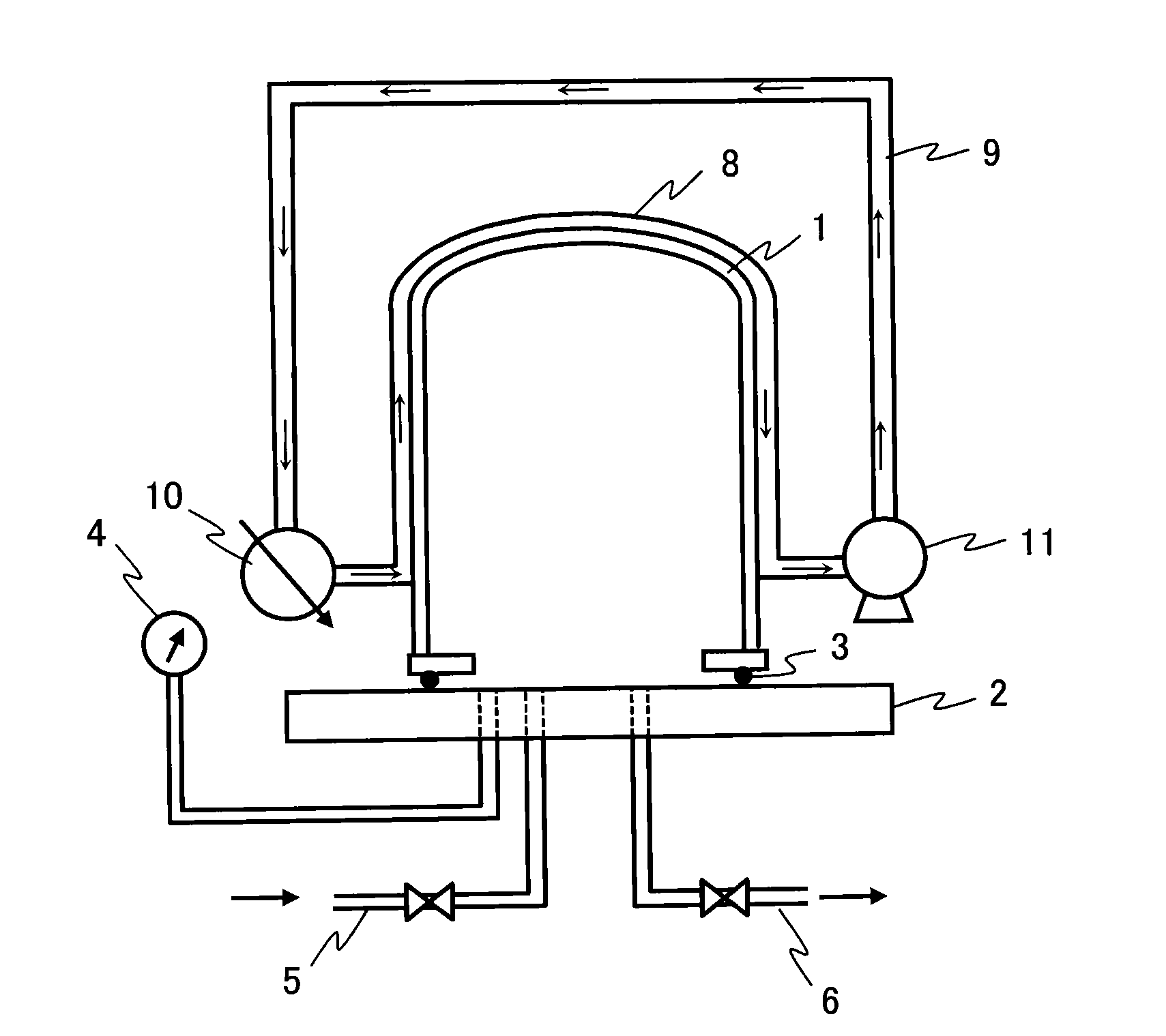

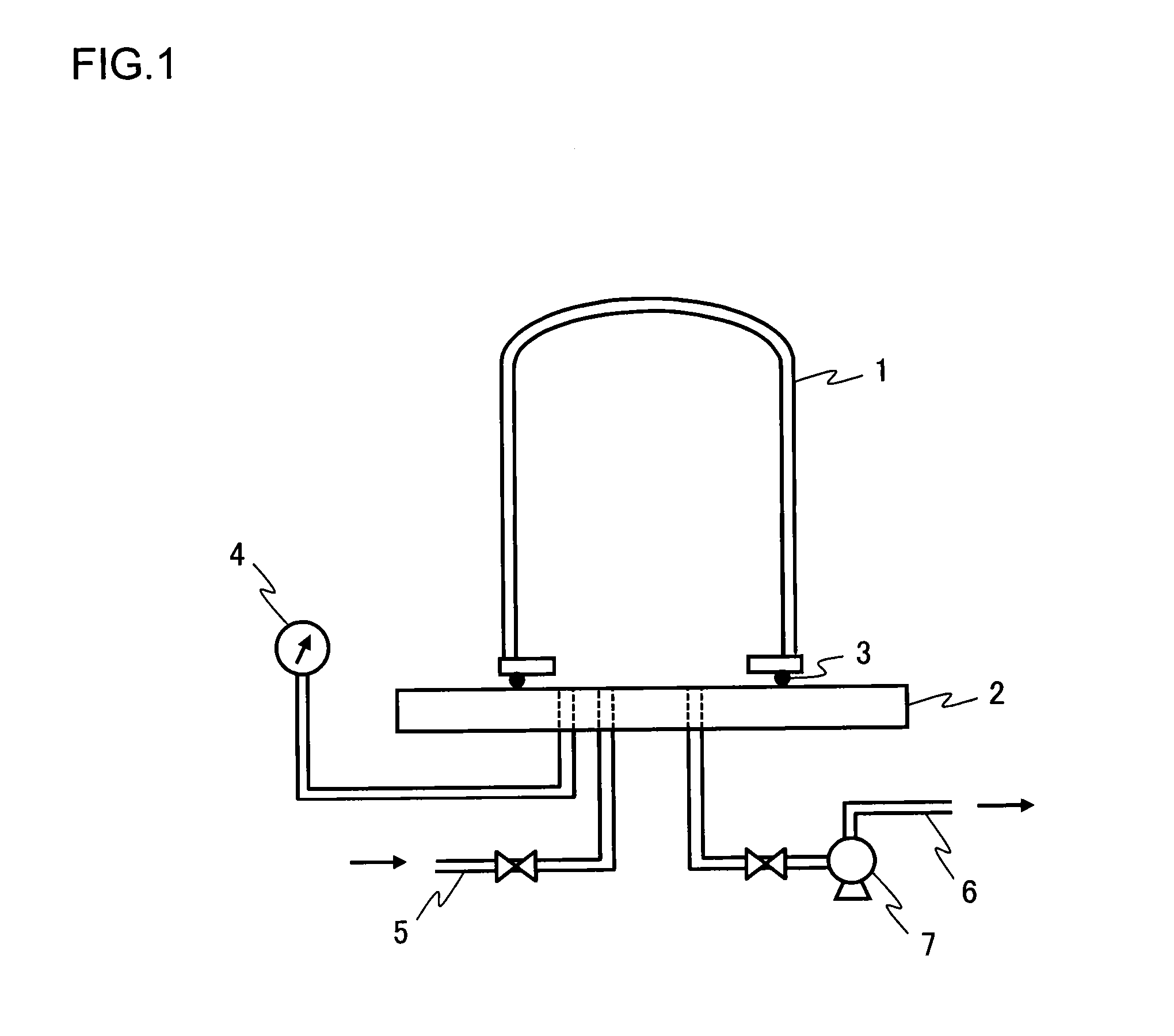

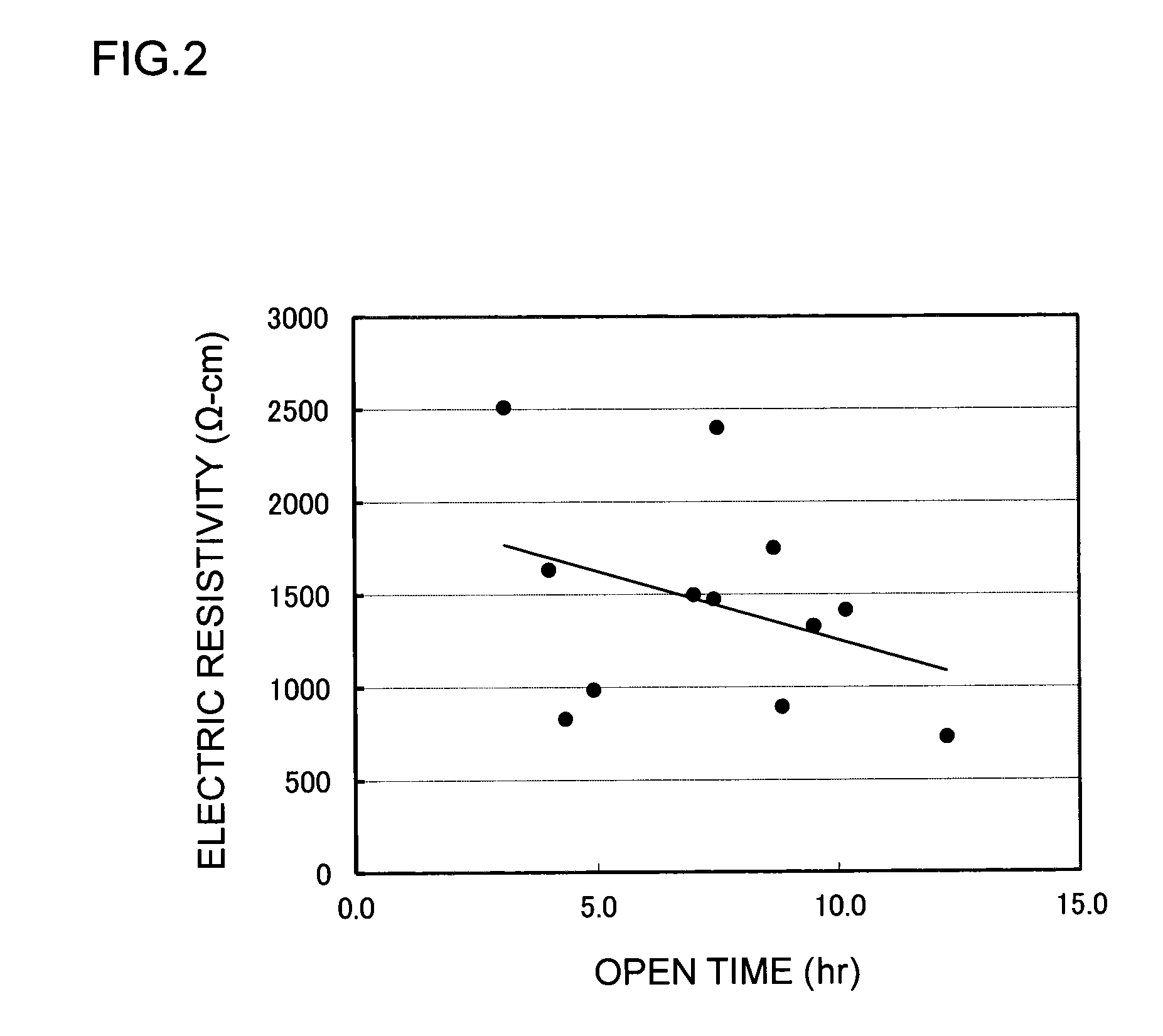

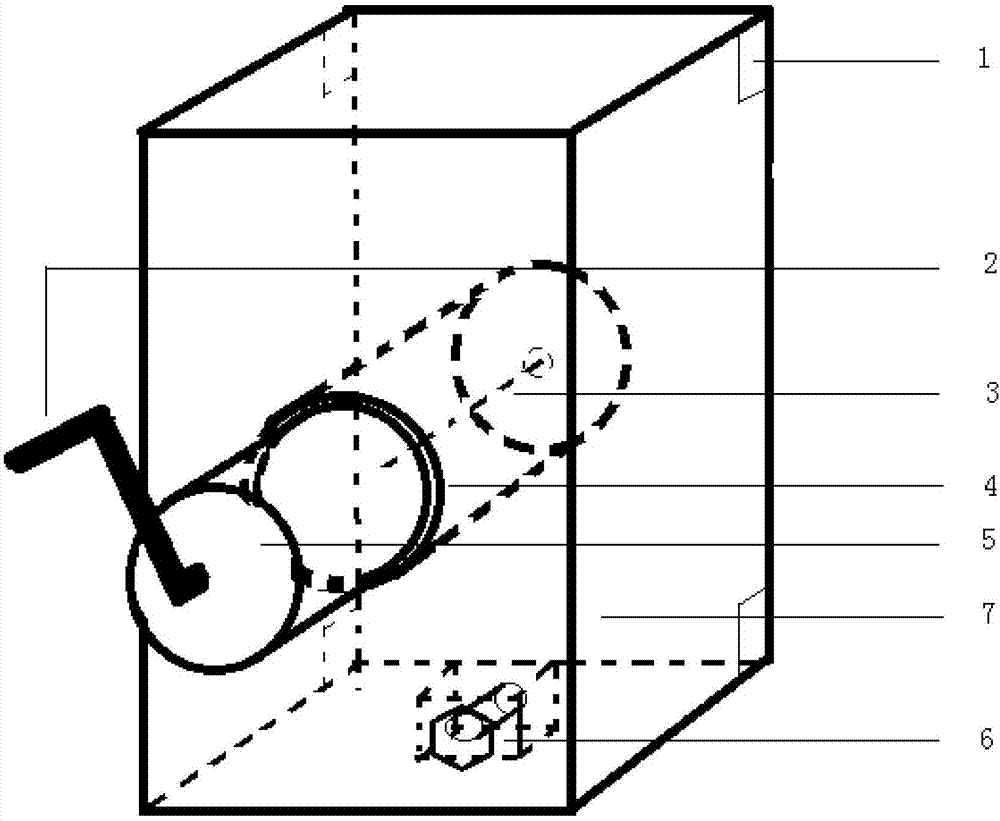

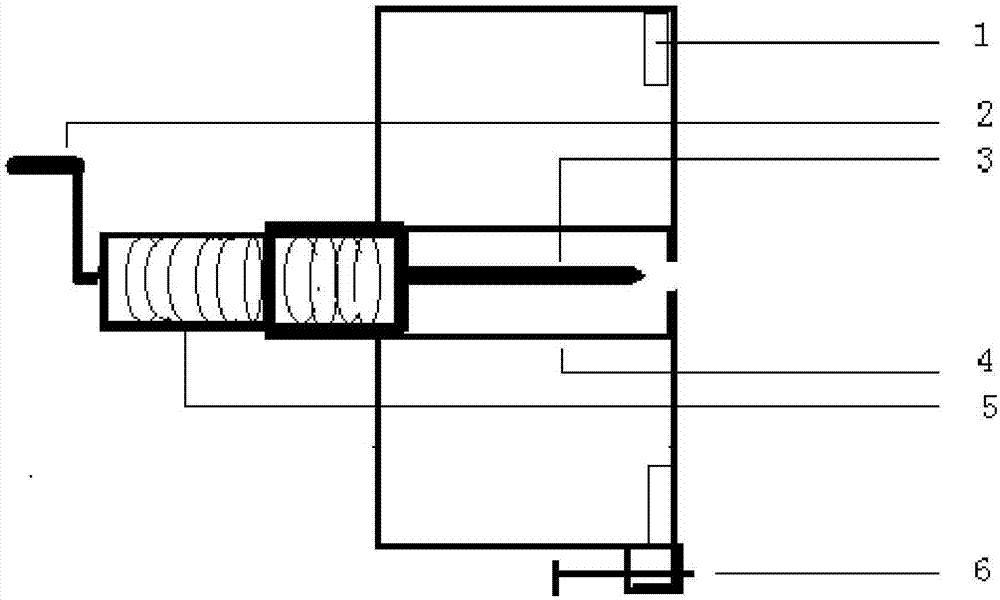

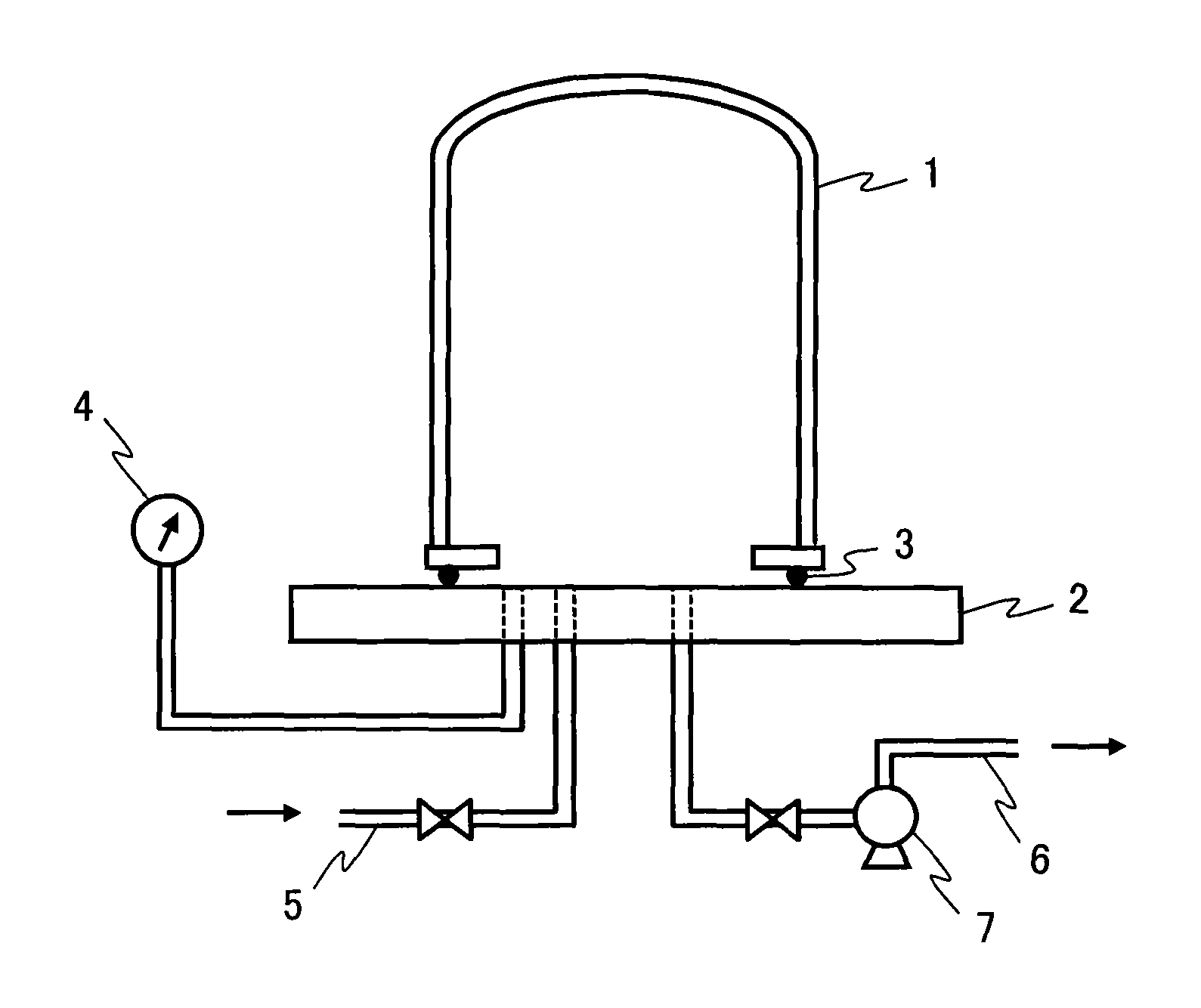

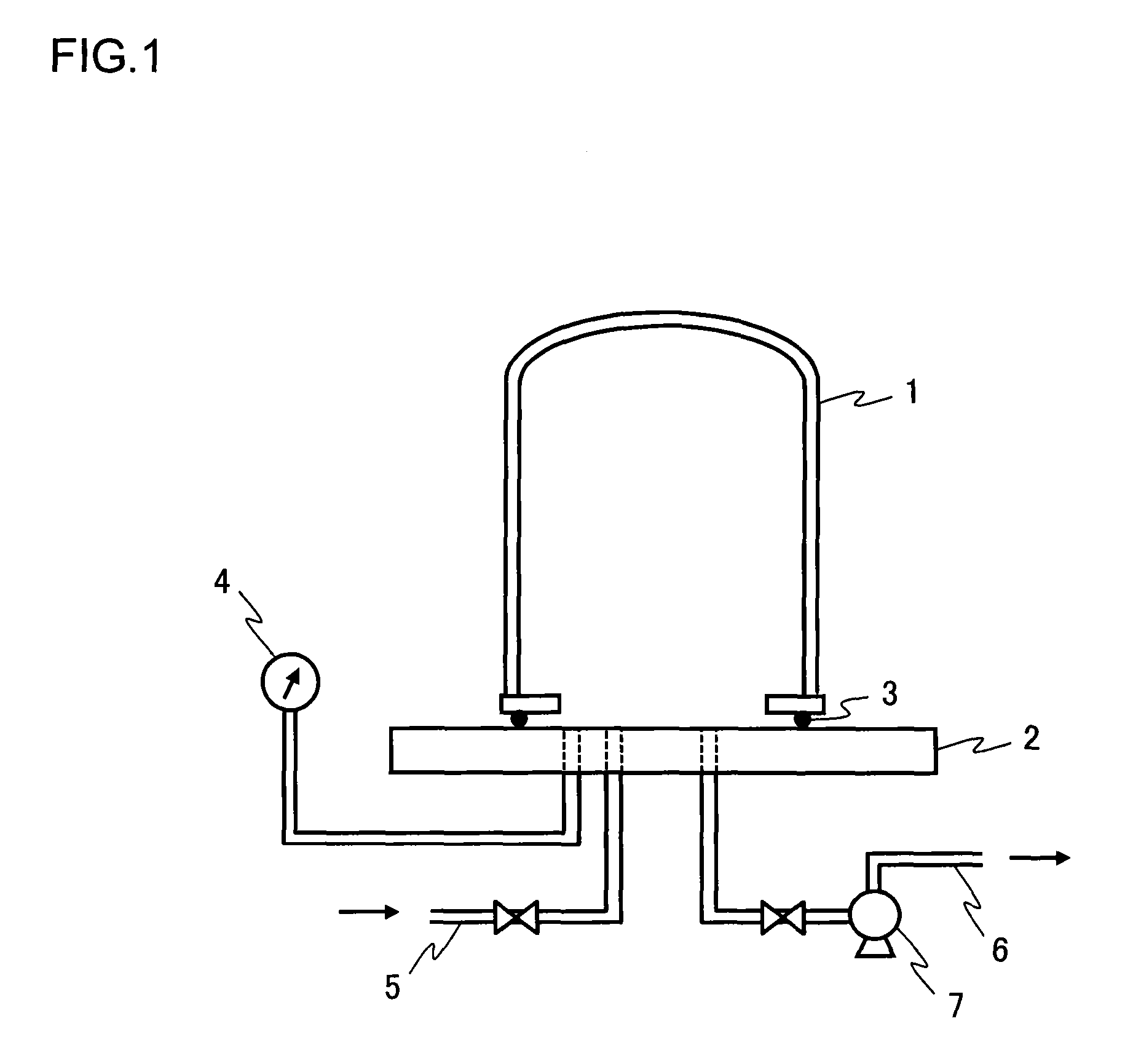

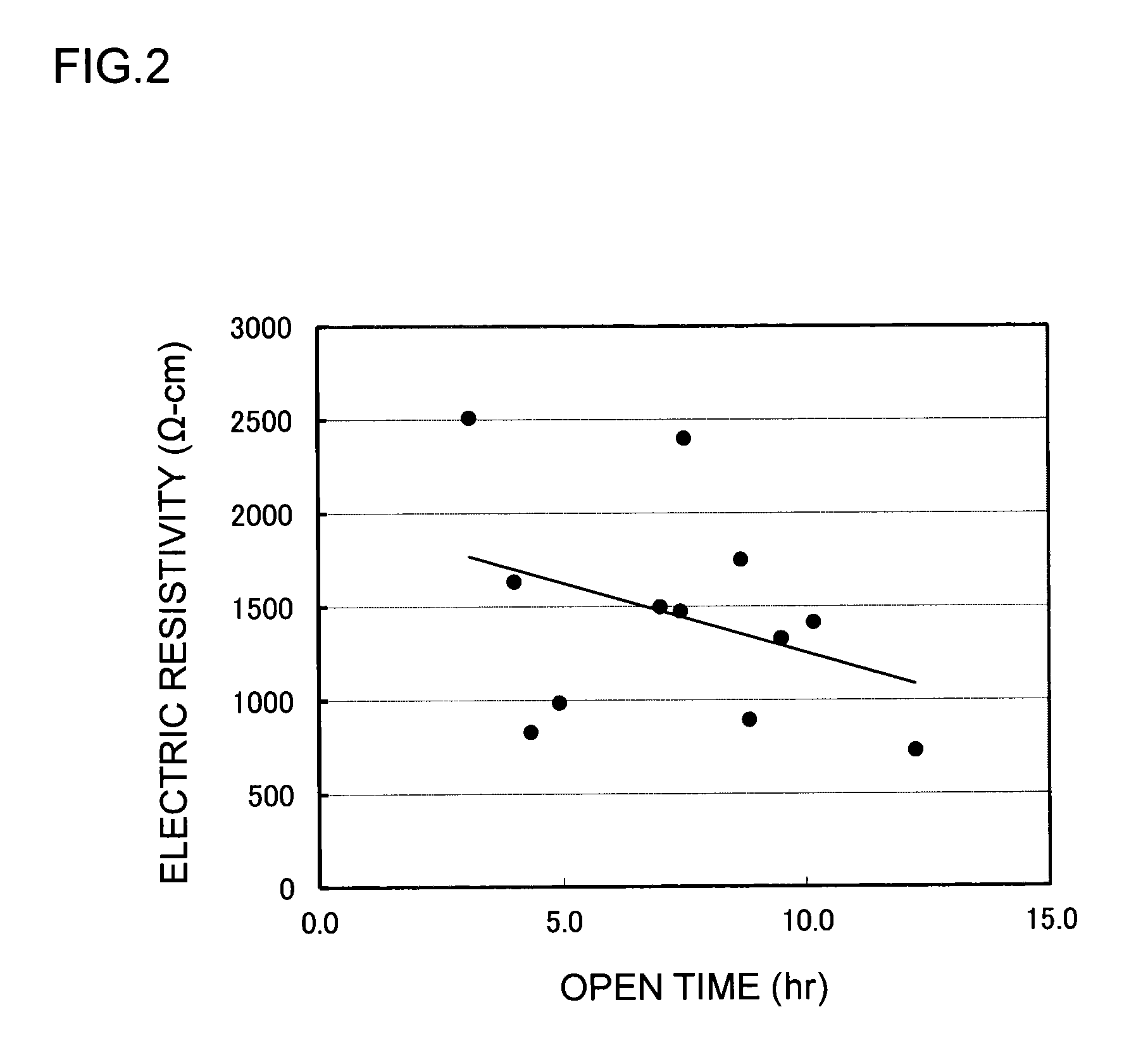

Method for cleaning bell jar, method for producing polycrystalline silicon, and apparatus for drying bell jar

ActiveUS20130089489A1Efficiently remove moistureIncrease the inner surfaceCleaning heat-transfer devicesSiliconInternal pressureSteam pressure

A bell jar includes a metallic bell jar (1), and a metallic base plate (2) on which the bell jar (1) is placed, and packing (3) seals an inside of a container. To the base plate (2), a pressure gauge (4), a gas introduction line (5), and a gas discharge line (6) are connected so as to allow monitoring of internal pressure of the bell jar (1) and introduction and discharge of a gas. A vacuum pump (7) is provided in a path of the gas discharge line (6), and the vacuum pump (7) reduces internal pressure of the bell jar so as to be lower than vapor pressure of water. The vacuum pump (7) reduces the internal pressure of the bell jar so as to be lower than vapor pressure of water, thereby efficiently removing moisture, and completing drying of the bell jar in a short time.

