Flexible installation of a hydrocarbon liquefaction unit

a hydrocarbon liquefaction and installation technology, which is applied in the direction of refrigeration and liquifaction, lighting and heating equipment, solidification, etc., can solve the problems of large societal risk, large available land, and high environmental restrictions, so as to reduce mechanical effects, reduce ground footprint, and limit thermal losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

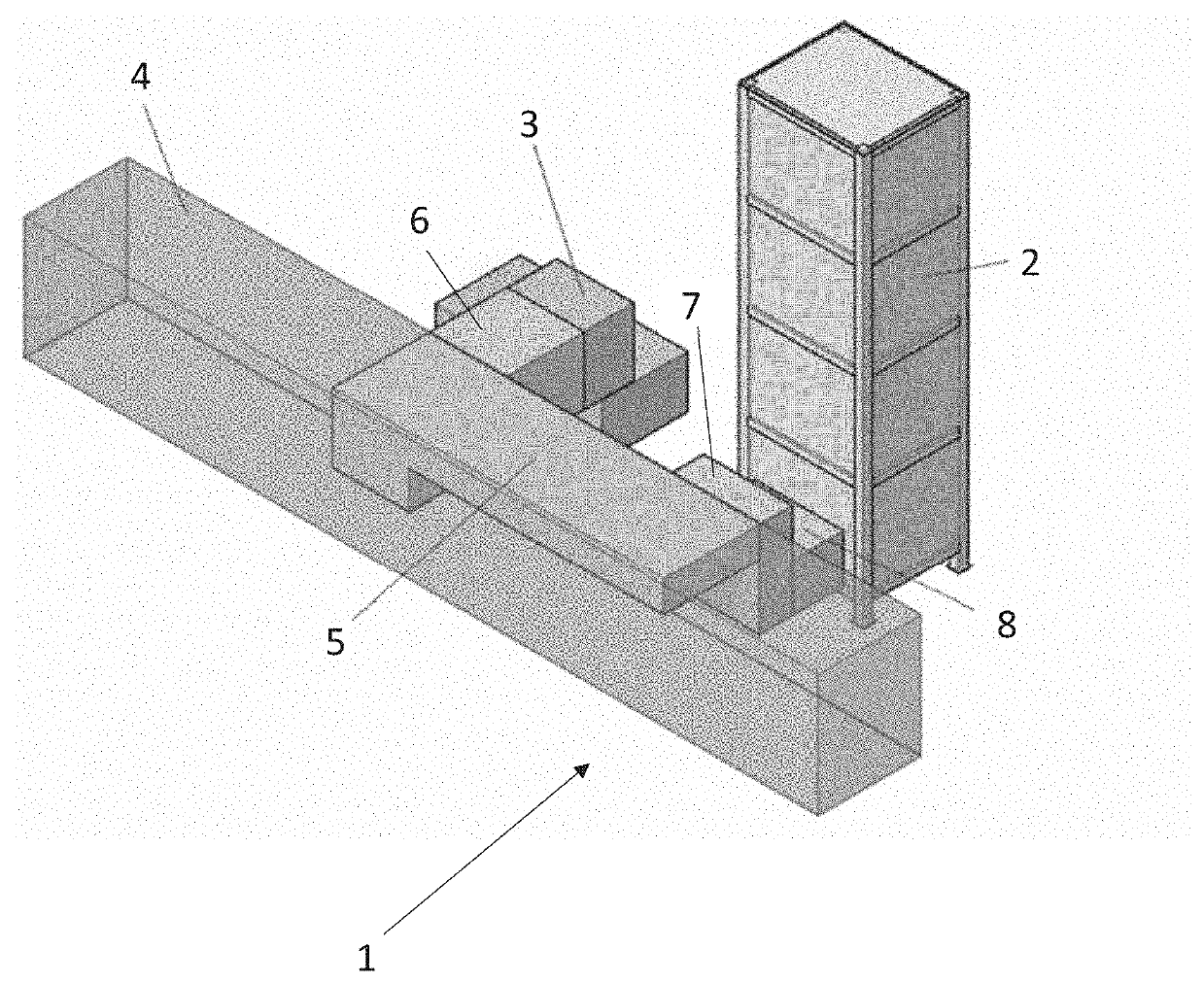

[0056]FIG. 1 shows a representation of a schematic diagram of a liquefaction unit according to one embodiment of the invention.

[0057]In FIG. 1, the hydrocarbon fluid liquefaction unit 1 comprises:[0058]at least one cryogenic cold box 2 comprising:[0059]at least one heat exchanger;[0060]a fixed assembly zone 8 on its outer wall;[0061]a device 3 for the various equipment required for implementing the cold fluid required for the liquefaction of a natural gas stream from a hydrocarbon supply stream;[0062]an interconnection module 4 comprising a pipe holder means and a set of pipes, control valves, and electricity connection and instrumentation 5, 6, 7, designed to connect said at least one cold box 2 to the at least one equipment device 3 for the cycle for refrigerating and / or separating C6+ type hydrocarbon elements contained in the natural gas.

[0063]The interconnection module 4 rests on a frame that allows it to be handled and is connected to the cold box in the vicinity of said assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com