AC plasma display panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

embodiment 1

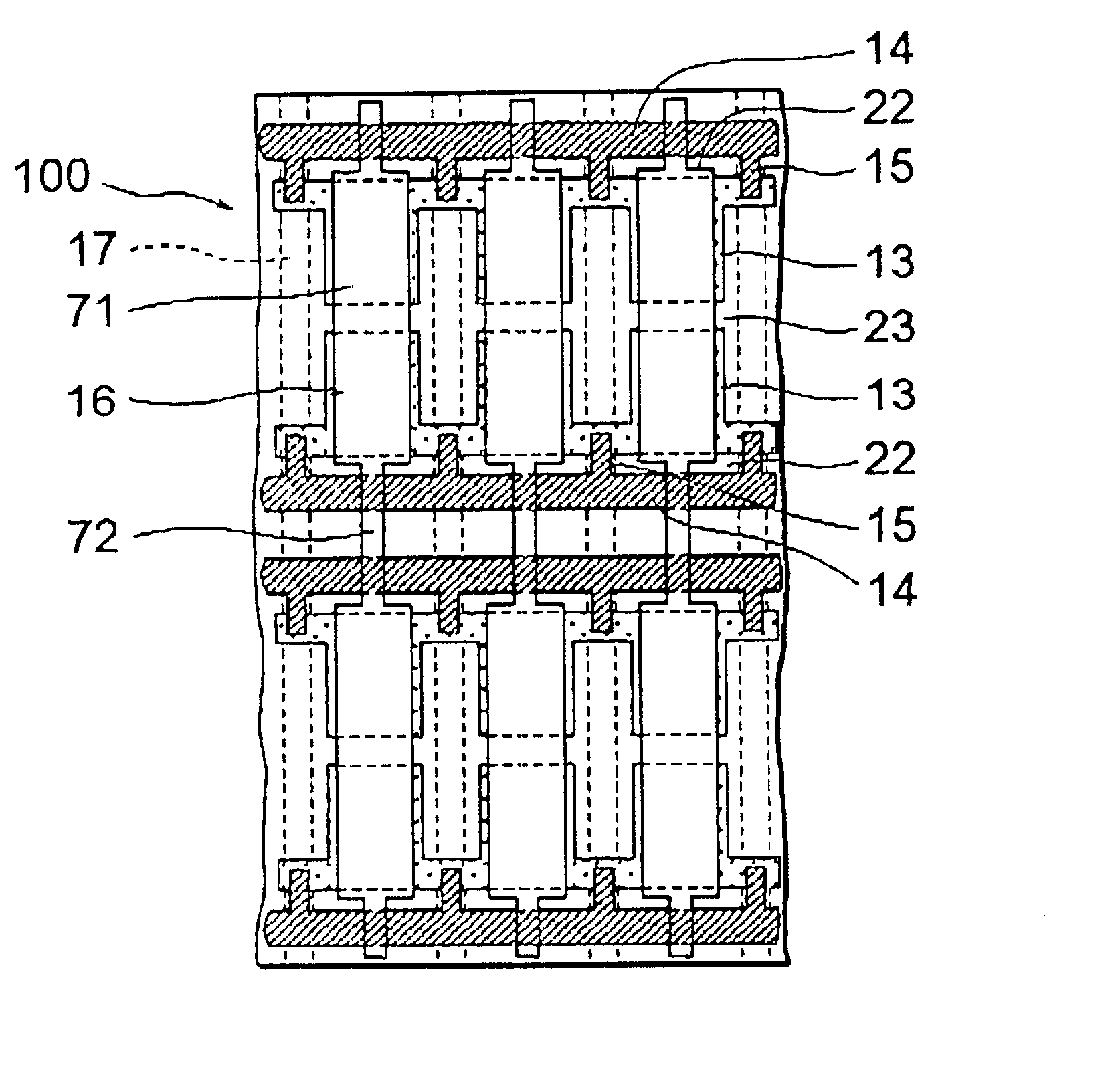

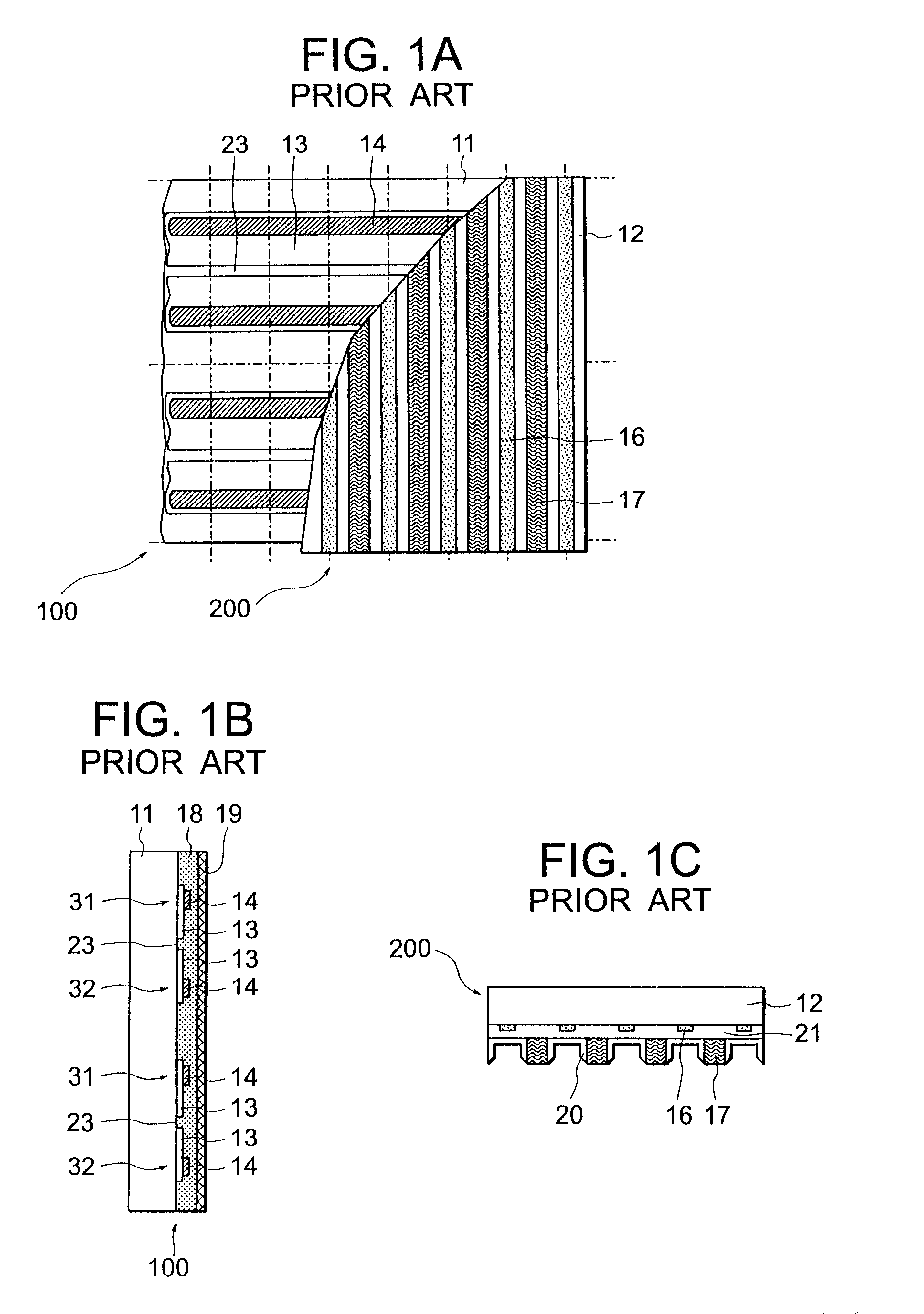

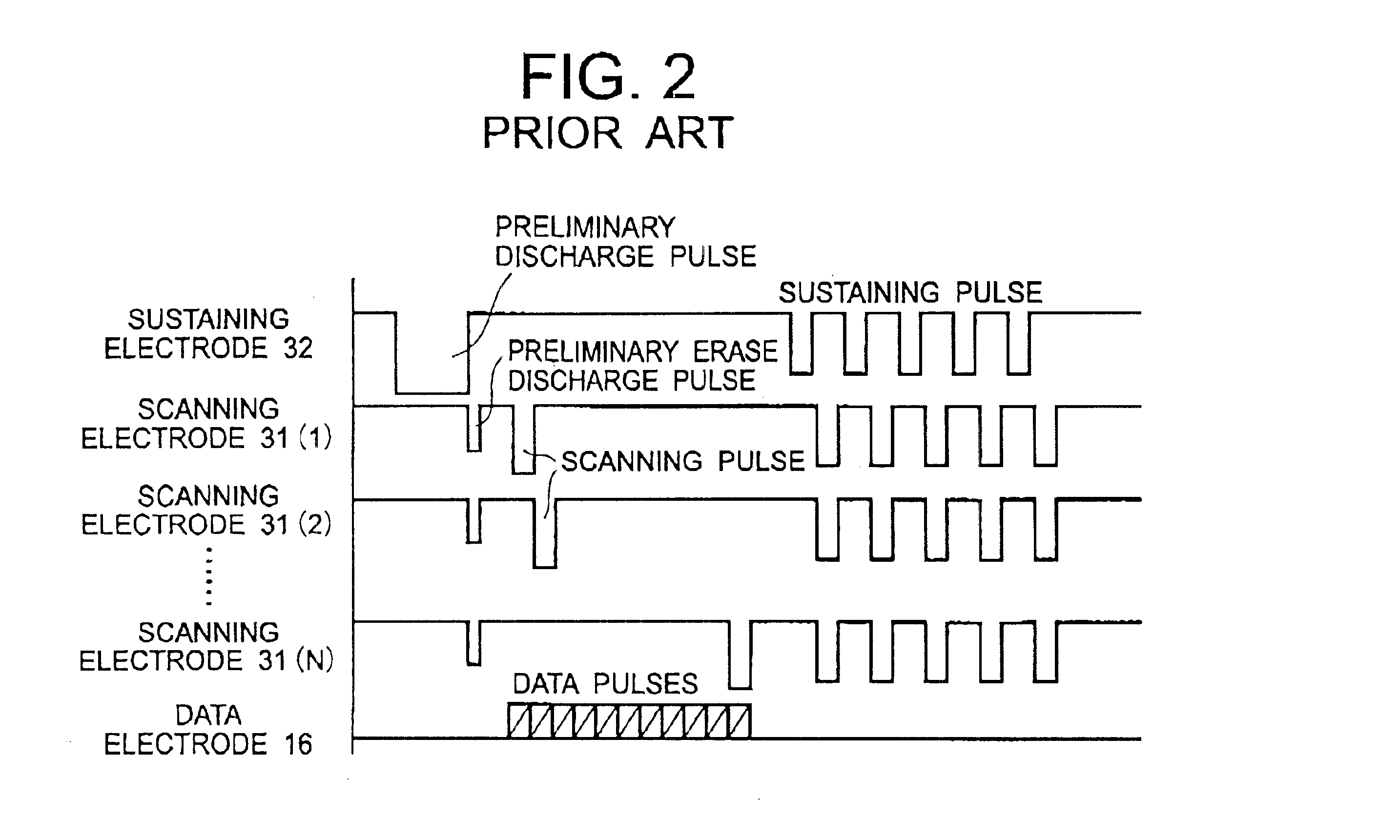

As shown in FIG. 5, an AC-PDP includes a pair of glass substrates 11 and 12, transparent electrodes 13, bus electrodes 14, coupling parts 15, data electrodes 16 and partition walls 17. The AC-PDP is fabricated as follows.

An ITO (indium-tin oxide) film is formed by sputtering on the glass substrate 11 functioning as a front surface substrate 110, and the transparent electrode 13 having comb-like projections as shown in FIG. 5 is formed by means of a photo-lithographic technique. The bus electrode 14 is formed to extend parallel to the transparent electrode 13 at the side of the transparent electrode 13 opposite to a surface discharging gap 23. A space 22 is formed between the transparent electrode 13 and the bus