Torsional severe plastic deformation method for metal bar, employing surface polishing to improve mechanical properties of metal bar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]Hereinafter, the present invention will be described in more detail on the basis of preferred embodiments of the invention. However, the following embodiments are merely examples for helping understanding of the invention, and the scope of the invention is not reduced or limited by the embodiments.

[0021]In the present invention, it is proposed that a process of continuously removing surface defects is added to an existing torsion process to delay a shear fracture phenomenon, and processes for forming ultrafine crystal grains or nanocrystal grains are improved by applying a sufficient amount of plastic deformation to a material.

[0022]When applying the surface treatment of the present invention, much greater deformation by further delaying surface fracture than existing torsional severe plastic deformation methods, and the degree of ultrafine crystallization or nano crystallization may be reinforced to be finer.

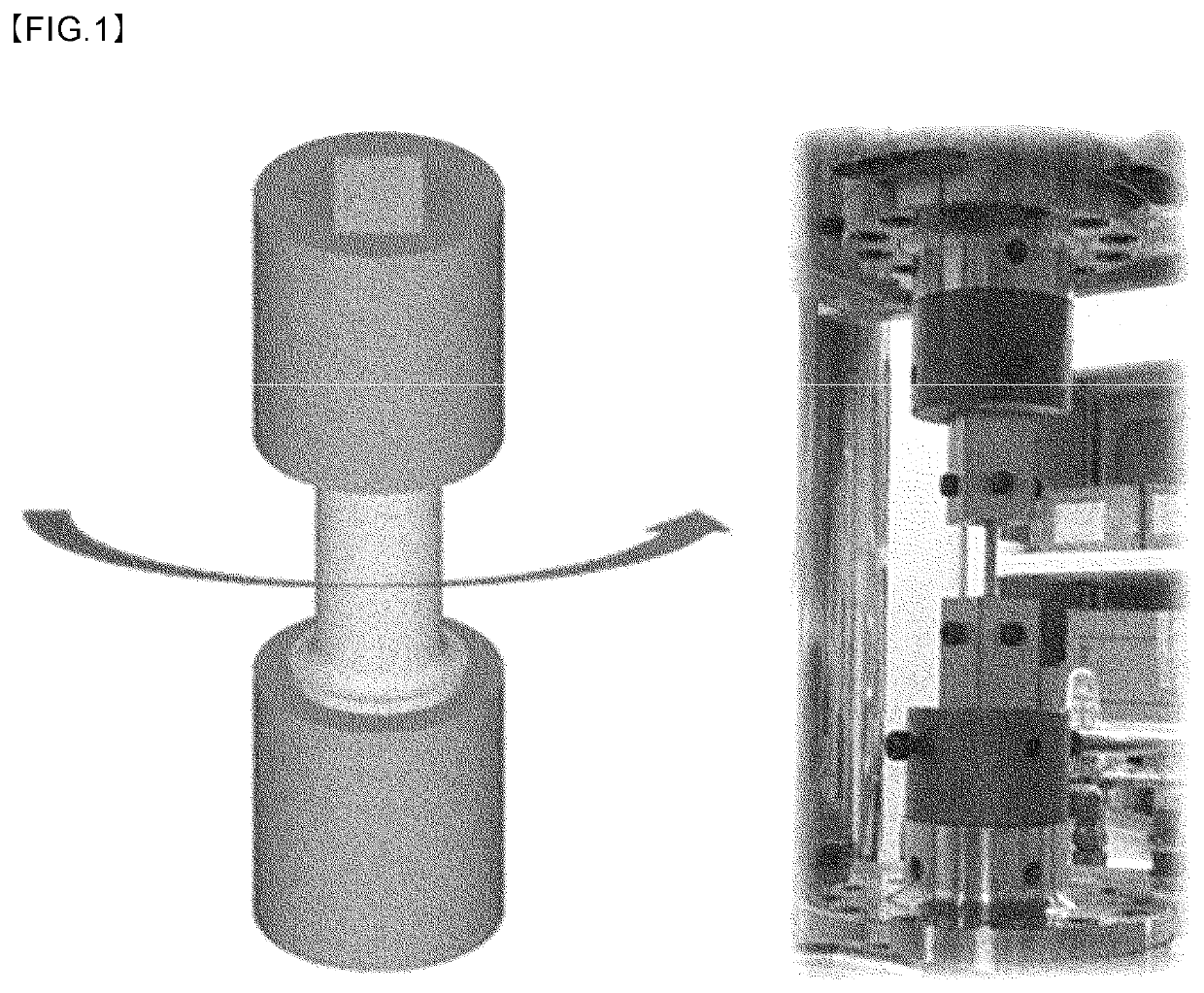

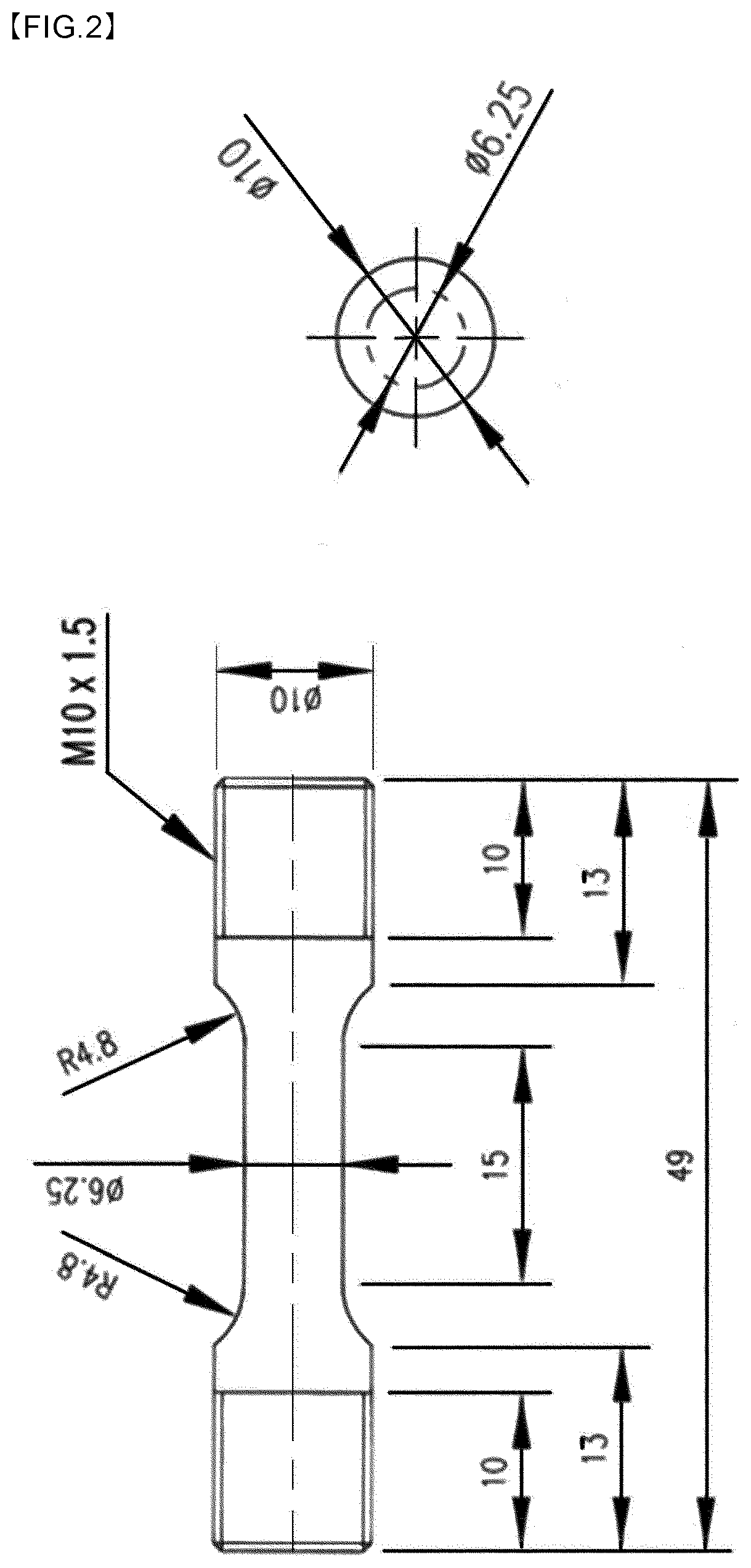

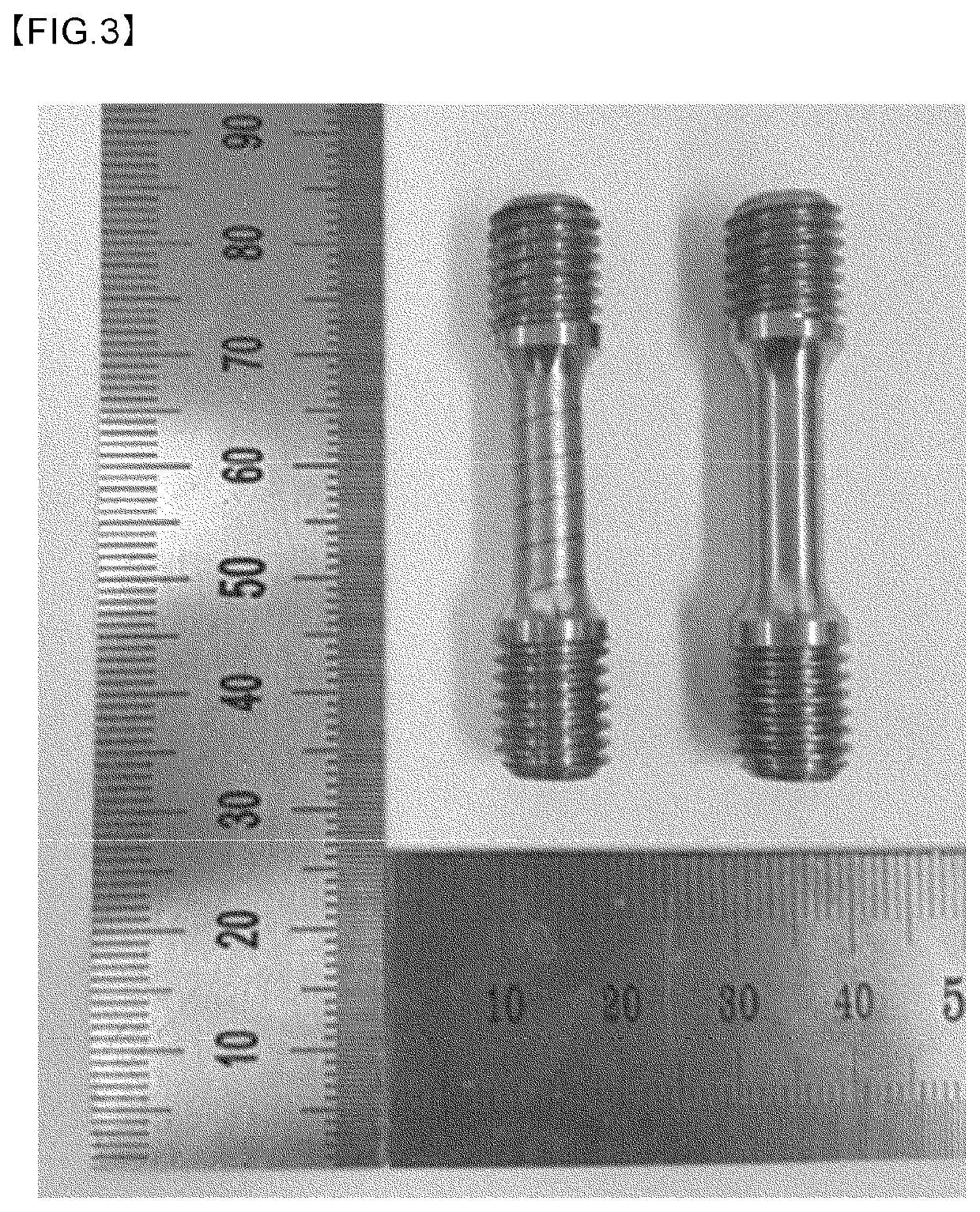

[0023]FIG. 1 is a view illustrating a torsional severe plastic defor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Mechanical properties | aaaaa | aaaaa |

| Strain point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com