Automatic Initiation of Priming Sequence for Metering Pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

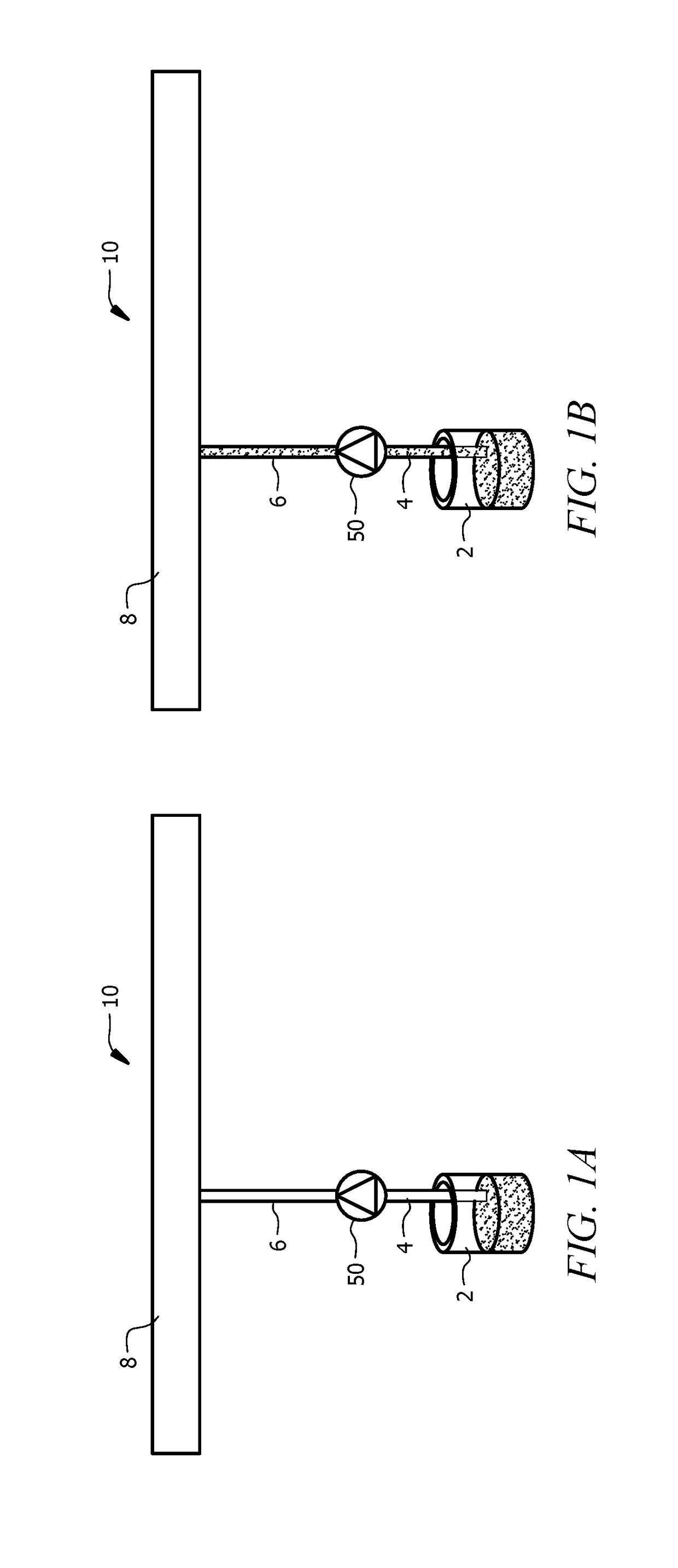

[0039]Referring now to FIG. 1A, an exemplary system using a metering pump is described. Metering pump system (10) for pumping a specified volume of liquid in a specified time includes a storage tank (2), a metering pump (50), and a process fluid tank (8). The metering pump (50) is fluidly coupled with the storage tank (2) by suction tubing (4), and the metering pump (50) is fluidly coupled with the process fluid tank (8) by injection tubing (6). Accordingly, the metering pump (50) can be operated to pump fluid from the storage tank (2) to the process fluid tank (8), as shown in FIG. 1B, in a specified time at a desired flow rate. The initial priming sequence of the pump (50) is the process of filling the tubing (4, 6) with fluid to a primed condition shown in FIG. 1B. Typically, this process takes several pumping cycles to fill the tubing (4, 6) adequately prior to being able to inject fluid into the process fluid tank (8). Although any type of metering pump can be incorporated into...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap