Algae reduction device for air handler systems

a technology of air handler and reduction device, which is applied in the direction of space heating and ventilation, lighting and heating apparatus, heating types, etc., can solve the problems of algae growth, possible corrosion, condensation, etc., and achieve the effect of reducing the need for a powerful and expensive pump, reducing the strain on the pump, and increasing the fluid latency of the pan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

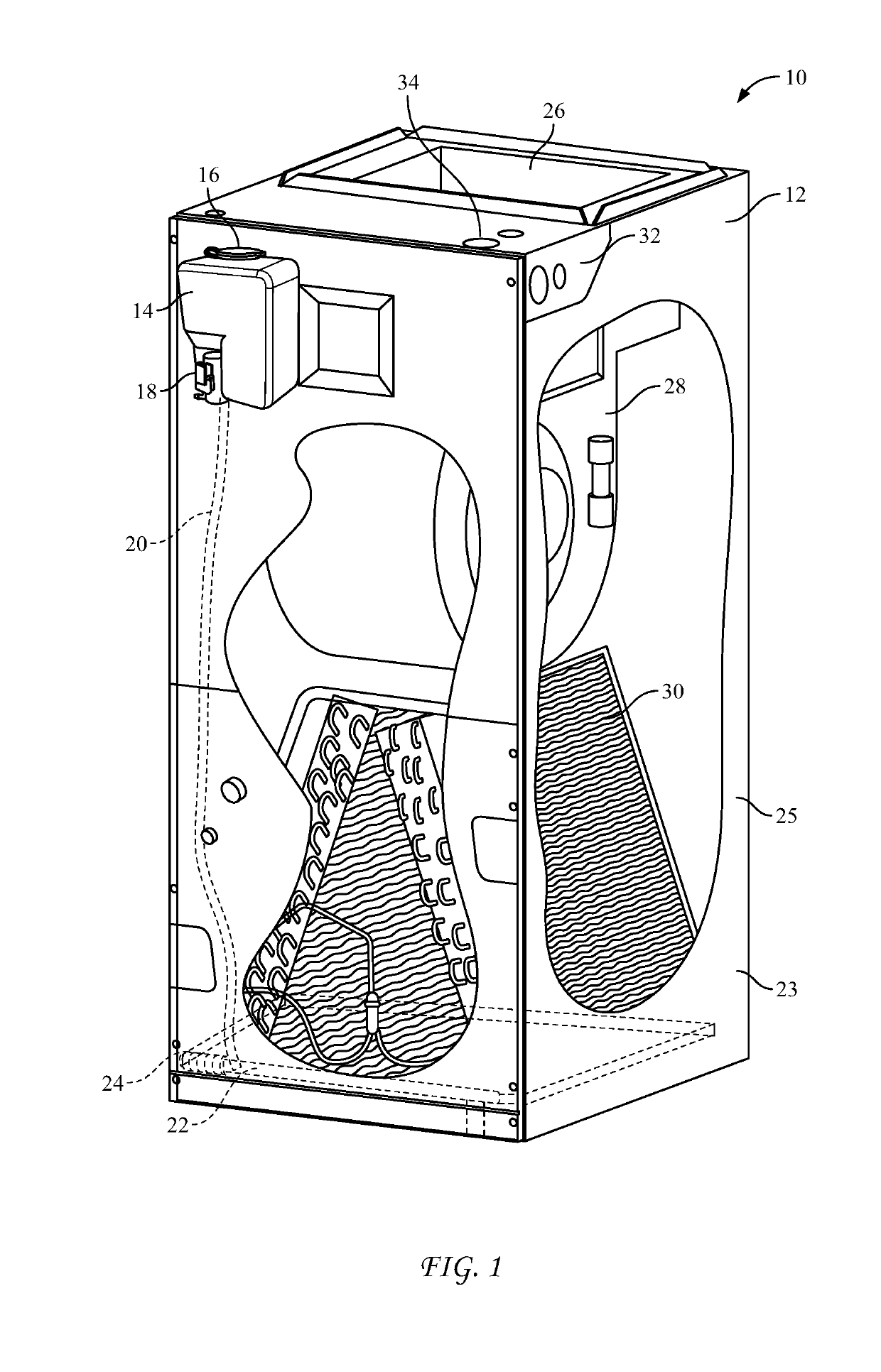

[0031]FIG. 1 shows an air handling system generally designated with the reference numeral 10. The air handling system 10 is an air handler with the housing 12. The housing 12 includes a kit of parts attached to the housing 12 for reducing algae growth.

