Ingredient dispensing cap for beverage container

a technology for beverage containers and ingredients, applied in the field of beverage ingredient dispensing caps, can solve the problems of adding a significant amount of cost to the manufacturing of such caps from plastic, affecting the dispensing process, so as to simplify the process of insertion and ensure the dispensing effect. the effect of accurate and complete dispensing of beverage ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0135]The inventions disclosed herein are described in the context of beverage ingredient dispensers that can be attached to beverage containers because they have utility in this context. However, the inventions disclosed herein can be used in other contexts as well, including but without limitation, dispensers for other types of ingredients, attachments to other types of devices, other food and beverage related contexts, pharmaceutical and Nutraceutical mixing and / or delivery devices, as well as other industrial and commercial non- food contexts, such as chemical organic / inorganics additives, plasticizers, coloring agents, etc.

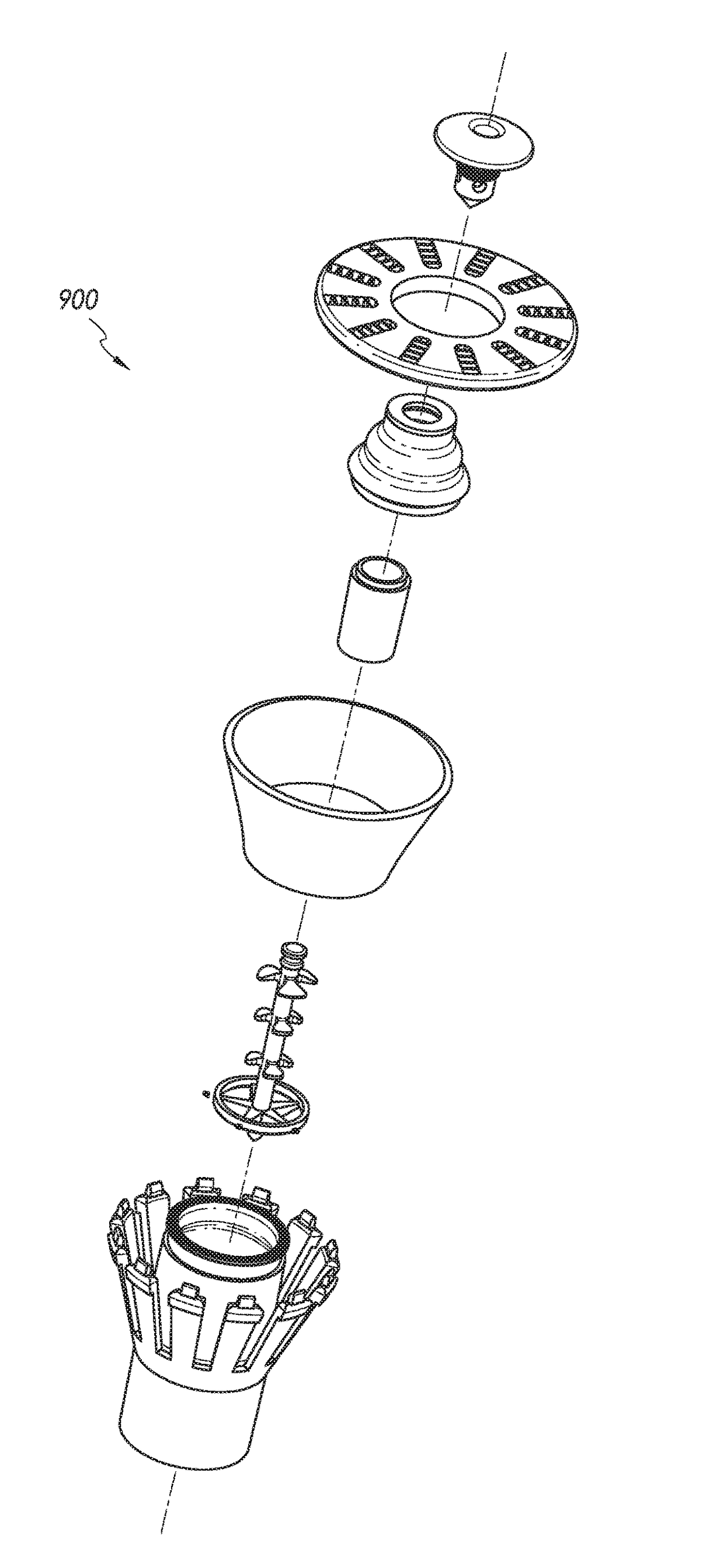

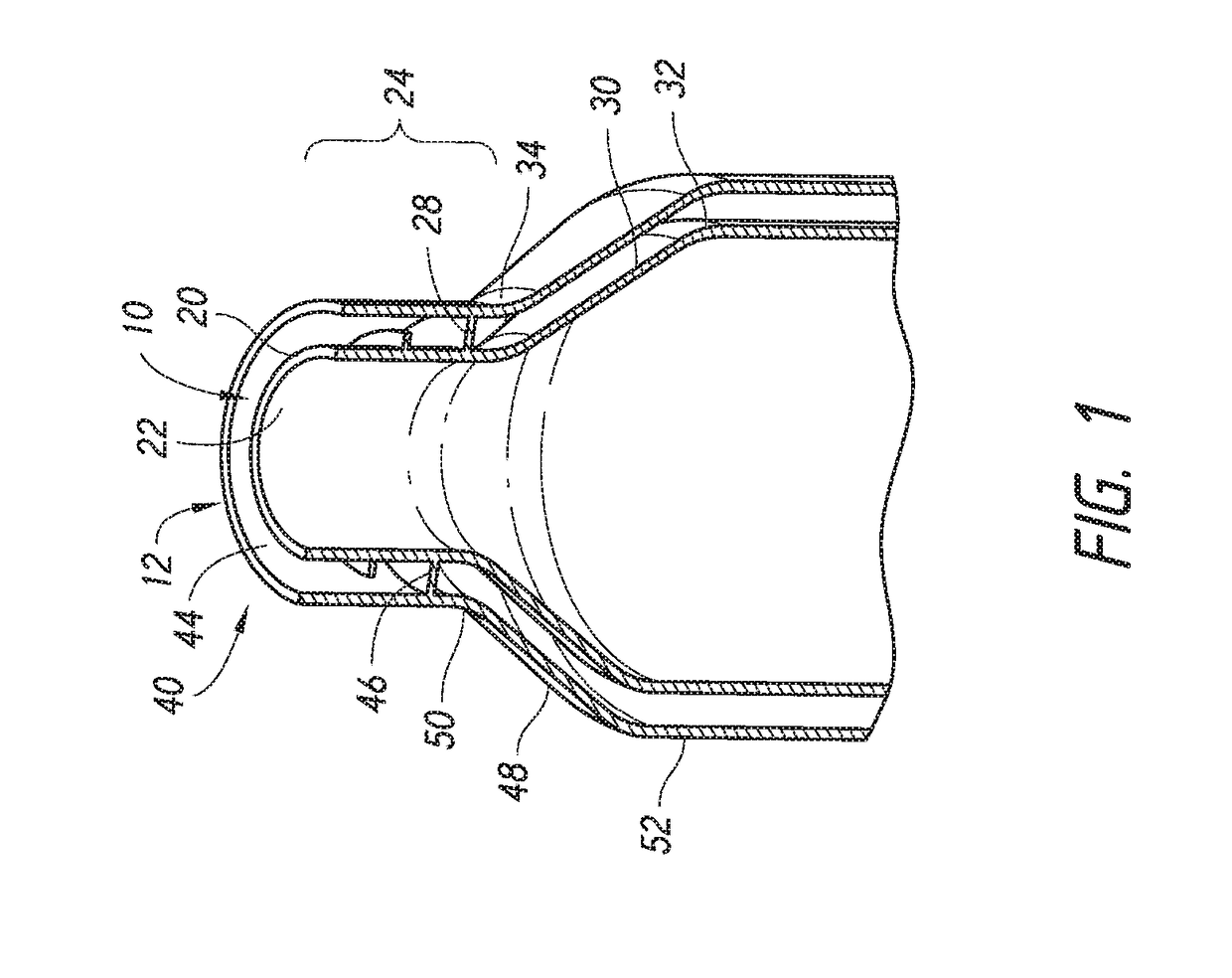

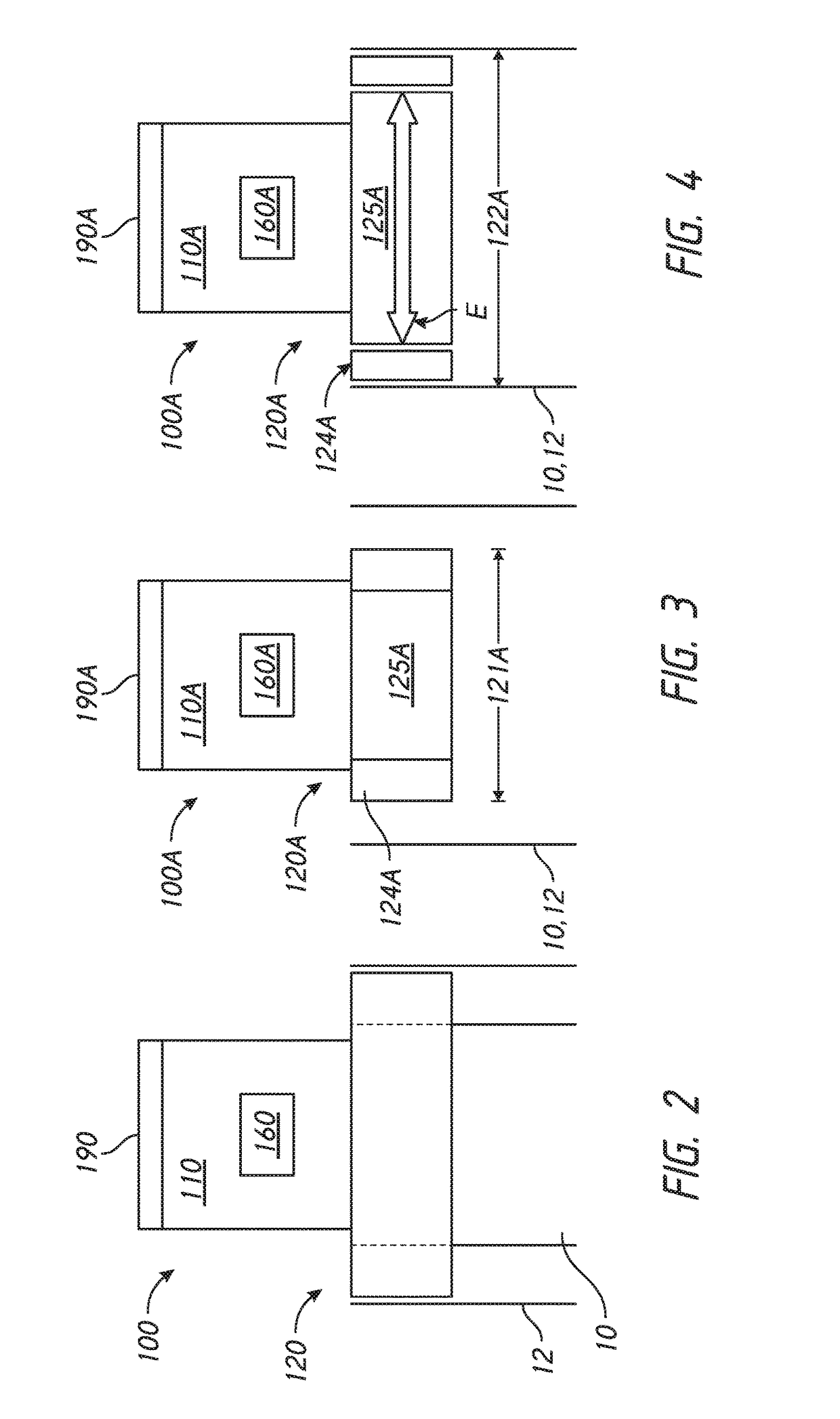

[0136]FIGS. 2-10 illustrate embodiments and variations of a beverage ingredient dispenser 100. FIGS. 11-82 illustrate variations and further embodiments of the dispenser 100. The embodiments of FIGS. 18-62 are identified generally by the reference numbers 200, 300, 400, 500, 600, 700, 800, 900, 1000, 1100, 1200, 3000, 3200. Various parts, components, and feat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com