Main stop valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]Hereinafter, a preferred embodiment of the present disclosure will be described in detail with reference to the accompanying drawings.

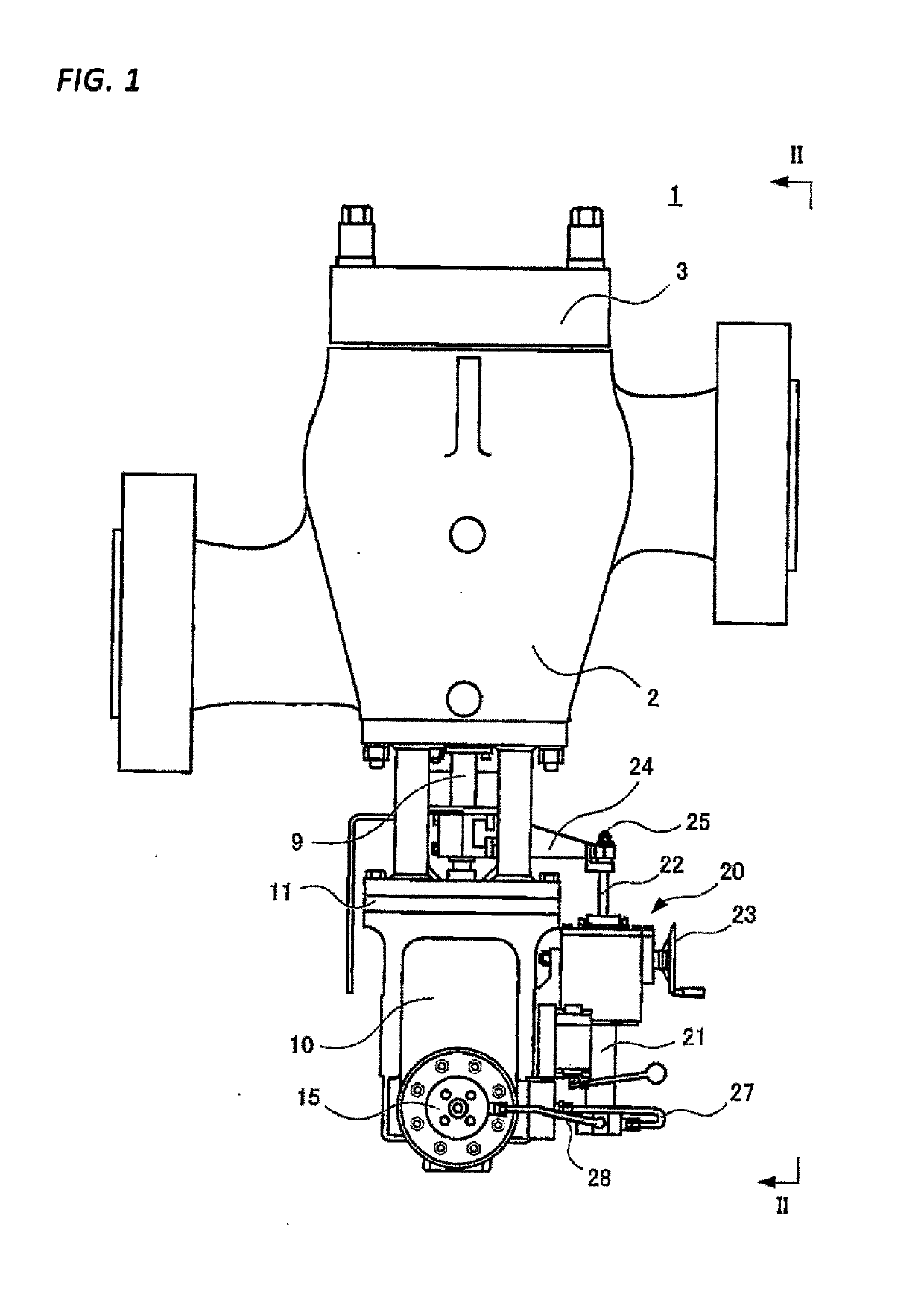

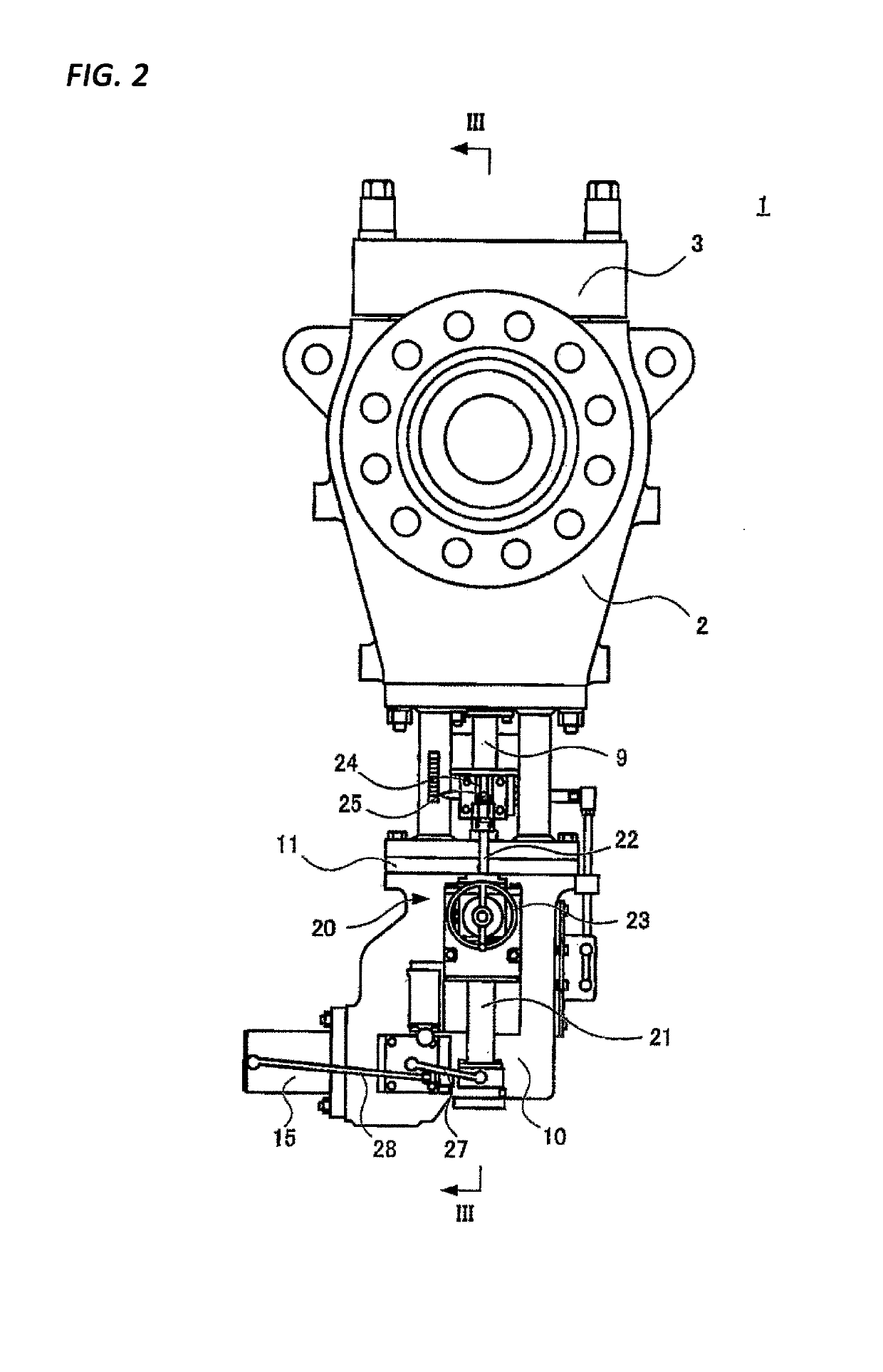

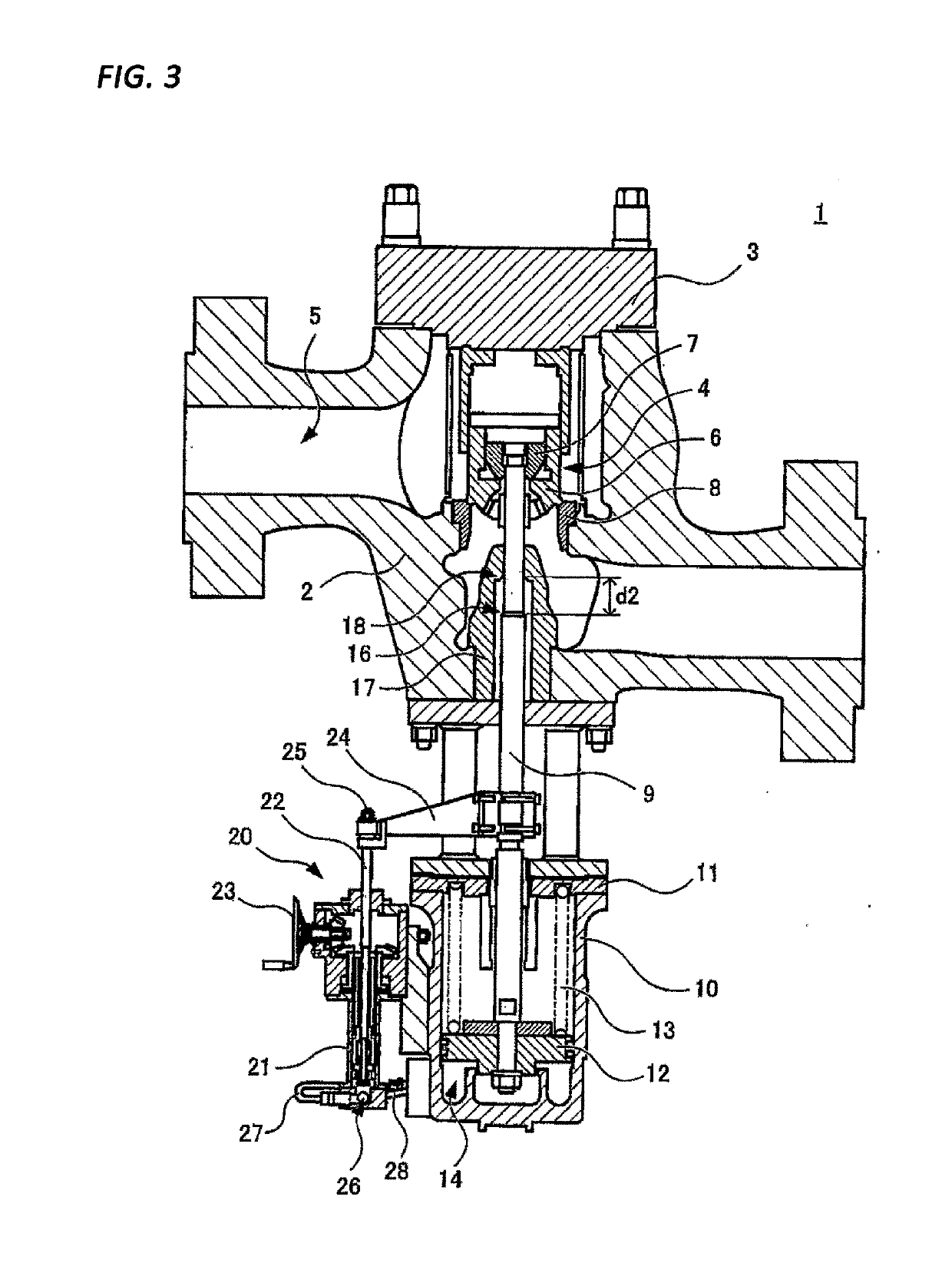

[0025]First, with reference to FIGS. 1 to 3, the overall configuration of a main stop valve 1 according to an embodiment of the present disclosure will be described. The main stop valve 1 is a hydraulic differential type T&T valve. FIG. 1 is a front view of the main stop valve 1. FIG. 2 is a side view of the main stop valve 1 (a view taken along a line II-II illustrated in FIG. 1). FIG. 3 is a vertical sectional view of the main stop valve 1 (a view taken along a line illustrated in FIG. 2).

[0026]The main stop valve 1 is a T&T valve that closes a steam passage 5 by a valve body 4 installed inside a casing 2 and a casing cover 3. As illustrated in FIG. 3, in the present embodiment, the valve body 4 includes a main valve 6 and a balance valve 7. A valve rod 9 connected to the valve body 4 is lowered, and when the valve body 4 is seated on a valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com