Owner:SHIN ETSU CHEM IND CO LTD

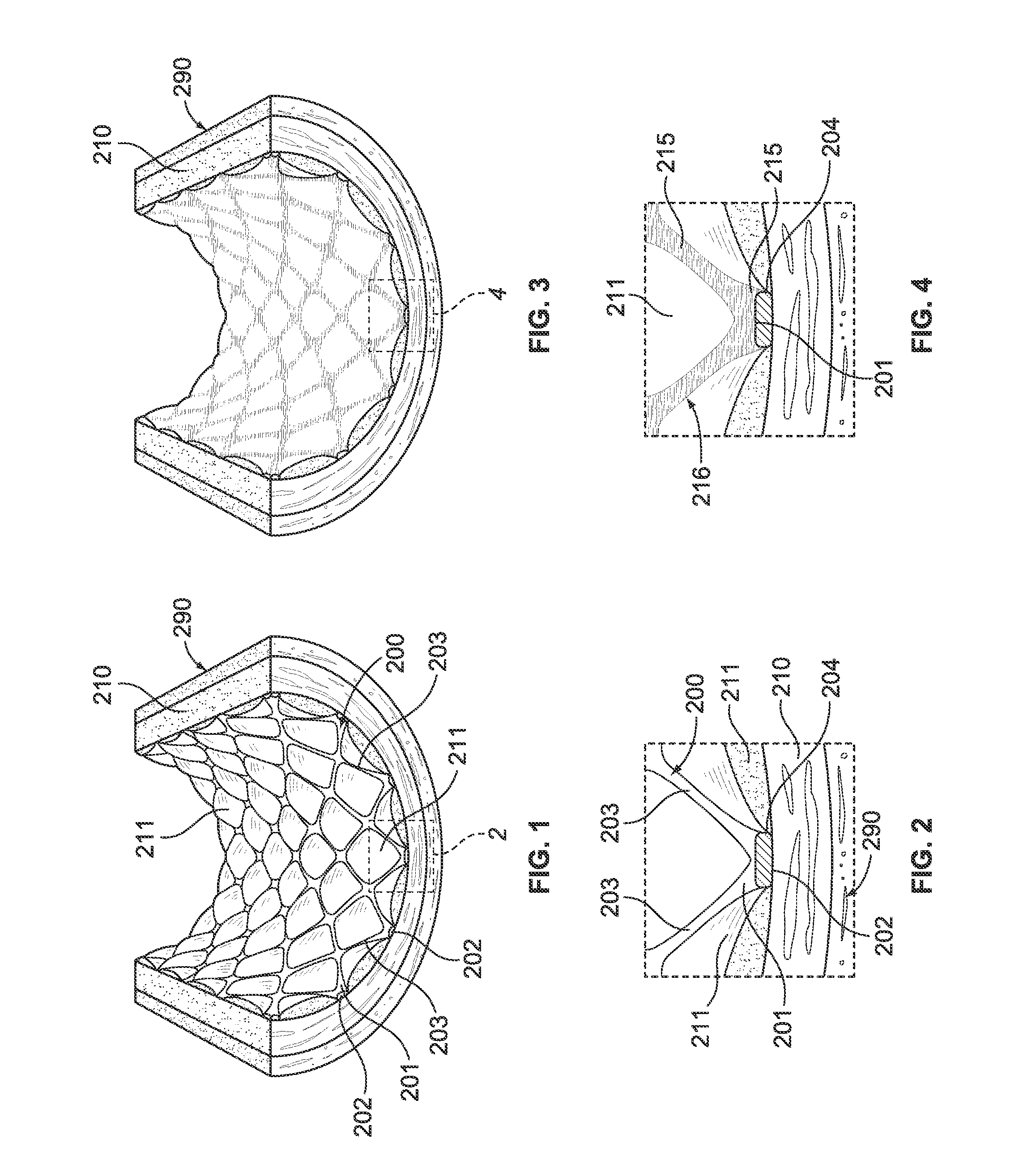

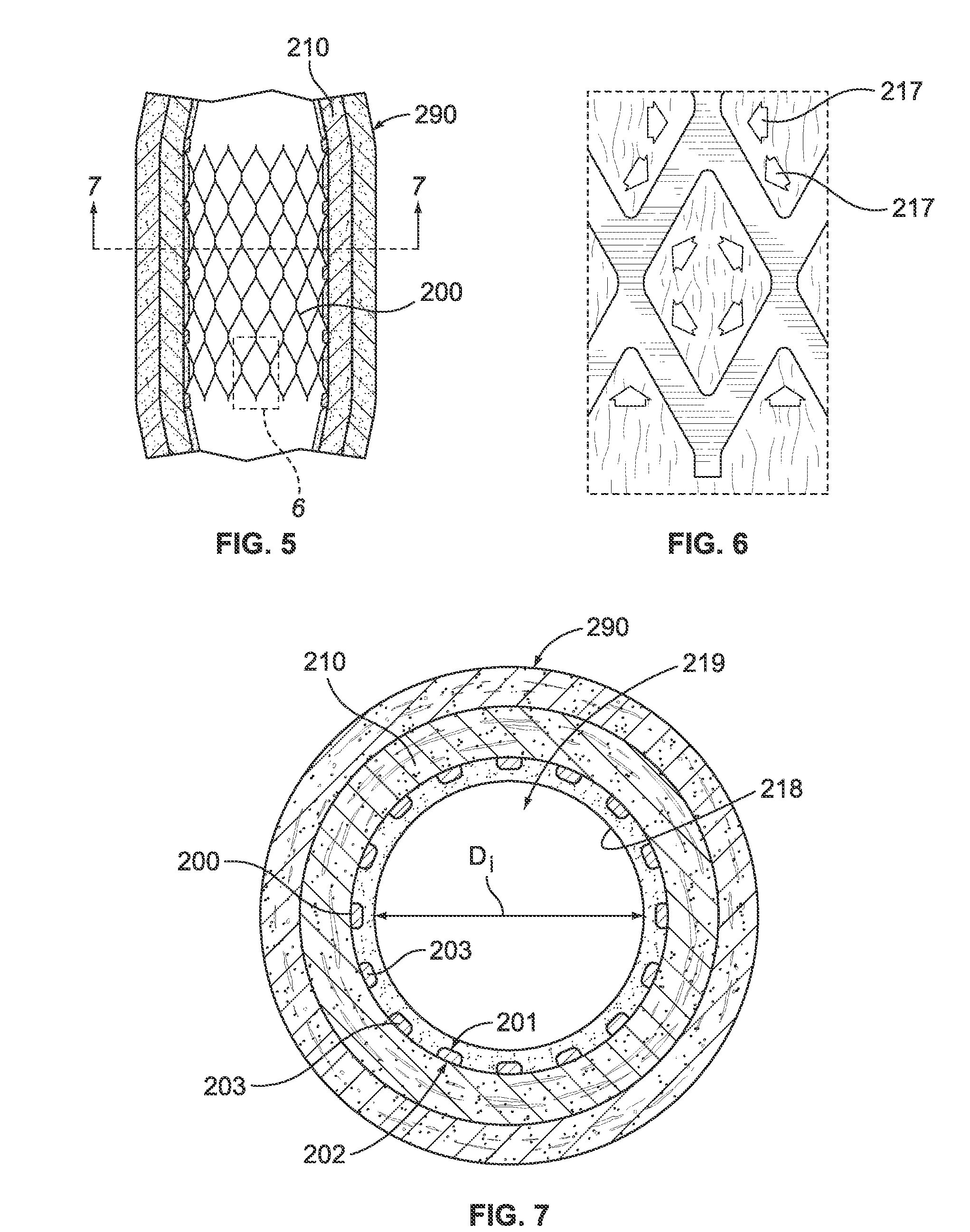

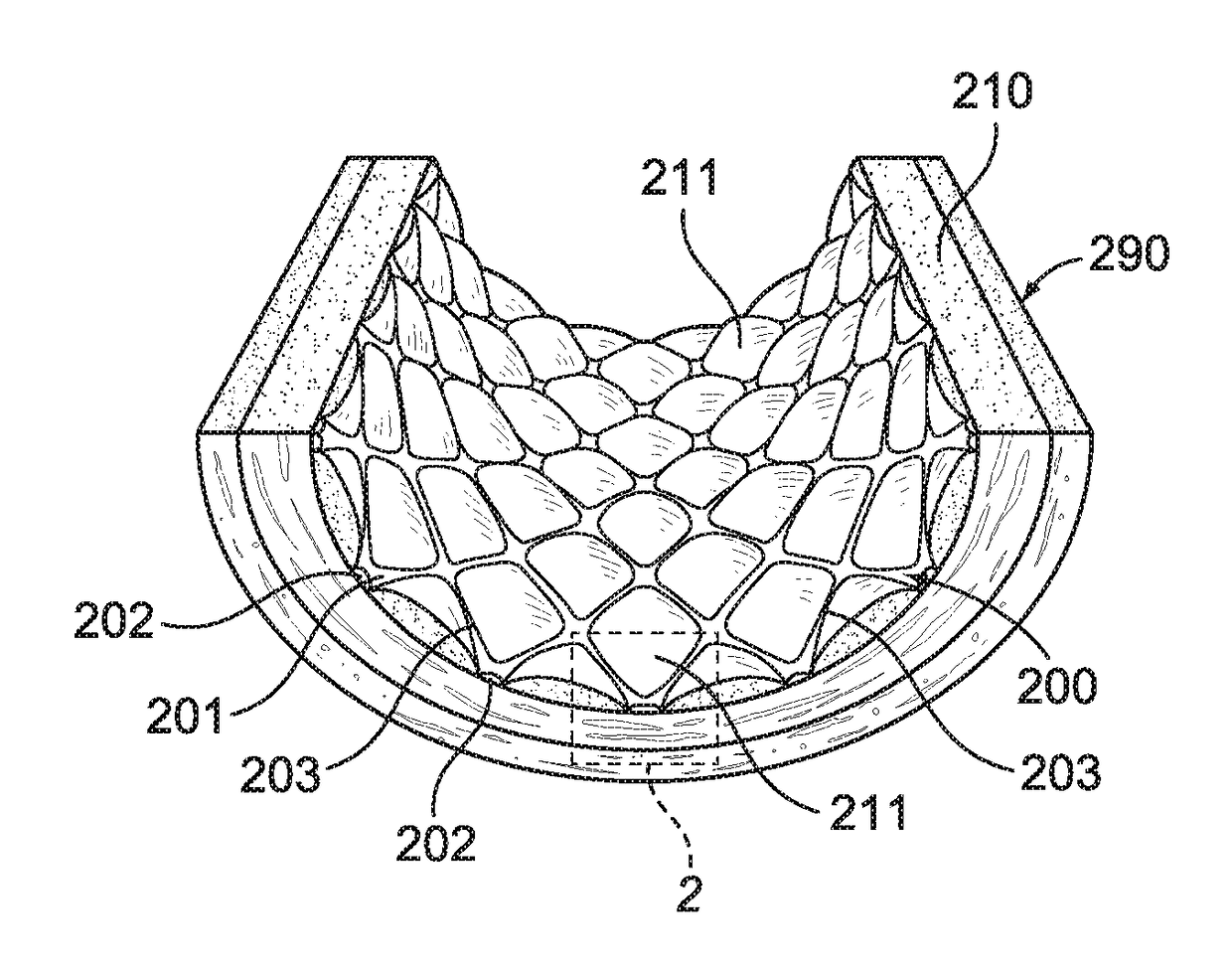

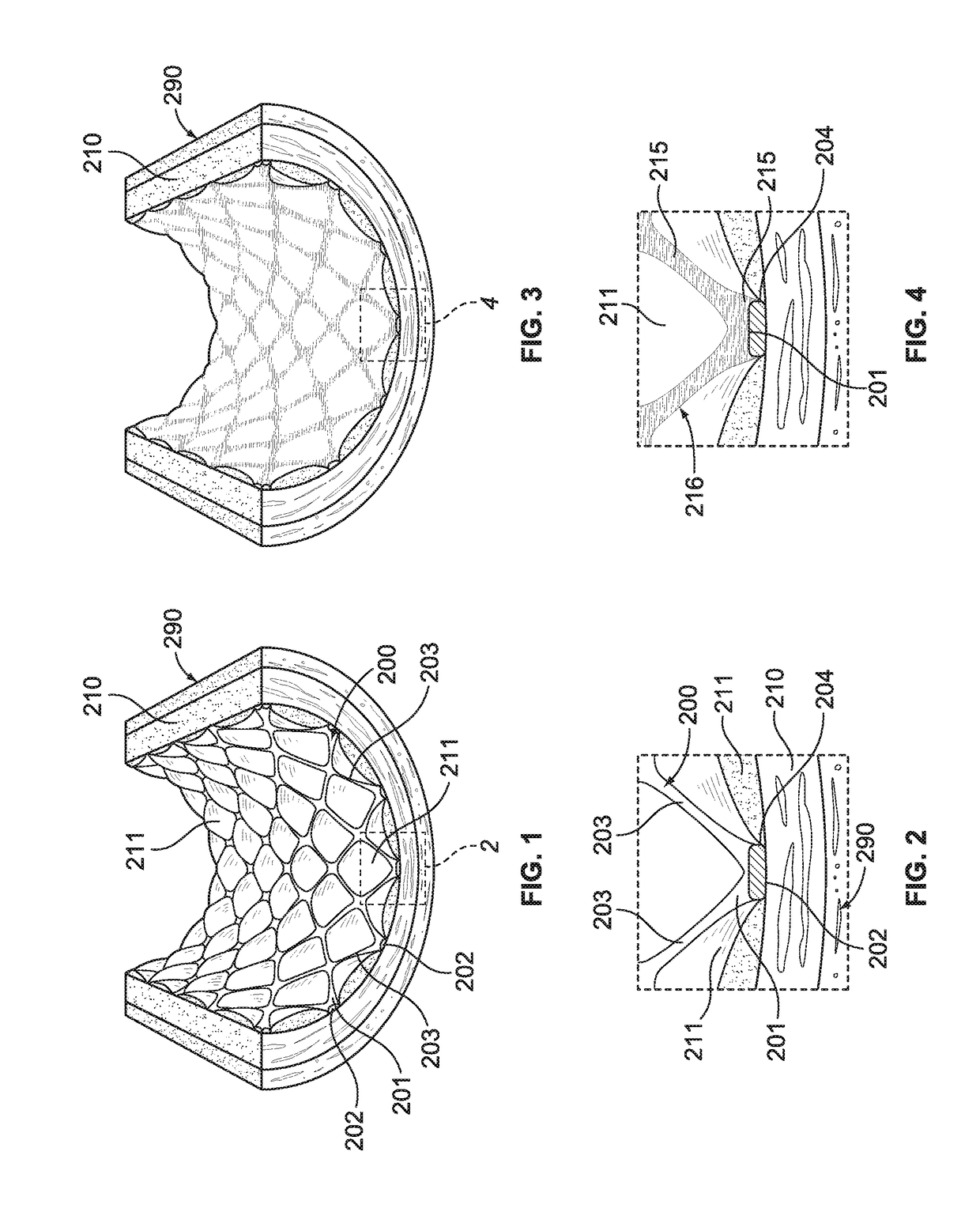

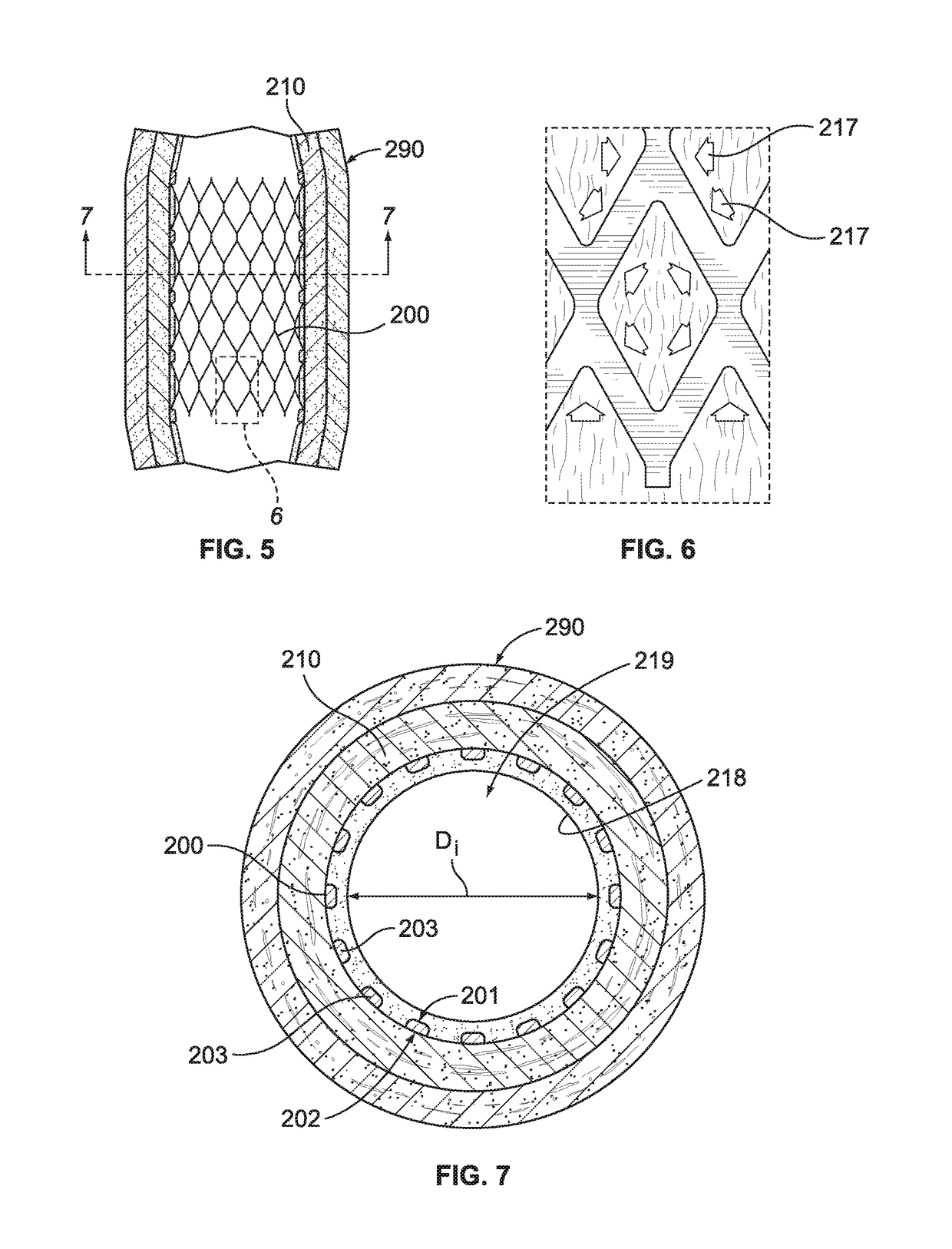

Grooved drug-eluting medical devices and method of making same

InactiveUS20120185037A1Promote rapid and healthy developmentRateStentsPharmaceutical containersMedicinePharmaceutical drug

The invention relates to methods and apparatus for manufacturing implantable medical devices, such as intravascular stents, wherein the medical device has a surface treated to promote the migration of endothelial cells onto the surface of the medical device. In particular, the surface of the medical device has at least one groove formed therein, the at least one groove may have a drug-eluting polymer disposed therein or a drug-eluting polymer coating may be provided on the surface of the medical device and grooves formed in the drug eluting polymer coating.

Owner:VACTRONIX SCI LLC

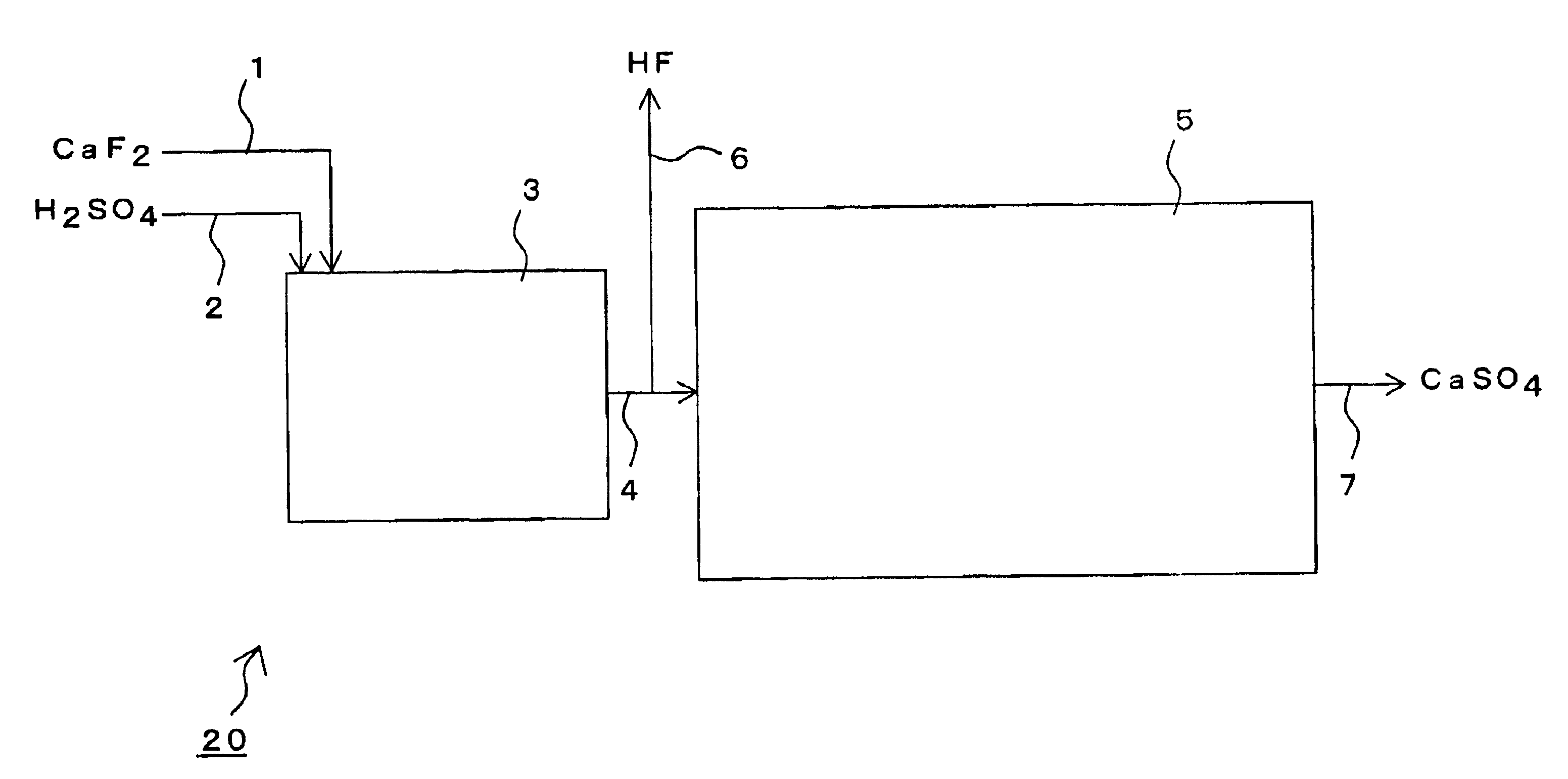

