Catalyst arrangement for industrial emissions control and method of assembling same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

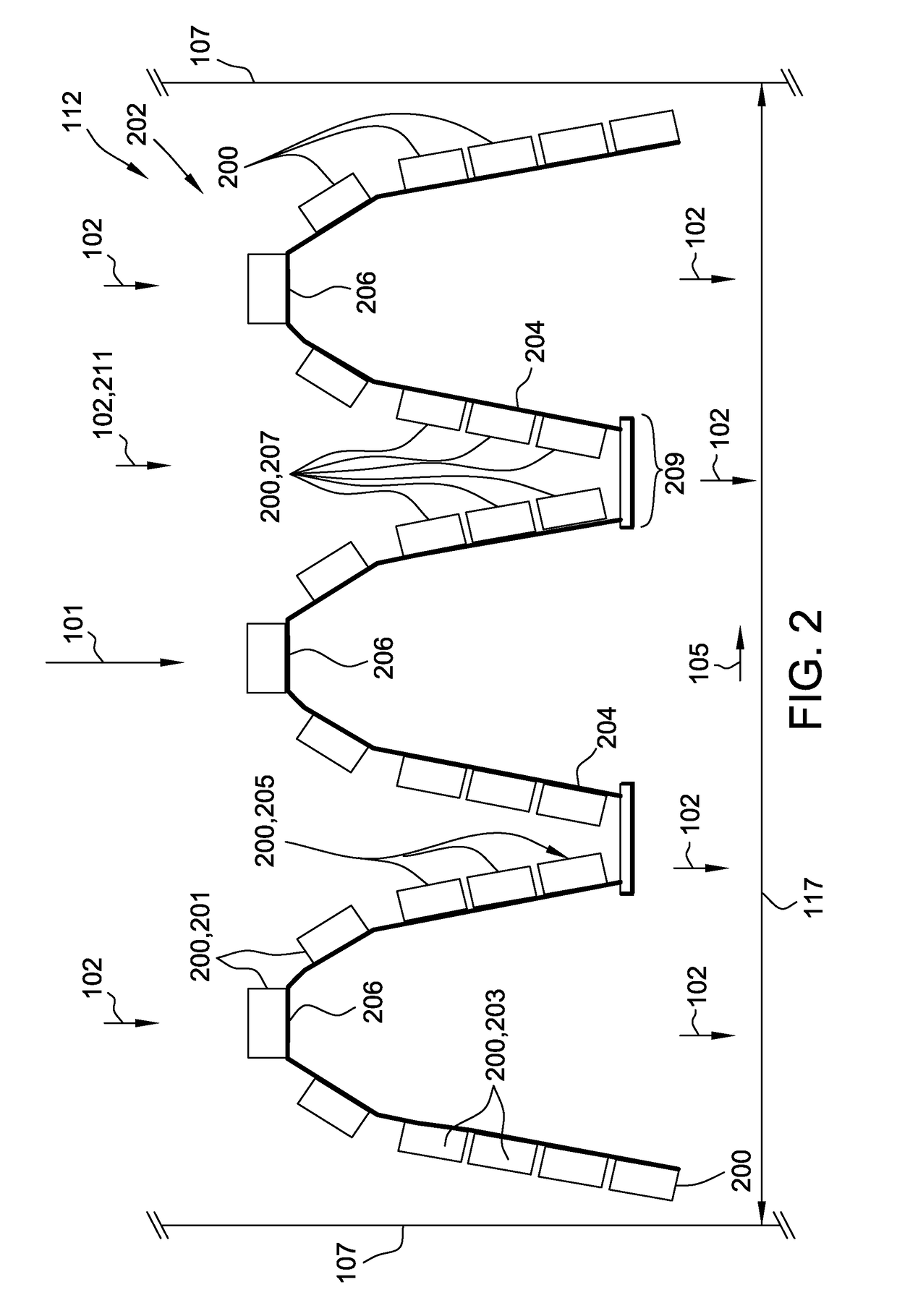

[0032]In catalyst arrangement 112 illustrated in FIG. 2, frame 204 at the illustrated vertical station 202 includes a series of transversely adjacent U-shaped sections 206, with a closed end of each U-shaped section 206 extending upstream towards the incoming flow of exhaust gases 102. Catalyst elements 200 are coupled to an upstream side of each U-shaped section 206, such that catalyst elements 200 are arranged at a plurality of axial positions, facilitating packing of an increased number of catalyst elements 200 along vertical station 202 as compared to a flat transverse wall of catalyst elements (not shown). In some embodiments, the legs of each U-shaped section 206 include at least one of catalyst element 203 positioned completely downstream from catalyst element 201, at least three catalyst elements 205 aligned in series along axial direction 101, and concentrated group 207 of catalyst elements 200 axially aligned with flow region 211 having at least one local flow characterist...

