Al-zn-cu alloy and manufacturing method thereof

Pending Publication Date: 2018-10-18

KOREA INST OF MATERIALS SCI

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

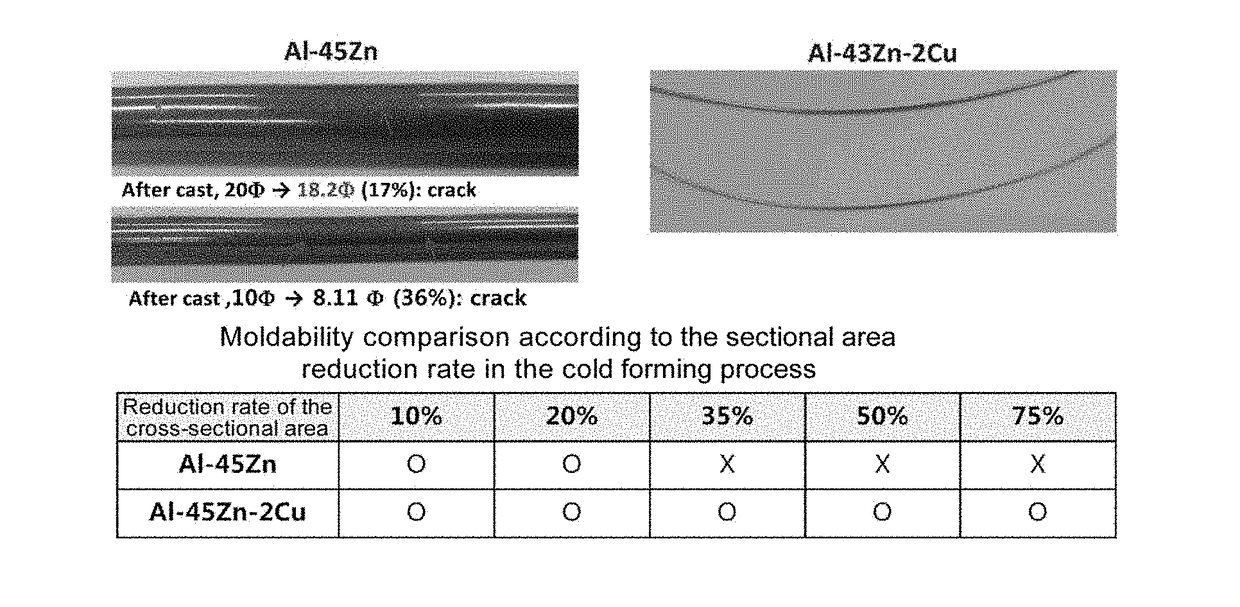

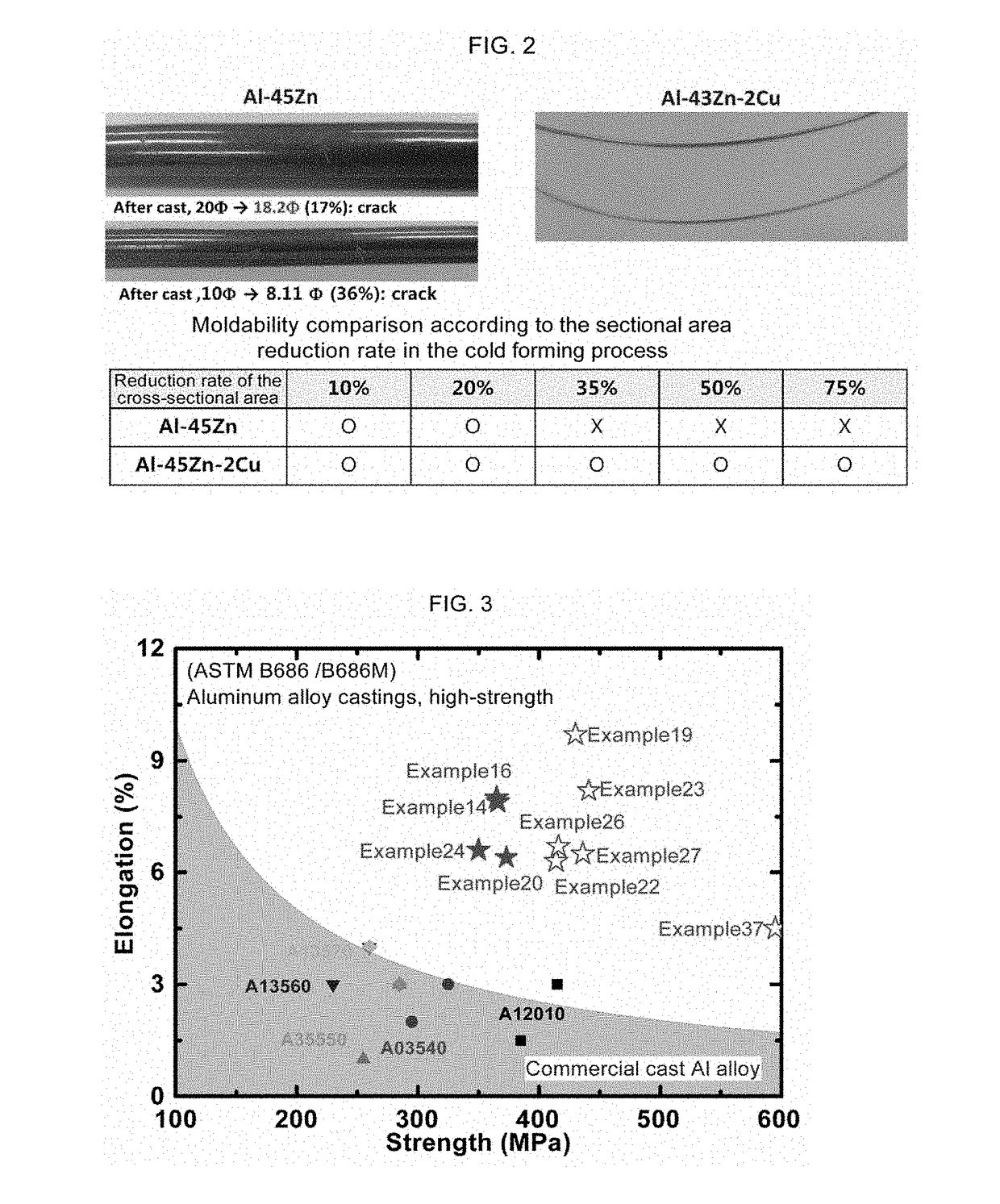

The patent is about a new Al—Zn—Cu alloy that has improved casting properties, meaning it is less likely to crack or have other issues during production. This alloy also has better moldability, meaning it can be easily shaped, as well as higher strength, elongation, and conductivity.

Problems solved by technology

Aluminum alloys such as Al—Si alloys and Al—Mg alloys, which have excellent casting properties, have been generally used as cast aluminum alloys, but their tensile strengths are low.

Such an aluminum alloy for plastic processing is excellent in plastic workability, but has a problem of poor castability in which cracking occurs during casting.

