Methods for producing a self-supporting bag and package

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The present invention will be illustrated below referring to the accompanying drawings.

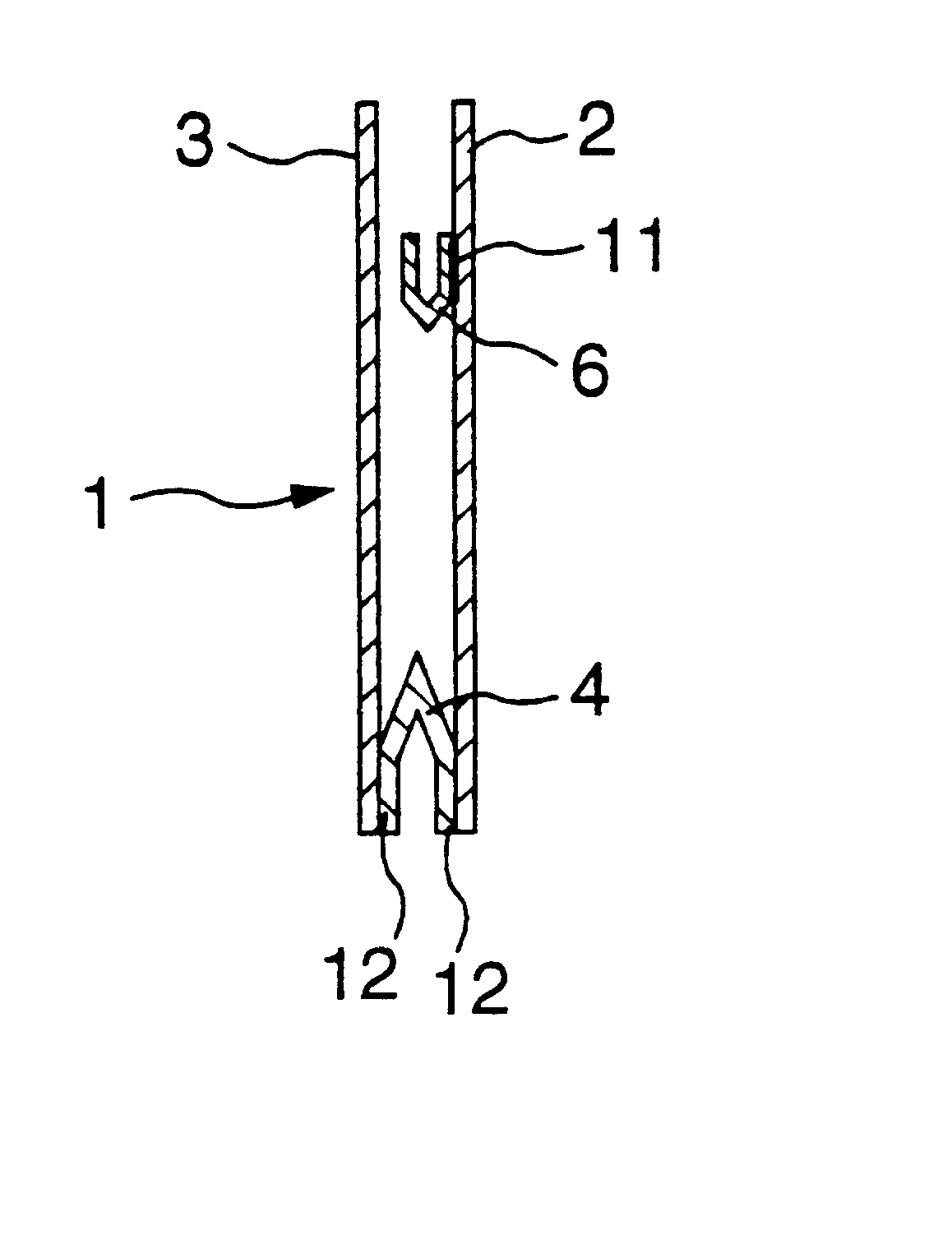

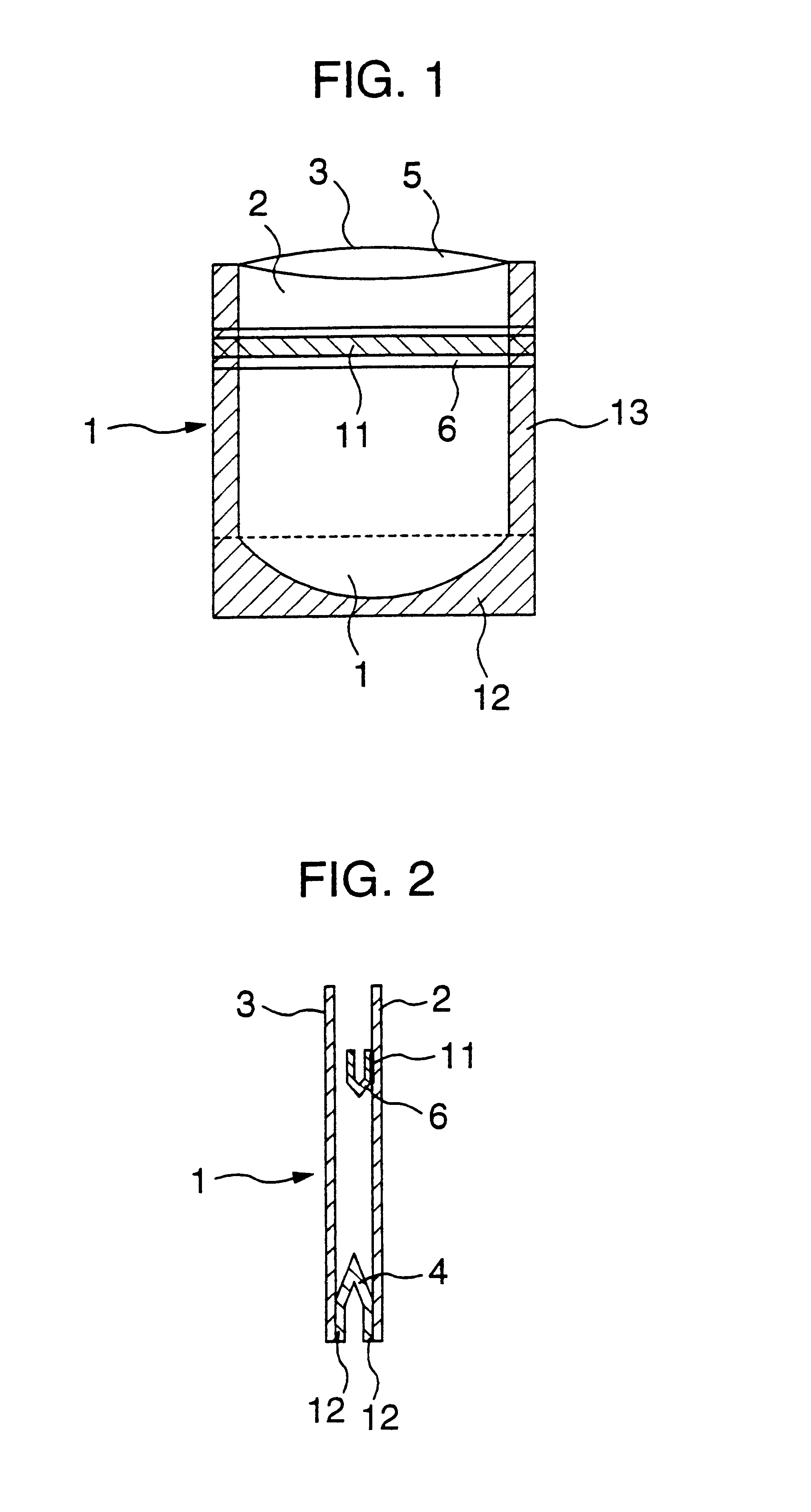

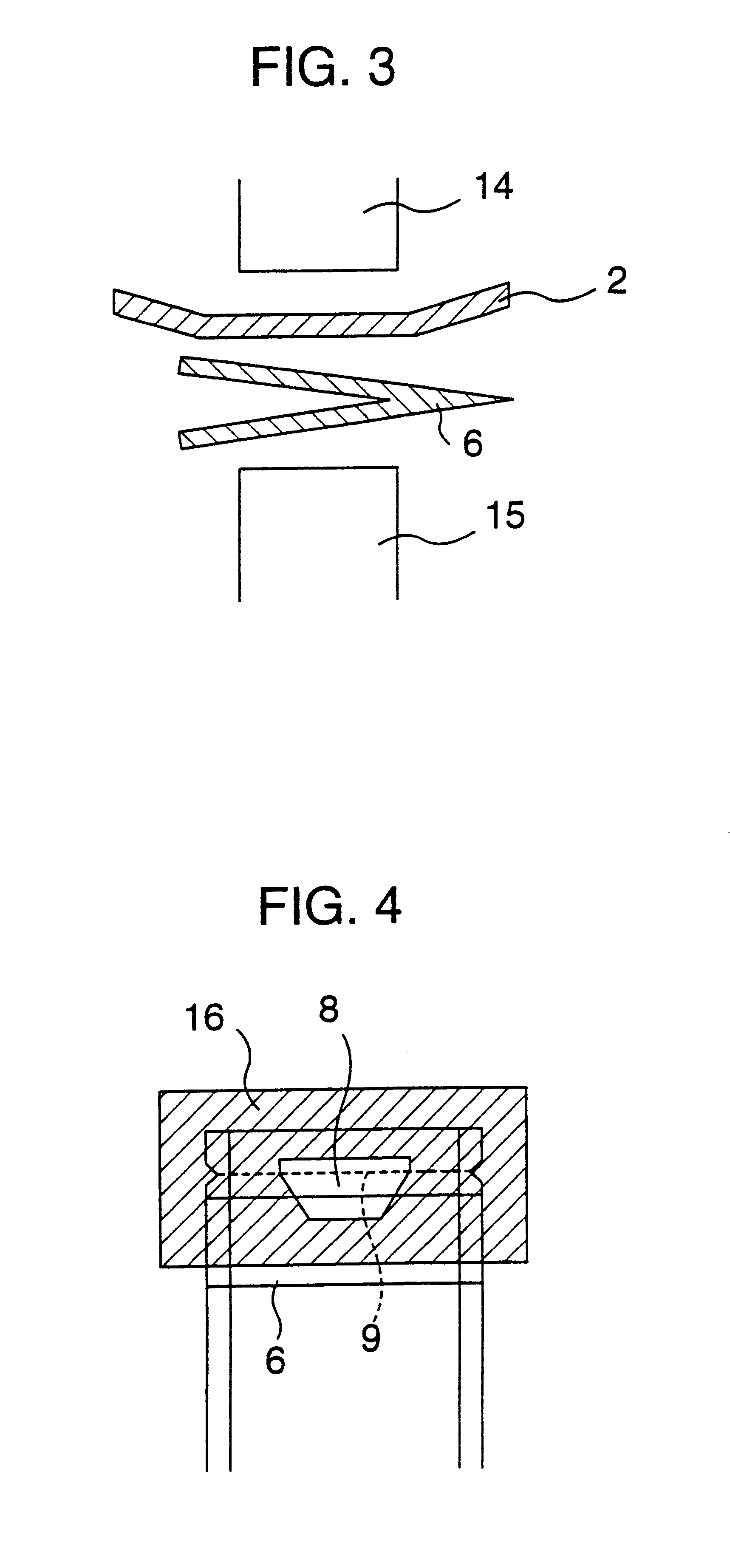

FIG. 1 and FIG. 2 show one example of the self-supporting bag of the present invention. The front material 2, the back material 3 and the bottom material 4 formed in the form of the letter V between the front and back materials in the self-supporting bag 1 each consist of a polyethylene terephthalate film of 12 .mu.m, an aluminum foil of 7 .mu.m, a nylon film of 15 .mu.m and a polyethylene film of 60 .mu.m in succession from the surface layer toward the seal layer. First, the straw-thrusting film 6 consisting of a polyethylene terephthalate film of 12 .mu.m, an aluminum foil of 7 .mu.m, and a polyethylene film of 40 .mu.m in succession from the surface layer toward the seal layer is folded with the seal layer facing outside between the front material 2 and the back material 3 in such a manner that the film 6 folded in half in the form of the letter V just in inverse direction to the bottom materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com