Cleaning method and film deposition apparatus

a cleaning method and film deposition technology, applied in the direction of chemical vapor deposition coating, vacuum evaporation coating, coating, etc., can solve the problems of increasing the cleaning time needed, ejecting the majority of cleaning gas, and high flow rate of cleaning gas supplied from the nozzl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]Embodiments of the present invention are described below with reference to the accompanying drawings. Throughout the specification and the drawings, the same reference number is assigned to substantially the same components, and repeated descriptions of those components are omitted.

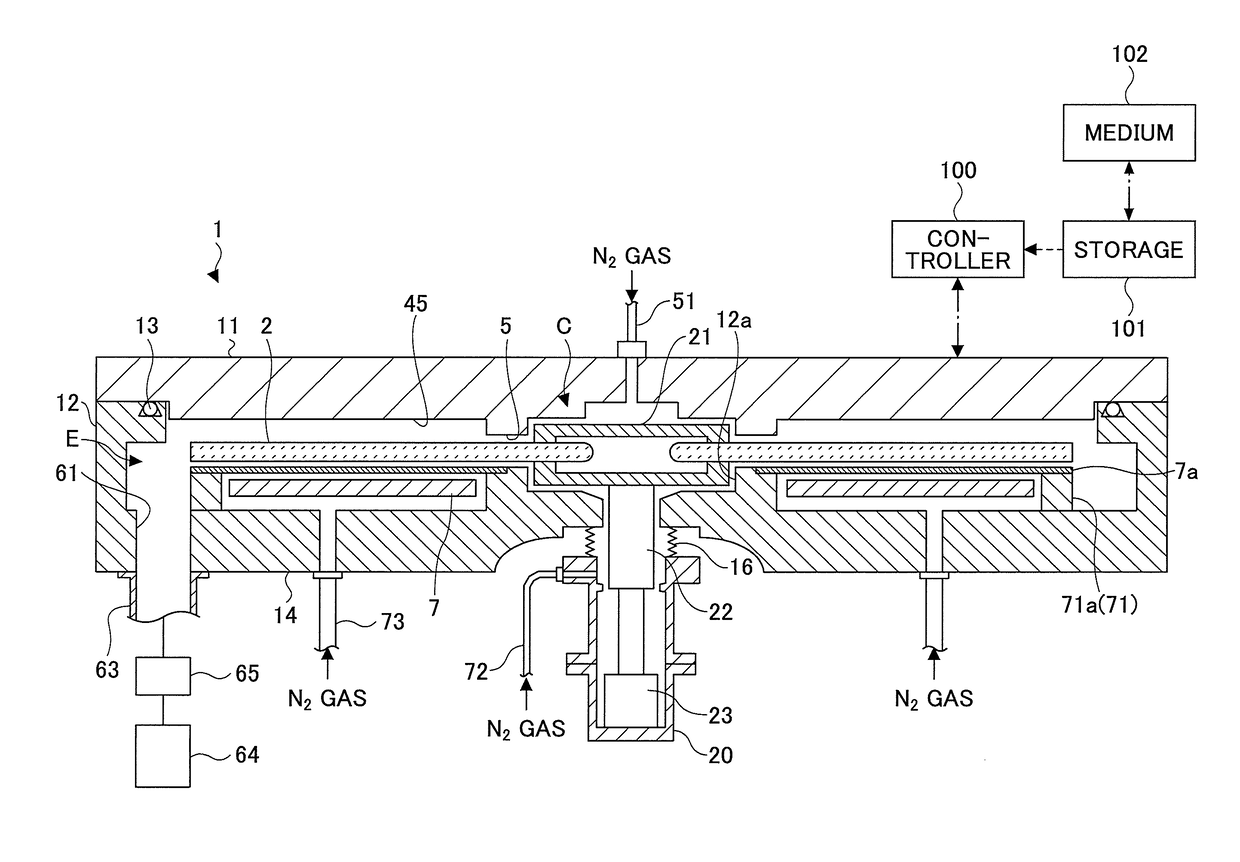

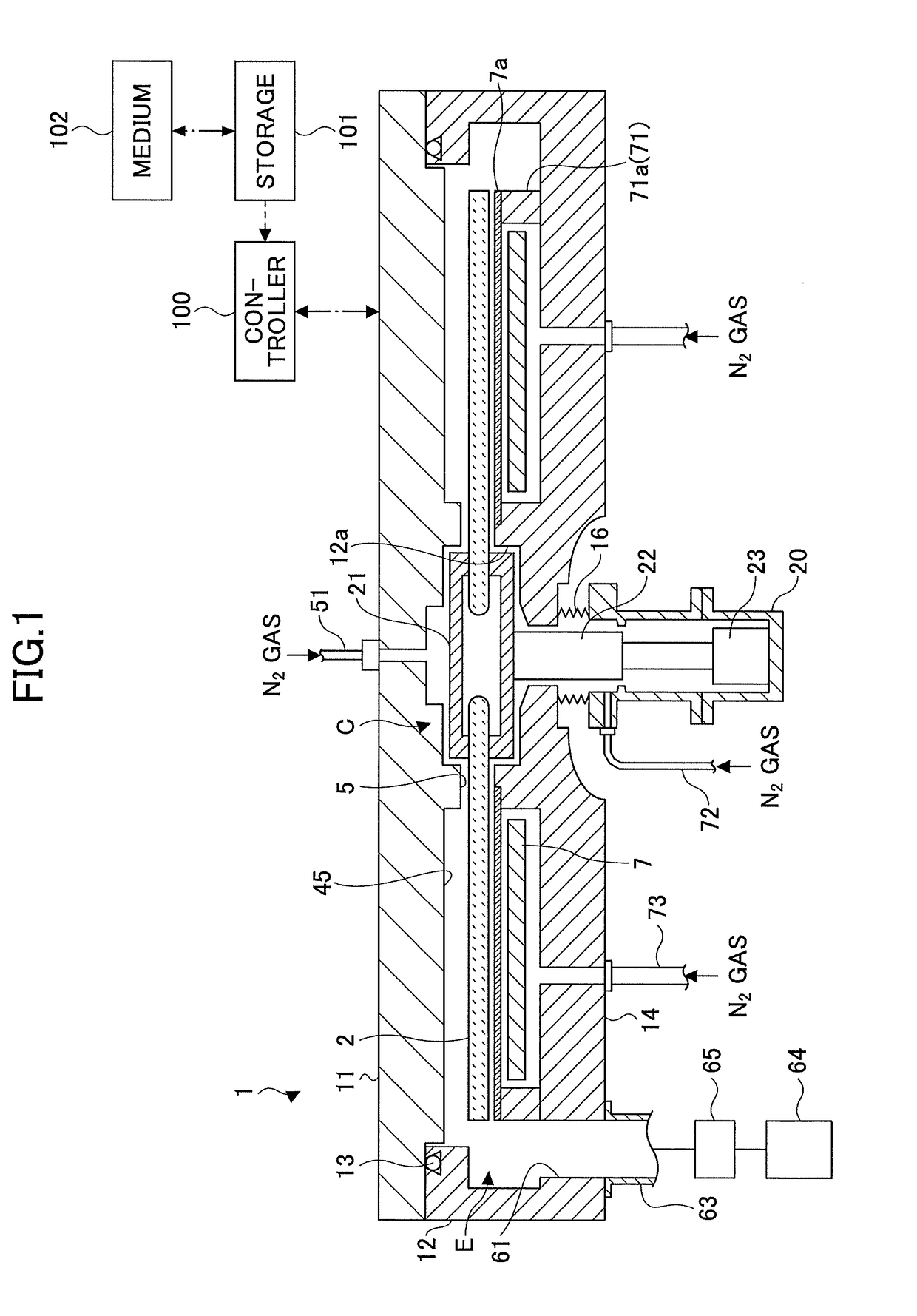

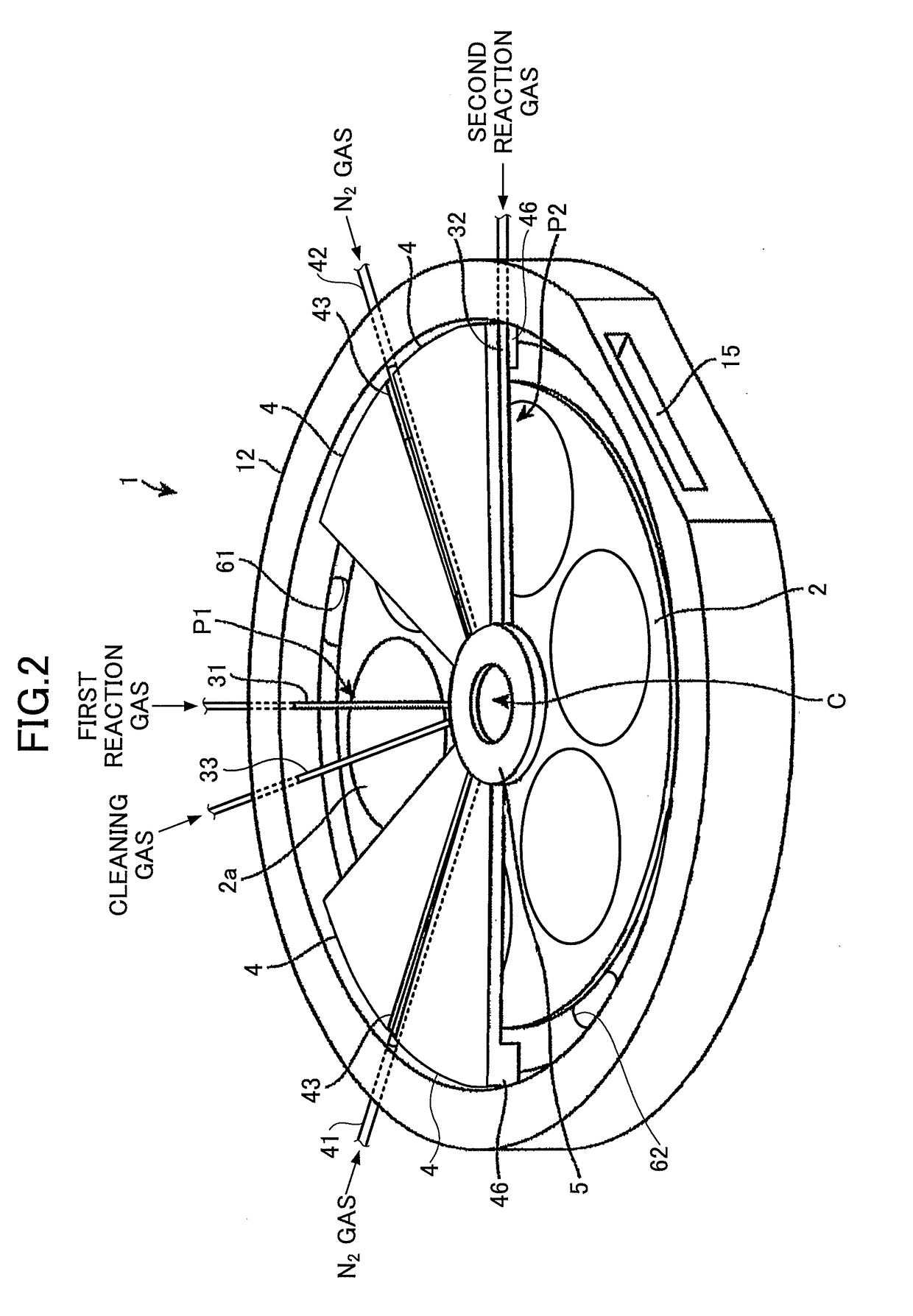

[0016]An example of a film deposition apparatus that can perform cleaning methods according to embodiments of the present invention is described. FIG. 1 is a cross-sectional view of a film deposition apparatus according to an embodiment. FIG. 2 is a perspective view of an internal configuration of a vacuum chamber of the film deposition apparatus of FIG. 1. FIG. 3 is a plan view of the internal configuration of the vacuum chamber of the film deposition apparatus of FIG. 1. In FIGS. 2 and 3, a top plate 11 is omitted for illustration purposes.

[0017]As illustrated by FIGS. 1 through 3, the film deposition apparatus may include a vacuum chamber 1 having a substantially circular planar shape, and a rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| flow rate | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap