Method for improving capacity of inner wall of tantalum shell of non-solid electrolyte tantalum capacitor

A tantalum capacitor and electrolyte technology is applied in the field of increasing the capacity of the inner wall of the capacitor shell to achieve the effects of increasing the amount of adhesion, increasing the capacity of the cathode, and increasing the adhesion space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

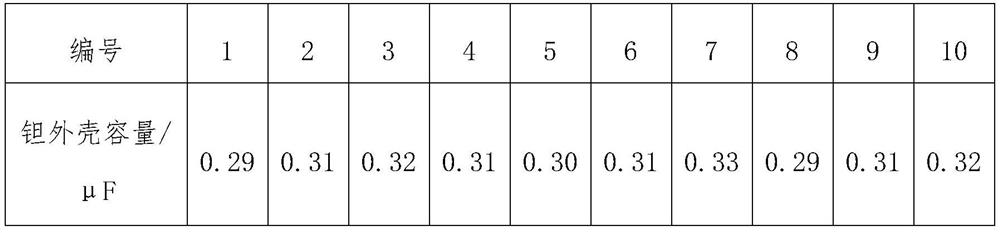

Embodiment 1

[0023] A method of improving the inner wall capacity of a non-solid electrolyte tantalum capacitor tantalum housing, including the following steps:

[0024] (1) Clean the φ9.52 × 27.0 tantalum housing with deionized water, and then naturally cooled after drying in an oven of 125 ° C, and the drying time is 2 h;

[0025] (2) Select the corresponding mold to press the tantalum shell in step (1), and the thickness of the cathode bucket is 0.5 mm, resulting in a cathode bucket semi-finished product.

[0026] The tantalum powder is 20000 μF.v / g;

[0027] (3) The semi-finished product in step (2) is vacuum sintered, the sintering temperature is at 1000 ° C, the sintering time is 30 min, and the cathode bucket is tightly combined with the tantalum housing after sintering;

[0028] (4) Dissolving trichloride in deionized water is prepared into an electrolyte, and the HCl is added to adjust the pH to 3;

[0029] (5) Putting the electrolyte in the tantalum housing in the step (3);

[0030...

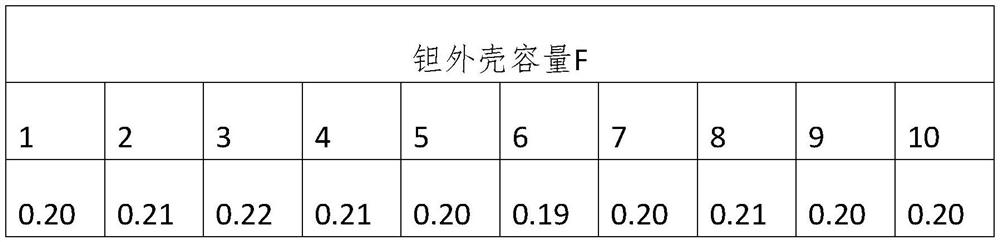

Embodiment 2

[0034] A method of improving the inner wall capacity of a non-solid electrolyte tantalum capacitor tantalum housing, including the following steps:

[0035] (1) Clean the φ7.14 × 16.3 tantalum housing with deionized water, and then naturally cooled after drying in an oven at 100 ° C, and the drying time is 2 h;

[0036] (2) Select the corresponding mold to press the tantalum shell in the step (1), and the thickness of the cathode bucket is 1.0 mm after molding;

[0037] The tantalum powder is 30000 μF.v / g.

[0038] (3) The semi-finished product in step (2) is vacuum sintering, the sintering temperature is at 1000 ° C, the sintering time is 50 min, and the cathode tub is tightly combined with the tantalum housing after sintering;

[0039] (4) Bromide is dissolved in deionized water to form an electrolyte, and the HCl is added to adjust the pH to 4;

[0040] (5) Putting the electrolyte in the tantalum housing in the step (3);

[0041] The electroplating is 30 mA / cm at a current ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com