Automatic system for collecting, weighing and releasing solid particles

a technology of automatic system and solid particle collection, which is applied in the direction of liquid/fluent solid measurement, volume measurement, volume measurement, etc., can solve the problems of not being very precise and accurate, measuring system, and length of sampling time,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

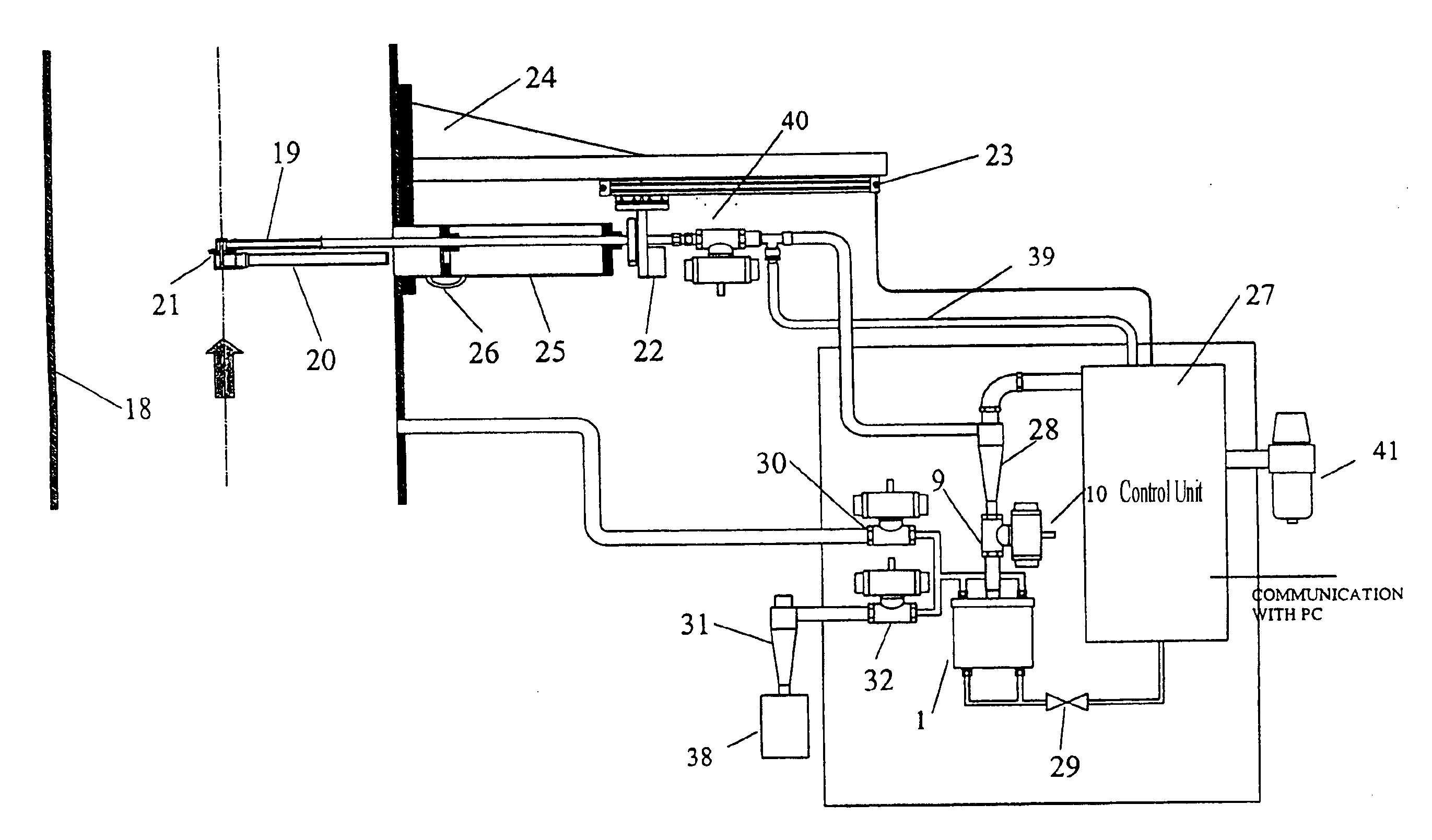

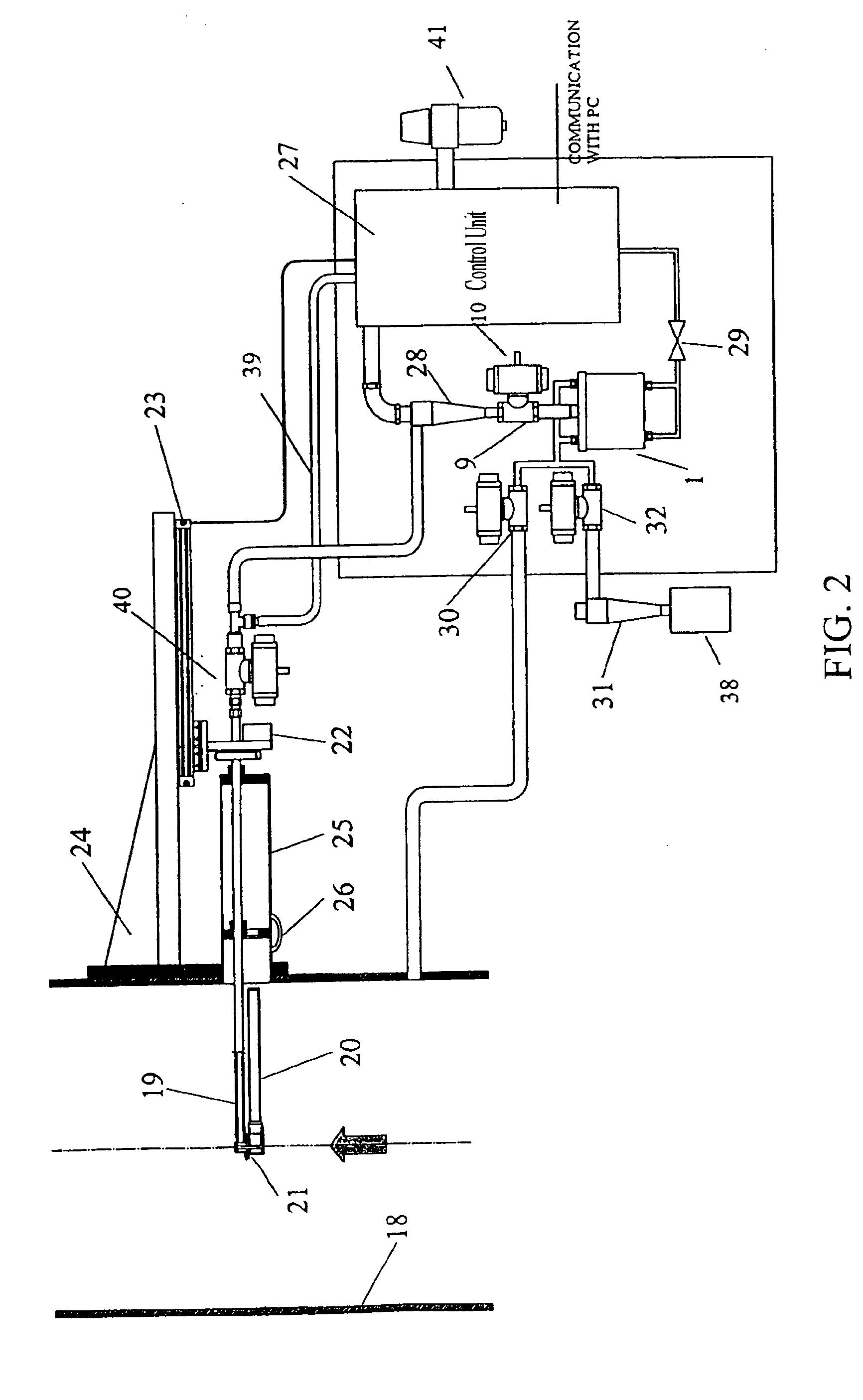

Embodiment Construction