second embodiment

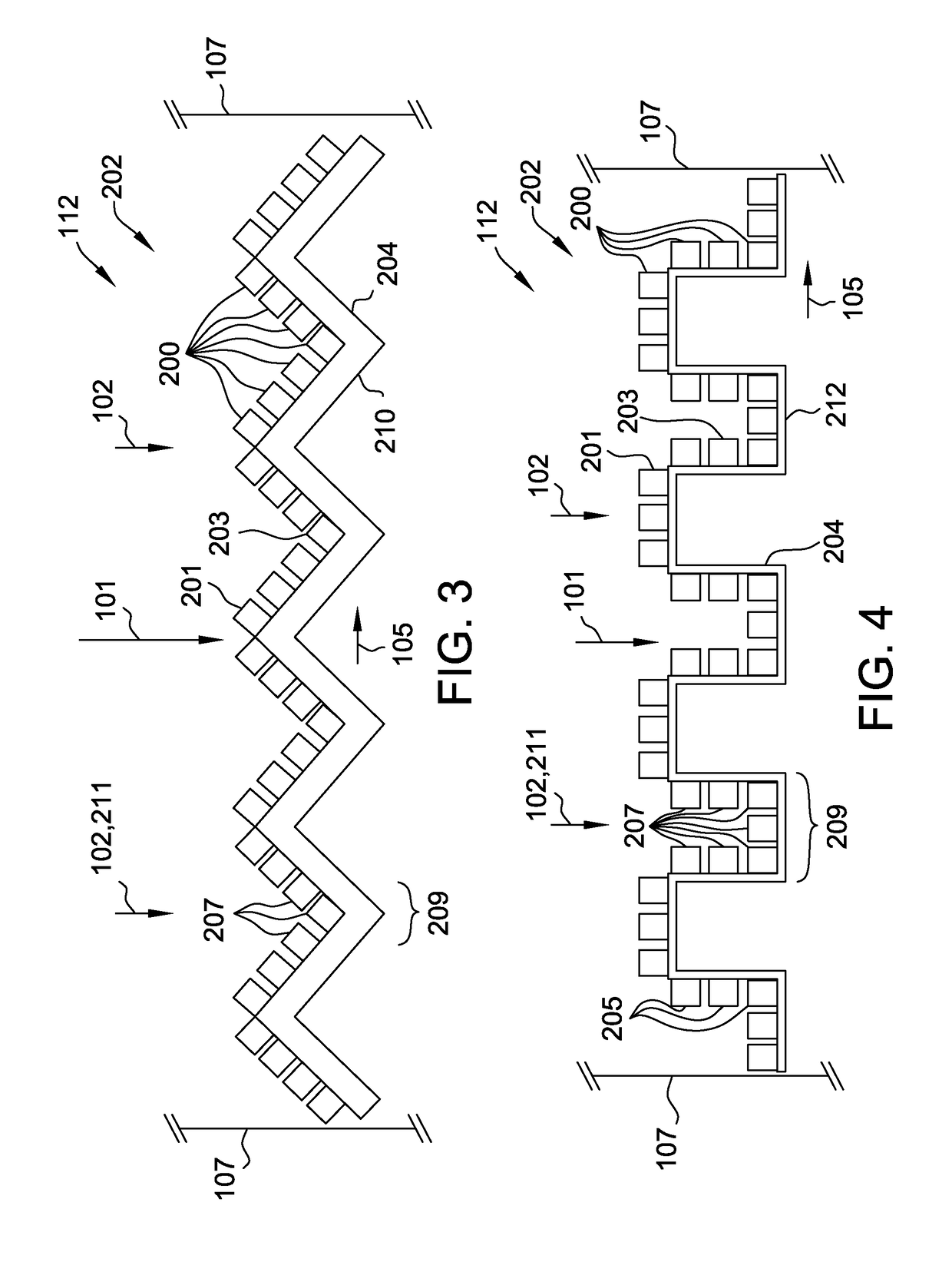

[0033]FIG. 3 is a view of a vertical station 202 of a second exemplary embodiment of catalyst arrangement 112. In catalyst arrangement 112 illustrated in FIG. 3, frame 204 at the illustrated vertical station 202 includes a transversely extending sawtooth shape 210. Catalyst elements 200 are coupled to an upstream side of sawtooth shape 210, such that catalyst elements 200 are arranged at a plurality of axial positions, facilitating packing of an increased number of catalyst elements 200 along vertical station 202 as compared to a flat transverse wall of catalyst elements (not shown). In some embodiments, the downstream vertices of sawtooth shape 210 include at least one of catalyst element 203 positioned completely downstream from catalyst element 201 and concentrated group 207 of catalyst elements 200 axially aligned with flow region 211 having at least one local flow characteristic of exhaust gases 102 incident at vertical station 202.

third embodiment

[0034]FIG. 4 is a view of a vertical station 202 of a third exemplary embodiment of catalyst arrangement 112. In catalyst arrangement 112 illustrated in FIG. 4, frame 204 at the illustrated vertical station 202 includes a transversely extending square-wave shape 212. Catalyst elements 200 are coupled to an upstream side of square-wave shape 212, such that catalyst elements 200 are arranged at a plurality of axial positions, facilitating packing of an increased number of catalyst elements 200 along vertical station 202 as compared to a flat transverse wall of catalyst elements (not shown). In some embodiments, the axially extending portions of square-wave shape 212 include at least one of catalyst element 203 positioned completely downstream from catalyst element 201, at least three catalyst elements 205 aligned in series along axial direction 101, and concentrated group 207 of catalyst elements 200 axially aligned with flow region 211 having at least one local flow characteristic of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com