Power saving welding helmet

a welding helmet and power saving technology, applied in the field of welding helmets, can solve the problems of reducing the power consumption of the conventional viewing lens, the weldinger may not see the surroundings clearly through the dark lens, and the viewing lens may flash, so as to save power, reduce power consumption, and save more electric power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

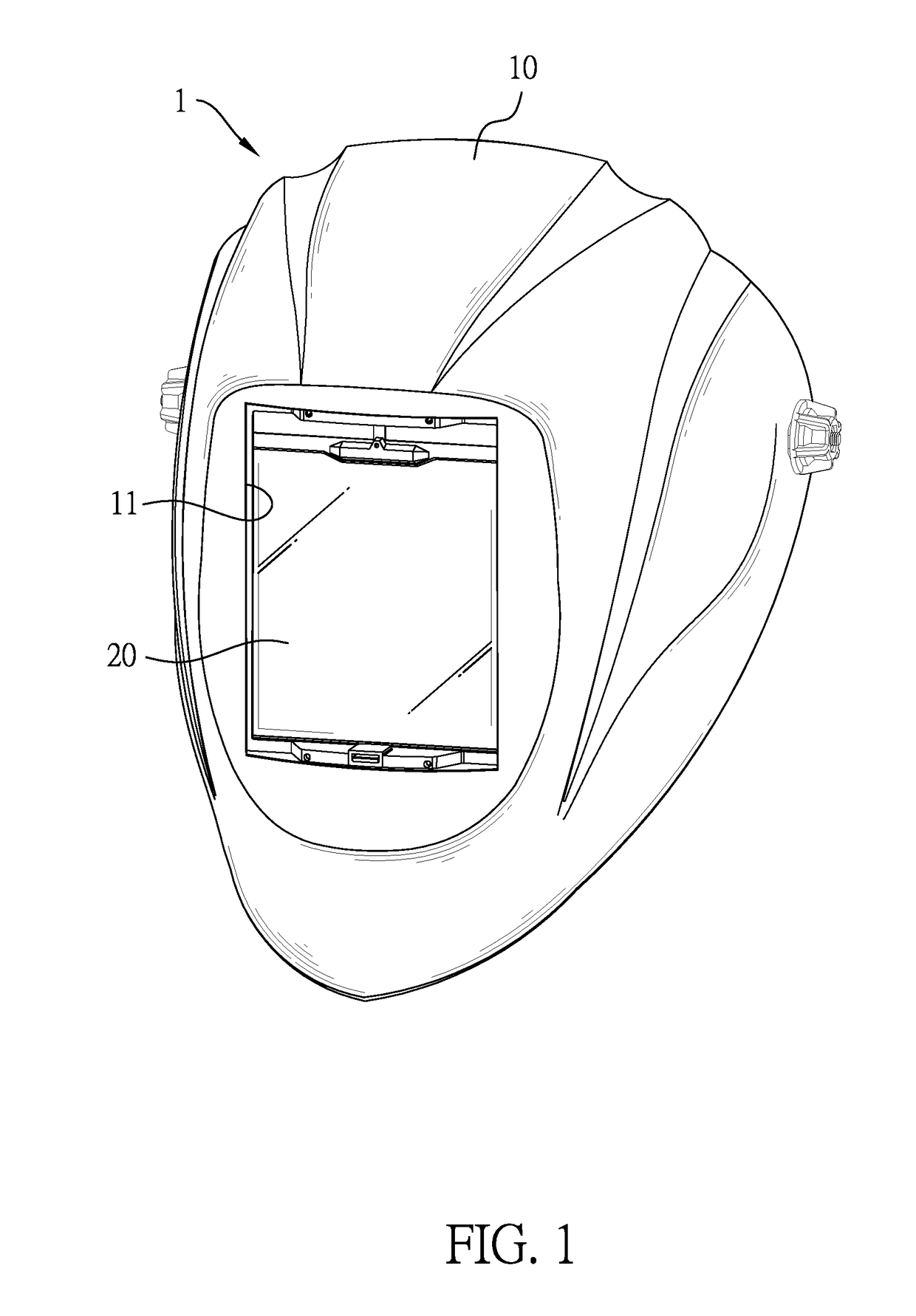

[0031]With reference to FIG. 1, the present disclosure is a power saving welding helmet 1. The power saving welding helmet 1 may reduce power consumption to save more electric power.

