Device to puncture wing environmental seals and reduce deployment force

a technology of environmental seals and wing, applied in the direction of projectiles, weapons types, weapons, etc., can solve the problems of guidance system failure, insufficient centripetal energy by itself to enable the wings, practicable limit of missile spin speed, etc., and achieve the effect of increasing the cutting action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

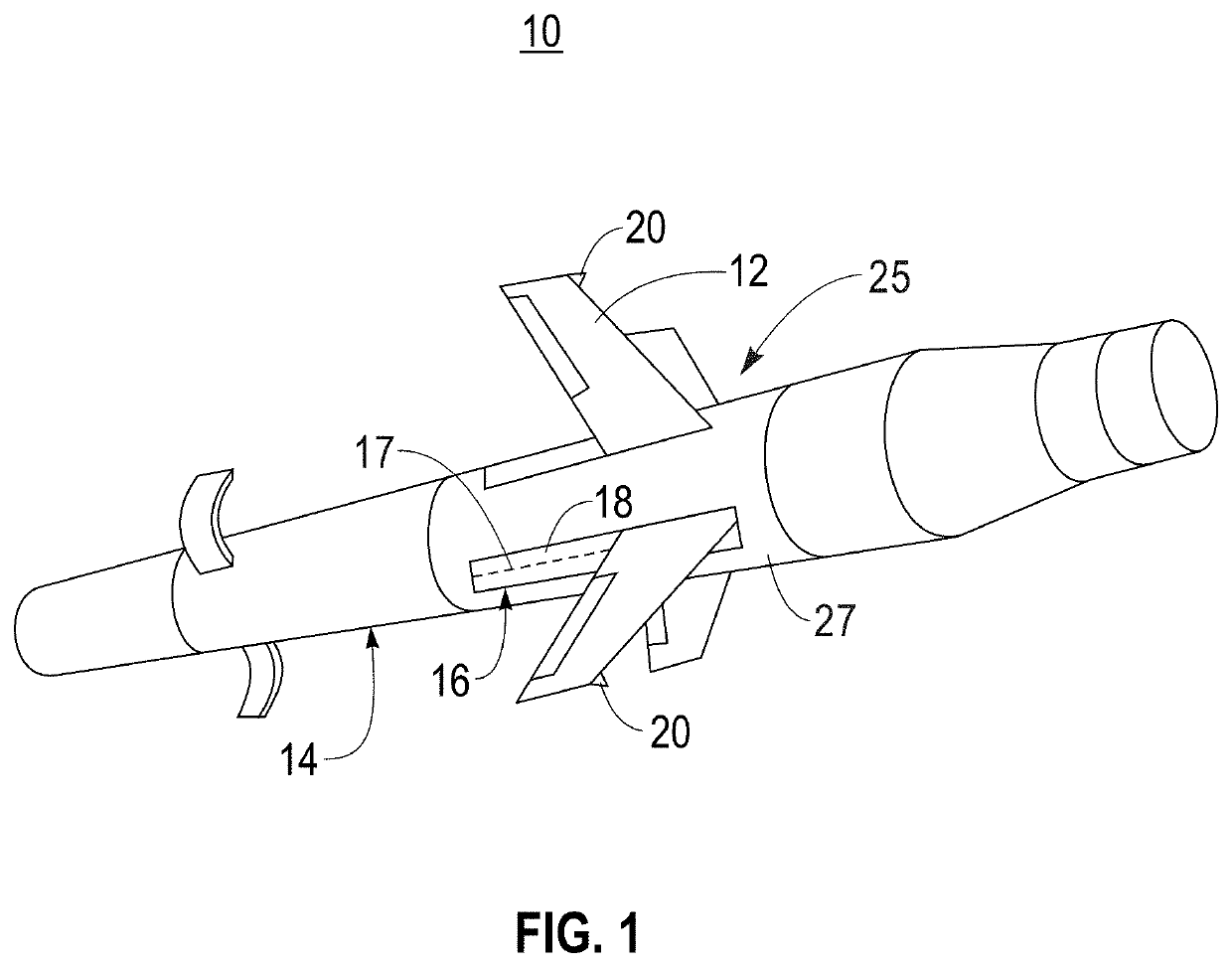

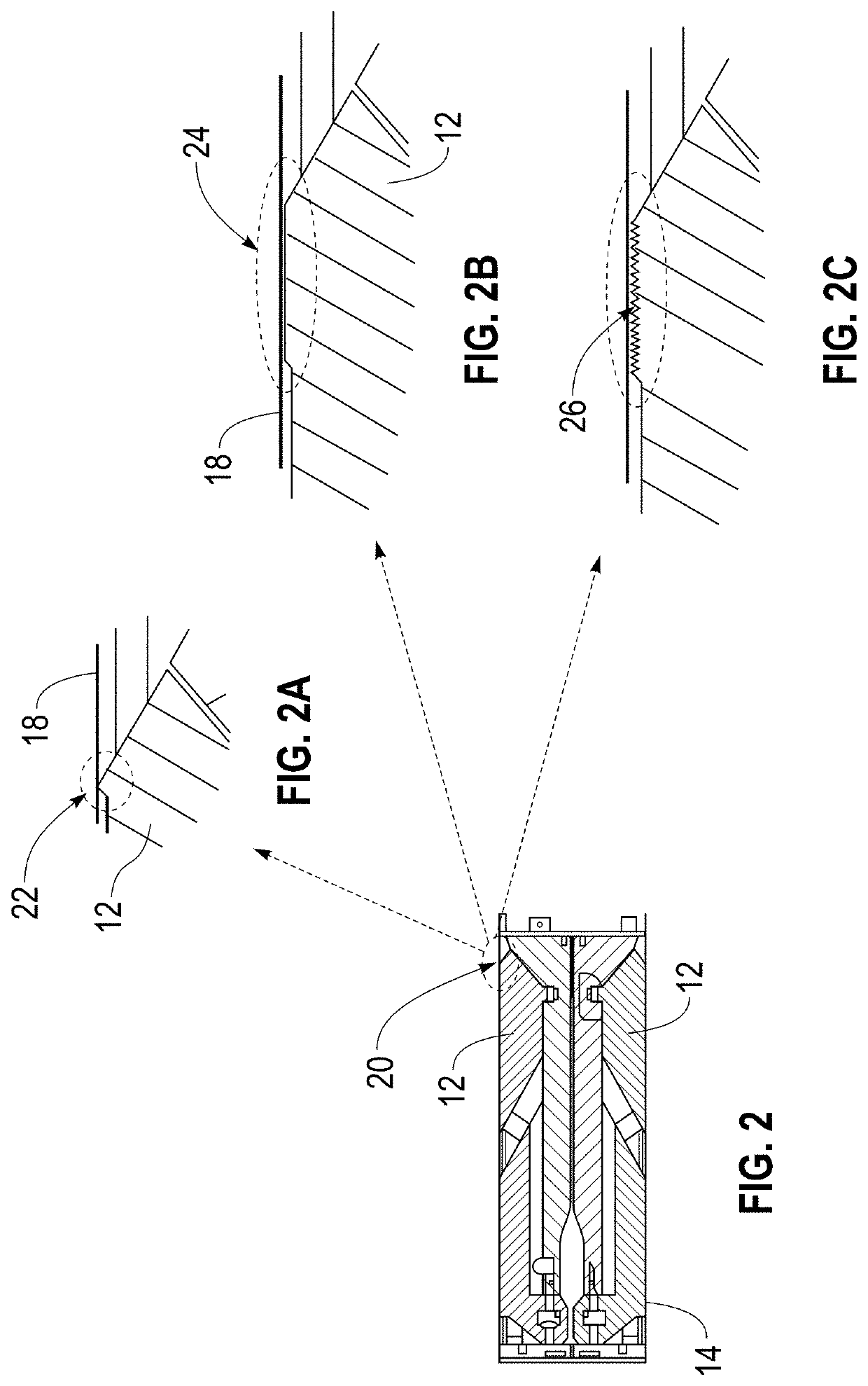

