Thrust slide bearing made of synthetic resin

A thrust sliding bearing, thrust bearing technology, applied in the direction of sliding contact bearing, rotating bearing, bearing, etc., can solve the problems of heavy driving operation, difficult to maintain stable driving operation, ball or needle fatigue damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

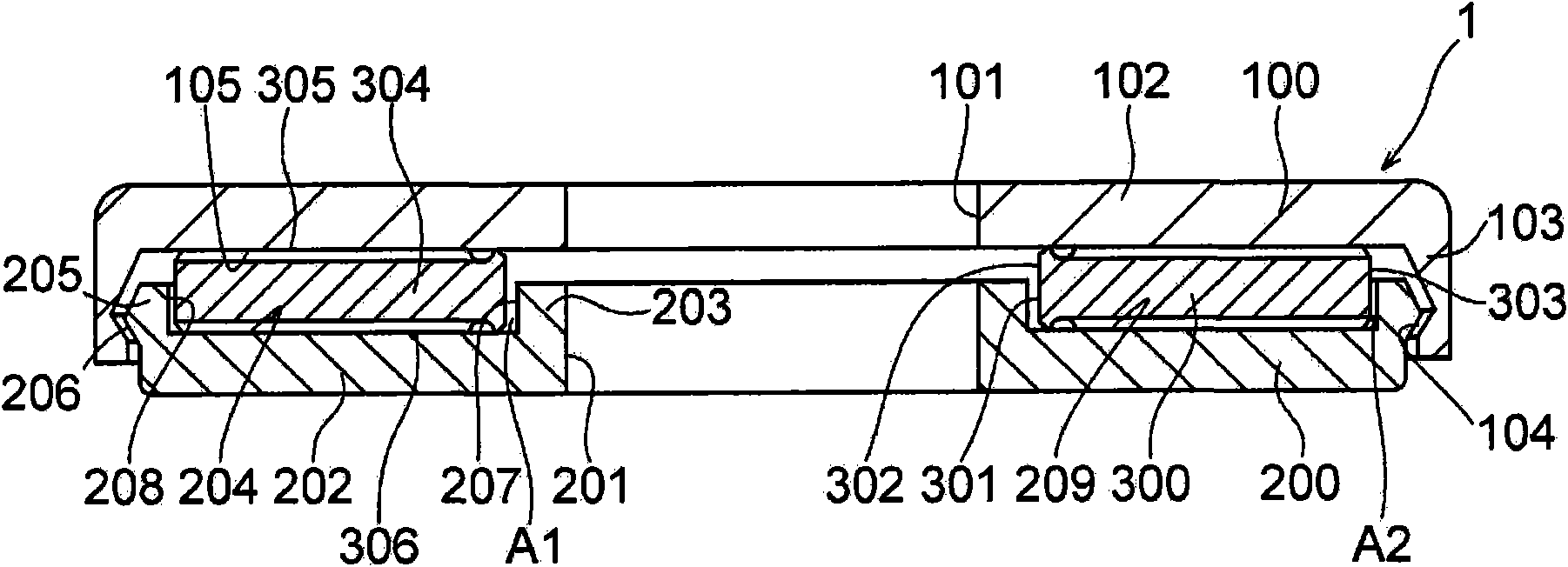

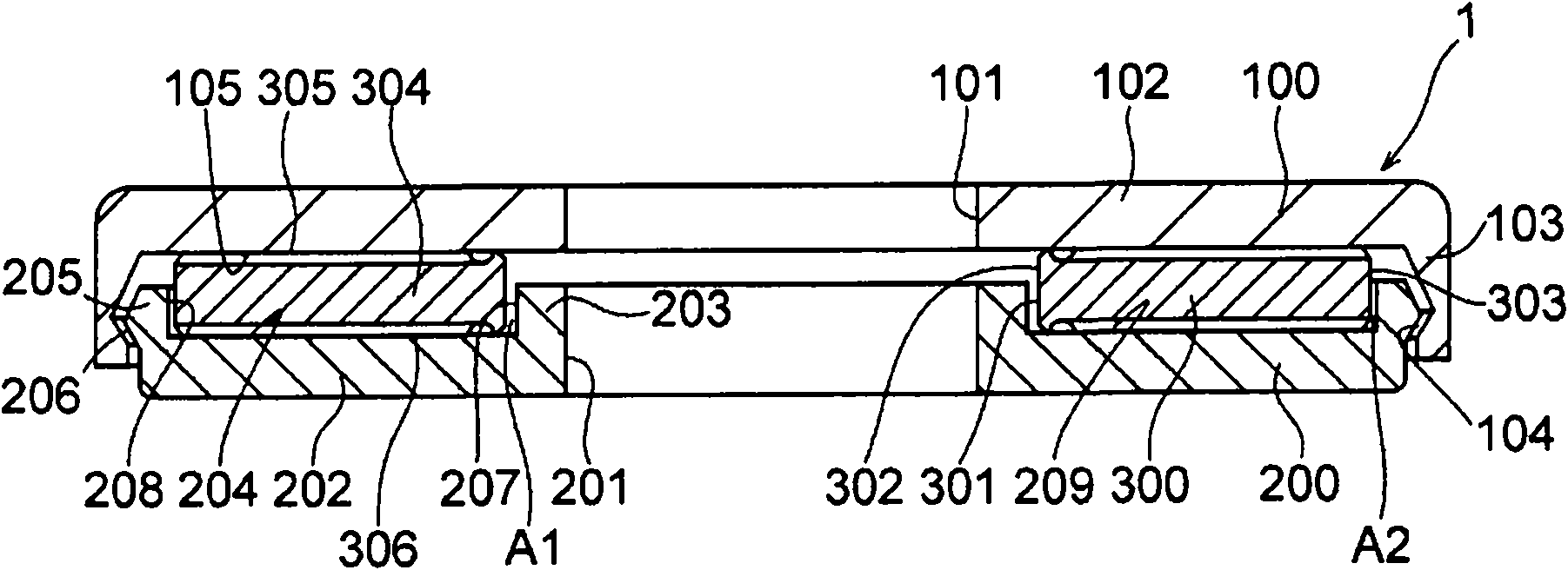

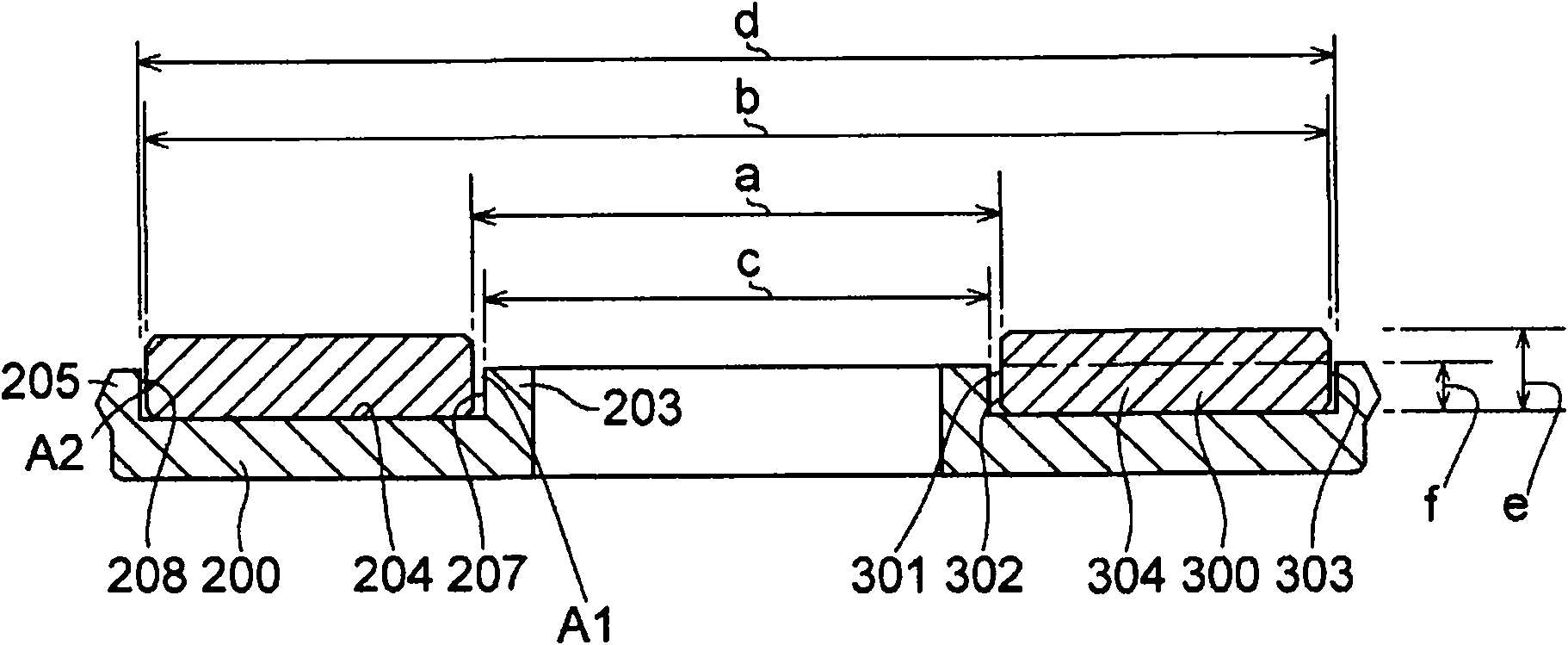

[0044] In FIGS. 1 and 2 , the synthetic resin thrust bearing according to the first embodiment of the present invention includes: a synthetic resin upper case 100 , a synthetic resin lower case 200 , and a synthetic resin case interposed between the upper and lower cases 100 and 200 The synthetic resin thrust sliding bearing member 300 .

[0045] The upper case 100 includes: an annular flat portion 102 having a circular hole 101 at a central portion thereof; a cylindrical fitting hanging portion 103 integrally formed at the outer peripheral edge of the annular flat portion 102; and a cylindrical fitting hanging portion formed The engaging hook portion 104 on the inner peripheral surface of the end portion 103.

[0046] The lower case 200 includes: an annular flat portion 202 having an insertion hole 201 having the same diameter as the circular hole 101 of the upper case 100 at its central portion; a first annular protrusion 203 having a diameter corresponding to the insertion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com