Mixer assembly for mixing an additive with an exhaust gas flow

a technology of mixing assembly and additive, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problems of large structural space required for the exhaust gas line, uneven droplet load of additive, and unsatisfactory nitrogen oxide formation, etc., and achieve high nitrogen oxide reduction rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The following description of the preferred embodiment(s) is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

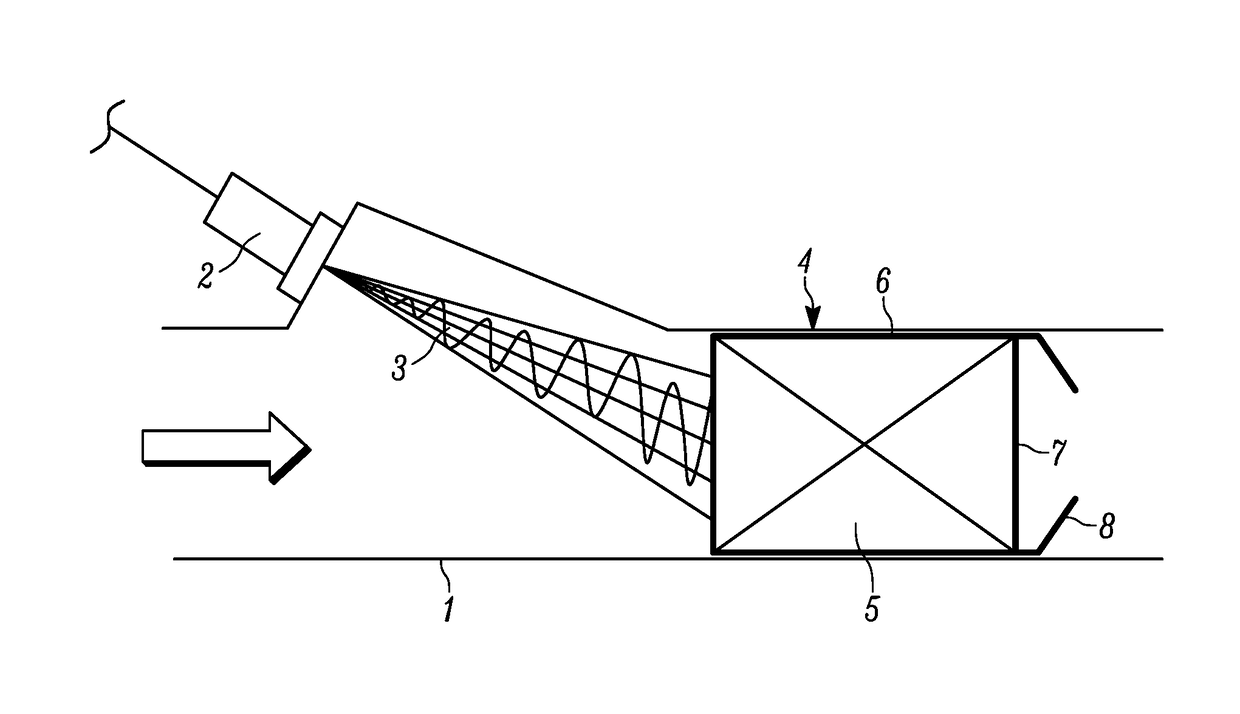

[0037]FIG. 1 shows a mixer arrangement having an exhaust-gas line 1 in a motor vehicle (not illustrated in any more detail). The arrow indicates the main flow direction of the exhaust gas flowing through the exhaust-gas line 1. By means of an injector 2 arranged on the exhaust-gas line 1, urea solution is injected into the exhaust-gas flow at an angle with respect to the main flow direction, such that the jet 3 strikes an exhaust-gas purification element 4 approximately centrally. The exhaust-gas purification element is an SCR catalytic converter 4. The SCR catalytic converter 4 is composed of a schematically illustrated honeycomb body 5, which forms a flow-over surface for the exhaust gas, and a casing 6, which fully encloses the honeycomb body 5. On the downstream-facing side 7 of the casing 6, a guide structure 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com