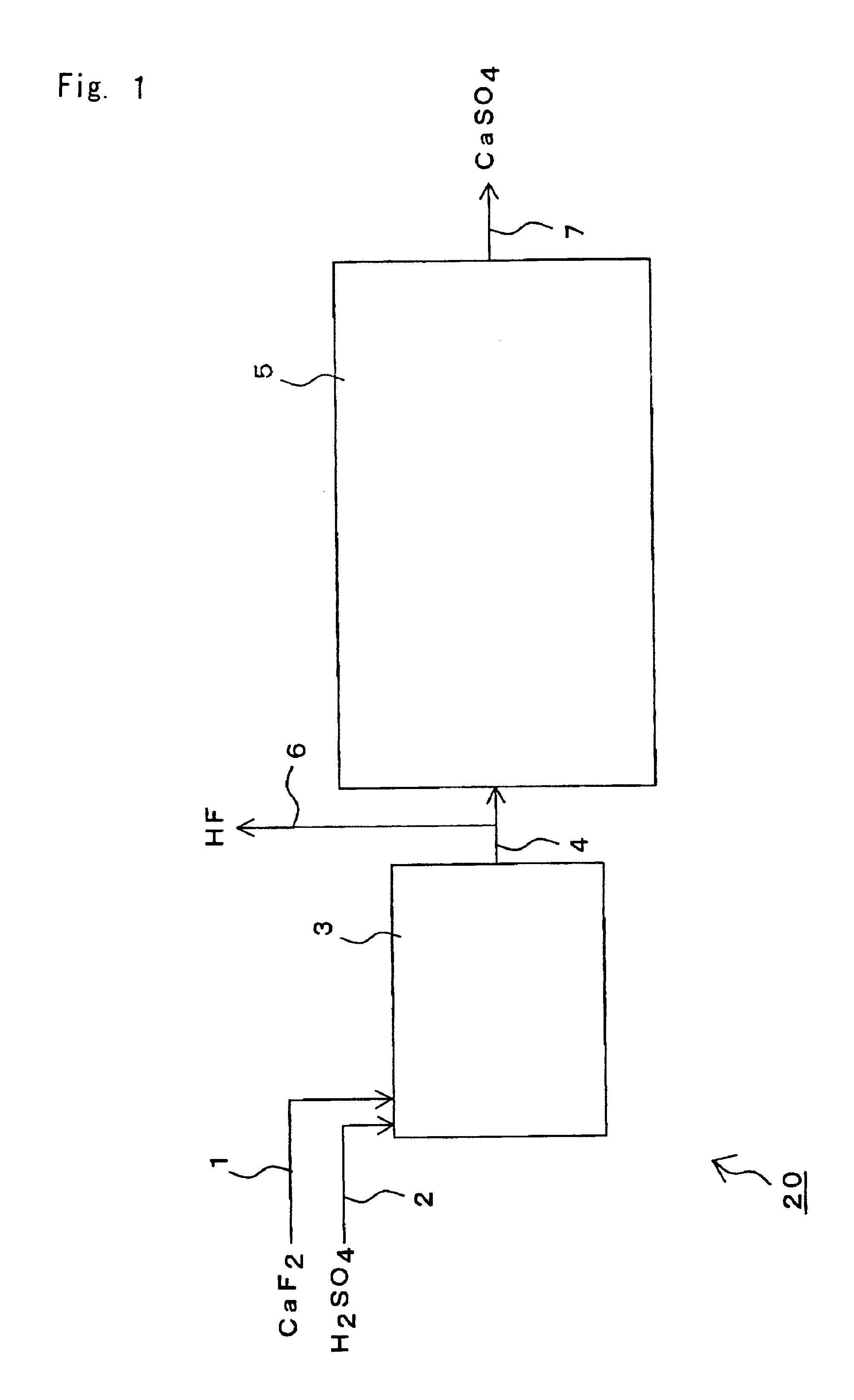

Method and apparatus for producing hydrogen fluoride

InactiveUS6841140B2Reduce wearIncrease the inner surfaceChlorine/hydrogen-chlorideTransportation and packagingHydrogen fluorideAlloy

As to a reactor which is used in a process for producing hydrogen fluoride through a reaction of fluorite with sulfuric acid, and which comprises means for applying a shearing force to a content therein between the means and an inner surface thereof, a metal material is used for at least a portion of a part of the means which part is opposed to the inner surface, the metal material comprising tungsten carbide and a material comprising at least one element, or an alloy comprising two or more elements, selected from the group consisting of nickel, chromium, cobalt, iron, tungsten and carbon, the metal material comprising 30 to 90% by weight of tungsten carbide. Thereby, it becomes possible to reduce the wear of an edge of the means for applying the shearing force to the content (the reaction mixture) between the means and the inner surface.

