Enzymatic pre-treatment of market pulp to improve fiber drainage and physical properties

a technology of pretreatment and fibers, applied in the field of treating pulp, can solve the problems of affecting the strength of the pulp, affecting further affecting the drying process, so as to improve the pulp drainage and strength properties, and enhance the quality of the pulp produ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

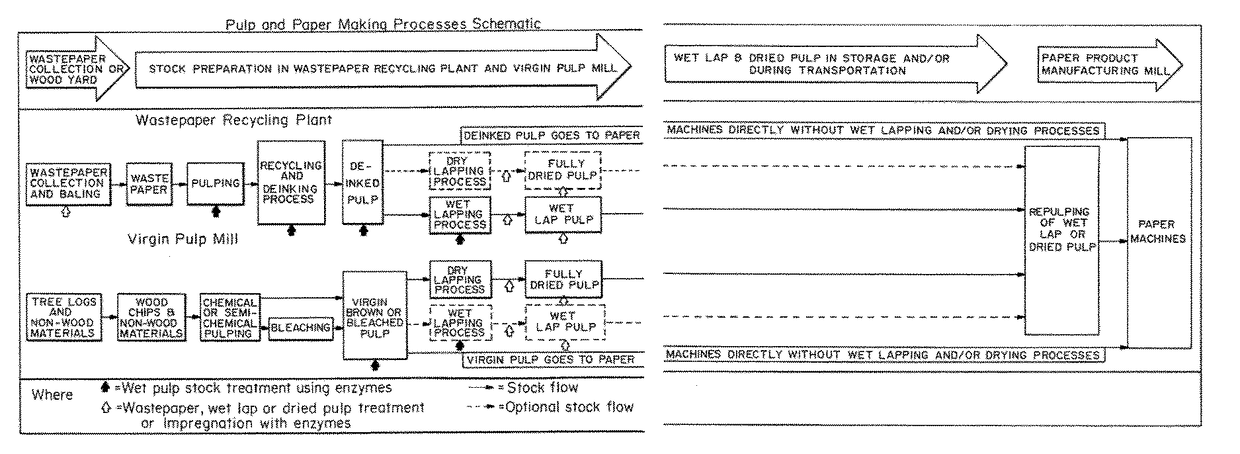

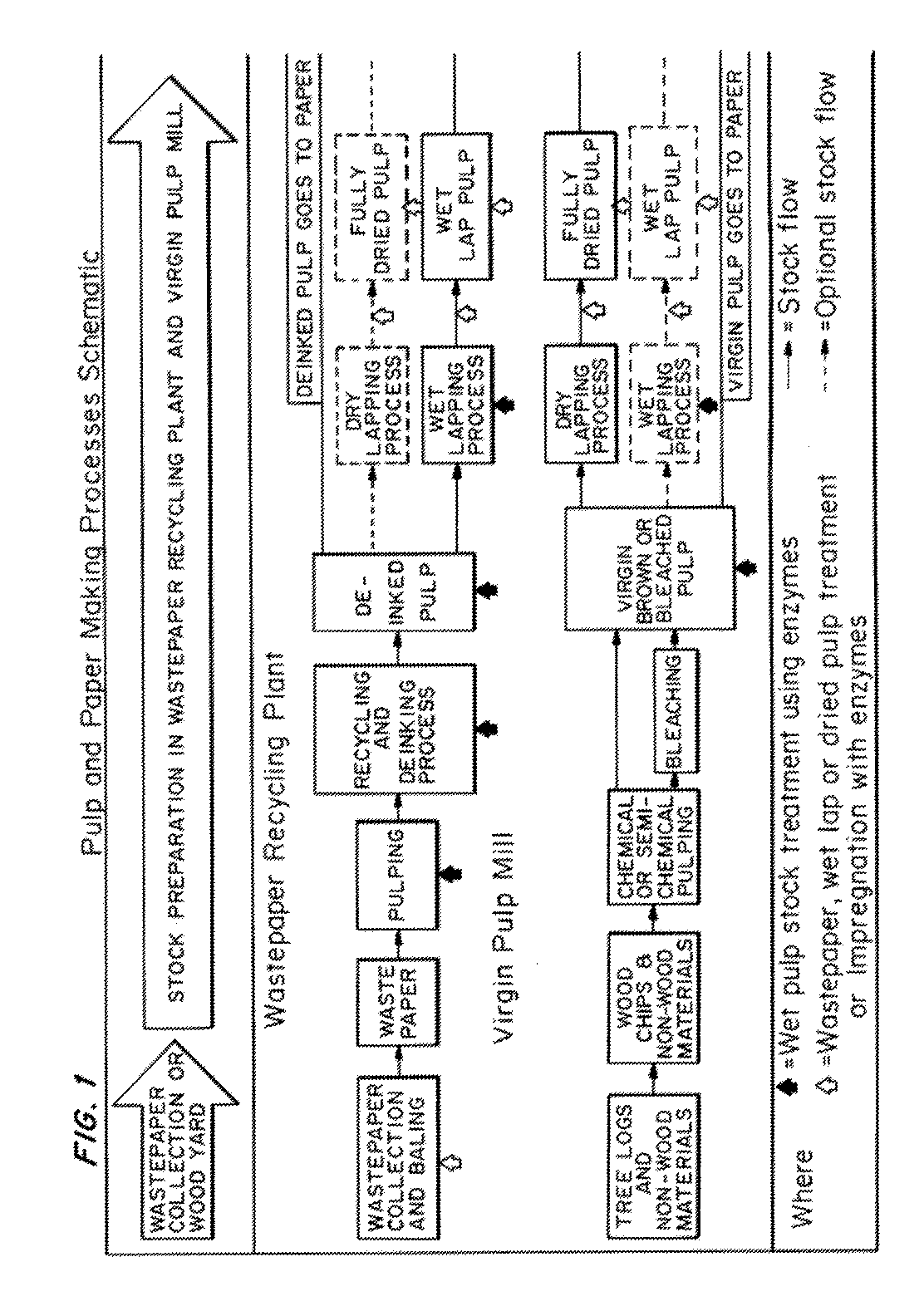

Image

Examples

example 1

Enzymatic Treatment and Wet Lapping and Drying on Fully Bleached Kraft Hardwood Pulp

[0084]Materials and Methods

[0085]Experiments were conducted to determine the effect of enzyme, the effect of starch, and the wetlapping, drying and repulping on the treated pulp. The sheets were produced from the treated and control pulps with the similar conditions as follows: treatment temperature at 45° C., stock at about pH 6.4 with continuing mixing at 3.5% consistency for 45 minutes. The wet stock from the pulp mill was treated with enzyme alone and starch alone and the individually treated stocks are compared to non-treated stock. The non-treated stock, enzyme treated stock and starch treated stock were then split into two portions. The first portion was used for analysis as non-dewatered and dried stock. In this case the treated stock was measured for drainage and then sheets were made to measure sheet physical properties. The second portion was used for analysis of the post dewatering and dr...

example 2

Enzymatic and Starch Treatment on Deinked Pulp Stock

[0090]Materials and Methods