electrode 14. A plurality of the coupling parts 15 of the transparent electrode 13 projecting towards the bus electrode 14 are formed at a constant pitch on the transparent electrode 13, and the transparent electrode 13 and the bus electrode 14 are electrically connected to e...

embodiment 2

As shown in FIG. 7, the AC-PDP of Embodiment 2 has transparent electrodes 13A having an isolated structure. Embodiment 2 corresponds to a case where the coupling bar 62 exists only on one side of the discharge part 61. Although a dark defect may be generated when the electrode pattern has a defect, and shortcut or breakdown of the transparent electrode 13 cannot be electrically inspected because the projection 63 with the bus electrode 14 exists only on one side, an emission efficiency can be further improved because the coupling bar 62 exists only on one side. When an ability of manufacturing the transparent electrode pattern is high, the transparent electrode of FIG. 7 is effectively employed to elevate the emission efficiency.

Since the AC-PDP of Embodiment 2 is constituted as described above, the following effects can be obtained in addition to the effects of Embodiment 1.

Since the coupling bar 62 exists only on one side, the emission efficiency can be further improved.

When the a...

embodiment 3

In the AC-PDP of Embodiment 3 shown in FIG. 8, the coupling bar 62A and the projection 63 which act as the coupling part 15A are formed as a part of the pattern of the bus electrode 14A. In Embodiment 3, the bus electrode 14A may not extend to the coupling bar 62A, and it may include only the projection 63. The formation of the projection 63 and the coupling bar 62A as a part of the bus electrode 14A is useful when the transparent electrode 13 is a thin film which is liable to be breakdown due to a fine crack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com