Owner:DAIKIN IND LTD

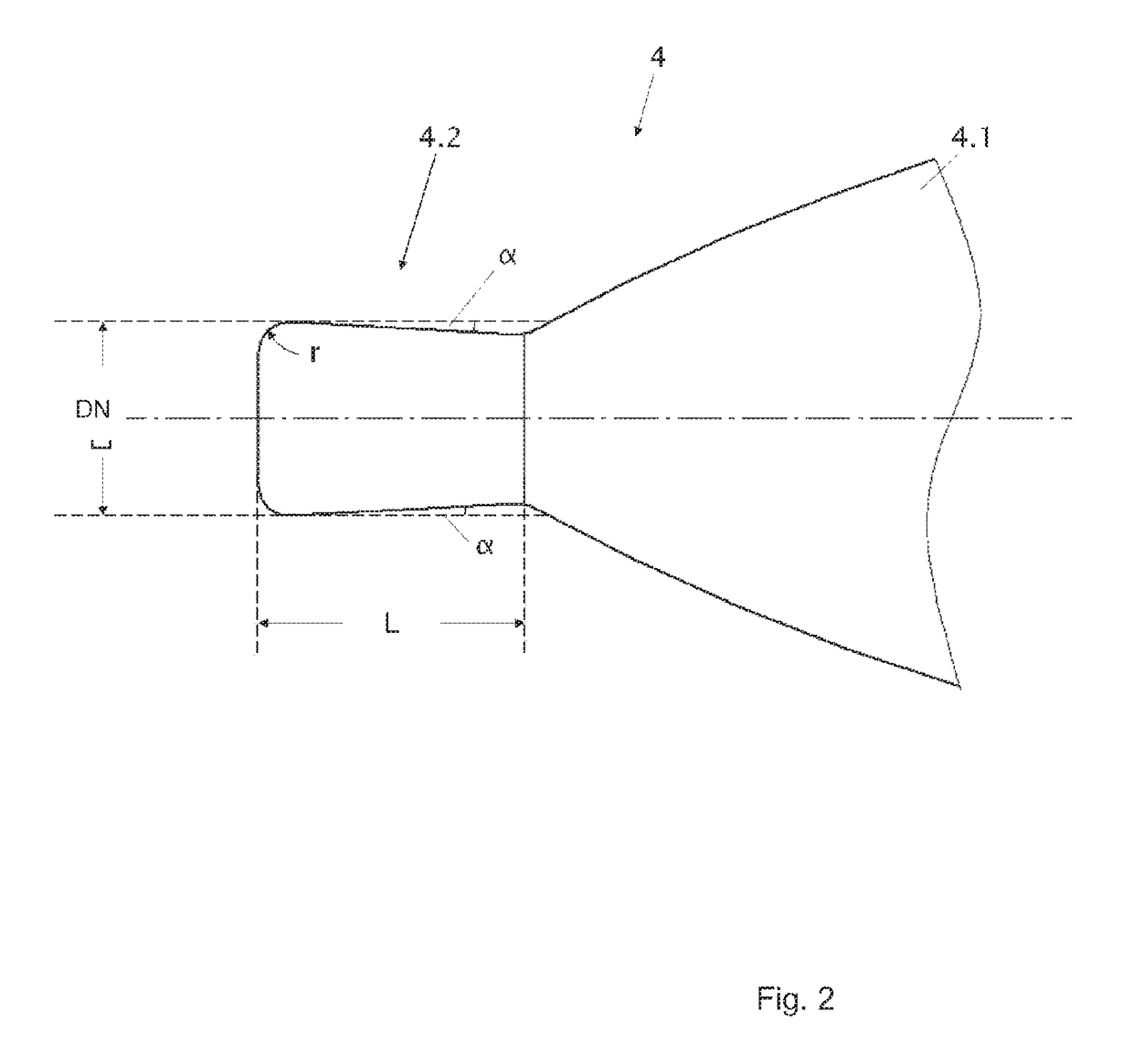

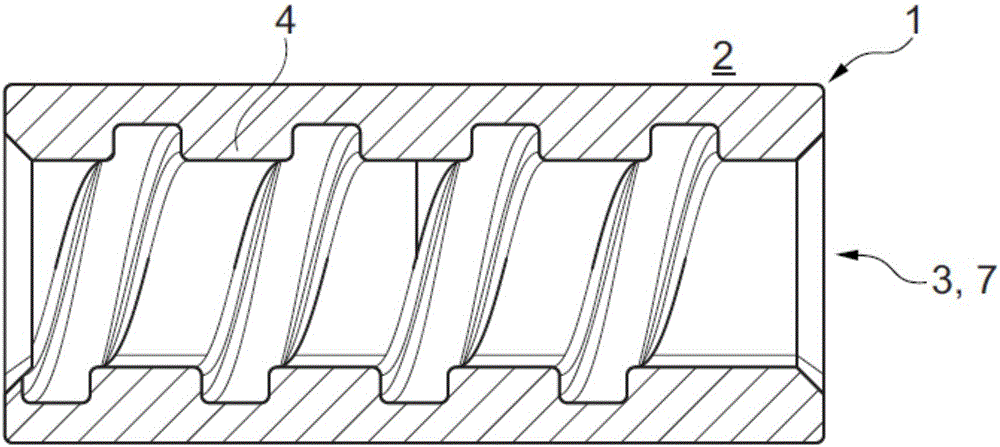

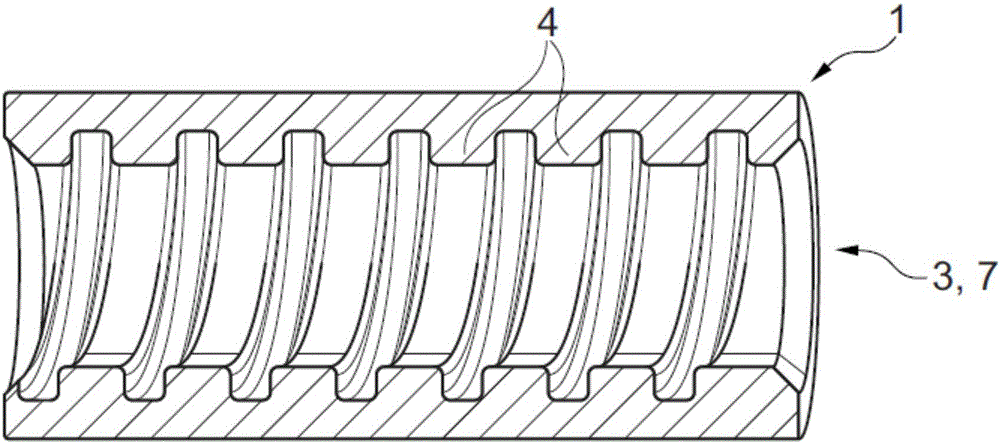

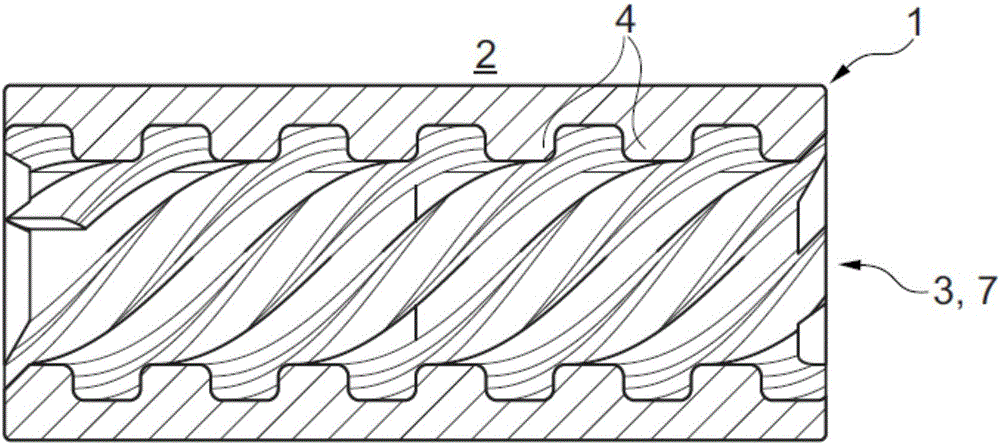

Tube having an increased internal surface, used in furnaces, manufacturing process and applications

InactiveUS20100230083A1Simple to implementIncrease internal surfaceThermal non-catalytic crackingBoiler flue tubes/fire tubesEngineeringLaser beams

A tube used in furnaces includes at least one attached radial bar fastened by welding to the internal face of the wall of the tube. A method of manufacturing such a tube includes at least one electron-beam of laser-beam welding step, in which at least one attached radial bar is welded, from outside the tube, to the internal face of the wall of the tube. The tubes may be used in reforming, steam-cracking or DRI furnaces.

Owner:MANOIR INDUSTRIES

Tree trunk punching machine and application method thereof

The invention belongs to the technical field of the conservation of horticultural plants, the technical deficiencies of the technique of hole punching in the tree trunk in the infusion process of the tree trunk, the high reliance on electricity in the prior art, the increase in the number of wounds on the trunk skin and the like are fixed. In particular, a tree trunk punching machine and an application thereof are provided. The punching machine comprises a machine frame, a transmission device and a fixing device. When the punching machine is in use, an axle sleeve is firstly fixed well on the machine frame, a drill is fixed on a transmission shaft, then the transmission shaft is encased in the axle sleeve, fixed holes are threaded with rope stripes, the punching machine is fixed on the main trunk, the control feet are wrung, after the angle of hole is adjusted well, the rope stripes are buckled tightly, the crank hand is turned, the punching work is conducted, after the impelled depth is fit, the crank hand is reversely turned, and the drill is backed out of the main trunk, and the punching work of the main injection hole is completed easily. When the tree trunk punching machine is used, electricity is not required; the tree trunk punching machine is widely applied in the tree trunk transfusion of big tree transplanting in landscaping, fruit tree pest control and the like, the machine is simple in structure, flexible in operation, and easy to promote.

Owner:SHENZHEN WENKE GARDENING IND

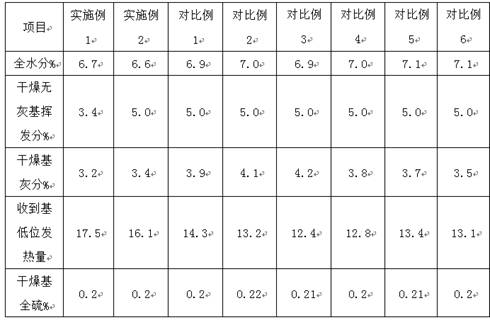

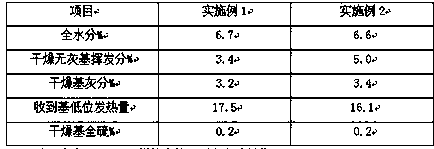

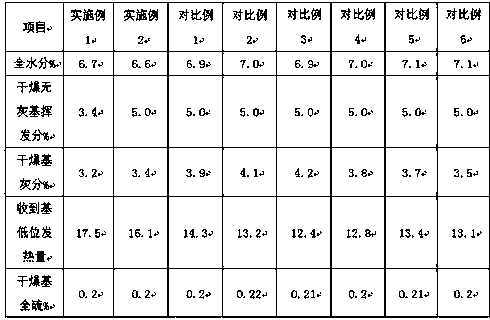

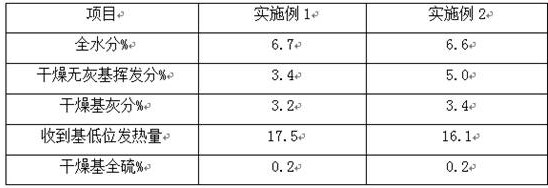

A kind of preparation method of moisture-proof high-energy biomass particle fuel

The invention discloses a preparation method of a moisture-proof high-energy biomass granular fuel, belonging to the technical field of biomass fuels. The moisture-proof high-energy biomass granular fuel is prepared by using activated sludge to carry out hydrothermal treatment on biomass raw materials plant straw powder and the like, using digested sludge to position and synthesize energetic polymers, and after the components are mixed, granulating, and organically combining the biomass energy activated sludge, nitrated sludge and the plant straw powder, and the produced biomass granular fuelhas good adhesion, high calorific value, high combustion efficiency and small combustion pollution, the construction of the ecological environment is facilitated, by proper addition of some charcoal slag powder, the combustion effect can be enhanced, and the combustion heat value can be improved. In addition, through combination and matching of various raw materials including the nitrated sludge,an activator, polyethylene glycol nitrate and the like in the fuel, the storage of the fuel can be facilitated, the fuel is prevented from being affected with damp and moisture regain, the combustionquality is further improved, and the problem of poor combustion heat value caused by the fuel being affected with damp can be simultaneously avoided.

Owner:安徽杰沃循环农业发展有限公司

Preparation method of composite high-energy biomass fuel rod

ActiveCN110684580AConducive to high energyHigh energyBiofuelsSolid fuelsProcess engineeringHeat of combustion

The invention discloses a preparation method of a composite high-energy biomass fuel rod, belonging to the technical field of biomass fuels. According to the invention, a silicon dioxide aerogel is used for loading treatment of biomass straw powder and the like, thereby increasing the contact surface area of a fuel; inorganic and plant straw powders are organically combined for use; the produced biomass fuel rod is good in bonding degree, high in heat energy value, large in surface area, high in combustion efficiency, small in combustion pollution and beneficial for ecological environment construction, facilitates fuel storage, has sufficient combustion contact area and can prevent the fuel from damp and wetting-back; and thus, the combustion quality of the fuel is improved, and the problem of poor combustion heat energy value due to wetting of the fuel is overcome.

Owner:安徽省宗正农业科技开发股份有限公司

Preparation method of moisture-proof high-energy biomass granular fuel

The invention discloses a preparation method of a moisture-proof high-energy biomass granular fuel, belonging to the technical field of biomass fuels. The moisture-proof high-energy biomass granular fuel is prepared by using activated sludge to carry out hydrothermal treatment on biomass raw materials plant straw powder and the like, using digested sludge to position and synthesize energetic polymers, and after the components are mixed, granulating, and organically combining the biomass energy activated sludge, nitrated sludge and the plant straw powder, and the produced biomass granular fuelhas good adhesion, high calorific value, high combustion efficiency and small combustion pollution, the construction of the ecological environment is facilitated, by proper addition of some charcoal slag powder, the combustion effect can be enhanced, and the combustion heat value can be improved. In addition, through combination and matching of various raw materials including the nitrated sludge,an activator, polyethylene glycol nitrate and the like in the fuel, the storage of the fuel can be facilitated, the fuel is prevented from being affected with damp and moisture regain, the combustionquality is further improved, and the problem of poor combustion heat value caused by the fuel being affected with damp can be simultaneously avoided.