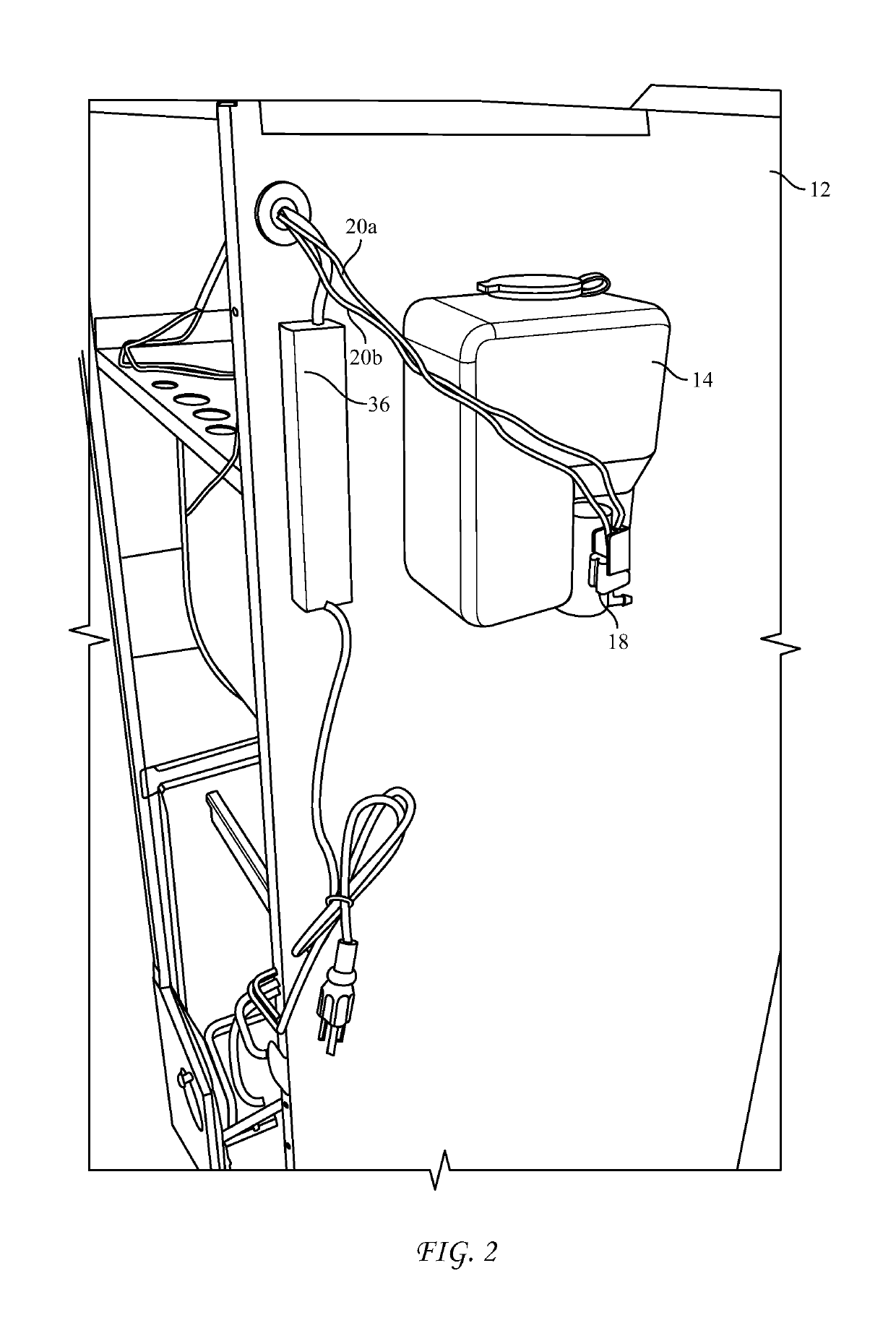

[0032]The kit of parts includes the reservoir 14 having a removable lid 16 and a pump motor 18. The reservoir 14 is preferably a heat resistant plastic reservoir designed to hold fluids having a pH range of 2-7.

