Electrostatic chuck device

a technology of electrostatic chuck and chuck body, which is applied in the direction of electrostatic holding device, metal-working machine components, manufacturing tools, etc., can solve the problems of affecting the performance of the electrostatic chuck device, and achieve the effect of prolonging the li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

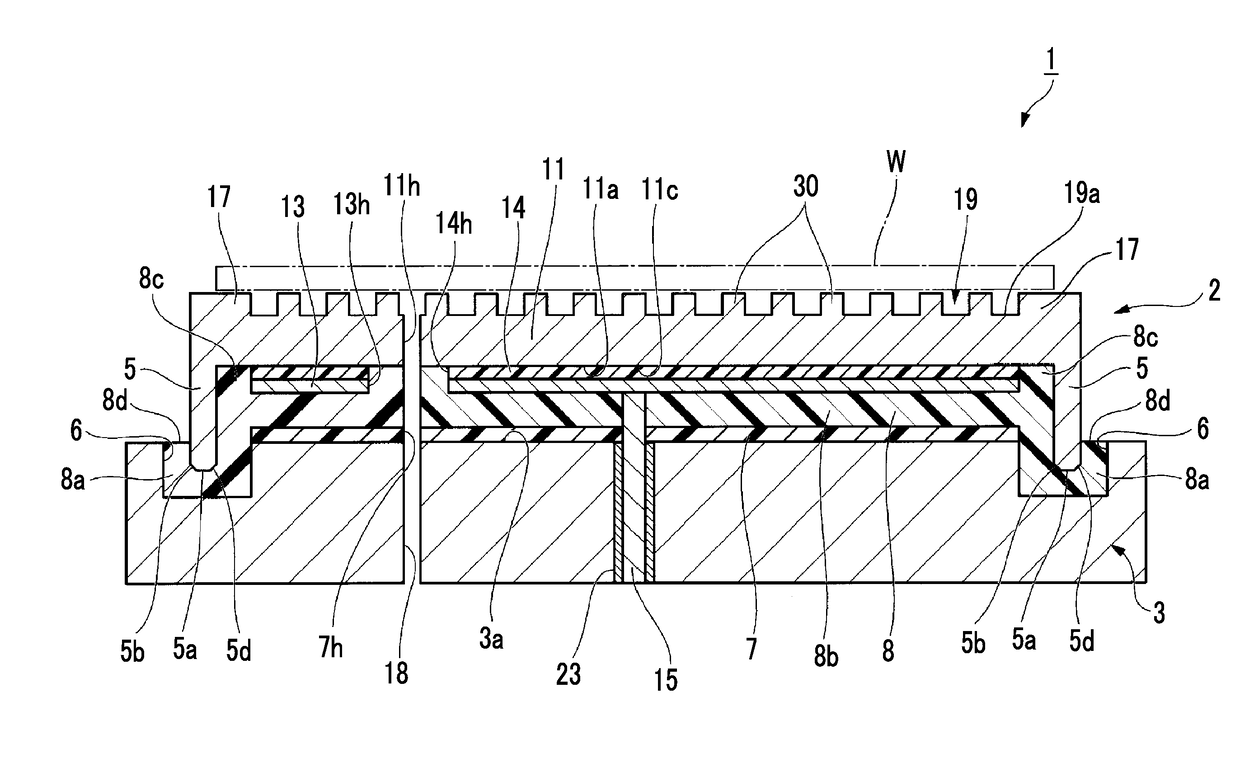

[0029]Hereinafter, an electrostatic chuck device 1 according to a first embodiment which is a preferred example of the present invention will be described with reference to FIG. 1. In the drawings which are used in the following description, in order to make the features easy to understand, there is a case where characteristic portions are shown in an enlarged manner for convenience. Therefore, dimensions, ratios, or the like of the respective constituent elements is not necessarily the same as the actual.

[0030]FIG. 1 is a sectional view of the electrostatic chuck device 1. The electrostatic chuck device 1 of this embodiment has a circular shape when viewed in a planar view. The electrostatic chuck device 1 is provided with an electrostatic chuck member 2 having an upper surface which is amounting surface 19 on which a plate-shaped sample W such as a semiconductor wafer is mounted, a temperature controlling base member 3 for controlling the temperature of the electrostatic chuck mem...

modification example 1

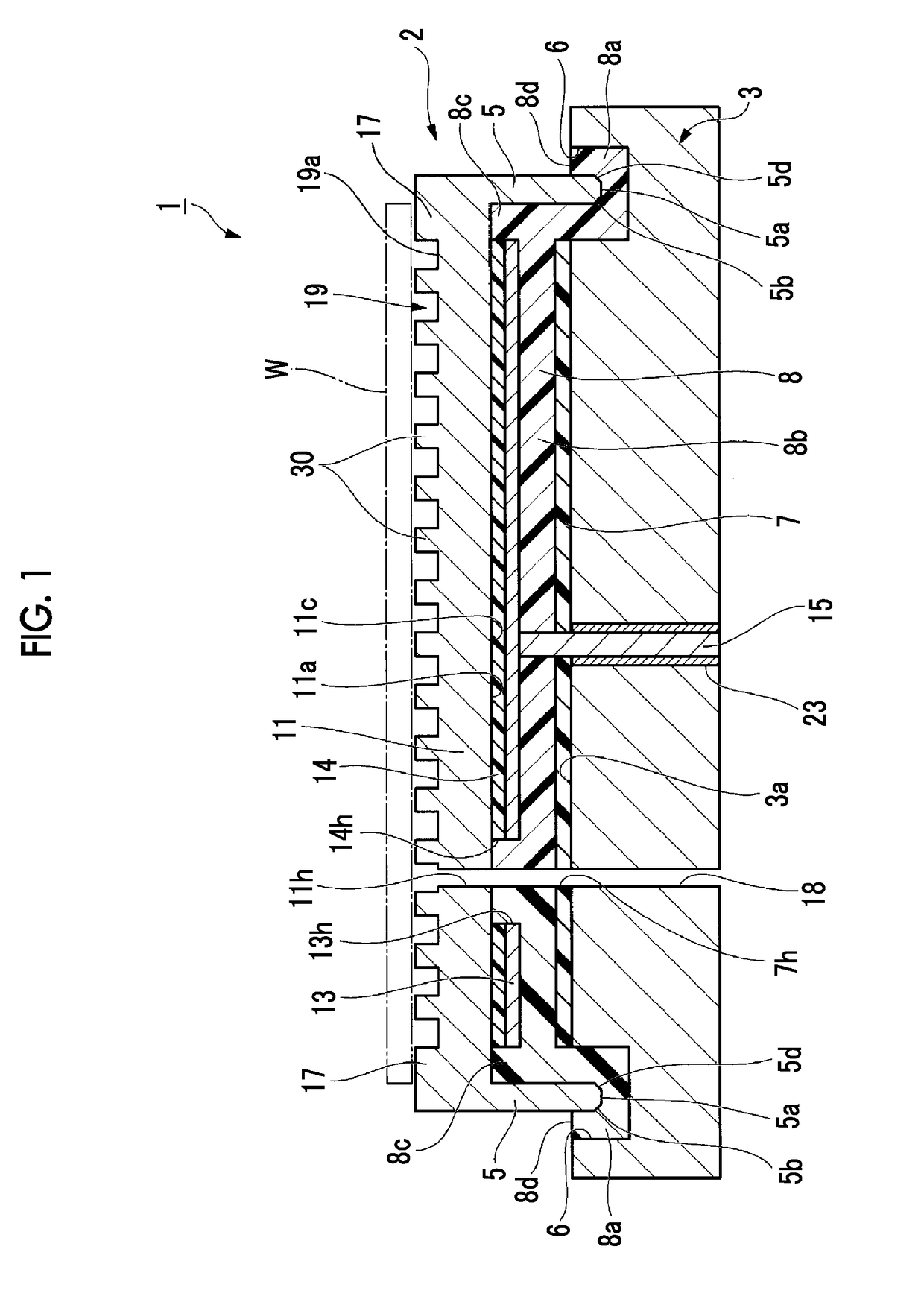

[0092]Next, an electrostatic chuck device 101 of Modification Example 1 which is a preferred example of the present invention will be described.

[0093]FIG. 2 is a partial sectional view of the electrostatic chuck device 101. The electrostatic chuck device 101 of Modification Example 1 is different from the electrostatic chuck device 1 of the above-described embodiment mainly in terms of the configurations of the dike portion and the groove portion. The constituent elements of the same aspect as that of the above-described embodiment are denoted by the same reference numerals and description thereof is often omitted.