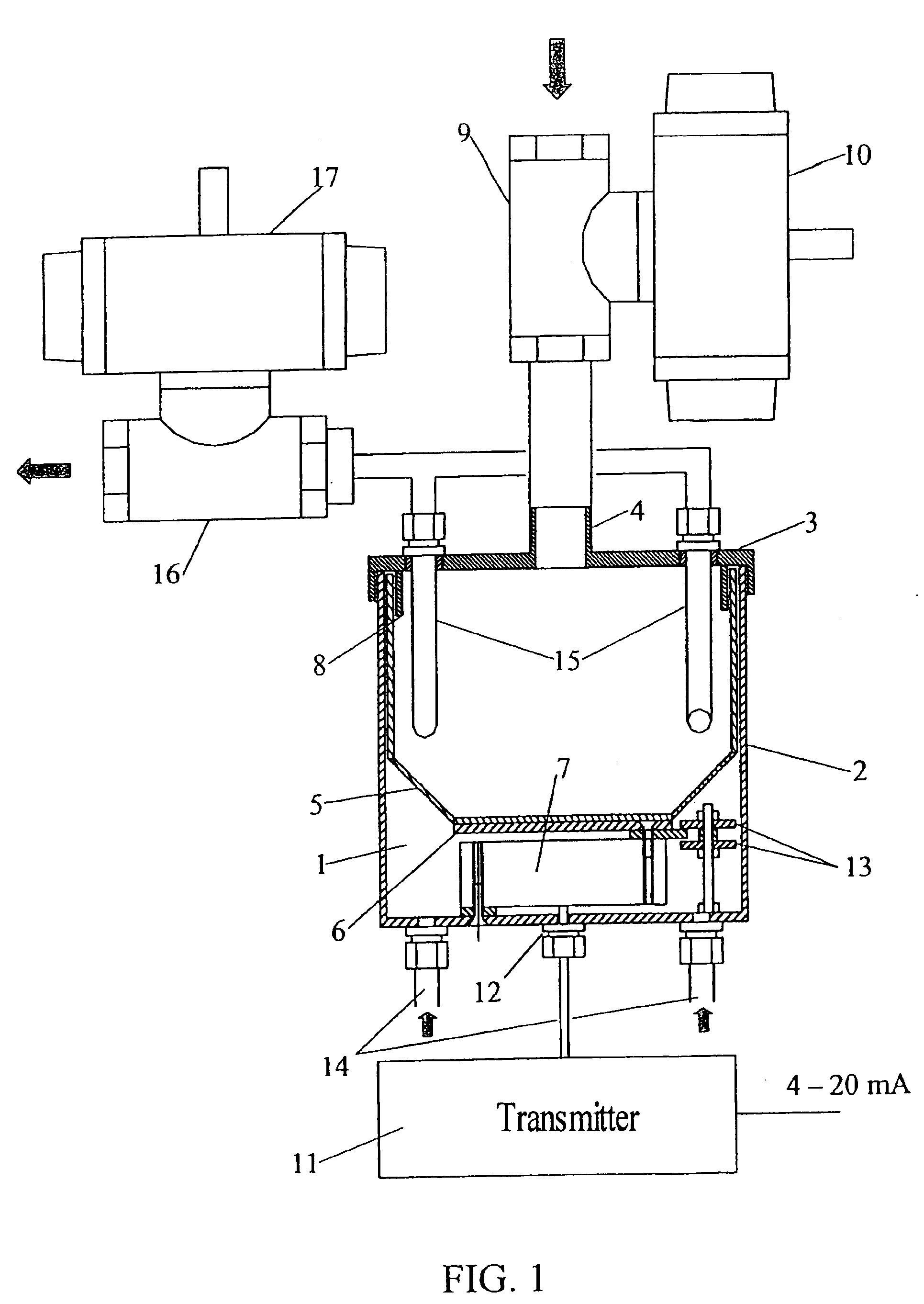

The solid particle capture, weighing, and expulsion system consists of a weighing chamber (1) made up of a cylindrical outer container (2) and a screw lid (3). The lid (3) has a particle entrance duct (4); the particles enter the chamber (1) by gravity and are collected in a container (5) which is also cylindrical with an exterior diameter two millimetres less than the internal walls of the container (2). The container (5) has a conical base to facilitate the elimination of the particles, and is joined to a platform (6) attached by screws to a load cell (7) on the base of the container (2) and supported above it by two screws. In this way the weight of the sample is transmitted to the load cell (7) as the sample is collected.

The arrangement of the container (5) inside the chamber (1) composed of parts (2) and (3) is concentric to these, and so between the container (2) and the container (5) there is a one millimeter space in the form of a circular corona. The height of the container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com