[0032]The power saving welding helmet 1 includes a helmet shell 10 and a lens device 20. The helmet shell 10 includes a mounting hole 11. The lens device 20 is mounted in the mounting hole 11 of the helmet shell 10.

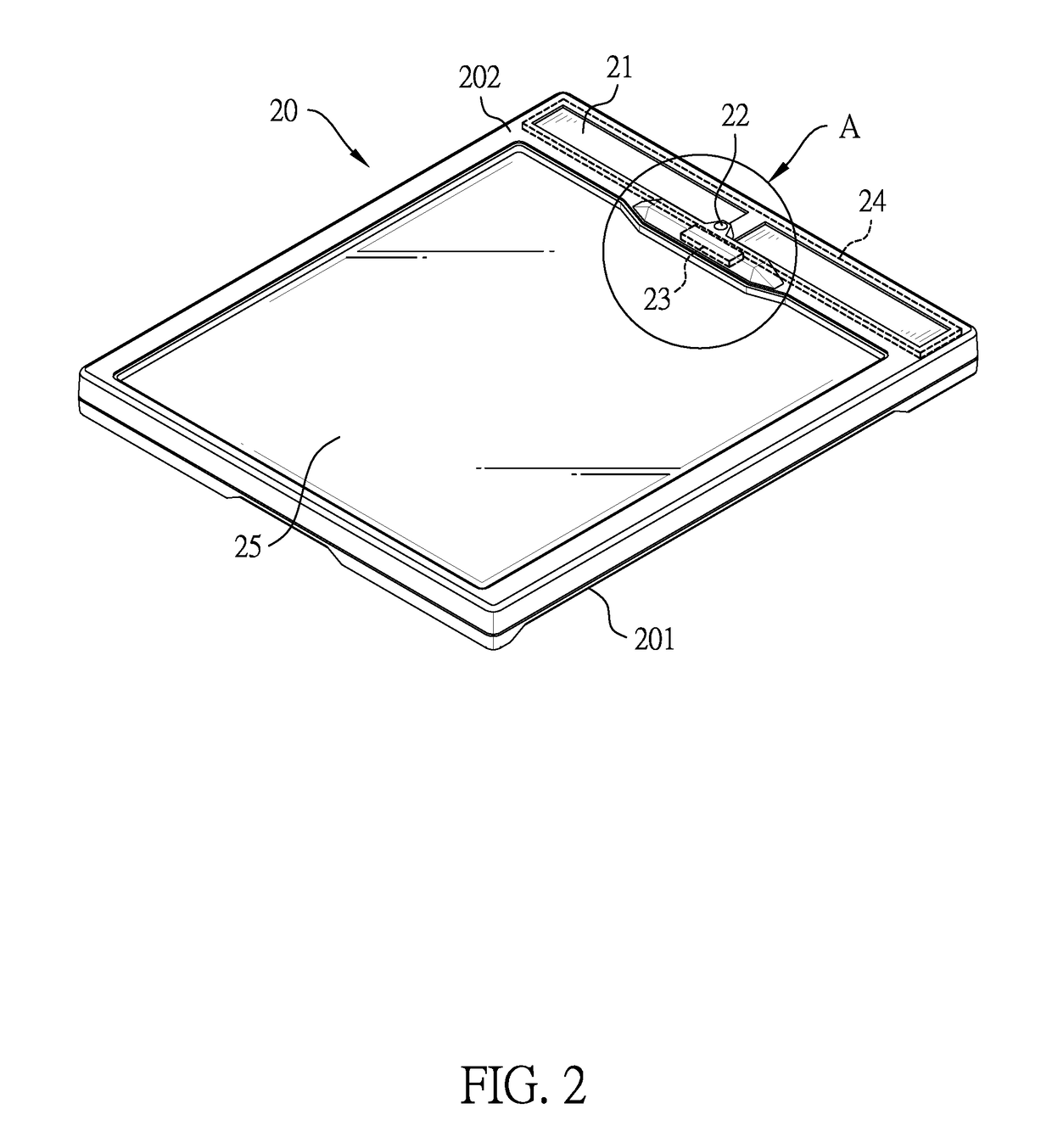

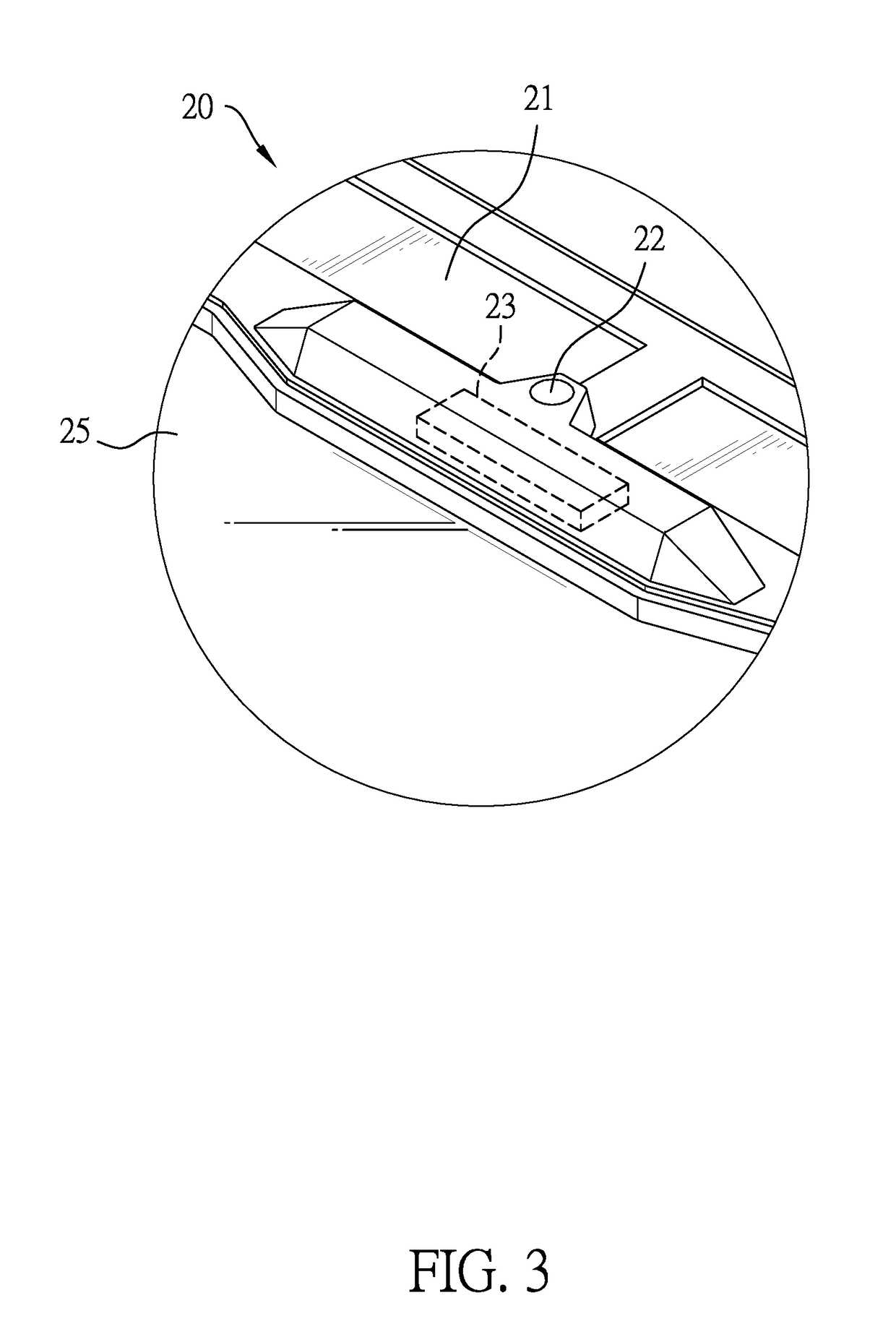

[0033]With reference to FIGS. 2 and 3, the lens device 20 has an inner surface 201 and an outer surface 202, and alternatively includes a solar panel 21, and a light sensor 22. The lens device 20 further includes a magnetic sensor 23, a filter control unit 24, and a filter lens 25.

[0034]With reference to FIG. 5, in one embodiment, the lens device 20 may not include the solar panel 21, and the light sensor 22, but may include the magnetic sensor 23, the filter control unit 24, and the filter lens 25. The filter control unit 24 is electrically connected to the magnetic sensor 23, and the filter ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap