Latch tool

a technology of latching tool and toolstring, which is applied in the direction of tubing catchers, drilling accessories, and accessories for wellbore/wells. it can solve the problems of safety hazards for well operators, tool catcher devices that do not automatically operate, and catastrophic damage to toolstrings and wellbores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

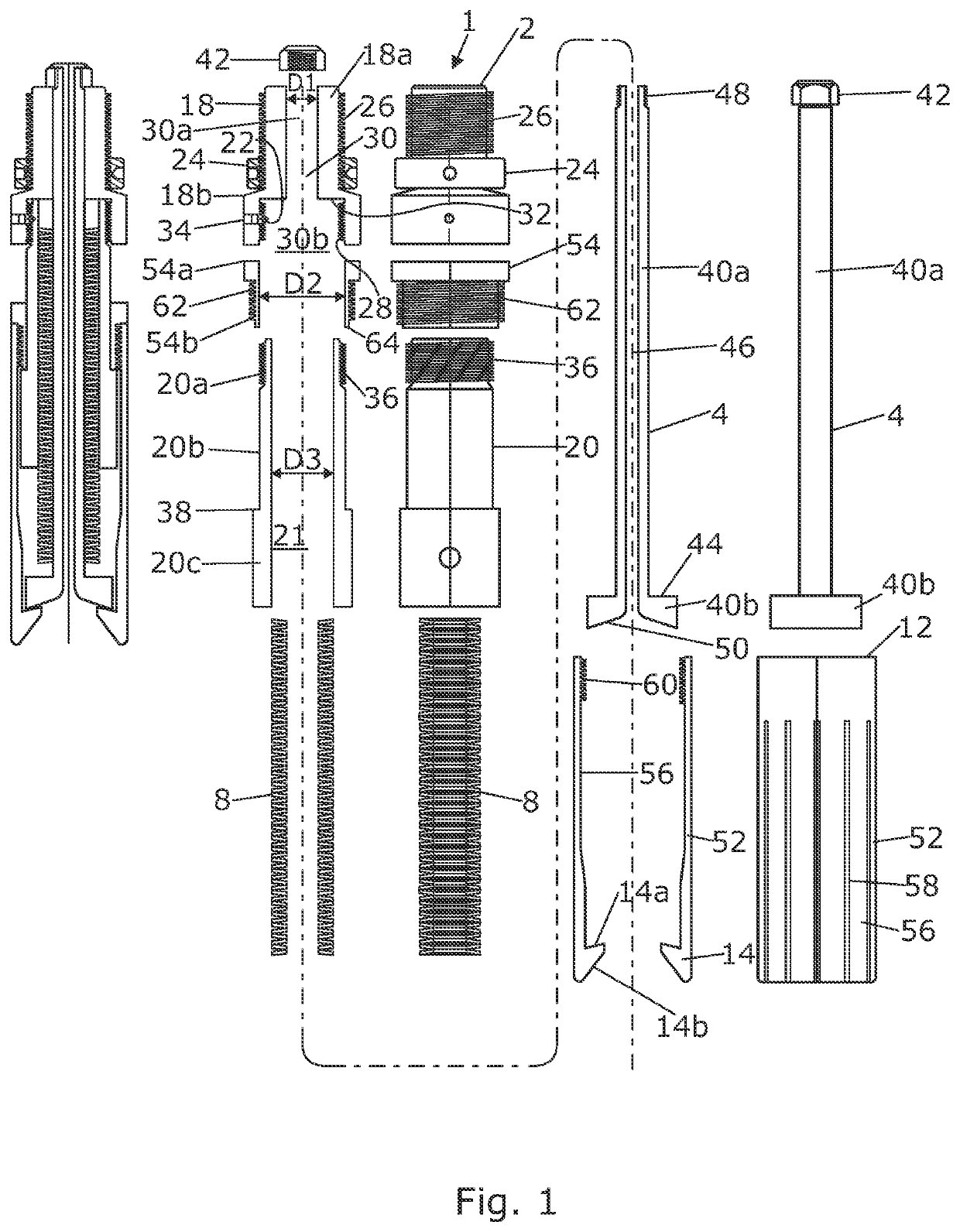

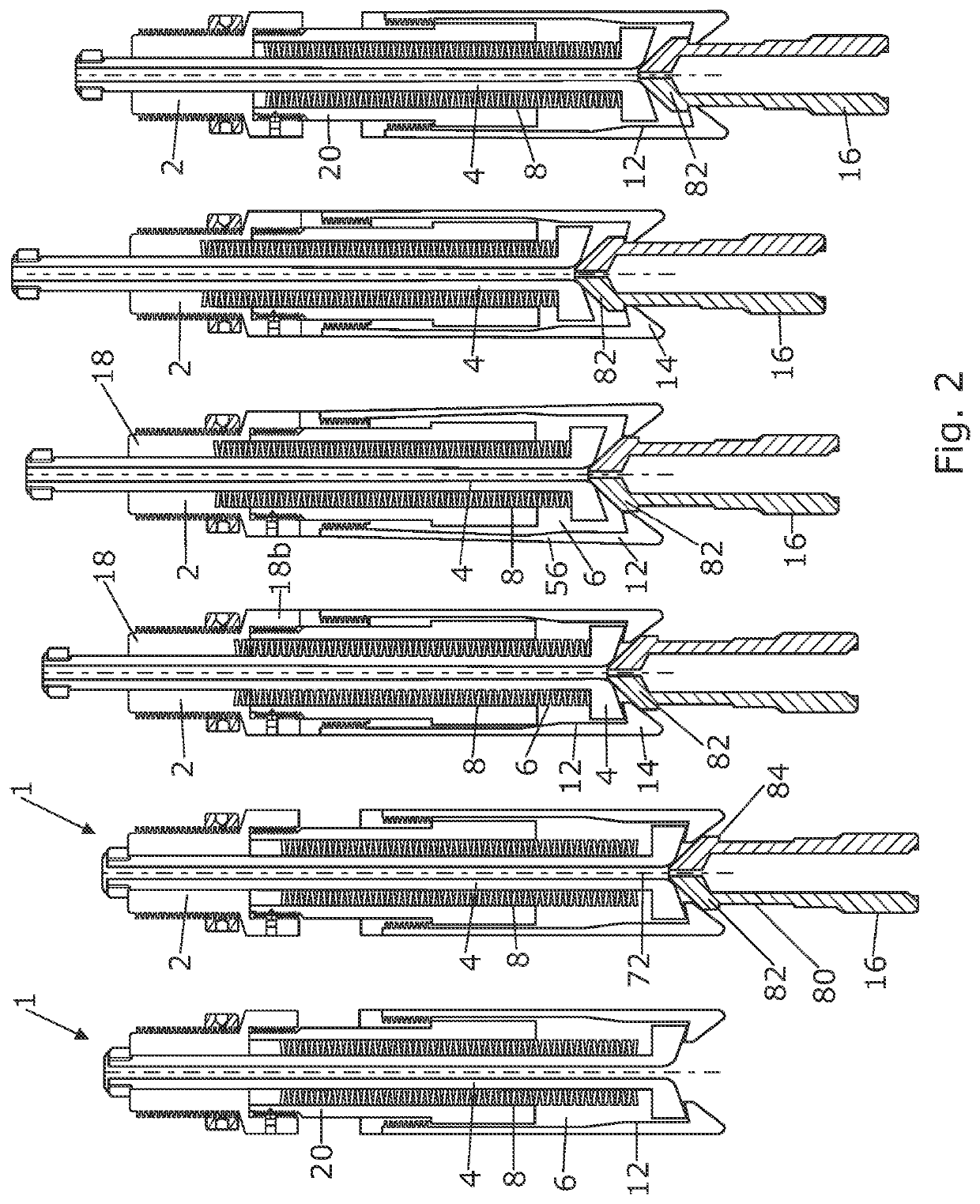

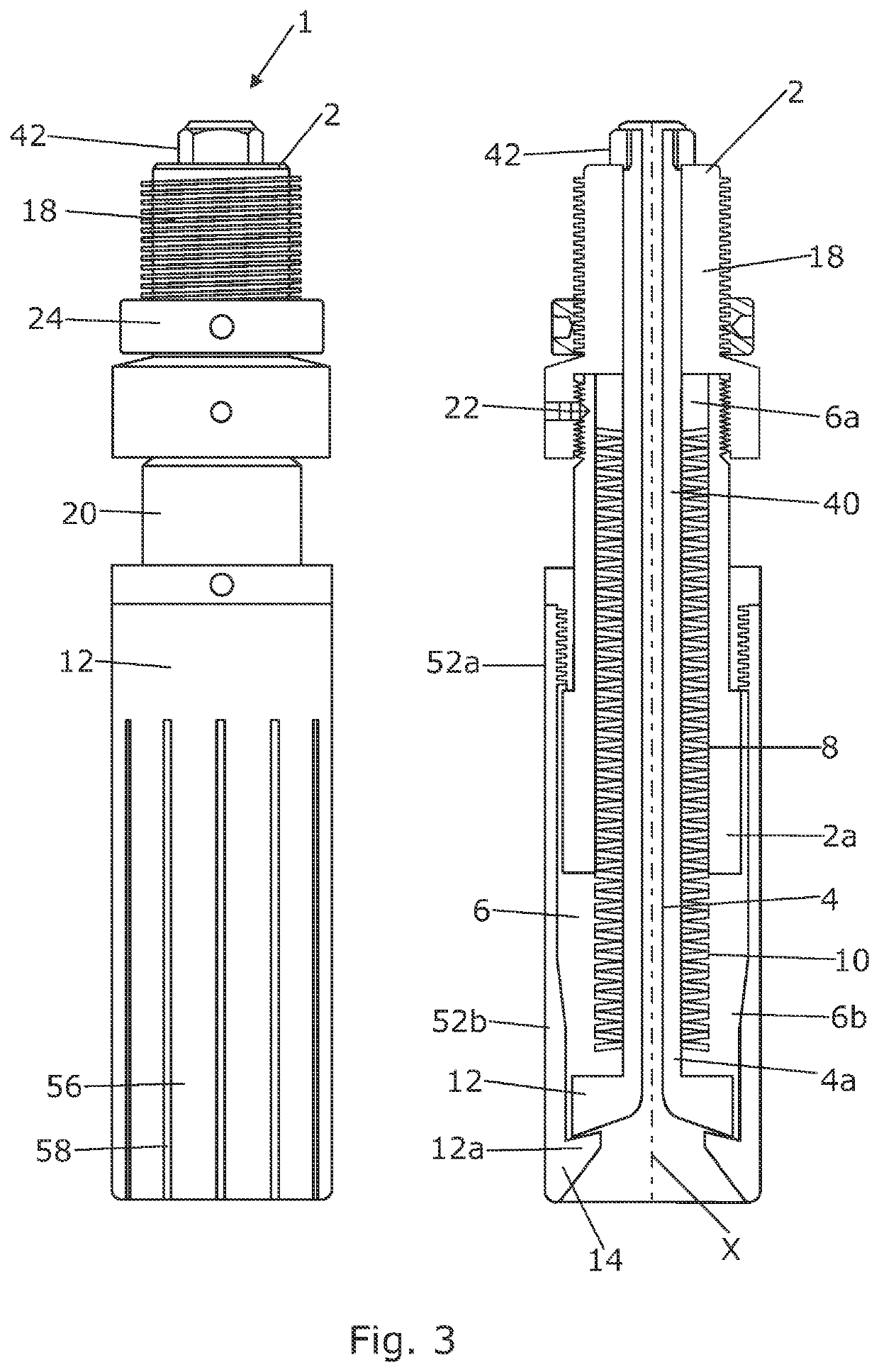

lass="d_n">[0023]The main components / assemblies of the bumper latch are shown in FIGS. 1 and 3. These include a substantially tubular anchor assembly 2 that has a longitudinal axis X. A core assembly 4 extends axially through the anchor assembly 2 and is mounted for sliding movement relative to the anchor assembly.

[0024]The anchor assembly 2 and the core assembly 4 together define a spring chamber 6 that extends parallel to the axis X and is located in the annular space between anchor assembly 2 and the core assembly 4. The upper end 6a of the spring chamber 6 is defined by the anchor assembly 2 and the lower end 6b is defined by the core assembly 4. The length L of the spring chamber 6 therefore changes as the core assembly 4 slides axially relative to the anchor assembly 2.

[0025]A compression spring 8 is located within the spring chamber 6 between the upper end 6a and the lower end 6b. In this embodiment the spring 8 comprises a plurality of disc springs (e.g. Belleville washers) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com