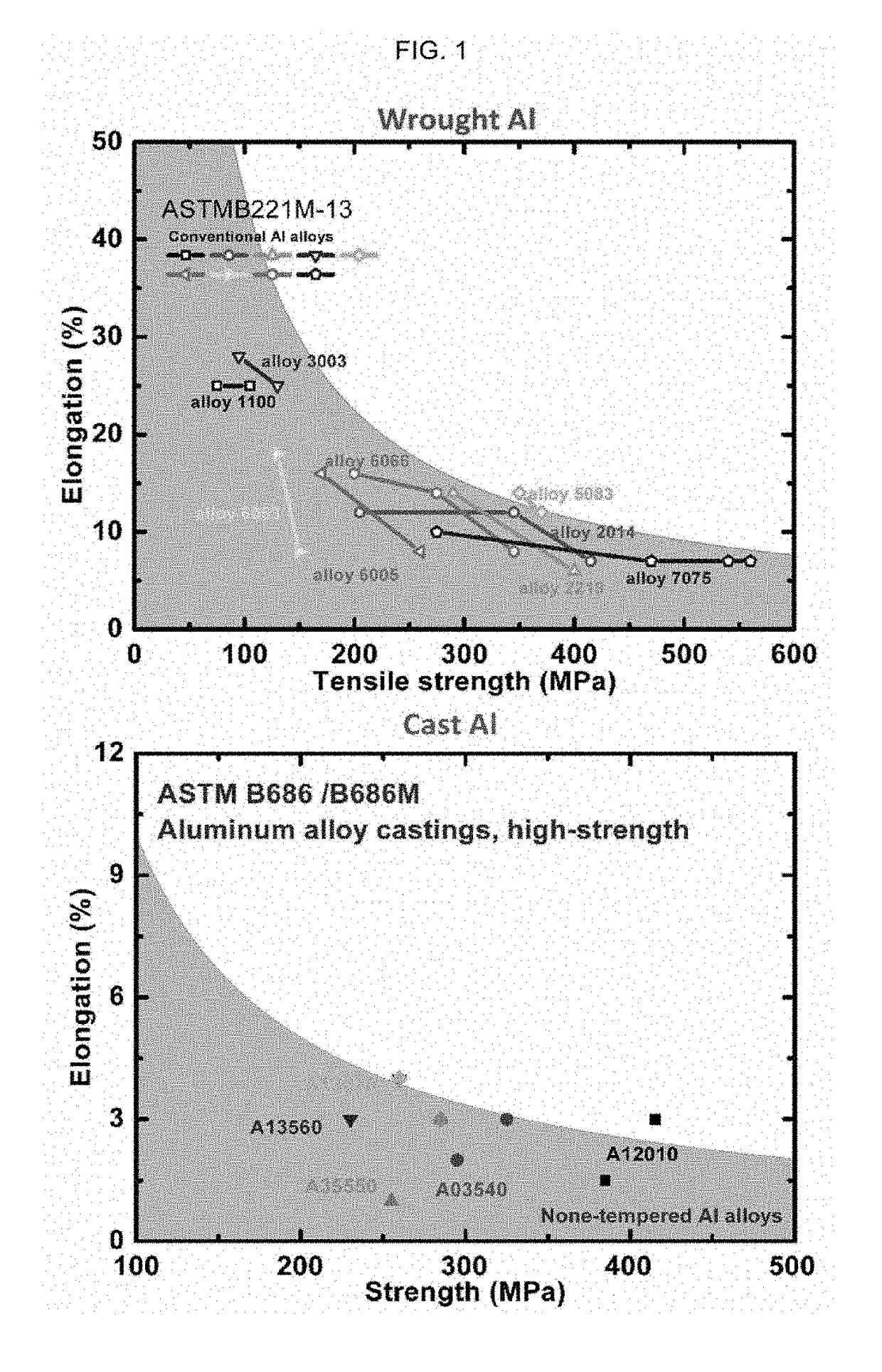

Generally, there is a problem that it is difficult to simultaneously improve the tensile strength and the elongation because there is a trade-off relationship in which one of the characteristics of the tensile strength and the elongation is attenuated when the other is improved (FIG. 1).

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

examples

[0118]Hereinafter, the present invention will be described in more detail with reference to specific production examples and comparative examples of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Login to View More

Abstract

The present invention relates to an Al—Zn—Cu alloy comprising: 18 to 50 parts by weight of zinc; 0.05 to 5 parts by weight of copper; and the rest being aluminum, based on the total weight of the alloy, wherein a tensile strength is 230 to 450 MPa and an elongation is 2.75 to 10% in the cast state. According to the present invention, it is possible to provide an Al—Zn—Cu alloy having improved casting property, strength and elongation at the same time.

Description

CROSS-REFERENCE TO RELATED APPLICATION[0001]This application claims the benefit under 35 USC § 119(a) of Korean Patent Application No. 10-2017-0048119 filed on Apr. 13, 2017 in the Korean Intellectual Property Office, the entire disclosure of which is incorporated herein by reference for all purposes.BACKGROUND1. Field[0002]The following description relates to an Al—Zn—Cu alloy and a manufacturing method thereof and more particularly, to an Al—Zn—Cu casting alloy, a heat-treated alloy and a wrought alloy having improved castability, tensile strength and elongation at the same time, and a manufacturing method thereof.2. Description of Related Art[0003]A casting process is widely used in various fields such as in the production of electric parts, optical instruments, vehicles, spinning machines, constructions, measuring instruments and the like, particularly automobile parts.[0004]Aluminum alloys such as Al—Si alloys and Al—Mg alloys, which have excellent casting properties, have been...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C21/10C22F1/053

CPCC22C21/10C22F1/053C22C1/026C22C30/02C22C30/06

Inventor HAN, SEUNG-ZEONKIM, KWANG-HOAHN, JEE-HYUKCHOI, EUN-AE

Owner KOREA INST OF MATERIALS SCI

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com