Interferometer system and method for lens column alignment

a technology of interferometer and lens column, applied in the field of projection exposure system, can solve the problems of not providing accurate alignment information, interfering with each other, and not properly detecting all alignment problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

Reference will now be made in detail to an embodiment of the invention, examples of which are illustrated in the accompanying drawings.

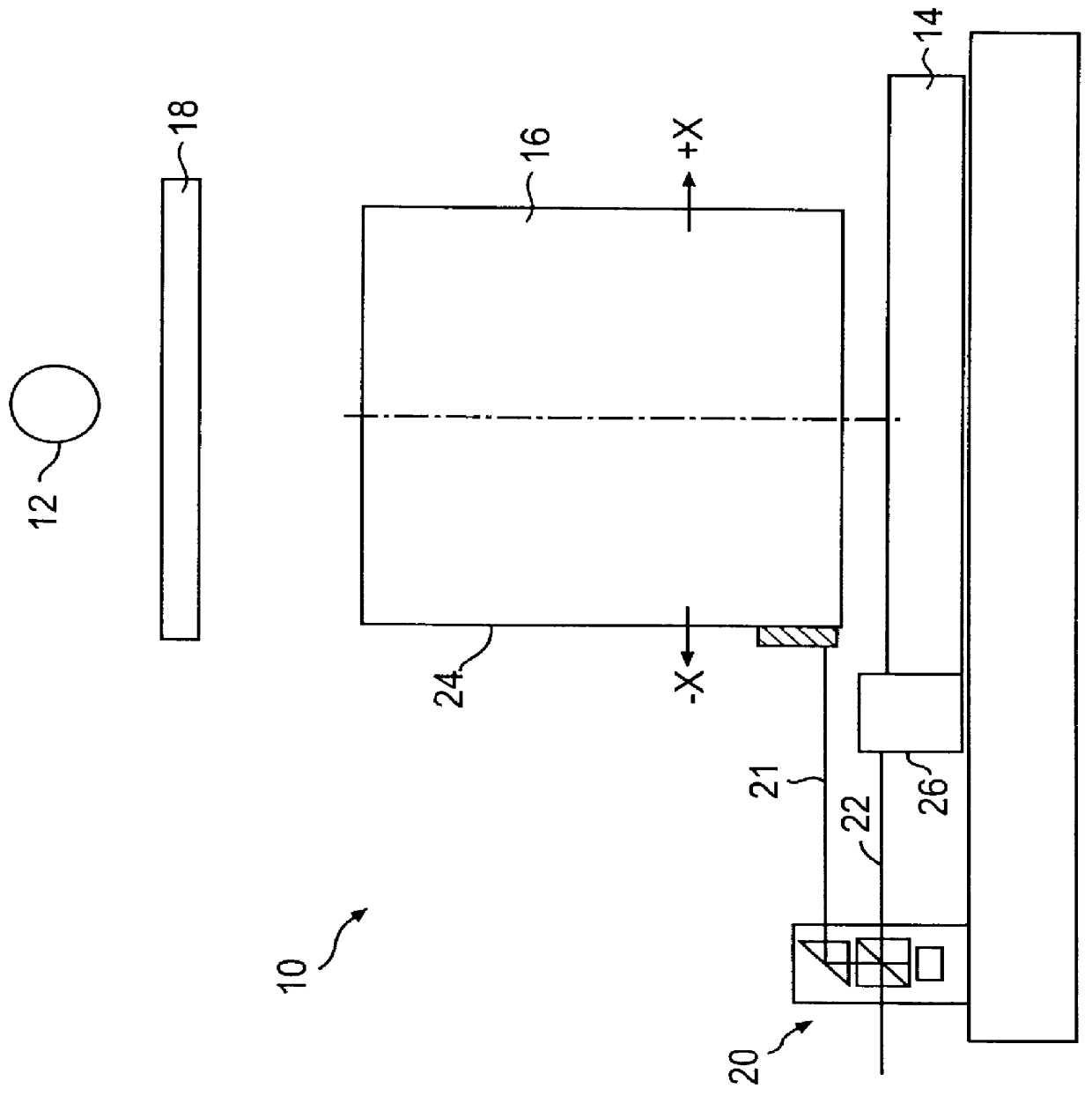

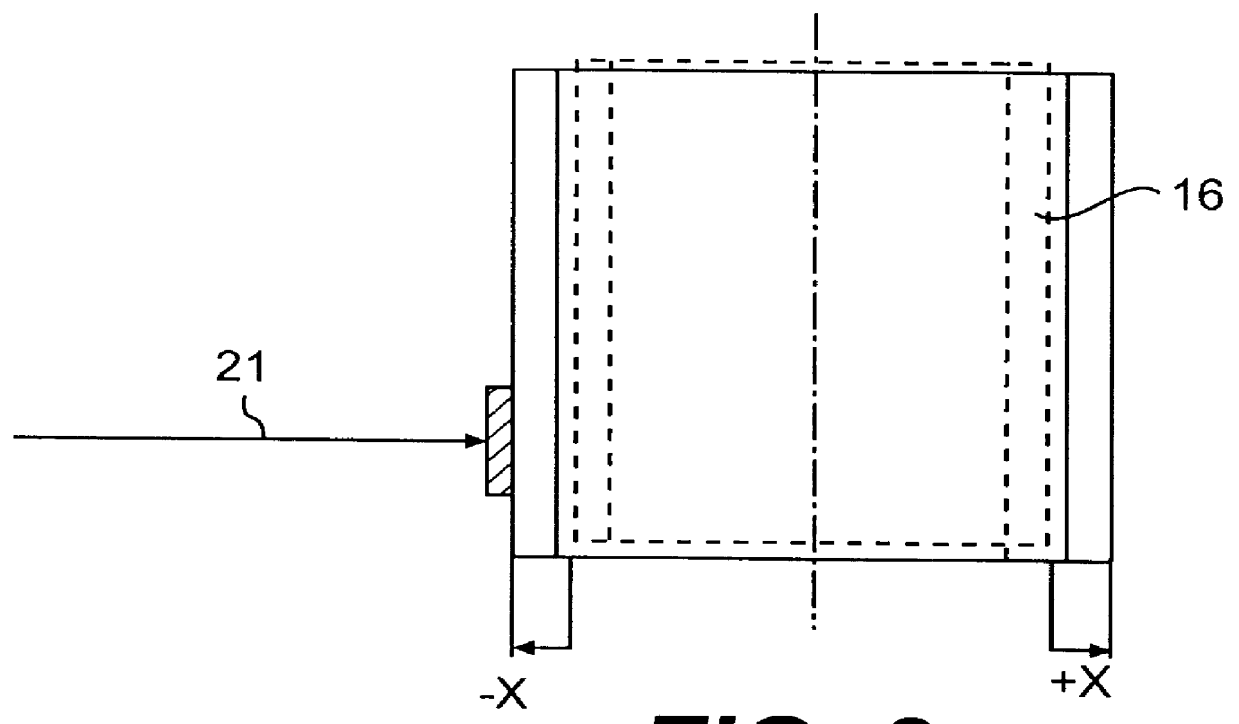

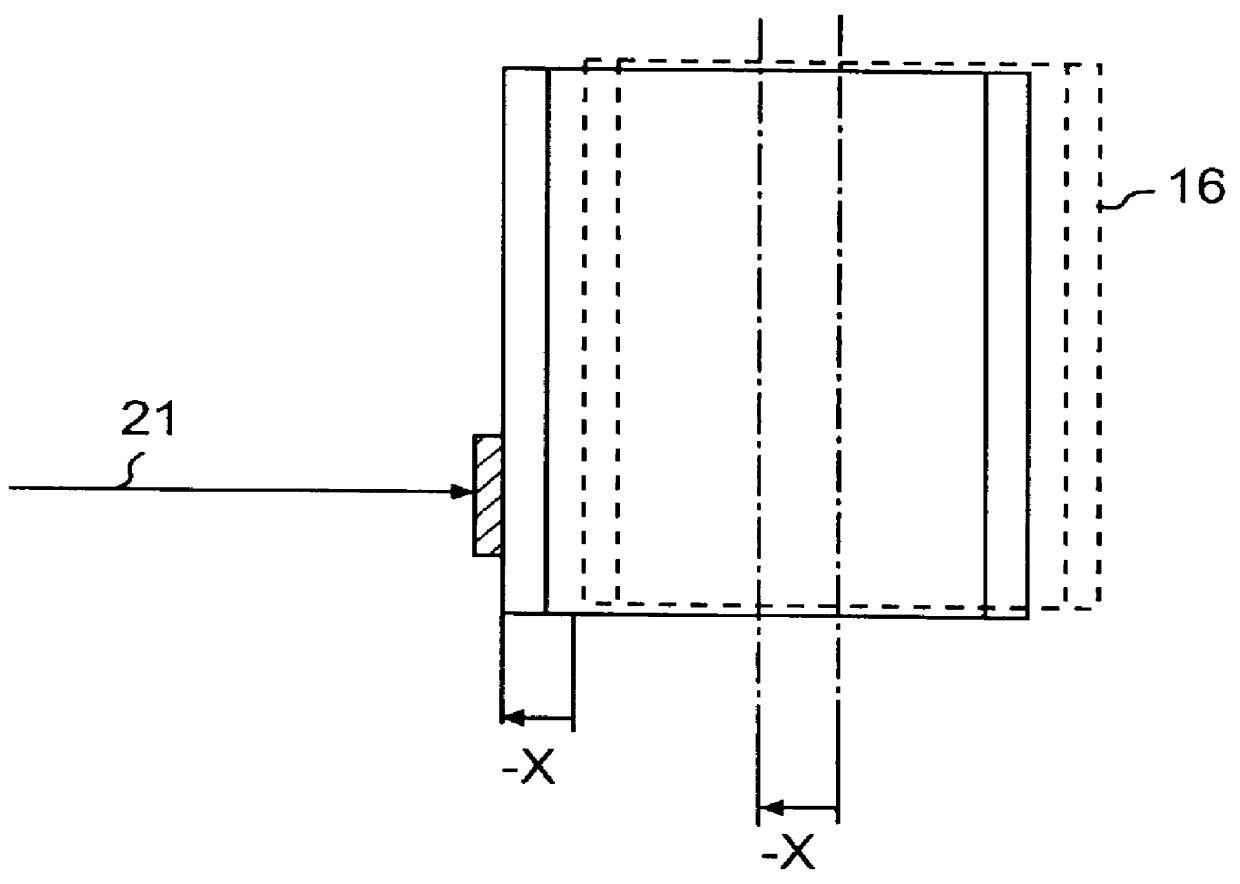

In accordance with the invention, there is provided a projection exposure apparatus and method for transferring an image of a pattern formed on a mask through a lens column along an optical axis perpendicular to a substrate, onto the substrate. Precise alignment of the substrate with the optical axis is achieved by the present invention, which detects proper alignment using one or more interferometers that pass at least one beam of light to an opposite side of the lens column.

The projection exposure apparatus of the present invention includes a projection optical system, one or more interferometers, and a control device. The one or more interferometers are oriented such that a plurality of beams are created. Each beam has a respective path, the length of which changes in response to a change in a dimension of the lens column along the path of the be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| photosensitive | aaaaa | aaaaa |

| optical axis | aaaaa | aaaaa |

| optical | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com