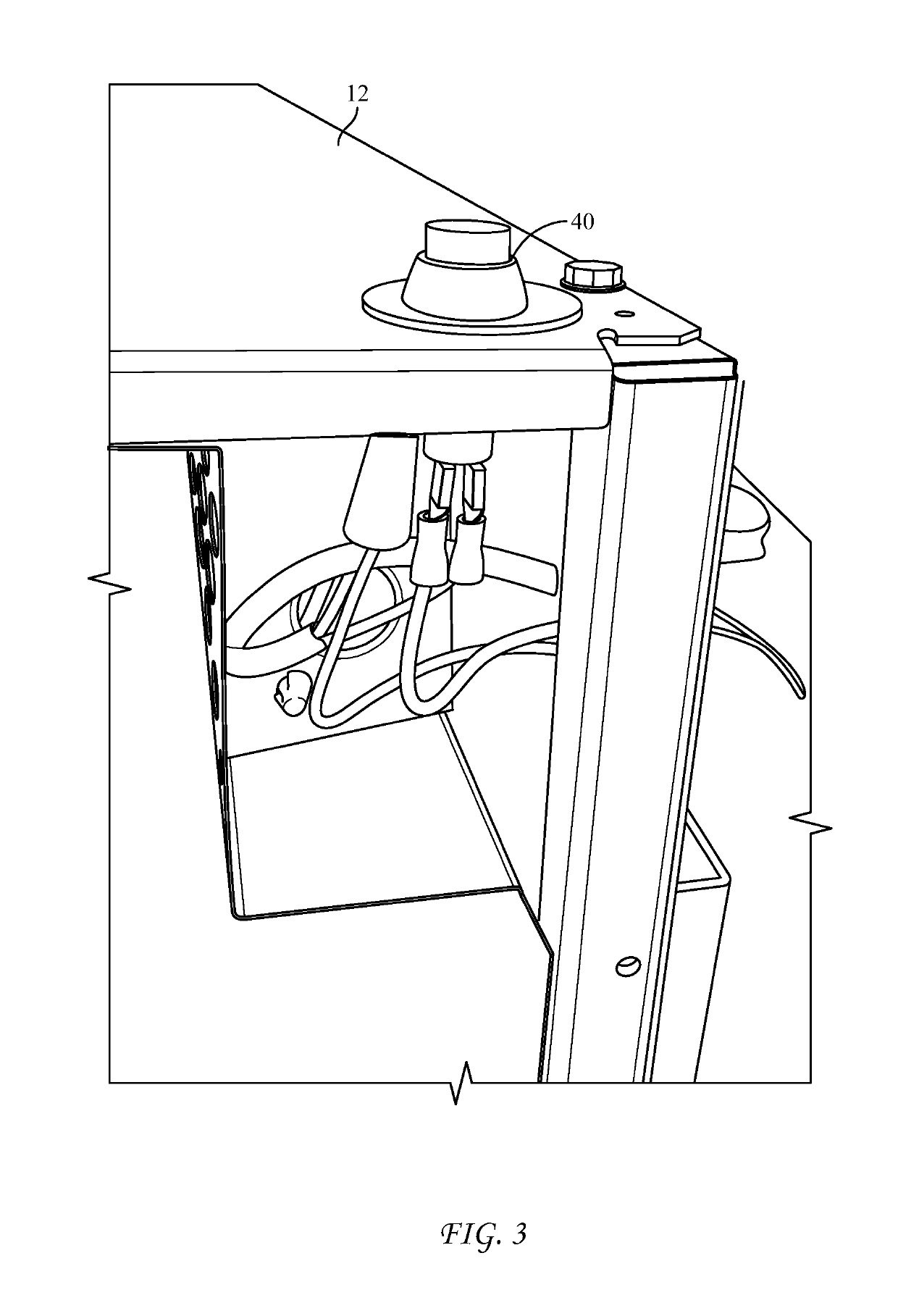

[0033]The tube 20 attaches to the pump motor for delivering fluid from the reservoir 14. The housing 12 includes a pan 22 removeably mounted at the bottom 23 of the housing 12 for capturing fluid such as condensate and leaking fluid. The tube 20 attaches to the pan 22 with a tube clasp 24.

[0034]Preferably the tube 20 is manufactured from a flexible and heat resistant material such as silicon. The housing includes a blower 28 and at least one heat exchanger 30. The blower 28 draws air past the heat exchanger 30 to either heat or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com