[0091]A similar set of experiments as described in Example 1 was conducted on deinked pulp stock taken from the end of the deink plant where mixed office waste paper was a major furnish component. The deinked pulp was very clean with very low residual dirt. Its brightness was about 75% ISO. The deinked pulp was treated similarly as the virgin hardwood pulp used in Example 1.

[0092]Results

[0093]The results are shown in Table 2.

TABLE 2Effect of enzymes and starch on drainage and strength of deinked pulp stockPhysical Refinase ®,Starch, propertiesTreatment conditionsControl0.05%1.0%Freeness, mlNever-dried466531415Dewatered, 438524485dried and repulpedBurst, kPa · m2 / gNever-dried2.83.23.1Dewatered, 2.32.72.2dried and repulpedTensile, N · m / gNever-dried43.751.647.6Dewatered, 33.338.332.9dried and repulped

[0094]The dewatering, drying and repulping once again showed significant deterioration in pulp properties in...

example 3

Enzymatic Treatment of Fully Bleached Kraft Loblolly Pulp

[0095]Materials and Methods

[0096]A wet pulp stock at about 3.6% consistency was collected from a southern Kraft pulp mill which makes bleached dry lap commercial products. The wet pulp stock was treated in a similar manner as described in Example 1 for hardwood pulp using Refinase® B at 0.05% based on OD fiber.

[0097]Results

[0098]The results are shown in Table 3.

TABLE 3Effect of enzyme on bleached Loblolly Kraft pulpPhysicalRefinase ®,Starch,propertiesTreatment conditionsControl0.05%1.0%Freeness, mlNever-dried682729589Dewatered, 665728683dried and repulpedBurst, kPa · m2 / gNever-dried2.73.13.0Dewatered, 1.92.42.1dried and repulpedTensile, N · m / gNever-dried32.237.736.1Dewatered, 24.228.422.1dried and repulped

[0099]As in examples 1 and 2, the enzymatic treatment of never-dried pulps provided material gains to drainage and strength which carried through the dewatering and drying process as compared to the non-treated control. As i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com