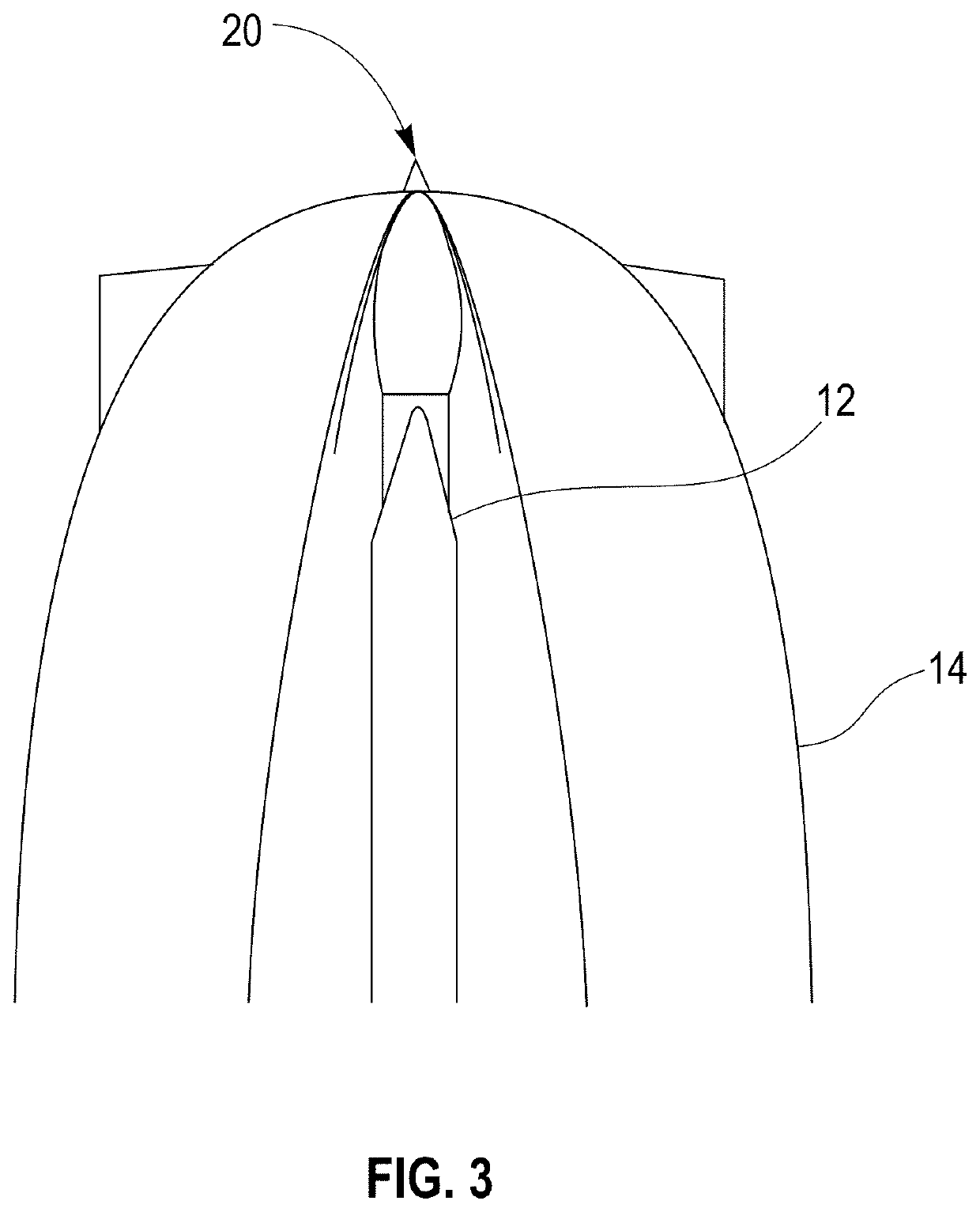

[0020]In one embodiment a puncturing feature is provided on the wing of the rocket to facilitate breaking through the wing slot seal. In one embodiment, the puncturing feature is small sharp region on the leading edge near the wing tip. This is the region of the wing that first contacts the wing slot seal. In one embodiment, the small sharp feature has a sharp point that will puncture the wing slot seal just like a bird's egg tooth.

[0021]In one embodiment, the puncturing feature is a sharp edge extended along the leading edge of the wing to provide a cutting action as the wing passes through the wing slot seal. In one embodiment the additional length of the sharp edge would slice the wing slot seal as the wing passes through just like a knife blade. In one embodiment, the extended sharp edge puncturing feature has serrations to increase the cutting action.

[0022]The puncturing feature is an improvement over the prior art deployment initiators by reducing the amount of force required ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com