Preparation method of composite high-energy biomass fuel rod

A biomass fuel and high-energy technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems that biomass particles are susceptible to moisture, affect the combustion effect, and mildew, so as to avoid moisture, facilitate storage, and burn pollution small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

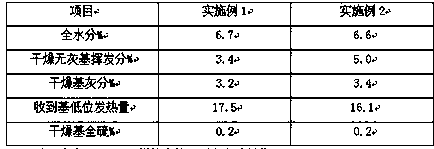

Embodiment 1

[0021] The present invention is achieved through the following technical solutions:

[0022] A method for preparing a composite high-energy biomass fuel rod, comprising the steps of:

[0023] (1) Put the straw powder into an oven and dry at 100°C for 20 minutes in the air atmosphere, take it out after drying and cool it quickly to obtain dry straw powder; After dilute hydrochloric acid solution is stirred and cleaned, carry out solid-liquid separation by suction filtration equipment; (3) directly add the sodium carbonate solution of 0.5mol / L to the wet filter residue cleaned in step (2), react 10 minutes under the above-mentioned solution boiling state, After the reaction, use suction filtration equipment to separate; (4) in parts by weight, 100 parts of the filtrate obtained by the separation of step (3) is transferred to the reactor, and then 5 parts of graphene airgel powder, mass fraction 12% Add 5 parts of ammonia water and 30 parts of absolute ethanol successively, stir...

Embodiment 2

[0034] A method for preparing a composite high-energy biomass fuel rod, comprising the steps of:

[0035](1) put the straw powder into an oven and dry at 200°C for 50 minutes in the air atmosphere, take it out after drying and cool it quickly to obtain dry straw powder; (2) dry plant ash with the same quality as the straw powder obtained in step (1) After dilute hydrochloric acid solution is stirred and cleaned, carry out solid-liquid separation by suction filtration equipment; (3) directly add the sodium carbonate solution of 1mol / L to the wet filter residue washed in step (2), react 15 minutes under the boiling state of above-mentioned solution, react Afterwards, separate with suction filtration equipment; (4) in parts by weight, 100 parts of the filtrate obtained by step (3) separation is transferred to the reactor, and then 10 parts of graphene airgel powder, mass fraction 14% Add 11 parts of ammonia water and 44 parts of absolute ethanol successively, stir evenly, then ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com