Passive purge injectors

a purge injector and passive technology, applied in the field of injectors, can solve the problems of adding a parasitic efficiency loss to the engine and engine damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

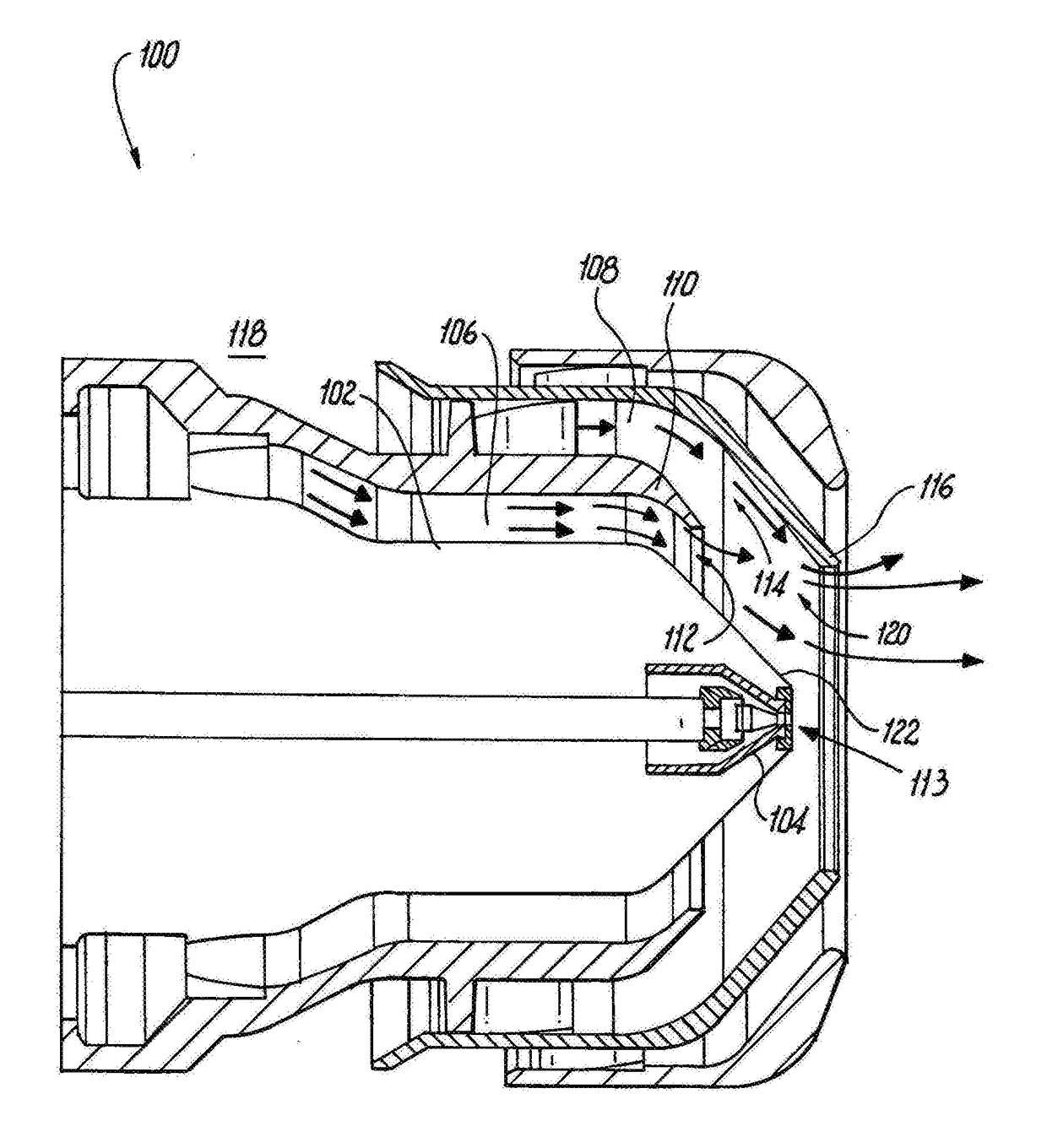

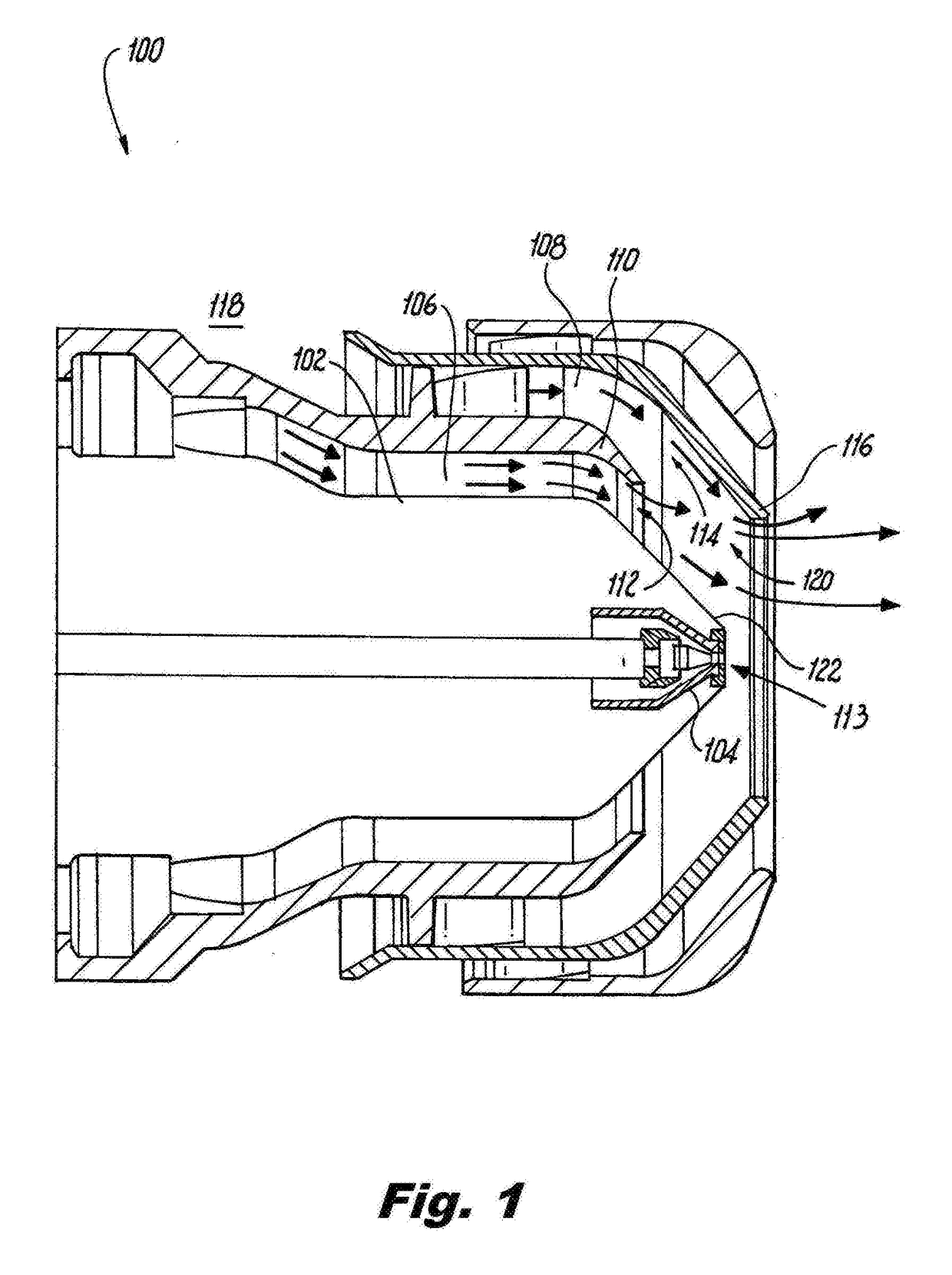

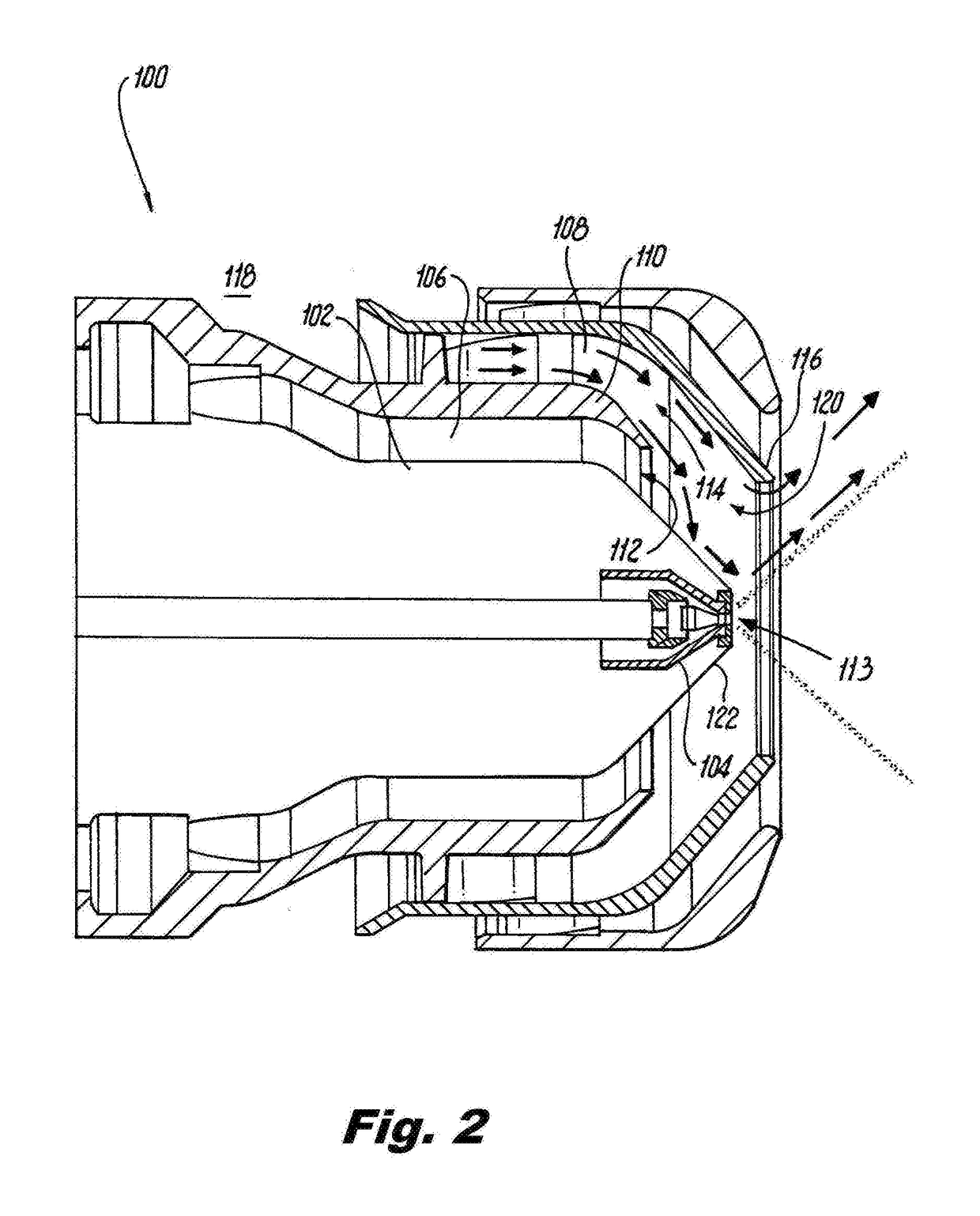

[0022]Reference will now be made to the drawings wherein like reference numerals identify similar structural features or aspects of the subject disclosure. For purposes of explanation and illustration, and not limitation, a partial view of an exemplary embodiment of an injector in accordance with the disclosure is shown in FIG. 1 and is designated generally by reference character 100. Other aspects of injectors in accordance with the disclosure are provided in FIG. 2, as will be described. The systems and methods described herein can be used to provide passive purge of liquid fuel in dual-fuel, e.g., gaseous and liquid fuel, injection for gas turbine engines over a wide range of Wobbe Index values for the gaseous fuel.

[0023]Fuel injector 100 includes a liquid injector 102 having a liquid fuel circuit 104 (two or more liquid fuel circuits can be used, e.g., a primary for low power and a secondary high power), a gaseous fuel circuit 106 outboard of the liquid fuel circuit 104, and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com