Cut-resistant safety shoe

a safety shoe and cutting technology, applied in the field of shoes, can solve the problems of shoe being completely or almost undamaged, and achieve the effect of avoiding damage to the sho

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

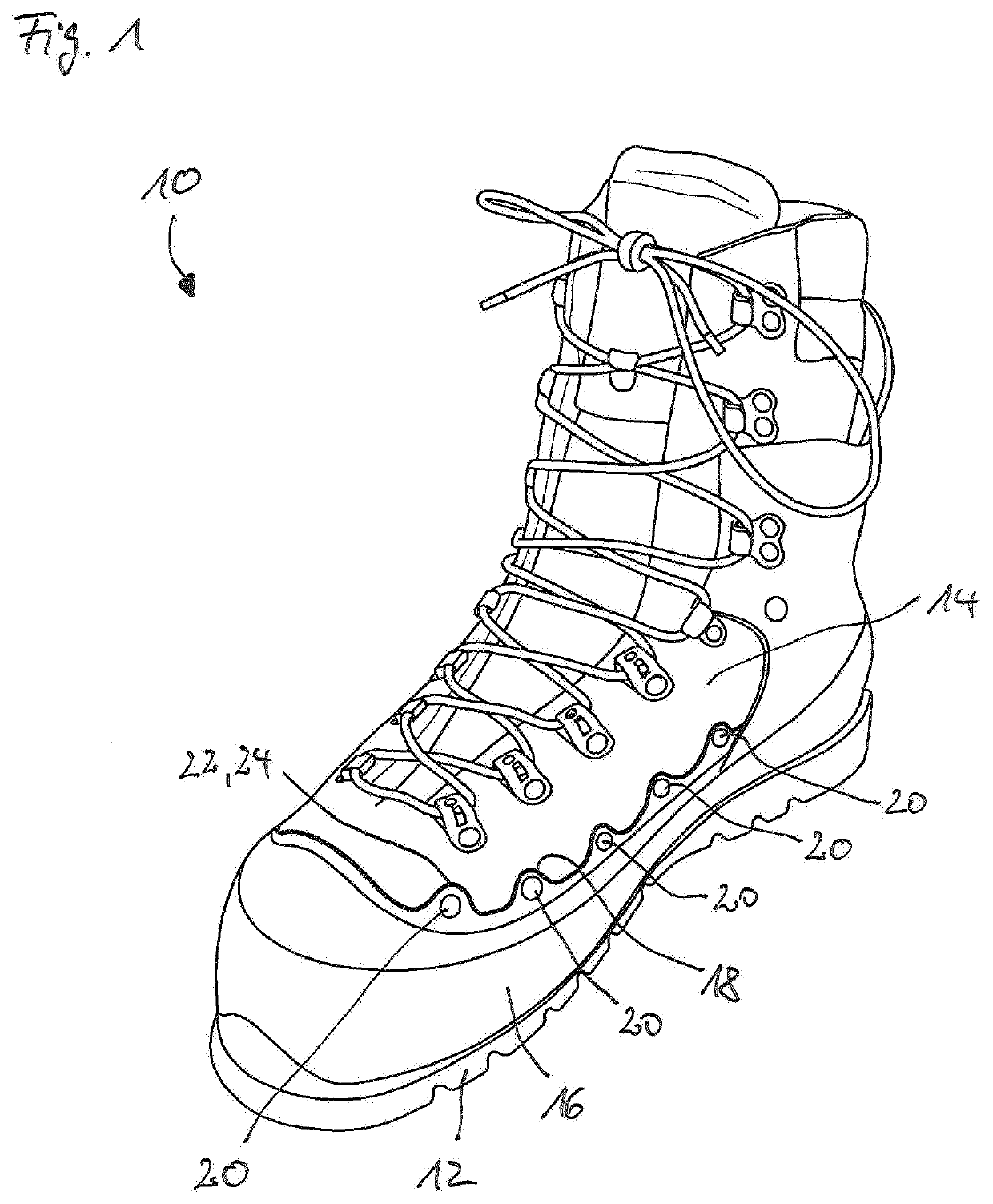

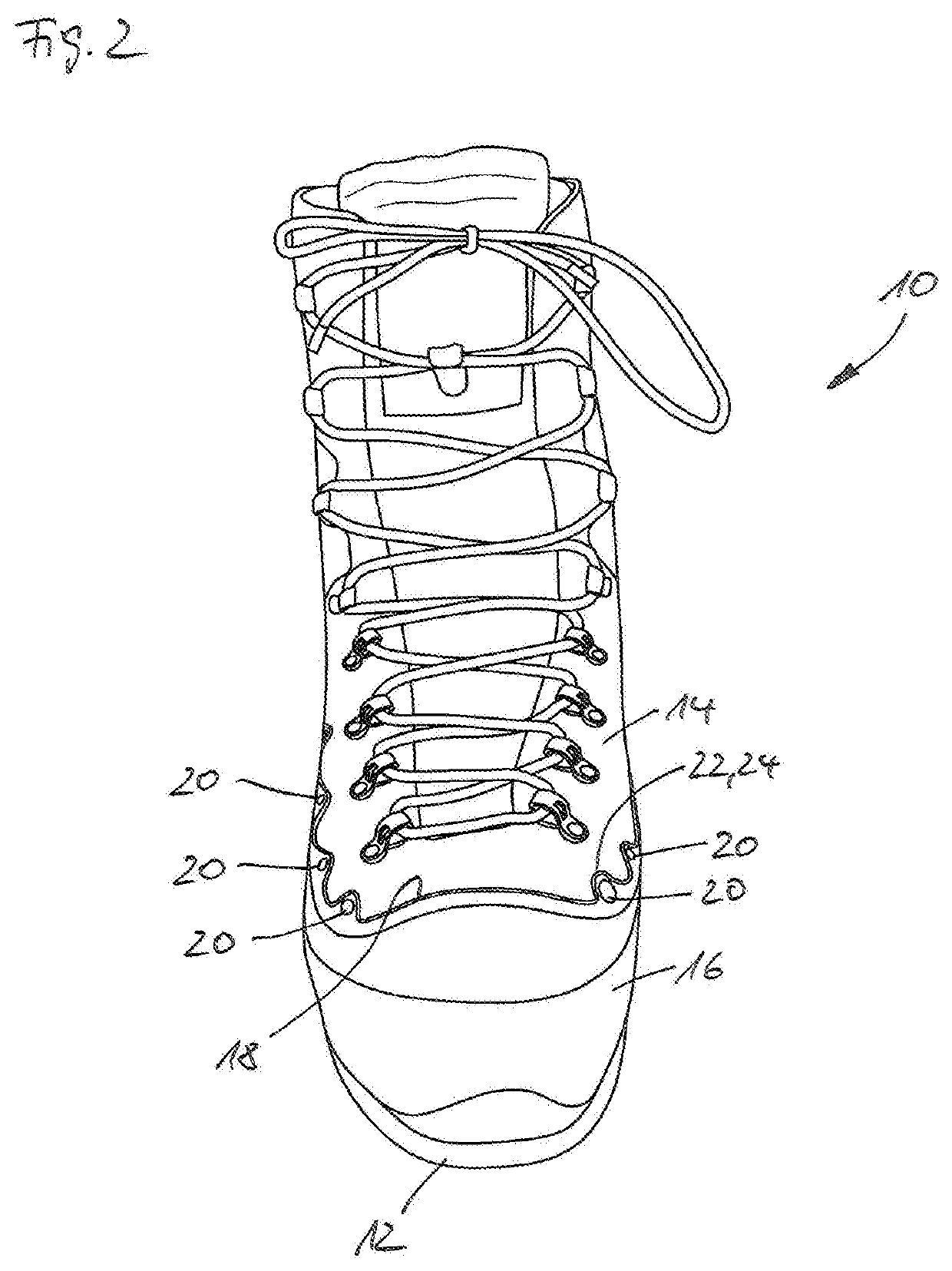

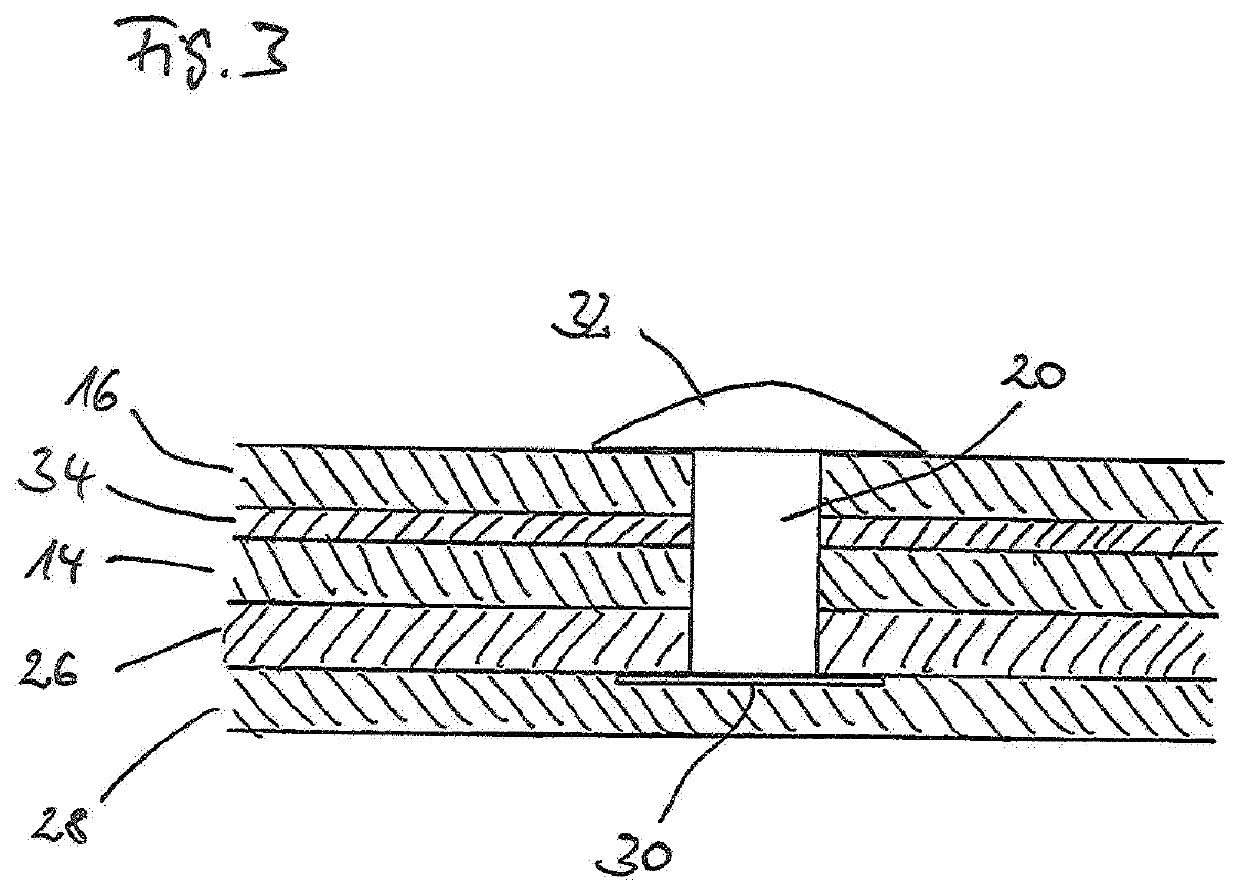

[0023]FIG. 1 shows a perspective side view of a shoe according to the invention. FIG. 2 shows a front view of a shoe according to the invention. The shoe 10 is, in the present case, a shoe 10 having a raised collar as common in, for example, hiking shoes, working shoes, and, in particular, in cut-resistant safety shoes. The shoe 10 has a profiled sole 12 made of rubber. The upper material 14 of the shoe 10 is, in the present example, at least in parts, made of fabric. The sole 12 is adjoined by a rand 16 adhesively bonded to the sole 12. The rand 16 is, in the present example, also made of rubber. The lateral reinforcement of the shoe 10 provided for by the rand 16 may completely surround the shoe 10 or may only be provided in sections. An edge 18 of the rand 16 is, in parts, designed so as to be undulated or serrated. The rand 18 is connected to the upper material by rivets 20. These rivets 20 are arranged in the wave crests 22 or spikes 24 of the undulated edge 18. In addition, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap