Preparation method of super-low friction lubricating oil additive

A lubricating oil additive and ultra-low friction technology, applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of low friction performance and achieve the effect of ultra-low friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

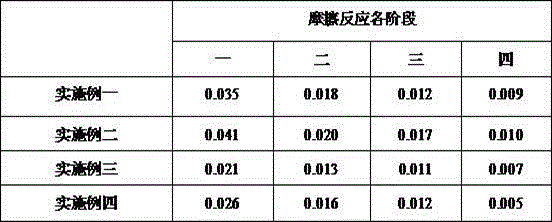

Examples

Embodiment 1

[0022] This embodiment includes the following steps:

[0023] Step 1: Weigh 0.5g of graphene powder and 10g of castor oil into the mortar, manually grind for 15-20 minutes until mixed evenly, and obtain a mixed solution;

[0024] Step 2: Weigh 5g of the above-mentioned primary mixed solution into beaker A, add 20-25ml of absolute ethanol to beaker B, then add 0.0025g of sodium dodecylbenzenesulfonate until fully dissolved, and then dissolve the solution in beaker B Pour it into beaker A, place it in an ultrasonic disperser for ultrasonic dispersion, set the temperature at 50°C, and ultrasonicate for 50 minutes;

[0025] Step 3: Weigh 2g of the above-mentioned mixed solution after ultrasonic dispersion and 2g of castor oil into the ball mill tank of the ball mill, the working speed is 650-750r / min, and after working for 10-12 hours, open the ball mill tank cover to collect the oil;

[0026] Step 4: Add the above-mentioned oil to the lower friction pair of the friction and wear...

Embodiment 2

[0029] This embodiment includes the following steps:

[0030] Step 1: Weigh 0.5g of graphene powder and 10g of castor oil into the mortar, manually grind for 15-20 minutes until mixed evenly, and obtain a mixed solution;

[0031] Step 2: Weigh 5g of the above primary mixed solution into beaker A, add 20-25ml of absolute ethanol to beaker B, then add 0.005g of polyvinylpyrrolidone until fully dissolved, then pour the solution in beaker B into beaker A , placed in an ultrasonic disperser for ultrasonic dispersion, set the temperature to 60°C, and ultrasonicated for 50 minutes;

[0032] Step 3: Weigh 3g of the above-mentioned mixed solution after ultrasonic dispersion and 3g of castor oil into the ball mill tank of the ball mill, the working speed is 650-750r / min, and after working for 10-12 hours, open the ball mill tank cover to collect the oil;

[0033] Step 4: Add the above-mentioned oil to the lower friction pair of the friction and wear testing machine. Friction experiment...

Embodiment 3

[0036] This embodiment includes the following steps:

[0037] Step 1: Weigh 1g of graphene powder and 10g of PAO oil into the mortar, manually grind for 15-20 minutes until mixed evenly, and obtain a mixed solution;

[0038] Step 2: Weigh 5g of the above-mentioned primary mixed solution into beaker A, add 20-25ml of absolute ethanol to beaker B, then add 0.015g of double polyisobutylene succinimide until fully dissolved, and then put the solution in beaker B Pour it into beaker A, place it in an ultrasonic disperser for ultrasonic dispersion, set the temperature at 50°C, and ultrasonicate for 50 minutes;

[0039] Step 3: Weigh 4g of the above-mentioned mixed solution after ultrasonic dispersion and 4g of castor oil into the ball mill tank of the ball mill, the working speed is 650-750r / min, and after working for 10-12 hours, open the ball mill tank cover to collect the oil;

[0040] Step 4: Add the above-mentioned oil to the lower friction pair of the friction and wear testin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com