[0094]The electrostatic chuck device 101 is provided with an electrostatic chuck member 102, a temperature controlling base member 103, an adhesive layer 108, and the second organic insulating layer 7. The electrostatic chuck member 102 has a mounting plate (a ceramic plate) 111 on which the plate-shaped sample W is mounted, the electrode for electrostatic attraction 13, a...

modification example 2

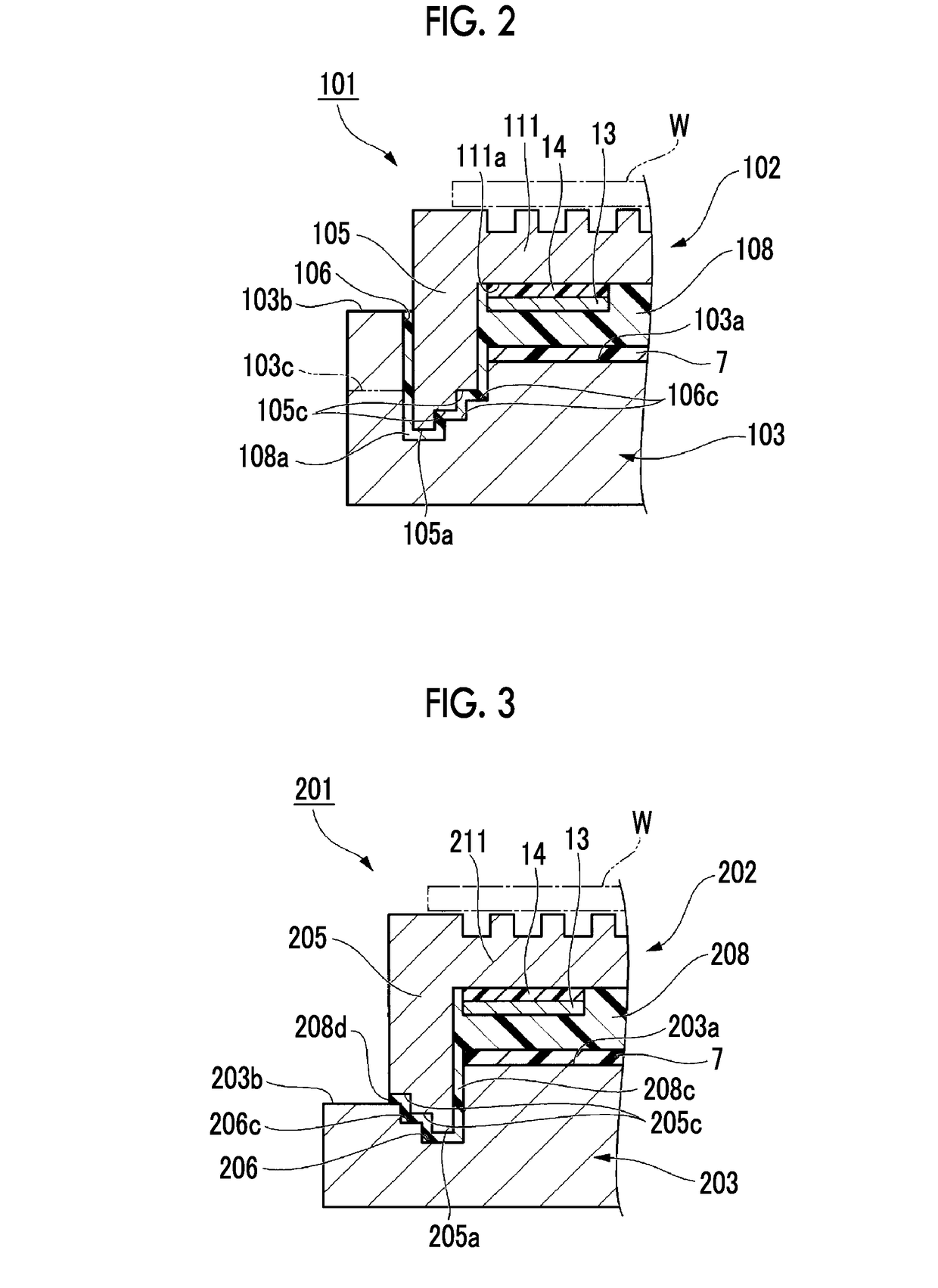

[0099]Next, an electrostatic chuck device 201 of Modification Example 2 which is a preferred example of the present invention will be described.

[0100]FIG. 3 is a partial sectional view of the electrostatic chuck device 201. The electrostatic chuck device 201 of Modification Example 2 has a combination of a dike-portion-side step surface and a groove-portion-side step surface, similar to the electrostatic chuck device 101 of Modification Example 1, and specifically has a dike-portion-side step surface 205c and a groove-portion-side step surface 206c. However, a position and a direction in which the dike-portion-side step surface 205c and the groove-portion-side step surface 206c are provided are different from those in Modification Example 1. The constituent elements of the same aspect as those of the above-described embodiment and modification example are denoted by the same reference numerals and description thereof is often omitted.

[0101]The electrostatic chuck device 201 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com