Owner:安徽杰沃循环农业发展有限公司

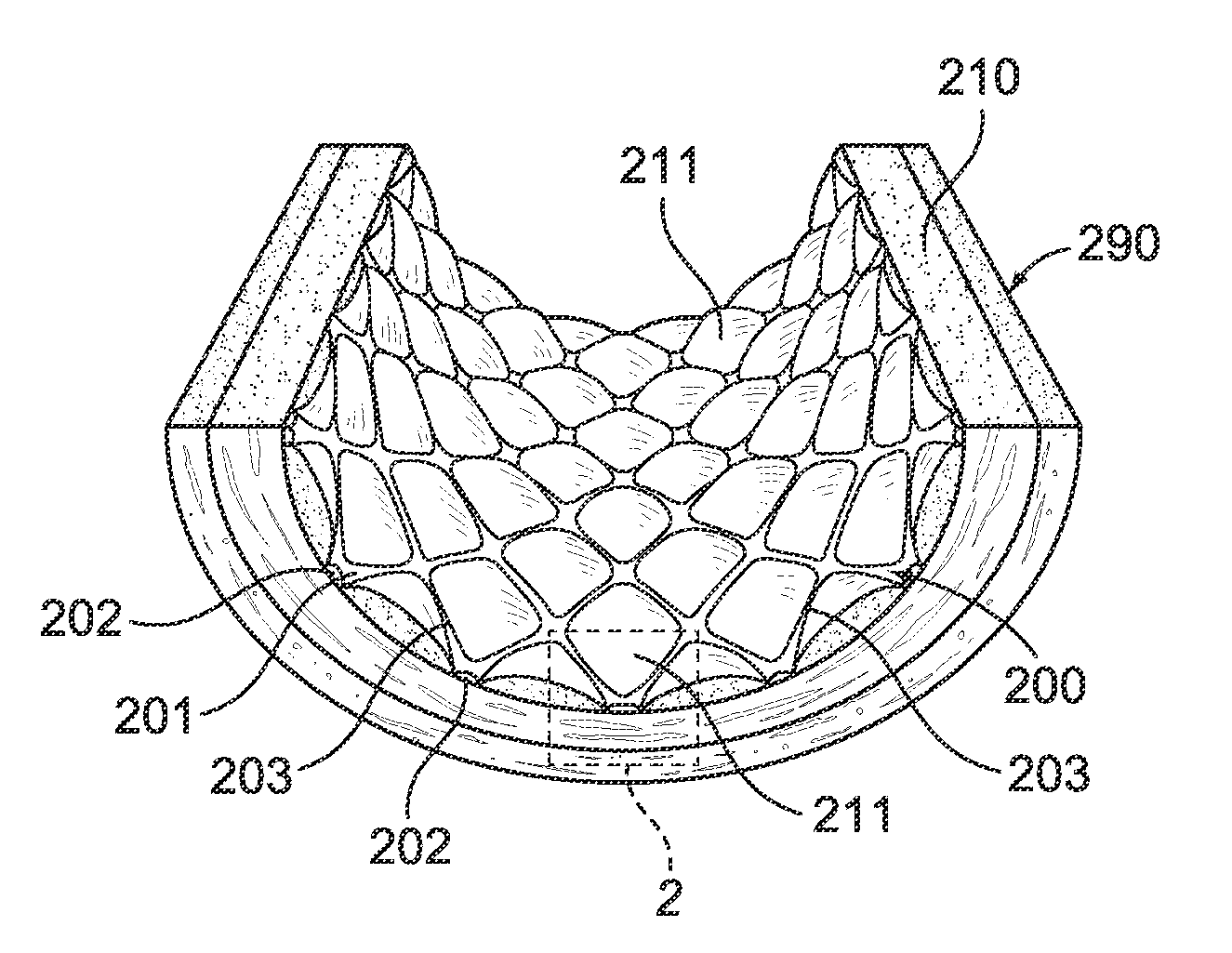

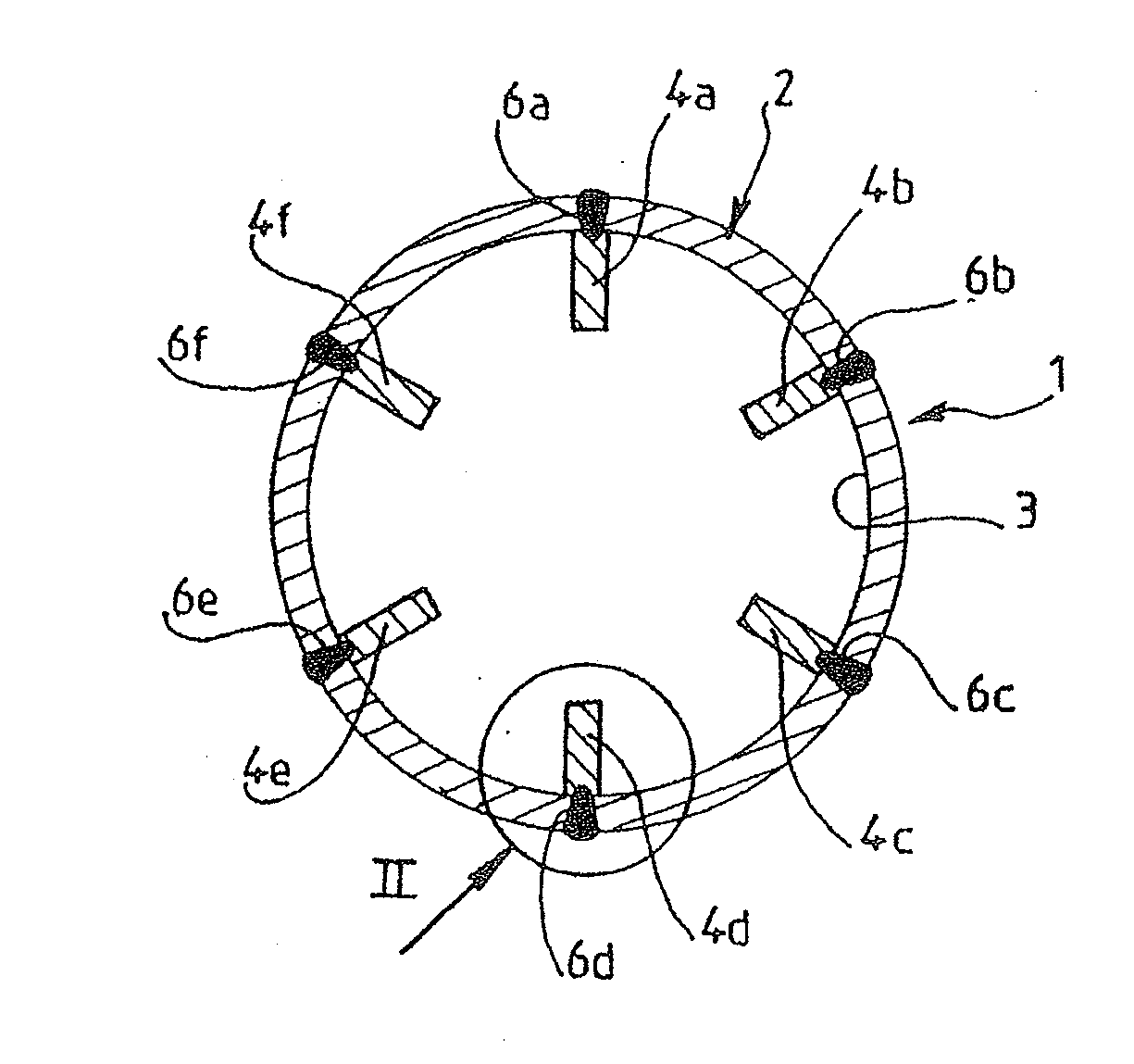

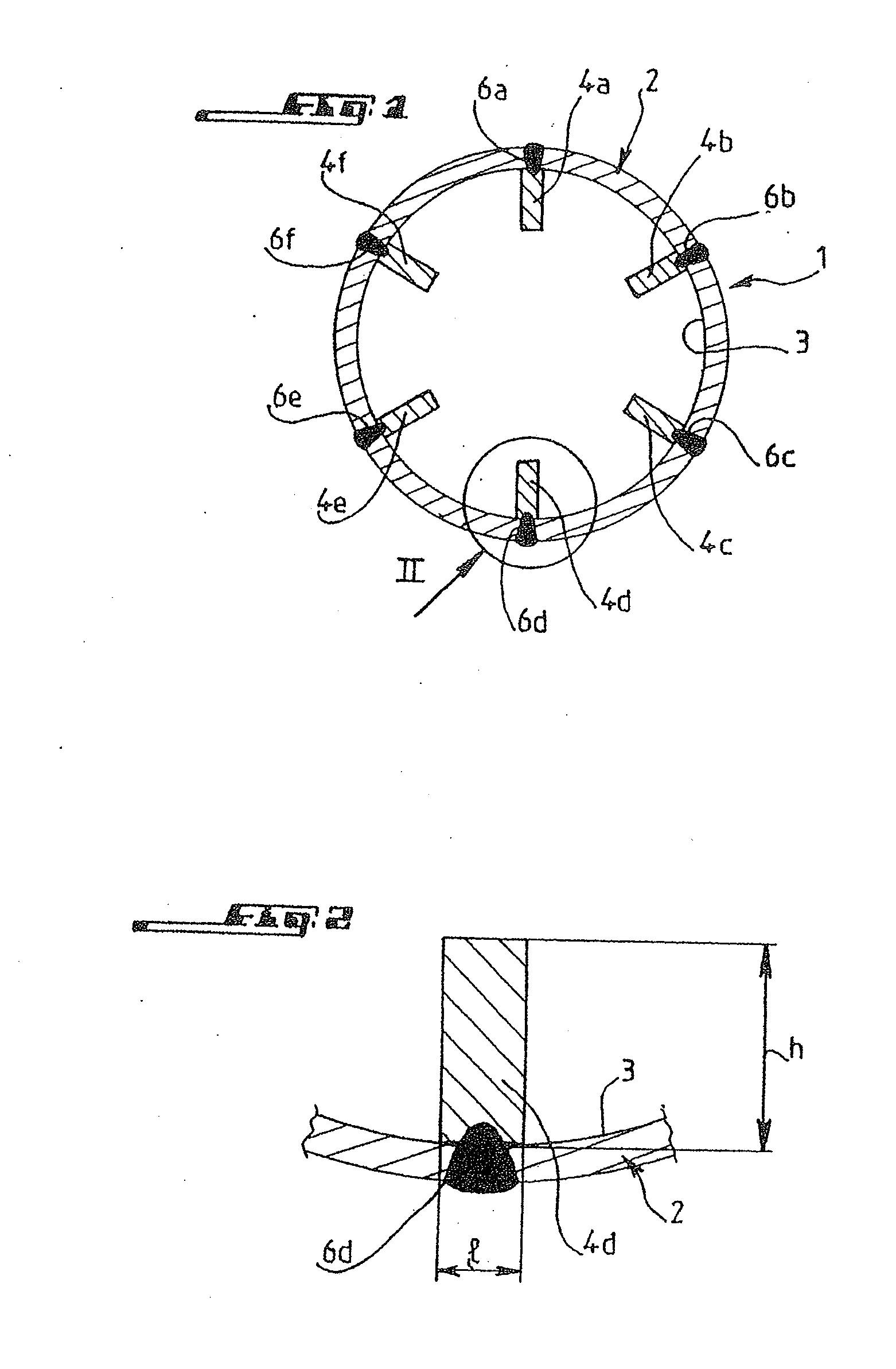

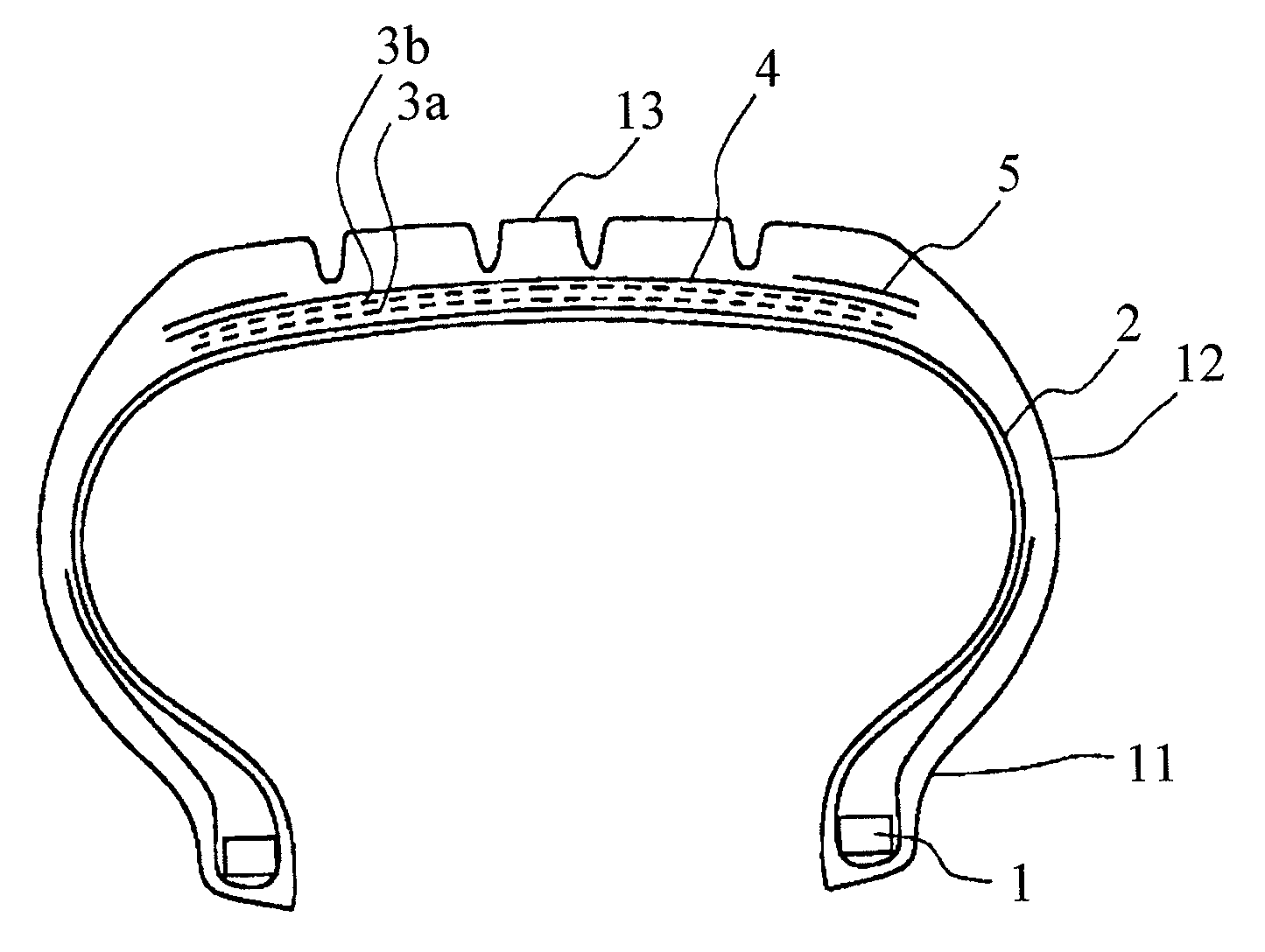

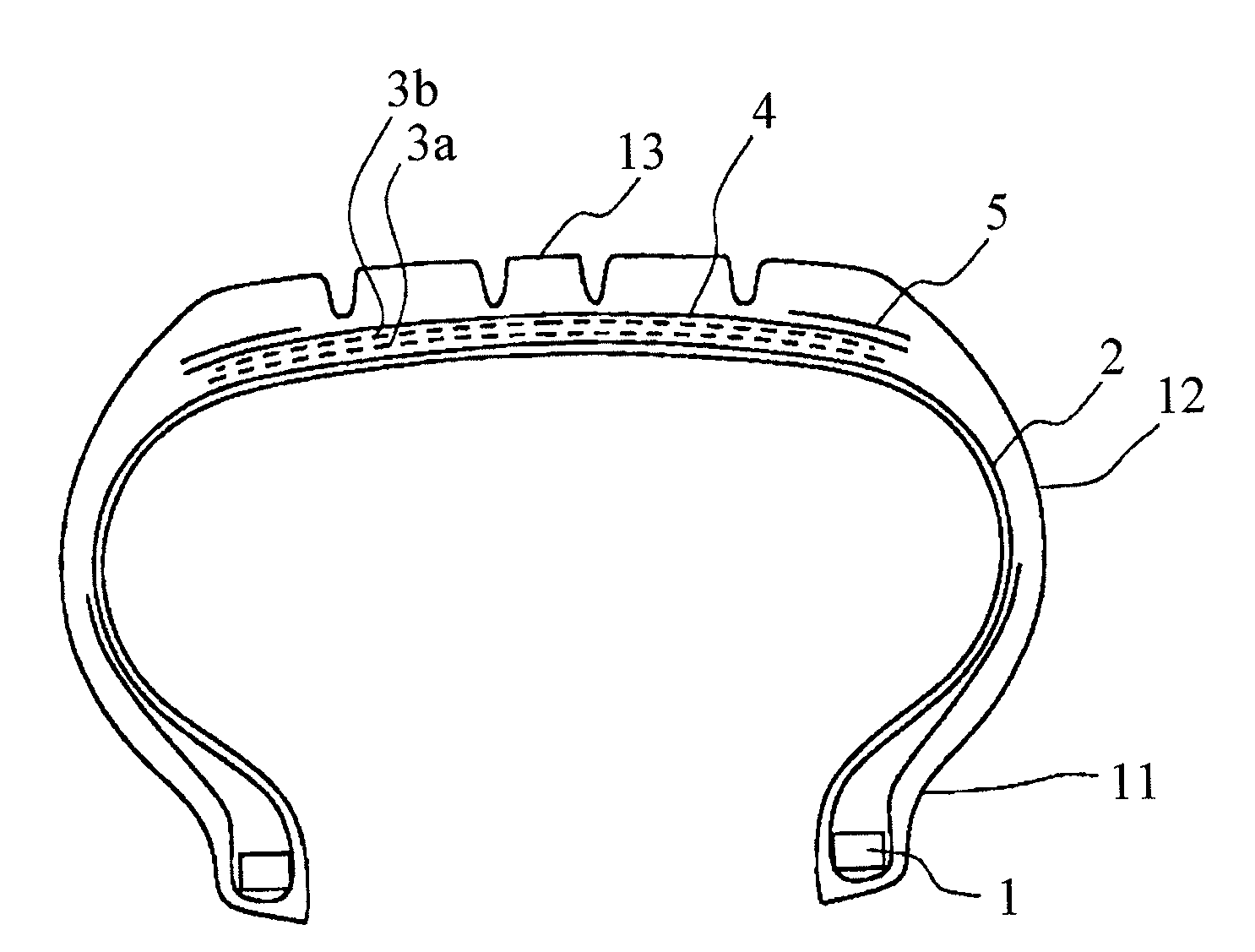

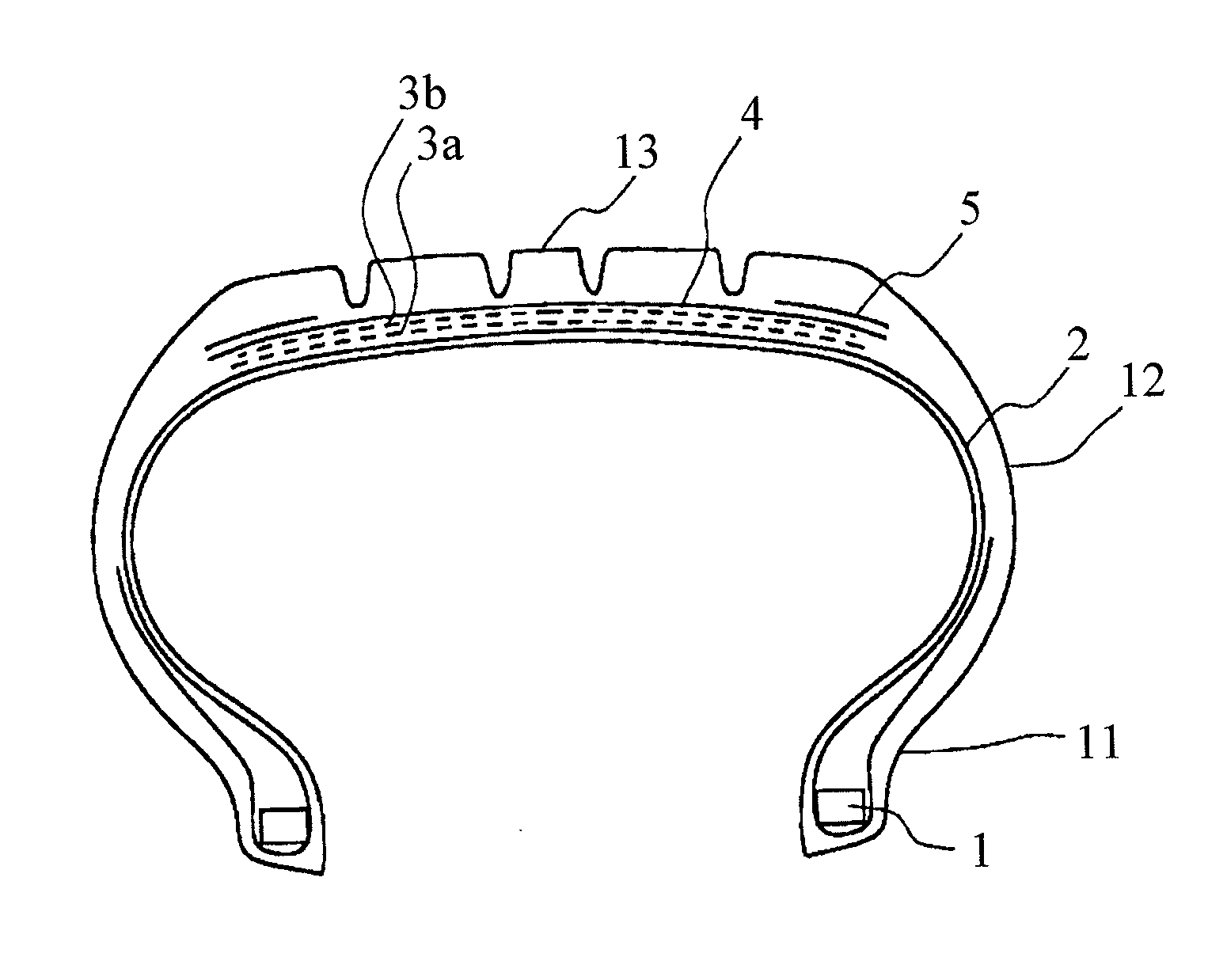

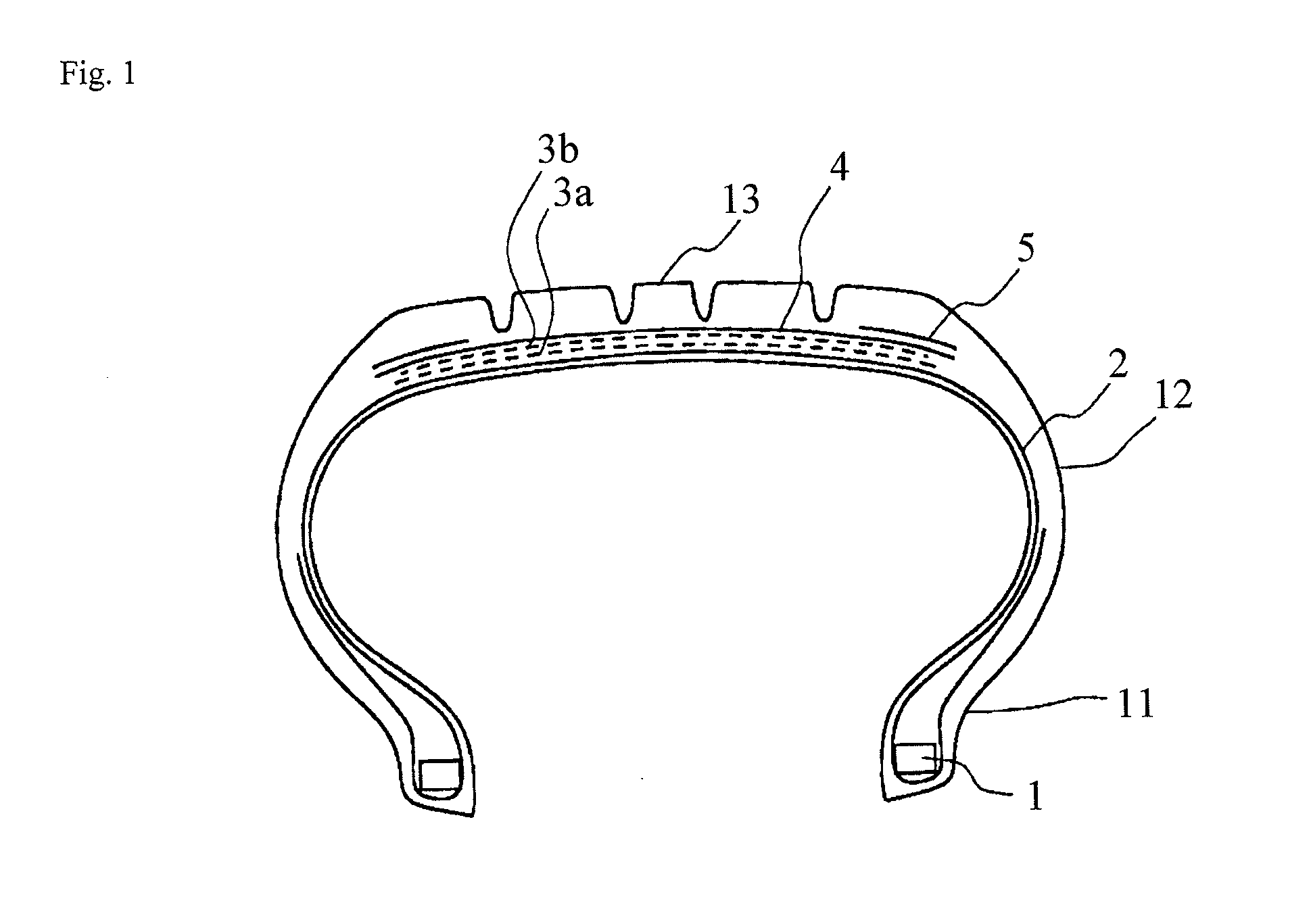

Pneumatic tire

Provided is a pneumatic tire whose safety factor and durability are improved without generating a problem of an increase in the weight of a tire and an increase in the inner surface cord protrusion failure. Provided is a pneumatic tire including one or more carcasses 2 extending toroidally between bead cores 1 embedded in a pair of bead portions 11 respectively. A polyester fiber cord whose total decitex as a twisted cord is 4300 to 5100 dtex, whose cord strength as a dip treated cord is 6.5 to 7.2 cN / dtex and whose cord elongation at a stress loading of 2 cN / dtex is 3.5 to 4.0% is used as a reinforcing cord of the carcass 2, and the tenacity of a treat which is the reinforcing cord covered with rubber per unit width is 2.9 to 3.2 kN / cm.

Owner:BRIDGESTONE CORP

Flat extruded aluminum multi-port tube whose inner surface is highly corrosion-resistant and an aluminum heat exchanger using the tube

ActiveUS20200124362A1Improve internal corrosion-resistanceExcellent internal corrosion-resistanceCoatingsTubular elementsMulti portMaterials science

In this flat extruded aluminum multi-port tube, the corrosion-resistance, at inner surfaces of a plurality of flow passages independently and parallelly extending in the tube axial direction, is effectively enhanced. In a flat extruded aluminum multi-port tube 10 formed by an extrusion by employing an aluminum tube material and an aluminum sacrificial anode material having an electrochemically lower potential than the aluminum tube material, the aluminum sacrificial anode material is exposed to form a sacrificial anode portion 18 at least in a part of an inner circumferential portion in each of the plurality of flow passages 12.

Owner:FURUKAWA SKY ALUMINUM CORP +2

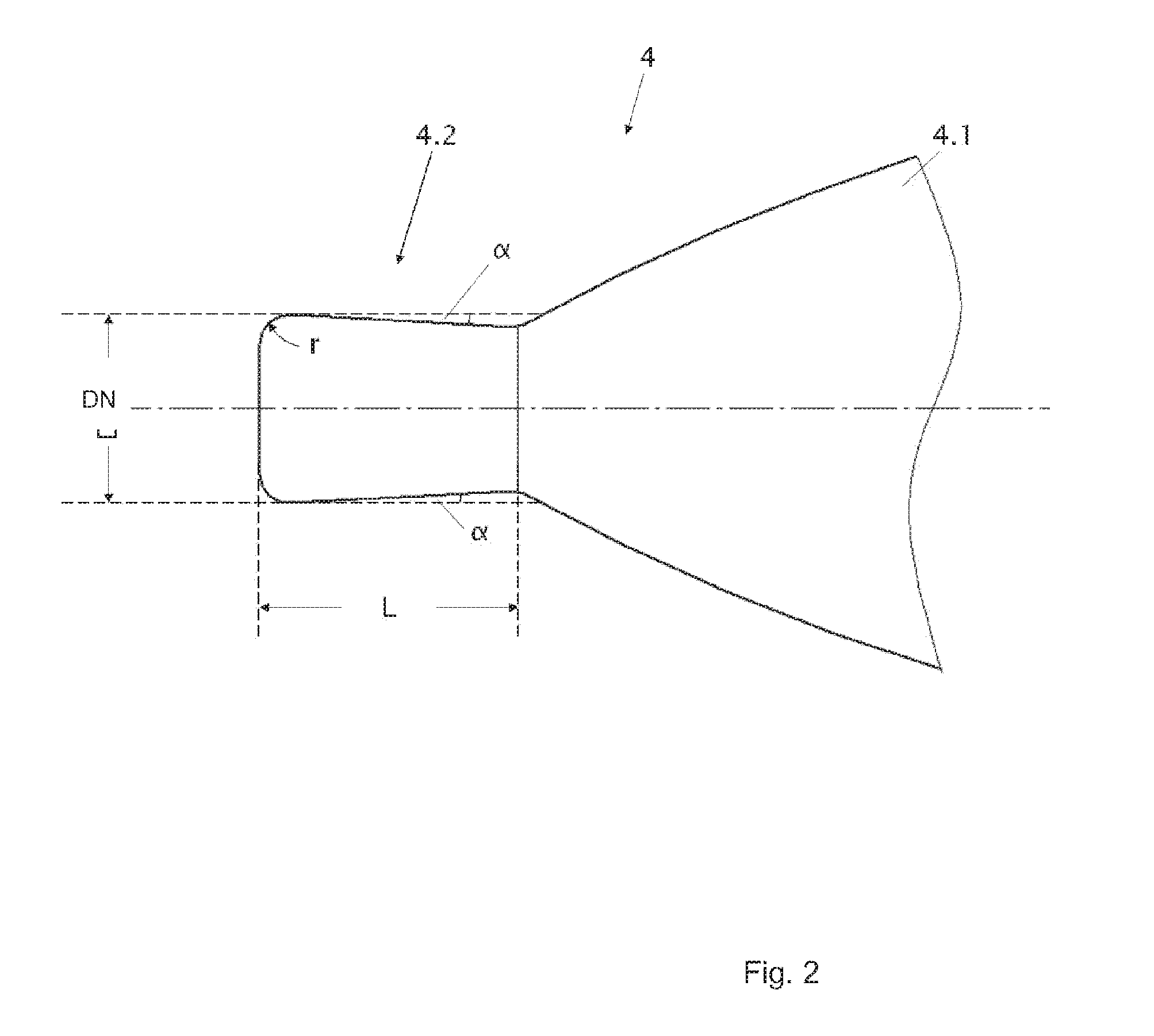

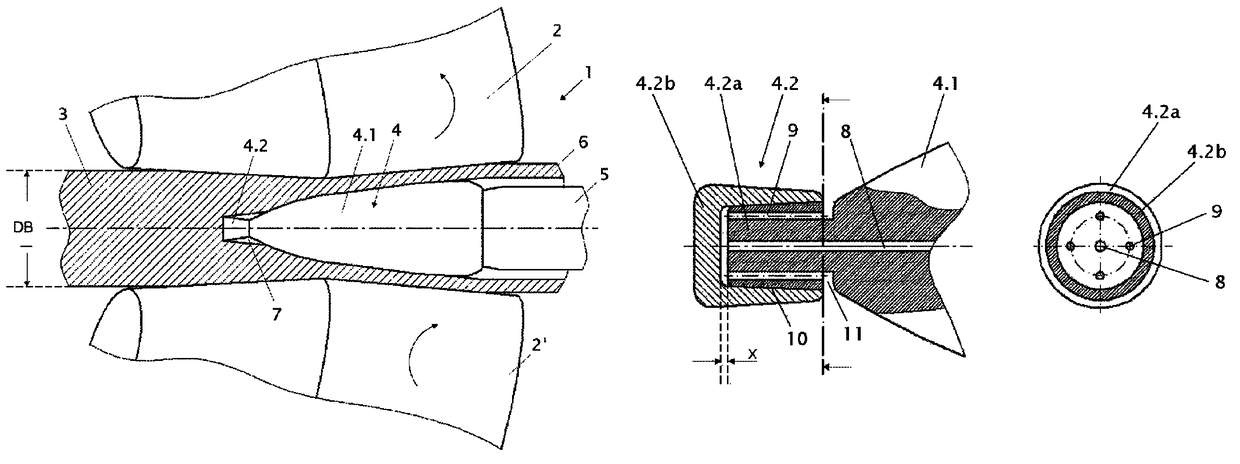

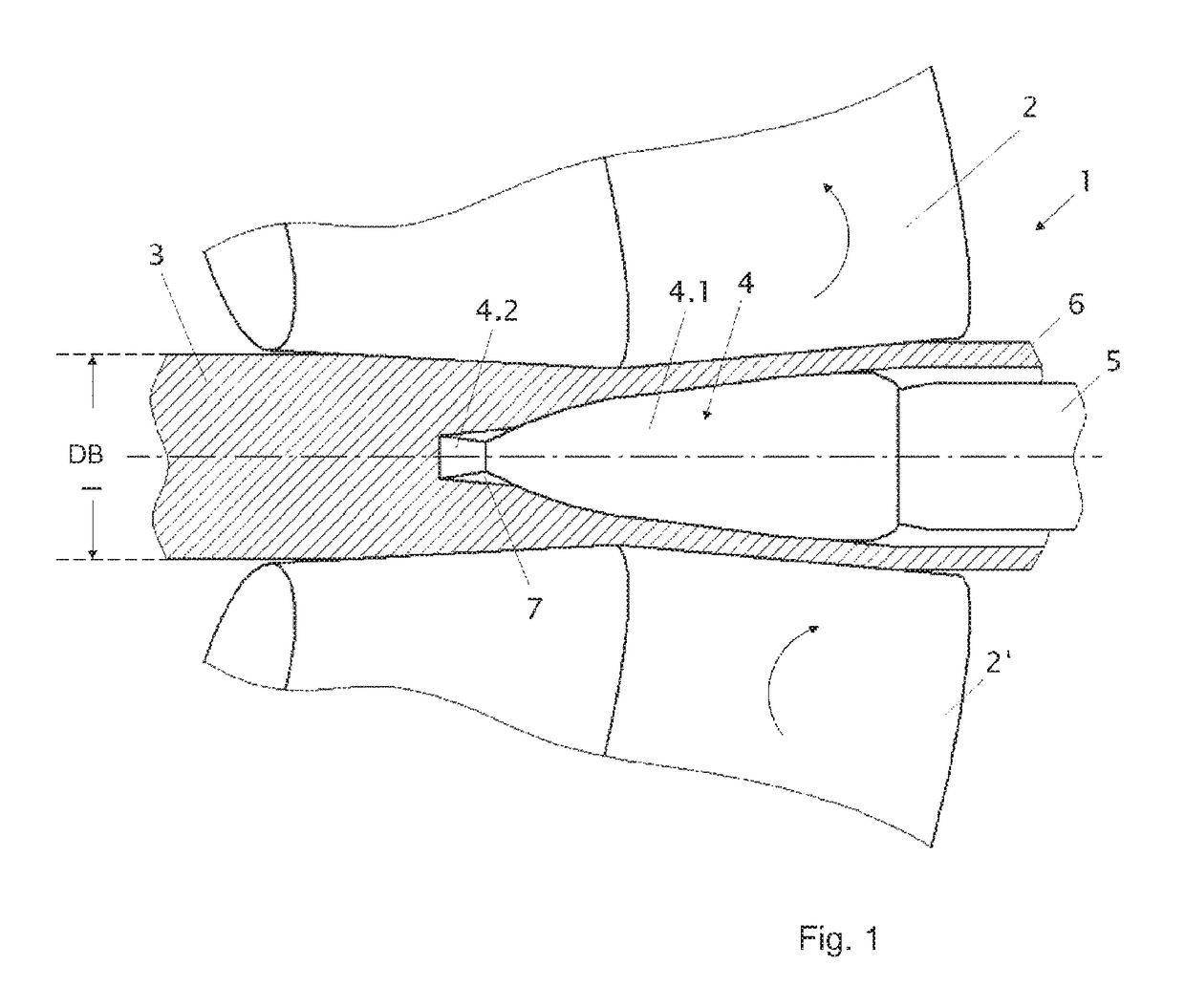

Piercing mandrel having an improved service life for producing seamless tubes

ActiveUS20160346820A1Increased durabilityReduce tooling costsMandrelsMetal rolling arrangementsEngineeringMechanical engineering

A piercing mandrel for piercing heated round blocks of metal for the production of seamless pipes, having a piercing mandrel nose and a piercing mandrel main body which can be connected to a mandrel bar. The outer diameter of the piercing mandrel nose is formed in a conically tapering manner in the longitudinal direction towards the piercing mandrel main body in order to increase the durability of the piercing mandrel when used for piercing round blocks of metal, in particular higher-alloyed steel materials which are difficult to work, by means of skew rolling providing a qualitative improvement of the inner surface of the pierced round block and reducing tool costs.

Owner:VALLOUREC DEUT

Pneumatic tire

Provided is a pneumatic tire whose safety factor and durability are improved without generating a problem of an increase in the weight of a tire and an increase in the inner surface cord protrusion failure.Provided is a pneumatic tire including one or more carcasses 2 extending toroidally between bead cores 1 embedded in a pair of bead portions 11 respectively. A polyester fiber cord whose total decitex as a twisted cord is 4300 to 5100 dtex, whose cord strength as a dip treated cord is 6.5 to 7.2 cN / dtex and whose cord elongation at a stress loading of 2 cN / dtex is 3.5 to 4.0% is used as a reinforcing cord of the carcass 2, and the tenacity of a treat which is the reinforcing cord covered with rubber per unit width is 2.9 to 3.2 kN / cm.

Owner:BRIDGESTONE CORP

Method for cleaning bell jar, method for producing polycrystalline silicon, and apparatus for drying bell jar

ActiveUS9126242B2Efficient removalIncrease the inner surfaceCleaning heat-transfer devicesSiliconInternal pressureEngineering

A bell jar includes a metallic bell jar (1), and a metallic base plate (2) on which the bell jar (1) is placed, and packing (3) seals an inside of a container. To the base plate (2), a pressure gauge (4), a gas introduction line (5), and a gas discharge line (6) are connected so as to allow monitoring of internal pressure of the bell jar (1) and introduction and discharge of a gas. A vacuum pump (7) is provided in a path of the gas discharge line (6), and the vacuum pump (7) reduces internal pressure of the bell jar so as to be lower than vapor pressure of water. The vacuum pump (7) reduces the internal pressure of the bell jar so as to be lower than vapor pressure of water, thereby efficiently removing moisture, and completing drying of the bell jar in a short time.

Owner:SHIN ETSU CHEM IND CO LTD

A kind of preparation method of composite high-energy biomass fuel rod

ActiveCN110684580BImprove porosity structureImprove reunionsBiofuelsSolid fuelsProcess engineeringEnvironmental engineering

The invention discloses a method for preparing a composite high-energy biomass fuel rod. The invention belongs to the technical field of biomass fuel. The invention uses silica aerogel to carry out loading treatment on biomass straw powder, etc. to increase the fuel contact surface area. The organic combination of inorganic and plant straw powder can produce biomass fuel rods with good cohesiveness, high heat energy value, large surface area, high combustion efficiency, and low combustion pollution, which is conducive to the construction of the ecological environment and can be beneficial to the production of fuel. For storage, there is a sufficient combustion contact area and can avoid the fuel from getting damp and regaining moisture, thereby improving its combustion quality, and at the same time avoiding the problem of poor combustion heat value caused by the fuel being damp.

Owner:安徽省宗正农业科技开发股份有限公司

Container for the transport and/or storage of nuclear materials, the container comprising a mobile heat conduction structure

ActiveUS9200839B2Increase the inner surfaceReduce playDucting arrangementsDrying gas arrangementsNuclear engineeringNuclear material

Owner:TN INT (FR)

Piercing mandrel having an improved service life for producing seamless tubes

ActiveUS9937540B2Increased durabilityReduce tooling costsMandrelsMetal rolling arrangementsEngineeringMaterial Perforation

A piercing mandrel for piercing heated round blocks of metal for the production of seamless pipes, having a piercing mandrel nose and a piercing mandrel main body which can be connected to a mandrel bar. The outer diameter of the piercing mandrel nose is formed in a conically tapering manner in the longitudinal direction towards the piercing mandrel main body in order to increase the durability of the piercing mandrel when used for piercing round blocks of metal, in particular higher-alloyed steel materials which are difficult to work, by means of skew rolling providing a qualitative improvement of the inner surface of the pierced round block and reducing tool costs.

Owner:VALLOUREC DEUT

Preparation method of modified cellulose/polylactic acid composite material

A modified cellulose / polylactic acid composite preparation method belongs to the technical field of biomass energy chemical engineering and comprises the following steps: hemicellulose of maize straw is hydrolyzed through acid, and then maize straw is pretreated by alkaline-soluble lignin to prepare a cellulose precursor; the cellulose precursor is crushed and dispersed to prepare fibrillation cellulose, and then fire-retardant impregnation and low-temperature oxidation treatment are performed to obtain dehydroxylation cellulose; dehydroxylation cellulose is scattered, and low-temperature carbonization is performed to prepare carbon fibers; the fibrillation cellulose is oxidized by sodium hypochlorite to prepare carboxylated cellulose, and carboxylated cellulose and polyethylene glycol are esterified to prepare esterified cellulose; and dehydroxylation cellulose, the carbon fibers and the esterified cellulose are added into an internal mixer to be subjected to kneading mixing with polylactic acid, and an open mill is adopted for homogenization scattering to prepare a modified cellulose / polylactic acid composite. Cellulose is modified by different methods, particularly mechanical scattering and crushing, flame-retardant impregnation, low-temperature oxidation, high-temperature carbonization, carboxylation and esterification, so that the strength and the mobility of cellulose are improved, and the polylactic acid interfacial compatibility is improved.

Owner:JILIN UNIV

Piston BOLTS

InactiveCN106884982AIncrease bending resistanceIncrease the inner surfacePlungersRod connectionsHoneycomb PatternEngineering

Owner:MAHLE INT GMBH

Grooved drug-eluting medical devices and method of making same

InactiveUS20170135800A1Promote rapid and healthy developmentRateStentsProsthesisMedicineIntravascular stent

Owner:VACTRONIX SCI LLC

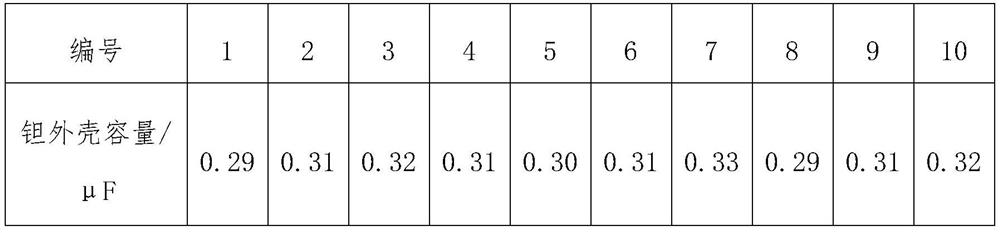

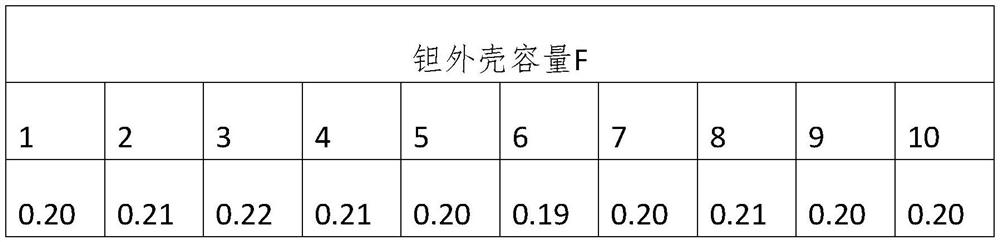

Method for improving capacity of inner wall of tantalum shell of non-solid electrolyte tantalum capacitor

PendingCN113972073AIncrease the inner surfaceGood adhesionCapacitor electrodesElectrolytic capacitor manufactureTantalum capacitorHigh capacitance

The invention belongs to the technical field of capacitor shell inner wall capacity improvement, and relates to a method for improving the capacity of the inner wall of a tantalum shell of a non-solid electrolyte tantalum capacitor. A cathode barrel formed by pressing tantalum powder is of a porous honeycomb structure and can serve as an attachment object of ruthenium dioxide, equivalently, the inner surface of the tantalum shell is increased, the attachment amount of ruthenium dioxide is increased, and therefore the purpose of increasing the capacity of the inner wall of the tantalum shell is achieved.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com